Aluminum 6061 T6 vs T651 vs T6511: What is the Difference?

Aluminum alloys are available in many grades and it is not an easy task to differentiate between them. This article provides you with a comparison of two of the most used tempering processes being used for aluminum alloys. These tempered alloys have the s

Jul 23,2024

Jul 23,2024

Surgical Steel vs Titanium: Deep into the Properties, Piercings, and Suitability

You surely know that the strongest metal is titanium, and the alloy is steel that we frequently use in our daily lives. Both are superior in their perspective because having excellent chemical and physical properties. But their alloys are totally differen

Jul 24,2024

Jul 24,2024

Anodized Titanium: The Definitive Guide

Anodizing is a famous electrochemical technique to develop colours on different metal and alloys. Anodizing of titanium is different than aluminum anodizing as it doesn’t involve any dye. An electrochemical process is implied and colour variation is

Jul 23,2024

Jul 23,2024

6061 vs 6082 Aluminum Comparative Guide

Aluminum is a very demanding material in engineering applications because of being strong and lighter in weight. By adding alloying elements in Al alloys and providing heat treatment, its mechanical properties like shear strength and toughness further inc

Jul 24,2024

Jul 24,2024

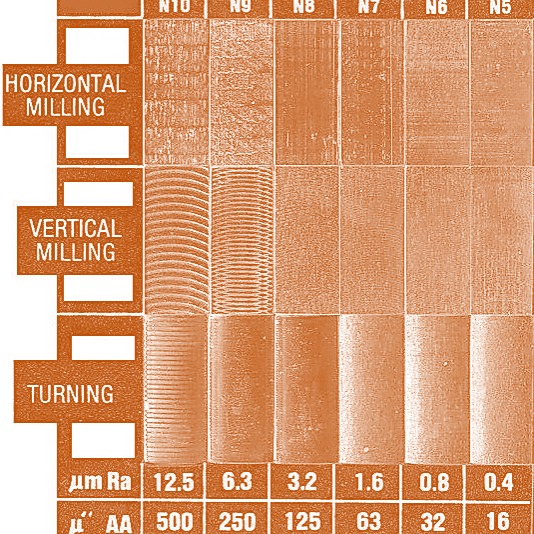

Surface Finish Chart: The Complete Guide

Metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. In addition to physical properties like strength, ductility or toughness etc. surface provides material an overall appearance. A smooth surfac

Jul 24,2024

Jul 24,2024

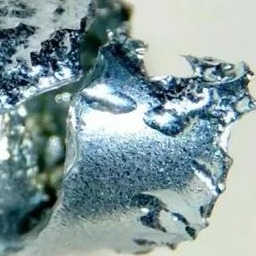

3Cr13 Steel: The Complete Guide

3Cr13 martensitic stainless steel has intrinsic metallurgical properties. These properties decide the category of the 3Cr13 item. One has to understand the edge retention and corrosion behavior of a knife. Edge retention decides the life and maintenance o

Jul 24,2024

Jul 24,2024

How to Clean Oxidized Aluminum: 4 Ways

Cleaning oxidized aluminum and making it stain free The versatility of aluminum metal made it durable and the most commonly used metal for vast applications ranging from household items like kitchen utensils to industrial level products. This special meta

Jul 24,2024

Jul 24,2024

What Is Duralumin Material? Know Its Properties & Applications

Duralumin is an incredible aluminum alloy when it comes to high specific strength and light weight. While it has one of the lowest densities out of all structural metal, its strength is really impressive. Since its discovery in 1909m, duralumin is highly

Jan 20,2026

Jan 20,2026

What Is Oxygen Free Copper? A Complete Guide for You

Copper contains traces of impurity depending on its sources, including oxygen. The content of oxygen is very small, however, it‘s still enough to possibly cause damage with time. Therefore, the projects where durability and conductivity are co

Jan 16,2026

Jan 16,2026

What is 41Cr4 Steel? Everything You Should Know

41Cr4 steel is a strong alloy that beats many steels like C45 in hardening. It also possesses remarkable mechanical properties, making it suitable for machineries manufacturing. Other technical and mechanical aspects of 41Cr4 alloy steels are discussed in

Jan 13,2026

Jan 13,2026

Leaded Brass: A Properties, Grades, and Machining Guide

Huge numbers of metals and metal alloys are used in this world in multiple applications. At the end of the 18th century, Brass (Cu-Zn alloy) was commonly used in different applications. At the start of the 19th century, leaded brass was introduced because

Jan 12,2026

Jan 12,2026

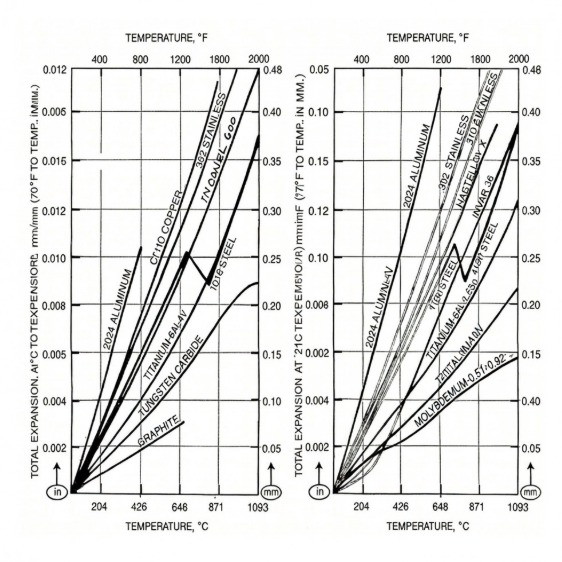

Does Metal Expand When Heated? Understanding Thermal Expansion

At times, a conflict might occur between the CNC manufacturer and the client regarding dimensional accuracy. The CNC manufacturer makes parts as per CAD given by the client. But still dimensions deviate from the design. The client wonders: “does met

Jan 09,2026

Jan 09,2026

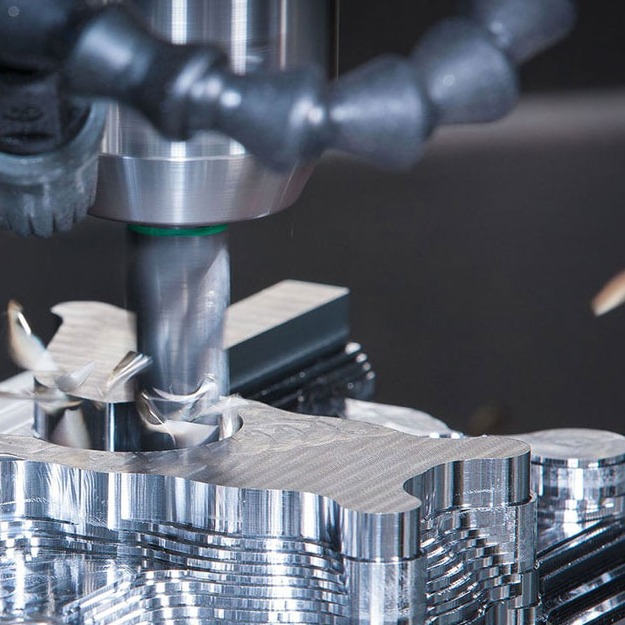

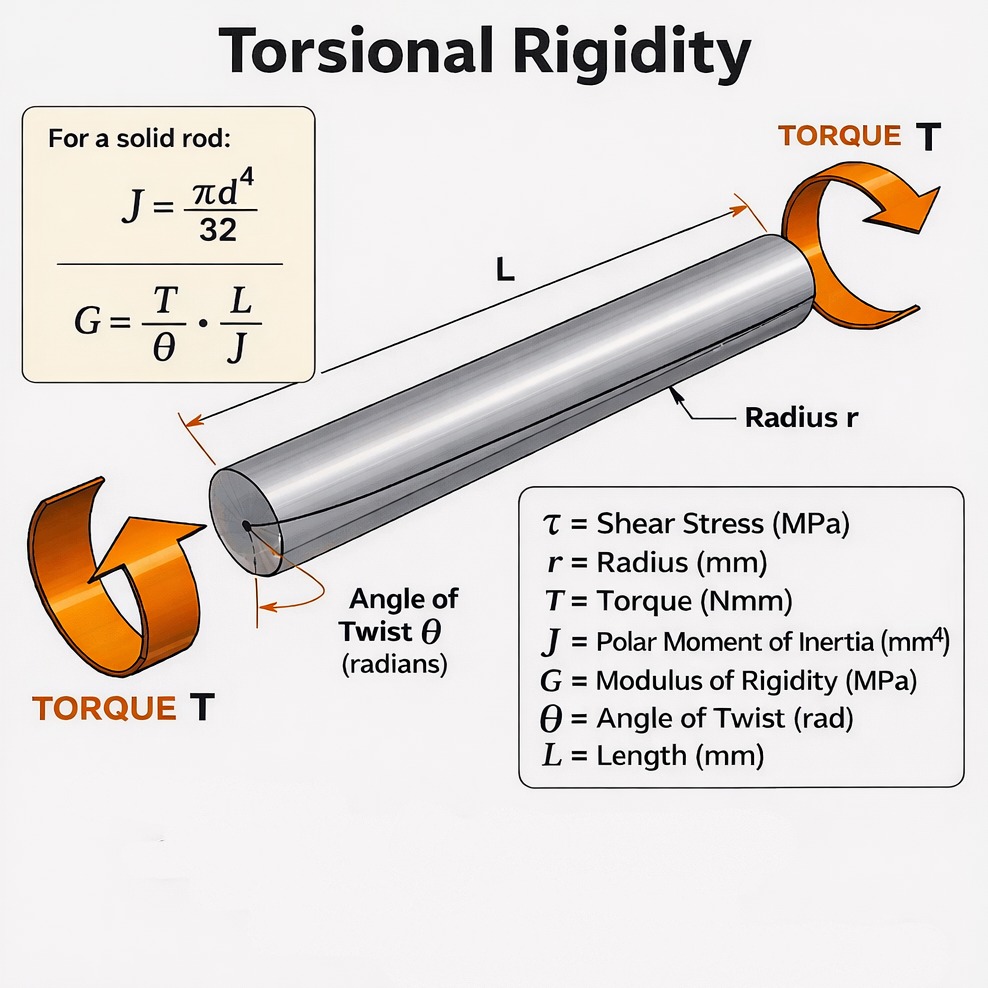

Torsional Rigidity in CNC Machined Parts: Design Methods

Torsional rigidity is an important engineering factor in CNC machined parts. In simple words, it is twisting rigidity and correct amount of rotational stiffness is crucial in engineering designs. For example, if rigidity is high, it makes part heavy and b

Jan 06,2026

Jan 06,2026

Titanium Cost Per Pound and The Cost of Titanium Machining

In the world of critical applications, where it is most important to avoid failure, Titanium stands tall with its excellent properties. Despite its excellent mechanical properties, Ti is not commonly used as other metals, such as stainless steel or alumin

Dec 31,2025

Dec 31,2025

What Is 40Cr Steel? A Complete Guide for You

Quite often a material is required that offer a high performance at a comparatively lower cost. 40Cr steel is one such option. Compared to its alternatives like 42CrMo4 steel or 4130 steel, it offers comparable strength at a low price. A slight addition o

Dec 31,2025

Dec 31,2025

6063-T5 Aluminum: Temper, Properties, Weld & Machining

6063 T5 is a versatile aluminum alloy and famous across many industries due to its lightweight, workability characteristics and superior finish. Also, a balance of moderate strength and superior finishing makes it an ideal choice for decorative applicatio

Dec 27,2025

Dec 27,2025

MIC 6 Aluminum: Properties, Machinability, and Best Uses

For applications such as vacuum chucks, tooling, or machine bases, materials with exceptional flatness and dimensional stability are required. This article presents a material that offers both flatness and dimensional stability, which makes it able to be

Dec 19,2025

Dec 19,2025

Nitriding Steel: Importance, Comparison, Applications & CNC Machining

Nitriding perfectly complements CNC machining by adding hard nitride layers on complex shaped steel parts. This creates superior and long-lasting parts for aerospace, automotive and tooling. However, some challenges occur in Nitriding steel like alloy sel

Dec 16,2025

Dec 16,2025

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address