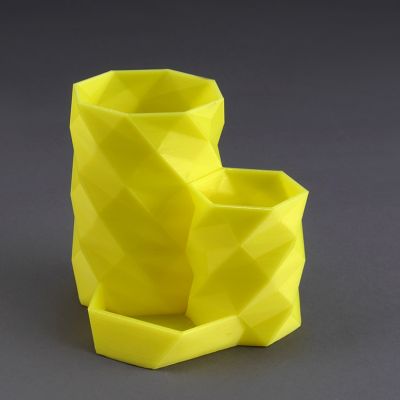

Plastic 3D Printing

Driven by companies such as 3D printing materials, equipment, and additive manufacturing service providers for high-volume production and innovative end-users, plastic 3D printing technology is showing a clear trend beyond prototypes and toward final parts production, especially playing an increasingly important role in small-volume production and the large-scale production of complex parts.

Recent years have seen the production of polymer components and the market value generated by plastic 3D printing, including prototypes, tooling, and end-use production projects. From aerospace aircraft interiors and drone parts to dental and personalized surgical guides in healthcare, custom 3D printed plastic parts are already changing people's lives.

Custom 3D Printed Plastic

Tuofa provides a useful reference for customers in selecting materials and developing 3D printing product applications.

PLA

PLA has good biodegradability and can be completely degraded by microorganisms in nature after use, eventually producing carbon dioxide and water, which does not pollute the environment, which is very beneficial to the protection of the environment.

- Price: $$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances:±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

ABS

ABS has excellent overall physical and mechanical properties, excellent low temperature impact resistance. Dimensional stability. Electrical properties, wear resistance, chemical resistance, dyeing, finished product processing and machining are better.

- Price: $$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Nylon

Nylon is the first man-made synthetic fiber that appeared in the world. It is strong and wear-resistant, low density, light in size, good in elasticity, good in chemical stability, large in output and widely used.

- Price: $$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Resin

Resin material is very decorative, mainly because it is very delicate, and the prototype parts or products made with resin material are very realistic and can be designed exactly as required, in terms of color and size, etc.

- Price: $$$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size:200 x 80 x 100 cm

PETG

PETG material has outstanding toughness and high impact strength. It can be processed in a wide range, with high mechanical strength and good flexibility. Compared with PVC, PETG material has the advantages of high transparency, easy printing, and environmental protection.

- Price: $$$$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

TPU

TPU material not only has excellent high tension, high tensile strength, toughness, and aging resistance, itself has oil resistance, which is incomparable to other elastomeric rubber raw materials. Especially in the automotive industry, most of the oil pipelines are made of this material.

- Price: $$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

ASA

ASA plastic has a super anti-UV function, used for outdoor, outdoor injection products and direct contact with the sun, the anti-UV does not fade and does not yellow. No surface loss and fracture in areas with low temperatures, even if snow accumulates on roofs all year round.

- Price: $

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

PEI

As an engineering plastic, PEI has high heat resistance, excellent mechanical properties, high fire resistance, natural flame retardant, low smoke and non-toxic. It remains stable in a wide range of temperature (-40℃~150℃) and frequency.

- Price: $$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

3D Printing Plastic Service

Variety of Print Sizes

The 3D printing process of plastic products is mainly based on FDM technology, which is reliable in process and easy to use and maintain. Large-scale industrial-grade FDM 3d printers have become one of the items of interest to many manufacturing companies, which can obtain accurate and customized parts and are easy to process. If you need to make larger parts for prototype testing, plastic is the best solution.

High Printing Efficiency

Plastic was one of the first materials used in the 3D printing industry, providing an efficient way to produce one or more custom designed products. 3D printing is much more efficient than traditional injection molding, and in order to manufacture the final part, you can 3D print to obtain the mold and use it as the final tool for the composite structure. Plastic 3D printing materials are the best choice for the prototyping process.

Wide Range of Applications

Plastic 3D printing can be used in the medical industry to create 3D printed models of organs, in the automotive industry to replace car interior parts, to print architectural models, and even in the aerospace industry. Plastic 3D printing materials are useful for every step in the product development process, from proof of concept and prototyping to production. You are free to print any kind of intricate designs using plastic materials.

|

Try Tuofa Now!

Tuofa Engineer Support Team - Real human quotes are more accurate than software quotes

|

3D Printed Plastic Parts

3D printed plastic parts are parts that have been created using a 3D printer. 3D printing is a process of creating three-dimensional objects from a digital file. The process involves melting plastic filament and depositing it layer by layer to create the desired shape. 3D printed plastic parts are used in a variety of industries, including automotive, aerospace, medical, and consumer products.

Custom Plastic 3D Printing Parts

Custom plastic 3D printing parts are becoming increasingly popular in a variety of industries. From automotive to aerospace, medical to consumer products, 3D printing is revolutionizing the way parts are designed and manufactured. With 3D printing, parts can be designed and produced quickly and cost-effectively, allowing for greater customization and flexibility. 3D printing also offers a range of materials, from plastics to metals, allowing for a wide range of applications. With custom plastic 3D printing, parts can be designed to your highest ideal requirements, redefining manufacturing and bringing parts "to life".

Tuofa Precision Machining Shops provides online engineering customer support for your parts, 2D and 3D drawing design, and manufacturing questions. Assist in reviewing project plans; this includes case-by-case suggestions to help you reduce costs early on in the design process. 100 CNC machines for online CNC precision machining parts, making it an excellent choice for parts prototype design and low to high-volume production runs, instant CNC parts quotes, on-time delivery, 30+ materials and 10+ surface finishes for tolerances down to 0.01mm.

3d Printing Plastic Parts

People Also Ask

What plastic can be 3d printed?

The most common type of plastic used for 3D printing is acrylonitrile butadiene styrene (ABS). ABS is a strong, durable plastic that is easy to print with and is available in a variety of colors. Other types of plastic used for 3D printing include polylactic acid (PLA), Nylon, and polycarbonate, Formlabs Resins, 3D Systems Resins, PETG, TPU, ASA and PEI. How long does 3D printing plastic parts last?

The lifespan of 3D printed plastic parts depends on the type of plastic used and the environment in which the parts are stored. Generally, 3D printed plastic parts can last for several years if stored in a dry, temperature-controlled environment. The lifespan of 3D printed plastic parts can also be extended by using higher-quality plastics and post-processing treatments such as painting or coating. Is 3d printing plastic toxic?

3D printing plastic is generally not considered to be toxic. However, some 3D printing plastics may contain hazardous chemicals, such as phthalates, which can be released into the air during the printing process. It is important to research the type of plastic being used and take appropriate safety precautions when 3D printing. Will 3d printing replace injection molding?

3D printing is not likely to completely replace injection molding, as injection molding is still the most cost-effective and efficient way to produce large quantities of parts. However, 3D printing can be used to produce small batches of parts quickly and cost-effectively, and can be used to produce parts with complex geometries that would be difficult or impossible to produce with injection molding. What will be the trends 2023 for Plastic 3D printing?

In 2023, the trends for plastic 3D printing are expected to include increased use of multi-material printing, improved post-processing techniques, and increased use of 3D printing for mass production. Multi-material printing will allow for the production of parts with multiple materials, such as plastics and metals, in a single print job. Improved post-processing techniques will allow for better surface finishes and improved part strength. Finally, 3D printing will be increasingly used for mass production, allowing for the production of large quantities of parts quickly and cost-effectively. |

Online Plastic 3D Printing Resources

What Is CNC Turning

CNC turning is the process of removing material from a rotating workpiece using the linear path of tools on a CNC lathe. In a simple perspective, the main elements involved in this process are the rotating spindle in which your work part is clamped and the cutting tool that is mounted on a turret.

Learn More

A Method for Calculating the Cost of Turned Parts

At present, the online CNC machining shop is widely used in the machinery industry, and it is inevitable to encounter some complex, special-shaped or similar hollow workpieces. When making such workpieces, it is a test of the experience and technology of the program and the machinist.

Learn More

CNC Machining Complex Cavity Parts

At present, the online CNC machining shop is widely used in the machinery industry, and it is inevitable to encounter some complex, special-shaped or similar hollow workpieces. When making such workpieces, it is a test of the experience and technology of the program and the machinist.

Learn More

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home