POM-H vs POM-C: Side-by-Side Guide for Engineers

Jun 18,2025

Jun 18,2025

Polyoxymethylene (POM) has arisen as a multifunctional, advanced polymer. POM is widely used in medical, automotive and electronics industries due to its thermos stability, and chemical resistance. They are one of the more common plastic materials in the CNC machining industry. This article will provide a deep insight into the properties, processing and machining and applications of POM polymers.

What Is POM Material?

POM is also known as acetal or polyacetal. It is a semi-crystalline thermoplastic and has high strength, rigidity, and wear resistance.

POM Material Definition

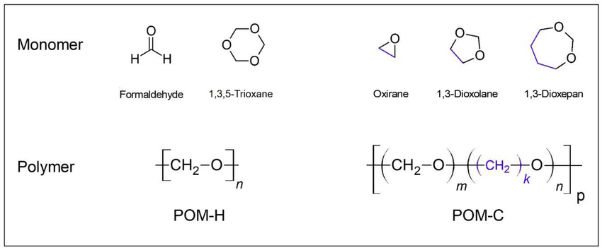

It is derived from formaldehyde and the chemical structure is based on repeating units of -CH2-O-. POM is versatile engineering polymer and is used in applications that require precise dimensions, low friction, and good fatigue strength.

• Terminal OH groups provide stability

• Higher crystallinity and strength

• Better chemical resistance

• Regular (-CH₂O-) repeating units

2 Common Types of POM Materials

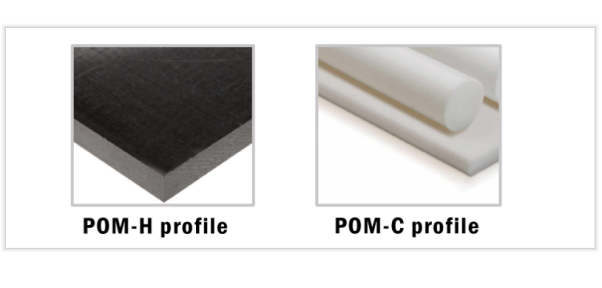

POM exists in two main types as acetals (Acetal c and Acetal h). Homopolymer (POM-H) which has slightly higher hardness and heat resistance. The other one is Copolymer (POM-C) which has better chemical resistance. It is mostly preferred in applications where high resistance to harsh chemicals or moisture is required.

Delrin®=POM-History Explain

Delrin, the first acetal polymer, was developed by DuPont. They marketize and commercialized POM production with the same brand name in 1960. At the same time, Celanese began producing and marketing its own POM production with the same name. This introduced the homopolymer and copolymer acetal options.

What Is POM-H?

POM-H is also called acetal homopolymer or Delrin®. It is a high-performance engineering thermoplastic and offers superior mechanical properties than acetal copolymers. It also possesses high fatigue resistance, and tighter dimensional control. Therefore, it is costly in applications where these performance benefits are important.

Homopolymer Chain Structure

POM-H homopolymer structure has shorter repeat unit and higher crystalline fraction. This increases its mechanical properties, which ultimately increases its stiffness and strength.

Delrin® Grade Examples

Some common examples of POM-H Delrin® grades are Derlin 150 and Derlin 100.

- Delrin 150

It has a range of colors like natural, black or other colors. It is considered as a general-purpose grade with high mechanical properties and dimensional stability.

- Delrin 100

This grade is in white and black colors. Its properties are almost the same as Derlin 150 but have some different features depending on the required applications.

POM-H Typical Applications

In the applications of POM-H, low creep and tight tolerance retention are crucial. This is because they have long-term dimensional stability and reliable performance under different temperatures and loads.

- POM-H Precision Gears:

POM-H used in gears allows gear teeth to maintain their shape and spacing. This prevents them from slipping, noise, and inaccurate power transmission. Tight tolerance retention in POM-H gears allow consistent meshing with other gears and provide smooth operation and preventing wear.

- POM-H Bearings:

POM-H bearings with tight tolerances offers smooth rotation and low friction. Tight tolerance is essential to attain the intended bearing performance and prevent premature failure.

- POM-H Snap-Fits:

POM-H Snap-fits can maintain their elastic properties that help to securely engage and disengage repeatedly. Tight tolerance retention of POM-H also plays an important role for consistent engagement and disengagement and prevents it from premature failure.

What Is POM-C?

POM-C thermoplastic has high strength, rigidity, good sliding properties, high mechanical strength, and excellent wear and impact resistances. It also has high resistance to chemically aggressive or hot-water environments than POM-H.

Copolymer Architecture with Ether Linkages

It is created by a copolymerization process. A comonomer is introduced during the formaldehyde polymerization which then adds ether linkage (C-O-C) into the polymer chain. This linkage is flexible and less prone to breaking under stress than the C-C bonds in the POM-H. This change increases toughness and stability in polymeric structure.

Common Trade Names: Celcon®, Hostaform®

Celcon® and Hostaform® are trade names for POM produced by Celanese. It is the primary manufacturer and supplier of Celcon® and Hostaform®. Another supplier is Ensinger similar to Celcon®. Ceclon has grades like M90UV, M25, and others. Hostaform® has various grades like C (for harsh chemical environments), and MT (for medical applications).

POM-C Ideal Uses

POM-C has many uses due to its lower formaldehyde out-gassing and better hydrolysis resistance. This makes it less likely to release harmful chemicals or degrade when exposed to fluids or moisture.

- POM-C Fluid-Contact Parts

In systems like pumps, valves, and seals, POM-C is used to minimize contamination of the fluid and potential adverse effects on downstream processes.

- POM-C Medical Devices

POM-C is used in medical applications due to minimal potential for harmful chemical release into the body. And it can maintain its structural integrity under various sterilization conditions.

- POM-C Fuel Systems

POM-C is used in fuel system due to its hydrolysis and corrosion resistance. It also has good wear resistance which helps it to function reliably in harsh environments.

POM-H vs POM-C: Property-by-Property Comparison

A brief comparison of POM-H and POM-C in terms of properties is given below:

POM-H>POM-C: Strength & Stiffness

POM-H has higher strength and stiffness than POM-C (copolymer). It shows tensile modulus of 2700-3800MPa, while POM-C has 2500-3000MPa tensile strength. A design example of gear tooth deflection which shows this difference. A POM-H gear will deflect less under the same load compared to a POM-C gear due to its higher stiffness.

POM-H<POM-C: Chemical & Oxidative Resistance

POM-C has higher chemical and oxidation resistance than POM-H, specifically in alkaline and chlorine-containing environments. POM-H can degrade in the presence of strong bases and oxidizing agents like chlorine water and 10% NaOH. Specific failure times of POM-H depend on parameters like concentration, temperature, and stress on the polymer.

POM-H and POM-C: Thermal Operating Window

Both POM materials have different thermal operating windows. POM-H has a higher melting point and can withstand higher temperatures. POM-C has higher chemical resistance and slightly lower temperature resistance. But both have good dimensional stability in their own thermal operating window.

POM-H vs POM-C in Machining Differences

The key machining difference of POM plastic materials lies primarily in their mechanical properties. POM-H has higher strength and stiffness, and POM-C has better chemical resistance. This affects their machining parameters like tool selection, annealing requirements and shrinkage.

Injection-Molding Window

POM-H requires a tighter processing window. This is due to its higher crystal system, which makes the mold filling and solidification difficult.

CNC Chip Formation

POM-H produces shorter and more brittle chips compared to POM-C. This requires proper chip removal to avoid buildup.

Shrinkage & Warpage Rates

POM-H has a higher shrinkage rate than POM-C. The value is around 2% vs. 1.6% which requires careful consideration in design and post-processing.

Post-Mold Annealing

Post-mold annealing is normally required for POM-H for its dimensional recovery, especially for tight-flatness parts. However, it is optional for POM-C. For both POM materials, proper handling and post-processing are required to get the desired dimensional accuracy and surface quality.

Selection Checklist for Designers

For design selection of POM plastic material, consider the application's required properties. POM-H has higher strength and stiffness, and POM-C has better chemical resistance and ease of processing. A decision workflow must assess some critical factors like load, temperature, chemical exposure, and dimensional stability to choose the best POM plastic material for their needs.

1.Load and Wear Conditions

Depending on load type like static loading, POM-H would be better for static loads and POM-C would be better for dynamic load. Both POM-H and POM-C works good in impact loading. Both POM-H and POM-C also have good wear and friction properties. Therefore, these are suitable for gears, bearings, and other sliding/rotating components.

2.Chemical Exposure Profile

POM-C has better resistance to a wider range of chemicals and solvents than POM-H. However, both materials have limitations, and thorough testing is required for certain chemical environments. For example, both POM materials can resist gasoline and other hydrocarbons found in fuels. POM-C is used for coolants, POM-H Derlin is not compatible with some coolants. And both are prone to degradation by strong oxidizing disinfectants.

3.Regulatory or Food-Safety Requirements

It is important to prioritize POM materials for applications with regulatory or food-safety requirements with relevant certifications such as NSF 51/61 or ISO 10993 compliance upfront. These standards check the material's suitability with potable water and food, and biocompatibility in medical applications. POM-C and POM-H selection is based on factors like their mechanical strength, chemical resistance, and temperature resistance.

4.Tolerance and Surface Finish Targets

Shrinkage, post-machining allowances, and gloss level targets are important parameters to consider while selectin both POM materials for dimensional and aesthetic requirements. POM-C has higher dimensional stability and has tolerance of ±0.10 mm. Surface finish of POM-C is around 3.2 µm as-machined to 0.4 µm.

Conclusion

POM-H and POM-C are both types of acetals (Acetal c and Acetal h) which is a high-performance engineering thermoplastic. POM-H has higher strength and stiffness, and POM-C has better chemical resistance and thermal stability. POM-C has more applications than POM-H due to its lower cost and better machinability.

FAQ

Is POM-H stronger than POM-C?

Yes, POM-H is stronger and stiffer than POM-C.

Which grade is better for fuel system components?

POM-C is used for fuel system components because it has higher chemical resistance, for fuels and solvents than POM-H Delrin.

Can POM-C replace Delrin® in precision gears?

Yes, it could be a suitable alternative to POM-H Delrin in some precision gear applications due to its lower cost and good machinability.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

PEEK vs PTFE: Which High-Performance Plastic Fits Your CNC Project?

PEEK vs PTFE: Which High-Performance Plastic Fits Your CNC Project?