Acrylic CNC Machining

Acrylic, abbreviated as PMMA, is a transparent thermoplastic polymer, which is by far the most excellent texture of synthetic transparent materials, with the advantages of high transparency, low price, easy mechanical processing, etc. It is an alternative material to glass and can also be called plexiglass.

CNC machined acrylic parts are used in every corner of our daily lives. Including; automotive industry, medical equipment, consumer electronics, machinery and equipment.

Choosing Acrylic for Manufacturing

Try Tuofa Now!

As a professional acrylic parts manufacturer, we can provide you with high-quality acrylic components and CNC machining services to make your products more personalized. Personalized custom services can ensure the accuracy and perfection of every detail. Choosing us, you can enjoy professional services with confidence, making your products more competitive in the market.

Acrylic Material Properties

Our engineers understand the performance of acrylic materials to better apply to the project, which is conducive to increasing the consumer experience.

| ASTM | Unit | Value | |

| Light Transmittance | D1003-61 | % | 93 |

| Refractiveindex | D542-50 | D542-50 | 1.49 |

| HotFormingTemp | ℃ | 140-180 | |

| HeatDistortionTemp | ℃ | 87 | |

| CLTE | D696-44 | Cm/cm℃ | 7.7 x 10-5. |

| SpecificHeat | Cal/gr℃ | 0.35 | |

| Specific Gravity | D792-60T | 1.2 | |

| Flexural Strength | ISO 1565 | MPa | no less than 65 |

| Shear Strength | D638 | MPa | 69 |

| Impact Strength | ft*lb/in2 | 1 | |

| Rockwell Hardness | KG/CM | M95 |

Acrylic Applications

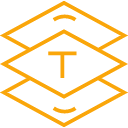

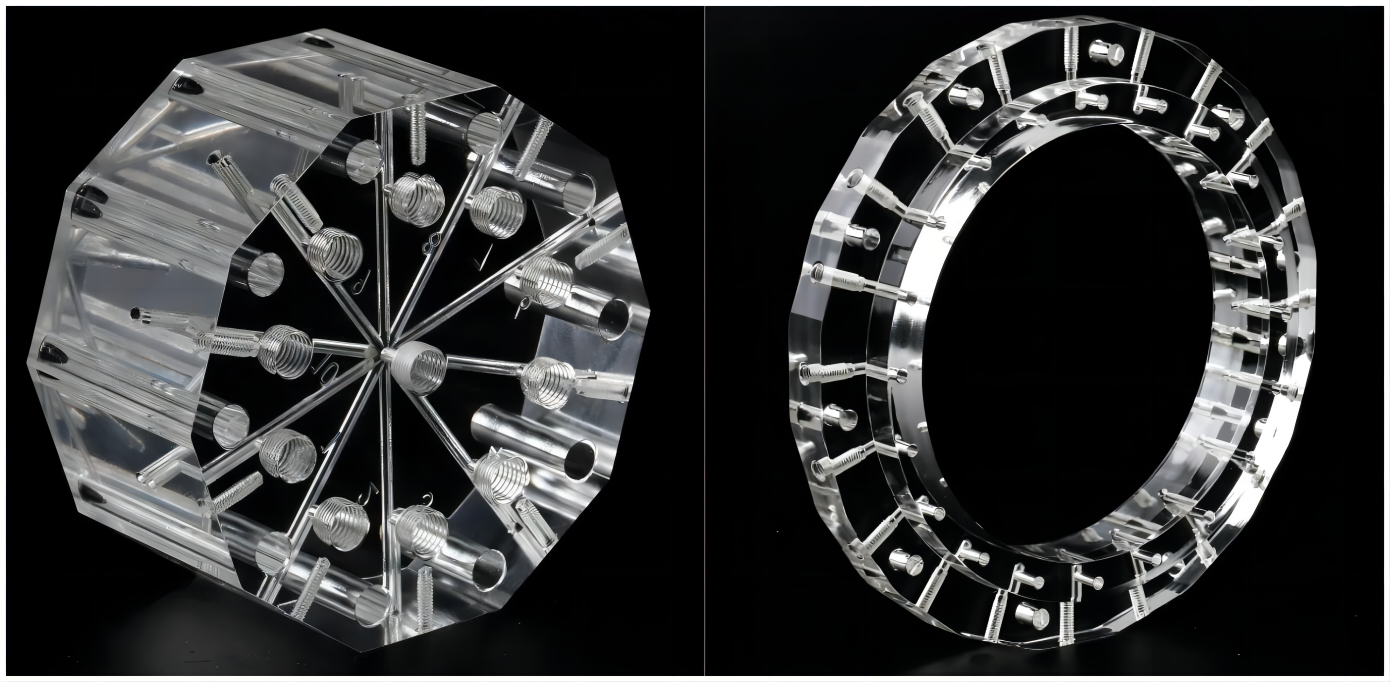

Acrylic material has the advantages of high hardness and good smoothness. Pure, environmentally friendly, translucent acrylic sheet, after China Tuofa CNC machining services, so as to enhance the product aesthetics and hierarchy, this precision accessories are widely used in the 3C field, automotive parts, medical equipment, instrumentation, pharmaceutical industry, petrochemical industry.

Engineering: due to its excellent toughness and hardness, used for door and window profiles, canopies, panels, exterior wall design can maintain good light transmission and insulation.

Engineering: due to its excellent toughness and hardness, used for door and window profiles, canopies, panels, exterior wall design can maintain good light transmission and insulation.

Lighting: acrylic is used to design LED lights, which help to limit the light. Due to its transparency and optical properties, it is also used in the construction of light z components.

Lighting: acrylic is used to design LED lights, which help to limit the light. Due to its transparency and optical properties, it is also used in the construction of light z components.

Automotive industry: automotive parts in the light and simple features, can better show the beauty of the vehicle's appearance, used in automotive windows, interior and exterior panels, automotive indicator light cover.

Automotive industry: automotive parts in the light and simple features, can better show the beauty of the vehicle's appearance, used in automotive windows, interior and exterior panels, automotive indicator light cover.

Electronic products: excellent optical clarity, high light transmission and scratch resistance, widely used in TV, laptop, smartphone display and electronic device display.

Electronic products: excellent optical clarity, high light transmission and scratch resistance, widely used in TV, laptop, smartphone display and electronic device display.

Energy: excellent UV resistance and excellent light transmission, acrylic has also been developed as a solar panel cover material, this move can achieve high energy conversion efficiency.

Energy: excellent UV resistance and excellent light transmission, acrylic has also been developed as a solar panel cover material, this move can achieve high energy conversion efficiency.

Medical: High purity and cleanliness, so it is used to manufacture incubators, drug testing equipment, storage cabinets in hospitals and research laboratories.

Medical: High purity and cleanliness, so it is used to manufacture incubators, drug testing equipment, storage cabinets in hospitals and research laboratories.

Furniture: durable, unbreakable, after the surface treatment can bring better visual effect, become a favorite material for designers to make mugs, dining chairs, door handles.

Furniture: durable, unbreakable, after the surface treatment can bring better visual effect, become a favorite material for designers to make mugs, dining chairs, door handles.

Tel:

Tel:  Email:

Email:

Home

Home