Custom CNC Machining Service in China

China Shenzhen Tuofa CNC machined parts manufacturer will meet your needs, no matter what. We are determined to get you CNC parts quickly and correctly at the right price. We're here to transform custom parts service by changing the way you get your parts. Online CNC Machining Services: Instant quotes, fast delivery, and great prices help bring your ideas and inventions to the world.

Since 2006, our team of custom precision machining services can proudly be part of our customer's supply chain, providing machined parts to their specifications. We are fast, innovative, responsive and friendly, reflected in every parts we make and the projects of the customers we work with.

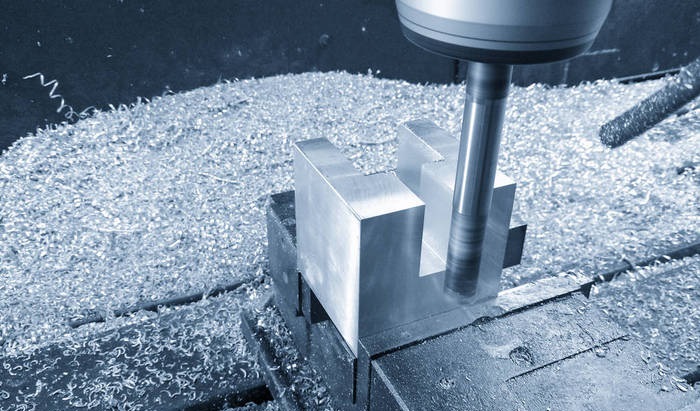

Custom CNC Machining Service - Low Volume On Demand Manufacturing

Tuofa CNC machining manufacturer is located in Longhua, Shenzhen, China. When visiting our online CNC machining shop, you'll see automated CNC machining lathes machining metals and plastics into complex parts and assemblies.

www.tuofa-cncmachining.com Tuofa has more than 17 years of professional CNC machining experience in Shenzhen, mainly engaged in precision 5-axis CNC milling, industrial 3D printing parts, CNC turning, metal stamping, casting parts, laser cutting, sheet metal bending and welding, etc.

Support prototype design and low-volume production of CNC parts. Get a free quote: info@tuofa-cncmachining.com.

Tuofa Lean Manufacturing OEM Project Experience in Numbers

Custom CNC Machining Tolerances and Standards

The concepts of component interchangeability and dimensional tolerances are an accepted part of manufacturing. Unfortunately, misuse of the latter can lead to a host of problems. For example, overly tight tolerances may require a part to undergo a secondary grinding or EDM operation to complete, unnecessarily increasing cost and lead time. Tolerances that are “too loose” or inconsistent with the tolerances of the mating parts can render the assembly impossible, requiring rework or, at worst, making the finished product unusable.

In order to avoid these unpleasant situations, Tuofa's innovative design process contains guidelines on how to correctly apply part tolerances, as well as definitions of some of the more commonly used callouts. Tuofa will also explore an industry standard for part tolerances known as Geometric Dimensioning and Tolerancing (GD&T).

| Standards | CNC Turning | CNC Milling |

|

Standard Tolerances |

Metals: ISO 2768-f Plastics: ISO 2768-m |

Metals: ISO 2768-f Plastics: ISO 2768-m |

|

Maximum Part Size |

7.9×19.7 in. |

157.5×59.1×23.6 in. |

|

Minimum Part Size |

0.079×0.079 in. |

0.1×0.1 in. |

|

Minimum Feature Size |

Φ 0.00197 in. |

Φ 0.00197 in. |

|

Linear Dimension |

+/- 0.001 in. |

+/- 0.001 in. |

|

Hole Diameters(Not Reamed) |

+/- 0.001 in. |

+/- 0.001 in. |

|

Shaft Diameters |

+/- 0.001 in. |

+/- 0.001 in. |

|

Edge Condition |

Sharp edges are broken and deburred by default |

|

|

Threads and Tapped Holes |

Tuofa can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review |

|

|

Surface Finish |

The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote |

|

|

Part Marking |

Minimum width of 0.5 mm, depth of 0.1 mm - Tuofa an use CNC engraving or laser carving to create standard text based on customers’ requirements |

|

|

Lead Time |

Machining prototype parts can be completed within 1 day at the fastest, and the delivery date is determined according to the actual quantity for mass production |

|

|

Tuofa complies with: metal standard CNC machining tolerance is ISO 2768-f, plastic standard CNC machining tolerance is ISO 2768-m. We can also achieve special tolerances as long as you specify your requirements on the drawing.

|

||

Custom CNC Machining Materials

Aluminum

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

- Price: $$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances:±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Aluminum CNC Machining

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

- Price: $$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

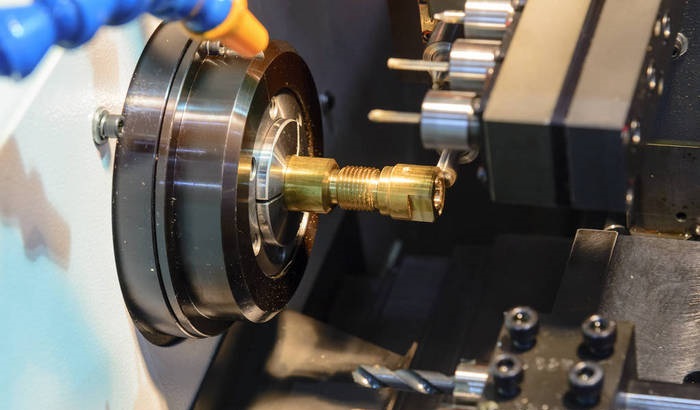

Copper CNC Machining

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

- Price: $$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Brass CNC Machining

Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

- Price: $$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size:200 x 80 x 100 cm

Stainless Steel CNC Machining

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

- Price: $$$$$

- Lead Time: < 10 days

- Wall Thickness: 0.75 mm

- Tolerances: ±0.125mm (±0.005″)

- Max part size: 200 x 80 x 100 cm

Titanium CNC Machining

Plastics

Plastics are also very popular option for CNC machining because of its wide choices, relatively lower price, and significantly faster machining time needed. We provide all common plastics for CNC machining services.

- POM

- Nylon

- ABS

- PEEK

- PTFE

- PC

- HDPE

- PVC

- PMMA

- PET

- PP

Custom CNC Machining Surface Finishes

You can choose a wide selection of metal surface finishing services after machining at Tuofa CNC machining manufacturer to improve the parts appearance, surface finishes, corrosion resistance, and other performance of your CNC machined parts.

| Name | Description | Materials | Color | |

|

Anodizing | The aluminum alloy is treated with hard anodic oxidation, and the surface can form a film layer with a thickness of 30-50 μm and a hardness of about 500HV, which has excellent corrosion resistance and wear resistance. | Aluminum | Clear, black, grey, red, blue, gold. |

|

Bead Blasting | Spray the powder coating on the surface of the workpiece. Under the action of static electricity, the powder will be evenly adsorbed on the surface of the workpiece to form a powdery coating. The surface color is combined with a silky and dry feel, which combines unique aesthetics with high performance of the product. | ABS, Aluminum, Brass, Stainless Steel, Steel | n/a |

|

Powder Coating | Used on some metal workpieces by spraying or fluidized bed, the powder is electrostatically adsorbed on the surface of the workpiece, and when it is completely dry, a protective film will be formed on the surface. | Aluminum, Stainless Steel, Steel,Titanium | Black, any RAL code or Pantone number |

|

Electroplating | The process of attaching a layer of metal film to the surface of parts by electrolysis, so as to prevent metal oxidation, improve wear resistance, conductivity, light reflection, corrosion resistance and improve appearance. The outer layer of many coins is also electroplated. | Aluminum, steel, stainless steel | n/a |

|

Polishing | The whole process of electrolytic polishing is basically completed automatically, so the labor cost is very low. Environmental impact: Electrolytic polishing uses less harmful chemicals. The whole process requires a small amount of water and is easy to operate. Metal parts can achieve the effect of delaying corrosion. | Aluminum, Brass, Stainless Steel, Steel | n/a |

|

Brushing | Make the metal surface obtain a non-mirror-like metallic luster, and at the same time, the brushed treatment can also eliminate the slight flaws on the metal surface. It is used in elevator door panels, faucets, cabinets, range hoods, sinks, etc. | ABS, Aluminum, Brass, Stainless Steel, Steel | n/a |

Machined Parts Online Applications Industries

Online machined parts are all around you; they may be important components of your car and can perform vital electrical equipment functions. Tuofa is an accomplished CNC parts supplier engaged in various CNC machining applications.

Electronic Industry

Medical Industry

Automotive Industry

Agricultural industry

Machine tool industry

Aerospace-industry

Tuofa Precision Machining Shops provides online engineering customer support for your parts, 2D and 3D drawing design, and manufacturing questions. Assist in reviewing project plans; this includes case-by-case suggestions to help you reduce costs early on in the design process. 50 CNC machines for online CNC precision machining parts, making it an excellent choice for parts prototype design and low to high-volume production runs, instant CNC parts quotes, on-time delivery, 50+ materials and 10+ surface finishes for tolerances down to 0.01mm.

From CNC Prototype to Mass Production

We understand that high quality and service are essential in today's market. The continuous success of Tuofa Machining Manufacturer can be attributed to the advanced technology and on-time delivery we provide for your prototype parts and the manufacturing specifications of mass production.

Prototype Manufacturing

Our minimum order quantity is 0. Tuofa's efficient R&D capability and advanced prototype manufacturing workshop can quickly bring your products to the market, which will help you save time to market.

Drawing Design

During design and manufacturing, our mechanical engineer team can ensure the stability of product performance for the best practice from product design to product testing. The development process you see is of high quality.

Mass Production

Provide all-round customization services from proofing, expediting, mass production and other aspects to help you shorten the cycle of mass production of products. Meet the capacity requirements of small batch orders and large batch manufacturing while ensuring quality

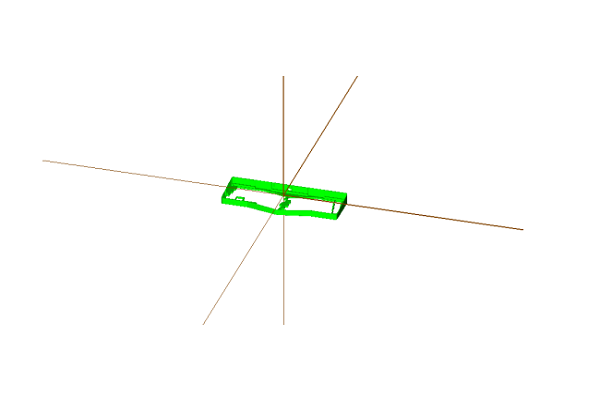

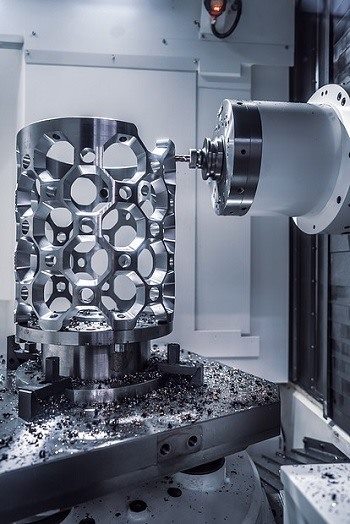

CNC Machined Parts Gallery

View our diverse parts, Tuofa precision machining workshop to reduce labor costs through higher automation equipment, can achieve online machining services with high precision and specific precision, tolerance and size, precision machining rapid prototyping and on-demand Manufacture projects that perfectly fit customers.

|

|

|

|

Why Choose Tuofa Custom CNC Machining Services?

Well-trained Support

Tuofa will make the necessary adjustments to the CNC machining machines before starting production. The step will complete the project on time as certain client requirements take the engine longer to prepare. The tweaks are necessary for implementing necessary and universal quality assurance protocols for the betterment of the stakeholders.

Quality Products

Tuofa is well aware the requirements vary according to the industry. Therefore, the production process alters too. In contrast, the inability to meet the needs means losing clients. The declining precision machining demand adversely affects quality assurance. As a result, Tuofa performs quality checks throughout the manufacturing process to eliminate inefficiencies.

Adjustability

Tuofa will make the necessary adjustments to the CNC machining machines before starting production. The step will complete the project on time as certain client requirements take the engine longer to prepare. The tweaks are necessary for implementing necessary and universal quality assurance protocols for the betterment of the stakeholders.

Compliance Standards

Tuofa is well aware the requirements vary according to the industry. Therefore, the production process alters too. In contrast, the inability to meet the needs means losing clients. The declining precision machining demand adversely affects quality assurance. As a result, Tuofa performs quality checks throughout the manufacturing process to eliminate inefficiencies.

View Customer Evaluation of Tuofa

The customer's evaluation is one of the reference standards for testing the manufacturer's ability. Compared with other similar machining companies, the reason why our customers choose Tuofa is actually very simple.

This is by far the best experience I've had on Google! Sechien Zeng is a great communicator, competent and patient with every detail, delivered parts on time, and was willing to review my drawings until the design was right! You can depend on her work and using this CNC machining service is well worth it to me. Be sure to give this professional mechanical team a huge compliment! It is well deserved! I will definitely come back and recommend Shenzhen Tuofa Suppliers to my circle.

When it comes to custom CNC machining service, I have used a lot of different companies and suppliers. But I can say without a doubt that Tuofa is the best I have ever worked with. From start to finish, Tuofa provided fantastic service. Sales engineer Tracy was always quick to respond to my questions and concerns, and she went above and beyond to make sure that the work was done right. As a result, I have seen the sales volume of products increase significantly, and my business has become better than ever. I will definitely choose Tuofa among all CNC machining projects in the future.

This review is way too late! Let me tell you about the Tuofa team! They are one in a million, the best among Chinese machining manufacturers. During the development process of my ready-to-design parts, they responded very quickly, guaranteed high precision and stability, and the final delivered product was perfect. They can understand everything I want to say and convey in my CNC machining project. I highly recommend Tuofa to anyone who is looking for an outsourcing factory.

Tuofa CNC Machining Company - The Best CNC Machining Manufacturer in Shenzhen, China

Tuofa custom CNC precision machining service custom manufacture car parts, motorcycle parts, bike parts, metal stamping, Medical Equipment parts, Aviation machinery parts, cabinets, frames, enclosures & other metal parts & components from various materials. Services include project audit, parts custom, shearing, punching, laser, saw cutting, rolling, forming, design, installation, assembly, MIG & TIG welding, design & installation. Quality Control ISO9001: 2015 Certified.

Let us know how we can help you with your next CNC machining project

Our blog columns and product galleries will provide you with the many applications for metal fabricating of unique custom sheet metal products and parts we have made over the years. From precision parts manufacturing in the medical industry to high-standard manufacturing in the aerospace industry. Our team of engineers is available to help you solve your CNC machining parts production needs..

CNC Machined Services Advantages

- Efficient CNC machining factory for mass production rapid prototyping service

- Average 10 days turnaround time and 99.88% on-time delivery

- Multiple options for machining materials to meet specific properties.

- Fast, free quotation within 24 hours after inquiry

- Have High customer satisfaction and loyalty

- Rich design and manufacturing experience

Suppose you are looking for quality CNC machining services near me. In that case, our low-cost CNC custom machining will review the design, build your quote, assess the cost, and get your non-metal or metal fabrication parts into production orderly and efficiently.

Machined Parts Online- OEM China CNC Machining Parts Manufacturer & Company

Tuofa CNC Parts factory (tuofa-cncmachining.com) main production modes are designing and proofing based on customer drawings, concepts and samples.

In terms of quality control, we stress the concept of quality as the life of our enterprise, following ISO standards and the whole production inspection ways for strict quality control.

Following the requests of RoHS and Heavy Element, we send products to the third-party notarization institute for internationally recognized inspection, with the complete inspection report.

Regarding product technology, Tuofa CNC machining parts suppliers have a group of professional engineering and technical personnel in design and production, providing professional advice, converting the concepts from guests into controlled products and helping customers solve professional problems reducing production costs.

Each department has several professional engineers with the most advanced equipment in the industry, improving our efficiency, quality and stability to produce high-quality and inexpensive products.

With precision 3-, 4- and 5-axis CNC machining centres, combined with precision sheet metal fabrication, 3D printing project advanced capabilities and our experienced team, we can handle all types of CNC machining parts in both metal and plastic materials. Whether you need prototypes or production parts, our machining services will be your best choice. Contact us today to complete your machining prototypes in as fast as 1 day!

Quality Assurance for Tuofa CNC Machining

- ISO9001-certified precision machining shops

- Performance tracking on lead time and quality

- Strict NDA agreements with Buyers

- Inspection report included in every order.

- Full dimensional inspection reports on request

- Material certifications and test reports available on request

- Batch inspection in concurrence with ISO2859

- Low Cost On Demand Manufacturing, On-Time Delivery

In the process of following up on samples/production, we have several sales personnel who will make all-out efforts and make quality/delivery/price/needs as per your requirements to meet your expectations as far as possible.

In terms of credibility, we guarantee the quality of our products, adhere to business ethics and keep commercial secrets. With us, your money is safe; your business is safe.

People Also Ask

How much does a custom CNC machined part cost?

Due to the great process flexibility in machining, a parts can have many kinds of process arrangements, so the cost is of course different. However, suppliers sometimes tell you that a complex process will increase the price when quoting, but other simple processes will be used in actual production, so your own reading of drawings and knowledge of parts processing will determine your grasp of costs. How much does machining cost per hour in China?

Machine cost: CNC machining center and CNC lathe ¥60~100/hour; Labor cost: ¥30~40/hour. The total cost of CNC services is approximately 120 RMB per hour. There is a big price difference between individual parts and mass production, and the time required for simple and complex parts is different, and the more advanced CNC machines, the higher the cost. So this is also very understandable. Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China, with 17 years of rich experience, covering 5000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports. How to enjoy the OEM services?

Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you. Can I get a quotation without drawings? Can your engineering team draw for my creativity?

Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions. (2) First inspection of production - ensure critical dimensions in mass production. (3) Sampling inspection - check the quality before delivery to the warehouse. (4) Preshipment inspection - 100% inspection by QC assistant before shipment. What will you do if we receive poor quality parts?

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week. |

Online CNC Machining Resources

What Is CNC Turning

CNC turning is the process of removing material from a rotating workpiece using the linear path of tools on a CNC lathe. In a simple perspective, the main elements involved in this process are the rotating spindle in which your work part is clamped and the cutting tool that is mounted on a turret.

A Method for Calculating the Cost of Turned Parts

At present, the online CNC machining shop is widely used in the machinery industry, and it is inevitable to encounter some complex, special-shaped or similar hollow workpieces. When making such workpieces, it is a test of the experience and technology of the program and the machinist

CNC Machining Complex Cavity Parts

At present, the online CNC machining shop is widely used in the machinery industry, and it is inevitable to encounter some complex, special-shaped or similar hollow workpieces. When making such workpieces, it is a test of the experience and technology of the program and the machinist

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home