What Is S235JR?-Complete Guide to the Most-Used Steel Grade

Jul 25,2025

Jul 25,2025

Steel is available in more than 1000 different grades, and almost every grade is in use in the form of different shapes, applications, etc. You will explore S235JR grade, one of these 1000+ grades in this article, its applications, which standard specifies it, chemical composition, etc.

What S235JR Means in the EN 10025 Standard

European standards were introduced in the early 1900s to guide people on how to manufacture or use specific alloy or non-alloy steel. EN10025 is a part of European harmonisation of steel norms. It defines requirements for hot-rolled structural steels, and S235JR is the most used grade under this standard.

What Is The “S235JR” Stand for?

Every part in this name has a specific meaning. Let's break down the name of steel "S235JR":

- S means structural steel.

- 235 is the minimum yield strength of the steel, i.e. 235 MPa.

- JR means its impact strength at room temperature, i.e. 20 °C.

JR can be changed as J0, J2 or JR:

- JR, as already mentioned, it is room temperature

- J0 means good to use at 0°C

- J2 means good to use in freezing conditions, i.e. -20°C

Place of S235JR Within The Non-Alloy Family

In European standard EN 10025-2, S235JR belongs to non-alloy steel, and its place is shown in the following table:

|

Grade |

Minimum Yield Strength (MPa) |

Tensile Strength (MPa) |

|

S185 |

185 |

290-510 |

|

S235 |

235 |

360-510 |

|

S275 |

275 |

410-560 |

|

S355 |

355 |

470-630 |

You can see that as the digit value increase, yield strength and tensile strength are increased.

Why ”JR” Matters for Impact

JR is very important in the world of S235JR, because it means impact strength. Higher impact strength means it can bear. As you know, steel is used in:

- Construction Beams

- Bridges and support structure

- Machinery frames and

- and Storage tanks, etc.

In these applications, JR ensures that non-alloy steel withstands impact loads successfully.

Chemical Composition of S235JR

As you know, it is the chemical composition of any material which defines its mechanical properties. So, let's discuss the chemical composition of S235JR:

Max C, Mn, Si, Residuals

If we compare the composition of S235JR with ASTM A36:

|

Element |

S235JR (EN 10025-2) |

ASTM A36 (Comparison) |

|

Carbon (C) |

≤ 0.17% |

≤ 0.26% |

|

Manganese (Mn) |

≤ 1.40% |

≤ 0.90% (typical) |

|

Silicon (Si) |

≤ 0.35% |

≤ 0.40% |

|

Phosphorus (P) |

≤ 0.045% |

≤ 0.040% |

|

Sulfur (S) |

≤ 0.045% |

≤ 0.050% |

EN 10025-2 has a lower amount of C content, which increases its weldability, and lower amounts of impurities improve its toughness. Higher content of Mn increases the strength of S235JR steel. In both steel grades, impurities are strictly controlled to retain ductility and reduce brittleness.

Effect of S, P, N

- If Sis controlled, it reacts with Mn and forms MnS inclusions, which reduce toughness and increase brittleness of the material.

- Preduces ductility and toughness but increases strength of the material.

- Nis added to increase the strength of the material, but it can cause strain-ageing, in which brittleness keeps increasing with time.

Heat- vs Ladle-Analysis

Both analysis are performed to analyse whether the chemical composition meets the actual requirement, i.e. standard requirements.

- Ladle Analysis

It is performed in the molten form of steel before casting to ensure that composition is according to EN 10025-2.

- Heat Analysis

Heat Analysis is performed after solidification to check whether there are any compositional deviations.

S235JR Mechanical Properties Across Thickness Ranges

Let us tell you that, in EN 10025, yield strength of S235JR decreases if you increase its thickness.

Yield-Strength Table

As you can see in the following table:

|

Thickness (mm) |

Yield Strength (MPa) Min |

|

≤ 16 mm |

235 MPa (nominal grade value) |

|

>16 - 40 mm |

225 MPa |

|

>40 - 63 mm |

215 MPa |

|

>63 - 100 mm |

215 MPa |

|

>100 - 150 mm |

195 MPa |

|

>150 - 200 mm |

185 MPa |

The reason why thinner steel has higher yield strength is fine-grain structure. Fine-grain structure provides strength to the steel.

What Is The Yield Strength of S355JR?

355 MPa is the yield strength of S355JR if its thickness is less than or equal to 16mm. But its thickness goes beyond 100mm; yield strength will reduce to 295 MPa.

Tensile & Elongation

- Tensile strength of this grade of steel is 360 - 510 MPa.

- In case of less than or equal to 40mm thickness, elongation is 26% and if the thickness exceeds 40mm, elongation decreases to 25%.

So, you can see that although yield strength decreases with increasing thickness, its elongation almost remains consistent.

Charpy Impact

|

Grade |

Test Temperature |

Minimum Impact Energy (Longitudinal, Standard Specimen) |

|

S235JR |

+20°C |

27 J |

|

S235J0 |

0°C |

27 J |

|

S235J2 |

-20°C |

27 J |

In EN 10025, the impact strength is found out through the Charpy impact test at three

different temperatures, as given in the following table. S235JR retains its impact energy from -20 degrees Celsius to 20 degrees Celsius. In the Charpy test, V-notch specimens are used to find out the impact energy of the respective material.

Global Equivalent Grades of Steel S235JR

As you know, steel S235JR is a grade of steel under EN 10025 standard. This standard is used in Europe only. But different regions have multiple standards equivalent to EN 10025. Let's figure out these standards in this section:

ASTM A36 / A283 C

In American Society For Testing Materials (ASTM), A36 is considered equivalent to S235JR. AWS D1.1 often allows substitution, because:

- Similar yield strength.

- Both are general-purpose structural steel.

- The C content is higher in A36 steel, so it needs preheat. S235JR steel has better toughness than this grade.

GB Q235B / Q235D

There are two equivalent standards in China for EN 10025:

GB Q235B is approximately S235JR

The only differrence is C content; Q235B has slightly more C, i.e. 0.22%, due to which it needs preheat before the welding process. GB Q235D is equivalent to S235J2.

JIS SS400

In Japan, JIS SS400 is equivalent to EN 10025. It has similar tensile strength, but impact strength is different. It is not suitable for low temperatures or dynamic loads.

Tips for Cross-Spec Ordering

You should follow these tips when you want or need to substitute S235JR:

- Primarily check yield and tensile strength.

- Check the toughness.

- Welding Compatibility.

- Check for certification.

- Check mill test reports.

S235JR Fabrication Guidelines - Cutting, Forming, Welding

As you know, S235JR is a non-alloy structural steel, which is why it has good weldability, forming and cutting. These properties are essential for structural properties.

Cutting S235JR

You can read some cutting methods for S235JR. You can see that different methods are suitable for different thicknesses.

|

Method |

Best For |

Thickness Range |

Advantages |

Limitations |

|

Plasma Cutting |

Fast, precise cuts |

Up to 50mm |

- High speed - Clean cuts |

- May cause edge hardening |

|

Oxy-Fuel Cutting |

Thick sections |

>20mm |

- Cost-effective for thick materials |

- Leaves hardened edge - Slower than plasma |

|

Laser Cutting |

Thin to medium plates |

<25mm |

- Extreme precision - Smooth edges |

- Limited to thinner materials |

Forming & Bending S235JR

- You should choose cold rolling because this grade has lower carbon content. Cold rolling increases its strength by refining the grains.

- You can do hot forming if the thickness of the part exceeds 50mm.

- Minimum bending thickness is 1X of the material's thickness.

Welding S235JR

If you want crack-free and strong welds, choose these welding processes:

- SMAW

- MIG

- TIG

If thickness is more than 30mm, then it is wise to preheat the part.

CNC Machining S235JR for Custom Parts

S235JR is a mild steel due to lower C content, 0.17%, which is why its machining is very easy. It remains always at high priority when manufacturers receive a custom CNC project.

Custom CNC Machining Operations

In this section, we will make you familiar with some common CNC operations:

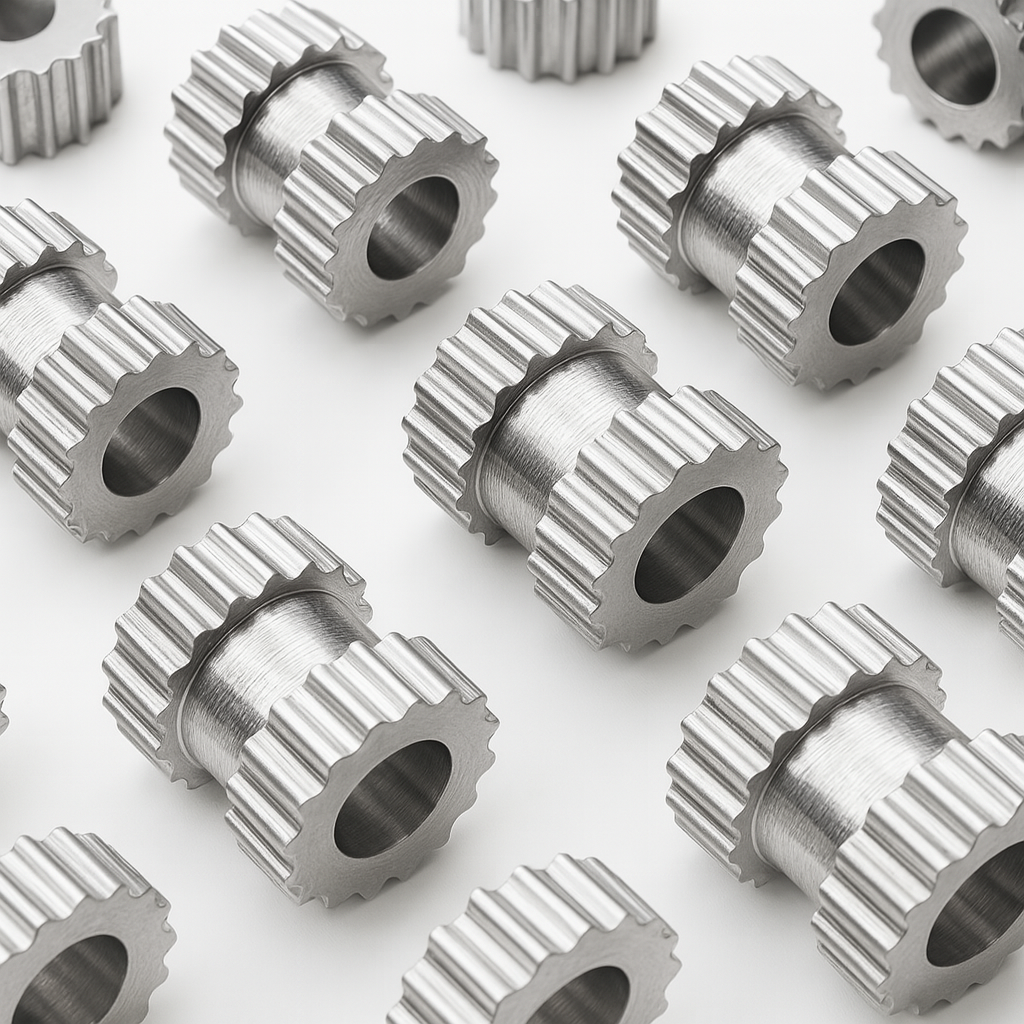

Custom CNC Turning

You can perform CNC turning operations for cylindrical parts to achieve smooth surfaces. This process is helpful in manufacturing gears, shafts, pushings and pins.

Custom CNC Milling

If you need to customise 2D or 3D parts, you can easily pick this operation. It provides good chip evacuation. In industries, this process is used for brackets, plates and structural parts.

Custom CNC Turn-mill

As the name of this operation itself, it's a combined operation of turning and milling. If you have to manufacture complex-designed parts, choose CNC turn-mill operation because of reduced setups. Fittings and flanged components are manufactured using this process.

Custom 5-Axis Machining

This is the most advanced CNC operation in manufacturing industries. If you need undercuts or deep cavities with high precision and single setup, choose this CNC operation. It is mostly used in aerospace and automotive industries.

Machinability Rating

Machining rating for any material is calculated based on the following three things:

- Machining Index:This grade has 70% free-machining

- Chip Formation:S235JR produces continuous and manageable chips

- Surface Finish:This grade can provide you Ra 6-3.2 µm surface finish if proper tools are used.

CNC Cutting Tooling and Coatings

This table gives insights about those tools and required coatings which are used in precision CNC machining.

|

Tool Type |

Recommended Coating |

Use Case |

|

Uncoated HSS |

None |

Light cuts, low-speed operations |

|

TiN-Coated HSS |

Titanium Nitride |

General-purpose machining |

|

Carbide Inserts |

TiAlN, AlCrN |

High-speed, high-volume production |

|

Cermet Inserts |

- |

Fine finishing, tight tolerances |

Suggested Feeds & Speeds

You can use these feed rates and speeds to achieve best results:

|

Operation |

Cutting Speed (m/min) |

Feed Rate (mm/rev) |

Depth of Cut (mm) |

|

Roughing |

80-120 |

0.2-0.4 |

2-5 |

|

Finishing |

150-200 |

0.05-0.15 |

0.2-0.5 |

Hold Tolerance After Stress-Relief

Generally, mild steel does not require holding tolerance after stress relief because of good machinability. But for the safe side, you can hold tolerance up to ±0.05mm.

What Is the Surface Treatment & Corrosion Protection

After machining, you can't use that part because Fe has a strong electronegativity for oxygen, due to which it rusts very quickly. To avoid rust, you need to apply one of these treatments:

Hot-Dip Galvanising

It is one of the oldest processes to protect the surface of the parts. In this method, a part is dipped into the molten zinc. A layer of Zn is deposited on the steel part. This Zn layer reacts as a barrier between the part's surface and the environment. This layer is also called the sacrificial layer because of its higher tendency to get corroded. In this way, material beneath this layer remains corrosion-free.

Blast & Paint Systems

As you know, during machining, dust, oil, grease, etc., make the surface dirty. To clean the surface, first, a sand blasting process is performed in which fast-moving small balls constantly hit the surface to clean it. Then the paint is applied, which further acts as a protective layer and prevents oxidation and moisture.

Why Do We Need the Corrosion Protection

If you use a mild steel part in an open environment like a tower made of mild steel, it will corrode completely within a few months. After some time, the material will lose its integrity and start to lose its strength. Ultimately, it will break catastrophically and cause serious loss (human injuries + money). That's why it is very important to protect every part from corrosion.

Typical Applications of S235JR Material

Let’s discuss some typical applications of S235JR material in this section:

Machine Bases

S235JR material is used in the bases of many machines. For instance, you can see this material in the bases of:

- Lathe Beds & CNC Machine Frames

The strength of this material enables it to withstand dynamic loads during machining of a part.

- Milling-Machine Sub-Frame Plate

For a stable and rigid foundation for heavy machinery, S235JR is a very good choice because of the combination of toughness and strength.

Vehicle Chassis

- 6 mm bend-formed truck trailer side-rails

To bear a heavy dynamic load, you will need a material of good impact strength. In such cases, S235JR is a good choice.

- Bus & Truck Chassis Components

Due to lower C content, S235JR has a good weldability. Due to this, this material is used in making chassis components.

Other Typical Applications

You will see S235 in many other applications, such as:

- Staircases and Handrails

- Storage Tanks and Shelving

- Construction Beams & columns

- Safety Barriers

S235JR vs Higher-Strength Structural Grades

Except S235JR, there are 3 other grades as well in EN 10025 standard, which are known as higher-strength structural grades.

What Is Higher-Strength Grade

The following grades are the higher-strength grades in EN 10025, which offer better mechanical properties, which is why they are more in demand for applications where loads are high.

As mentioned earlier in the case of S235JR, 235 shows its yield strength. Same is the case with these 3 grades:

- S275:275MPa yield strength

- S355:means 355MPa yield strength

- S420:420MPa yield strength

S235JR vs S355JR

A difference of mechanical properties between S235JR and S355JR is given below in the table:

|

Property |

S235JR |

S355JR |

|

Nominal Yield Strength |

≥235 MPa |

≥355 MPa |

|

Tensile Strength |

360-510 MPa |

470-630 MPa |

|

Elongation |

~26% |

~22% |

|

Weldability |

Excellent |

Good (requires preheat for thick sections) |

|

Typical Use Cases |

Light structures, machine frames, non-critical parts |

Heavy load-bearing structures, bridges, cranes |

Strength & Weight

If you use beams of S355JR material, you will need less quantity of material as compared to S235JR because S355 has higher yield strength. It means if you need strength and weight reduction, use S355JR instead of S235JR.

Cost and Availability

Both grades of steel are common and easily available in the markets. S355JR is 10-20% more expansive(€600-700/ton) than S235JR(€500-600/ton) but in case of larger structural applications, S355JR remains cost-effective due to less usage of material.

Fatigue & Dynamic Load

For dynamic loads such as in cranes, bridges and vehicle chassis, S355JR is a better choice than S235JR because of higher fatigue strength.

Conclusion

We conclude that S235JR is an important cost-effective material which is mostly used in structural applications. To maintain its structural integrity, further surface treatments are performed to increase corrosion resistance and durability. There are various grades in EN 10025 standard, so you first need to understand the requirements of your project before you choose the steel grade. For instance, in case of dynamic loads, choose S355JR grade instead of S235JR.

If you need assistance in your project, in any case, e.g. machining, come to TUOFA. We are equipped with the most advanced CNC machines and using our expertise, we can fulfil your requirements. We will deliver our services quickly and at lower prices than the market.

FAQs on S235JR

Is S355JR stronger than S235JR?

Yes, S355JR has a yield strength of 355MPa which is higher than yield strength of S235JR(235 MPa).

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

PA66 (Nylon 66): Properties, Processing, and Applications

PA66 (Nylon 66): Properties, Processing, and Applications