Stainless Steel CNC Machining

Steel containing more than 12% chromium has the characteristics of stainless steel, with excellent corrosion resistance, formability, compatibility, and toughness, used in heavy industry, light industry, household goods industry, and architectural decoration industries.

Among the materials available for CNC machining at Tuofa, there are numerous stainless steel grades to choose from, 201、 301、 303、 304、 304L、 316、 316L、 321、 410、 416、 420、 430、 440、 630、 6305, as you can see, we have a unique advantage in our hard metal CNC machining services, we can customize parts to any stainless steel grade you specify.

Advantages of Stainless Steel

Stainless Steel for CNC Machining Service

Tuofa is a highly respected CNC specialist in the bustling Shenzhen region of China. Our mechanical engineers have a deep understanding of the various stainless steel materials available for their precision CNC machining services. With a keen understanding of the underlying crystal structure, Topfa skillfully classifies these materials into four categories: austenite, ferrite, martensite, and duplex. Through the skillful use of these materials, CNC on-demand manufacturing services have become a true testament to our unparalleled mastery of craftsmanship.

Ferritic Stainless Steel

Ferritic stainless steel, a nickel-free chromium stainless steel, accounts for more than half of the total production of stainless steel.

Advantages

Has the formability, economy, corrosion resistance, oxidation resistance and other properties of nickel-containing stainless steel, and low cost, excellent stress corrosion resistance and other significant features, known as economic stainless steel

Applications

CNC Machining ferritic stainless steel material is mainly used to make corrosion-resistant parts such as gas turbine parts, etc.

Austenitic Stainless Steel

Austenitic stainless steel is a stainless steel material with stable internal austenite organization, which contains 18% chromium and about 8% nickel, but also contains a small amount of molybdenum, titanium, nitrogen and other elements.

Advantages

Good overall performance, corrosion resistance of a variety of media, toughness and plasticity are relatively good, easy to cut performance

Applications

Austenitic stainless steel CNC machining are widely used in major industries. Such as corrosion-resistant containers and equipment lining, transport pipelines, nitric acid-resistant equipment parts, etc., in addition to being used as the main material of stainless steel watch jewelry.

Martensitic Stainless Steel

Martensitic stainless steel belongs to is a hardenable stainless steel material.

Features

The mechanical properties of this stainless steel material can be changed by heat treatment.

Applications

At present, CNC machining martensitic stainless steel parts is mainly used in the processing and production of steam turbine blades, surgical instruments and other products.

Duplex Stainless Steel

Duplex stainless steel is a kind of internal austenitic and ferritic organization structure of each half of the stainless steel products, compared with ferritic stainless steel, the price is relatively high.

Advantages

Has the characteristics of austenitic stainless steel material and ferritic stainless steel material, and compared with ferritic stainless steel, its plasticity is better, higher toughness, and compared with austenitic stainless steel, its thermal conductivity is better and the expansion coefficient is smaller.

Applications

2205 stainless steel is widely used in the oil and gas industry, piping systems in the industrial manufacturing industry and heat exchangers.

Try Tuofa Now!

Are you looking for aluminum parts that offer superior performance and production specific flexibility to CNC machined aluminum manufacturers? Review Shenzhen Tuofa!

Commonly Used Stainless Steel Grades and Properties

304 stainless steel

It is one of the most widely used austenitic stainless steels in terms of application and use, suitable for manufacturing deep-drawn forming parts and acid transfer pipes, vessels, structural parts, various instrument bodies, etc. It can also be used for manufacturing non-magnetic, low-temperature equipment and parts.

It is one of the most widely used austenitic stainless steels in terms of application and use, suitable for manufacturing deep-drawn forming parts and acid transfer pipes, vessels, structural parts, various instrument bodies, etc. It can also be used for manufacturing non-magnetic, low-temperature equipment and parts.

304L Stainless Steel

Its corrosion resistance is significantly better than 304 stainless steel. In addition to slightly lower strength, other properties with 321 stainless steel, mainly used for welding and can not be solid solution treatment of corrosion-resistant equipment and components, can be used in the manufacture of various types of instrument bodies.

Its corrosion resistance is significantly better than 304 stainless steel. In addition to slightly lower strength, other properties with 321 stainless steel, mainly used for welding and can not be solid solution treatment of corrosion-resistant equipment and components, can be used in the manufacture of various types of instrument bodies.

316 Stainless Steel

In 305 steel based on the addition of molybdenum, so that the steel has good resistance to reducing media and pitting corrosion resistance. In seawater and various other media, corrosion resistance is better than 304 stainless steel, mainly used for pitting corrosion resistant materials.

In 305 steel based on the addition of molybdenum, so that the steel has good resistance to reducing media and pitting corrosion resistance. In seawater and various other media, corrosion resistance is better than 304 stainless steel, mainly used for pitting corrosion resistant materials.

316L Stainless Steel

Ultra low carbon steel, with good resistance to intergranular corrosion in the sensitized state, suitable for the manufacture of thick cross-sectional dimensions of welded parts and equipment, such as petrochemical equipment in the corrosion-resistant materials.

Ultra low carbon steel, with good resistance to intergranular corrosion in the sensitized state, suitable for the manufacture of thick cross-sectional dimensions of welded parts and equipment, such as petrochemical equipment in the corrosion-resistant materials.

Whether you need a custom CNC aluminum prototype or mass production, our aluminum machining engineers have the expertise and technology to deliver the quality and precision you need.

So why wait? Contact Tuofa today to learn more about our CNC aluminum machining and how we can help you achieve your goals!

Custom Stainless Steel Products

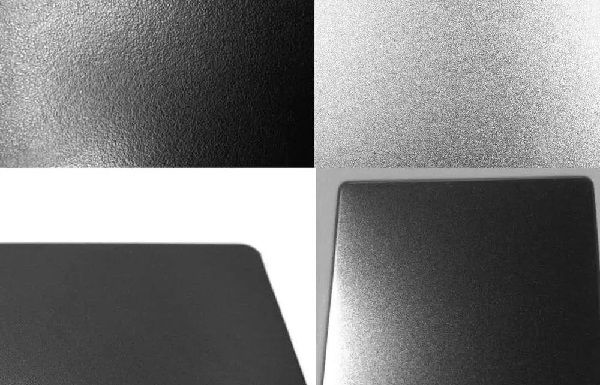

Stainless Steel Finishes

Due to the excellent corrosion resistance inherent in stainless steel, it is often used without any coating, directly using its bare metal. Thus, we only see its original color, silver white a color, it will make people feel a little monotonous. Thus, the color stainless steel was born.

Stainless steel application development prospects will become more and more extensive, depending on the degree of development of surface treatment technology.

Stainless steel surface treatment to choose which method, according to the product structure, material, and different requirements for the surface, choose the appropriate method for processing. Tuofa can currently provide six kinds of stainless steel post-treatment process, including: mill finishes, polished finish, brushed finish, paint, electroplating, and any chemical treatment process you specify.

People Also Ask

Why does stainless steel rust?

Yes! Stainless steel will rust, there are three main factors that affect the rusting of stainless steel. How to deal with stainless steel rust?

Chemical method What are the properties of 440C stainless steel and 904L stainless steel?

904L Stainless Steel |

Tel:

Tel:  Email:

Email:

Home

Home