Polypropylene Machining: Material Properties and Uses

There are hundreds of plastics suitable for CNC machining processing, but polypropylene material accounts for 10% of use, second only to PVC. The outstanding feature of polypropylene is the resistance to bending fatigue (7*10^7) times of folding and bending without damage marks.

Soft plastic materials, when machined, tend to heat up and cause deformation, so our machinists use spindle speed 15000-18000, feed rate 3000-5000, and carbide or high-speed steel(HSS) for tools in polypropylene machining.

What is Polycarbonate

Polypropylene(PP) is a thermoplastic resin, a polymer made of propylene through a polymerization reaction. As one of the lightest of the commonly used plastics, it is easy to machine and surface treat, and also has resistance to wear and tear, chemical resistance, and favorable economic conditions.

Advantages of Polypropylene Material

Best Solution for Polypropylene Parts

Polypropylene parts are able to withstand more load and less fatigue damage due to the higher crystallinity and lower defect density in its molecular structure; it also reduces minor defects and damage within the material.

Then have you considered which of your products' problems can be solved by this feature of it? Please leave these things to Tuofa, we will choose the right material according to your project, and completing the order is just the beginning of our value creation for you!

Polypropylene Material Properties

| Items | Test condition | Test method | Test data | Unit | |

| Basic performance | Density | ASTM D1505 | 0.9 | g/cm3 | |

| Water imbibition | After 24 hours | ASTM D570 | 0.02 | % | |

| Mechanical properties | Notched impact strength | 23°C(73.4F) | ASTM D256A | 2.6 | Kg.cm/cm |

| Tensile yield strength | ASTM D638 | 10 | % | ||

| Elongation at break | ASTM D638 | 360 | Kg/cm2 | ||

| Rockwell hardness | ASTM D758A | 97 | R scale | ||

| Thermal performance | Bending modulus | ASTM D790B | 17500 | Kg/cm2 | |

| Melting point | ASTM D648 | 170 | ℃ | ||

Polypropylene Uses

Polypropylene material is widely used in the production of medical devices, automobiles, bicycles, parts, conveying pipes, chemical containers, etc. It is also used for food, drugs and garments. CNC machined polypropylene parts can be manufactured including:

Machine cases

Machine cases

Bearings

Bearings

Bolts and nuts

Bolts and nuts

Handles and knobs

Handles and knobs

Pipe parts(Valves)

Pipe parts(Valves)

Pallets

Pallets

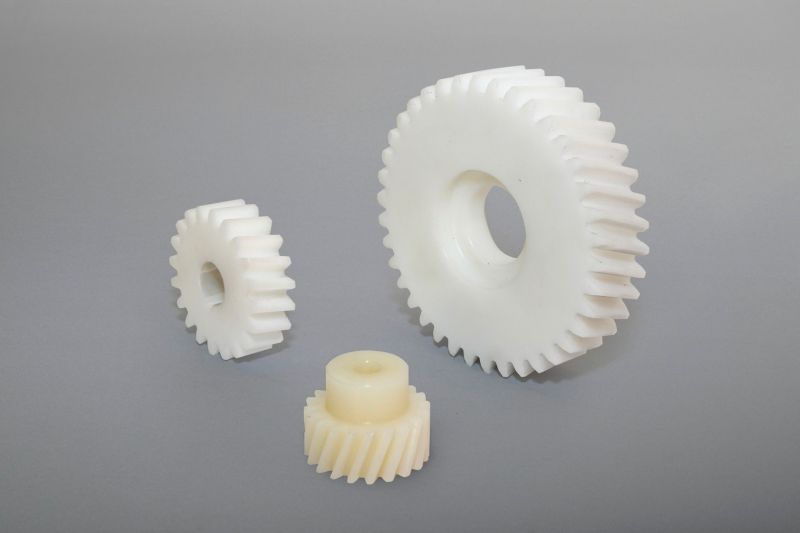

Custom Polypropylene Parts Display

Choose Tuofa's custom polypropylene parts. In our precision 5-axis CNC shop, engineers precisely control the parameters and tool paths of CNC machines, resulting in high-precision part machining.

People Also Ask

Polypropylene vs Polycarbonate

1. Difference in appearance: polypropylene material will be at a relative disadvantage, from the appearance, polycarbonate is not glossy enough and is a translucent material; while polycarbonate has a higher light transmission rate and is close to transparent. |

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home