PEEK vs PTFE: Which High-Performance Plastic Fits Your CNC Project?

Jun 20,2025

Jun 20,2025

Quite often in high performance applications, the selection of materials becomes even more important than the design. In specialized applications which require polymers to be employed due to chemical inertness, insulating behavior, biocompatibility, non-adhesiveness or any other factor PEEK and PTFE become a top choice. Both these materials have can withstand heat and chemical attack very well. Let's dive into some of the key aspects of these promising materials.

What Are PEEK and PTFE?

Polyether Ether Ketone (PEEK) and Poly-Tetra-Flouro-Ethylene (PTFE) belongs to a class of high-performance thermoplastics. They have exceptional properties that can withstand heat, chemical attack, wear and high loads. Thus, PEEK material and PTFE materials are selected by engineers in high demanding applications.

- The Relationship of PEEK and PTFE

PEEK and PTFE both have high mechanical strength, high wear resistance, high creep resistance, chemical inertness and low coefficients of friction. Both PTFE and PEEK are comparatively more expensive than ordinary thermoplastics.

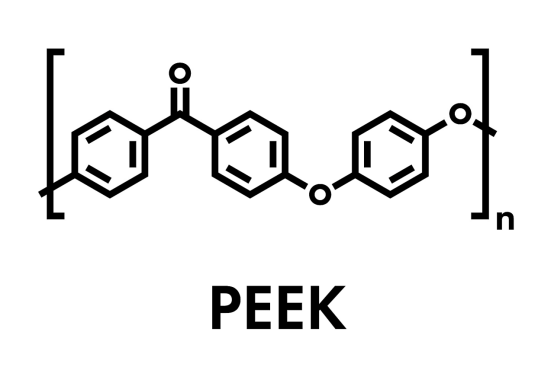

PEEK Molecular Basics

PEEK has an aromatic carbon backbone linked with ether (-O-) and ketone (-C=O) functional groups. PEEK material has a high level of crystallinity.

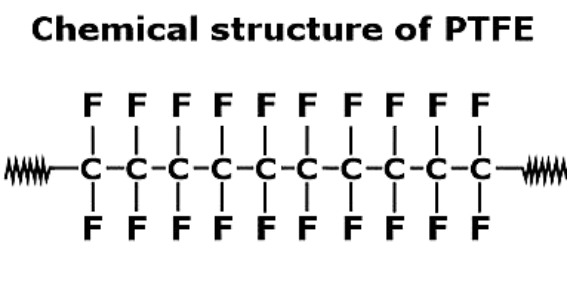

PTFE Molecular Basics

PTFE has a fully fluorinated carbon chain.

Why Are They Called High-Performance Plastics?

Owing to their exceptional properties, these polymers are used in advanced applications like medical implants, aerospace parts, and other high precision CNC parts.

How Do Their Molecules Differ?

Although, PEEK and PTFE have a lot in common when it comes to properties, but their molecular structure is fundamentally different. Both of these materials have different functional groups and different monomers that form the polymer chains. Let's look at the key aspects of their molecular structures.

Aromatic Backbone Strength in PEEK

PEEK polymeric chains have a good arrangement of aromatic carbon rings that are form a chain with ether (-O-) and ketone (-C=O) groups as depicted in figure 1. This high level of order in arrangement gives it a good crystalline structure. Due to the presence of the ether and ketone functional groups together with the aromatic rings, PEEK material has a high strength that can be maintained a high temperature (often around 250oC).

Full-Fluorination Inertness of PTFE

PTFE material has a carbon chain in which each carbon atom forms one bond with a Fluorene atom. In this way, in a PTFE monomer -(C2F4)n- , there are four Fluorene atoms, two carbon atoms having no hydrogen atom. This Fluorene backbone gives PTFE an excellent chemical inertness, hydrophobicity, ultra low coefficient of friction, resistance against UV exposure and high temperature stability.

How Does Structure Change Real-World Behavior?

|

Structure |

Effect |

|

Aromatic rings (PEEK) |

Strength and rigidity |

|

Ketone groups (PEEK) |

Heat and stress resistance |

|

Fluorine atoms (PTFE) |

Chemical inertness and non-stick behavior |

|

Flexible chain (PTFE) |

Softness and low wear durability |

Thermal Properties: About Temperature Resistance

Commonly polymers have a low resistance to heat. However, both PTFE and PEEK has a remarkable performance at high temperatures. So much so that they are sometimes used in place of metals, in hot environments where an electrical insulating behavior is required.

- How much heat can PEEK and PTFE take?

Normally PEEK can maintain it's strength at a working temperature of 250OC. PTFE too can withstand a temperature of 250oC before degradation begins, but it softens way below this temperature. Dimensional stability and load bearing capacity becomes a concern for PTFE at high temperatures.

What Is the Safe Working Temperature for PTFE?

As discussed above PTFE can withstand a temperature of 250oC before degradation begins. However, this temperature limit could well be considered for coating applications like non stick pans. But, PTFE material cannot bear load at high temperature.

Heat Limit Before PEEK Creeps

An exposure to high temperature for long durations cause creep. Although 250oC is considered as a safe operating temperature for PEEK, but for long- term exposure a significant effect of creep must be kept in mind. It happens in the following stages:

Stage 1: Initial rapid deformation (elastic strain and some plastic strain)

Stage 2: Steady-state creep (slow and linear increase in strain at a constant load)

Stage 3: Accelerated creep that leads to fracture (occurs in loads >10,000 hours)

Melting Point vs Glass Transition

Glass transition temperature is the temperature above which a material loses its crystallinity, thereby losings its stiffness. On the contrary, at melting point, the material transforms from a solid into a liquid. Melting point is always above the glass transition temperature. The below chart gives the melting point and glass transition temperature data of PEEK and PTFE:

|

Property |

PEEK |

PTFE |

|

Melting Point |

343°C |

327°C |

|

Glass Transition |

143°C |

Not clearly defined |

Do Fillers Raise the Heat Limit?

Fillers improve thermal performance, especially in PEEK. Although, unfilled PEEK can withstand high heat resistance but it offers lower dimensional stability under load. Filled PEEK offers better creep resistance, good thermal conductivity and enhanced mechanical strength.

PEEK vs PTFE: Chemical Resistance

Both PEEK and PTFE have superb chemical inertness. PTFE is known to be one of the most chemically inert materials having an exceptional endurance under UV exposure. Whereas, PEEK also has a good level of chemical inertness but it is not comparable to what PTFE offers.

Acid and Alkali Compatibility

Below is a PTFE and PEEK compatibility chart in different chemical environments:

|

Chemical Environment |

PEEK |

PTFE |

|

Strong Acids/Alkalis |

Very good |

Excellent |

|

Solvents |

Excellent |

Excellent |

|

Oxidizers |

Limited tolerance |

Highly resistant |

|

High temperature Steam |

Excellent |

Not ideal for long-term exposure |

|

Nuclear Radiation |

Very resistant |

Poor resistance |

|

UV |

Moderate |

Excellent |

Performance in Superheated Steam

PEEK can withstand frequent exposure to steam heated at 250-300oC. It is one of the few polymers that can be employed in super-heated steam environment. For PTFE, it is not recommended to be used in this environment. PTFE starts to deform at high temperatures. A long-term exposure to steam can degrade PTFE material and causes embrittlement.

Radiation and UV Endurance

PEEK withstands exposure to ionizing radiations. Thus, it can be employed in nuclear powerplants, medical radiation equipment and aerospace parts. PTFE has a poor resistance to radiation exposure.

PTFE has an excellent endurance to UV rays thanks to it Fluorene backbone. But PEEK shows an unimpressive and moderate performance in exposure to UV rays.

PEEK vs PTFE: Mechanical Strength

In a mechanical properties' comparison of engineering plastics, PEEK is clearly the winner. PTFE lags far behind. PEEK is mainly known for it's endurance under high stresses which it maintains even at high temperature. On the contrary, PTFE is mainly regarded for its inertness, UV endurance and exceptional non stick behavior which it maintains at high temperature.

Tensile and Flexural Data Comparison

Generally, PEEK is almost 5x stringer than PTFE. Here is a mechanical properties data comparison:

|

Mechanical Property |

PEEK |

PTFE |

|

Tensile Strength |

90 -100 MPa |

20 - 30 Mpa |

|

Flexural Strength |

150 - 170 MPa |

10 -20 MPa |

|

Young's Modulus |

3.6 GPa |

0.5 GPa |

Long-Term Creep and Fatigue Behavior

When it comes to creep and fatigue resistance, PEEK is an excellent choice. It can endure heat and temperature under cyclic loads. However, PEEK material performance degrades over time under constant heat, but still it is a very good choice in the polymers category.

Comparatively, PTFE show a low dimensional stability in hot environments.

- How durable is PEEK?

In the polymers category PEEK is a very durable material while considering factors like creep and fatigue.

Impact Resistance

PEEK has a good impact strength while PTFE tends to deform to absorb energy of impact.

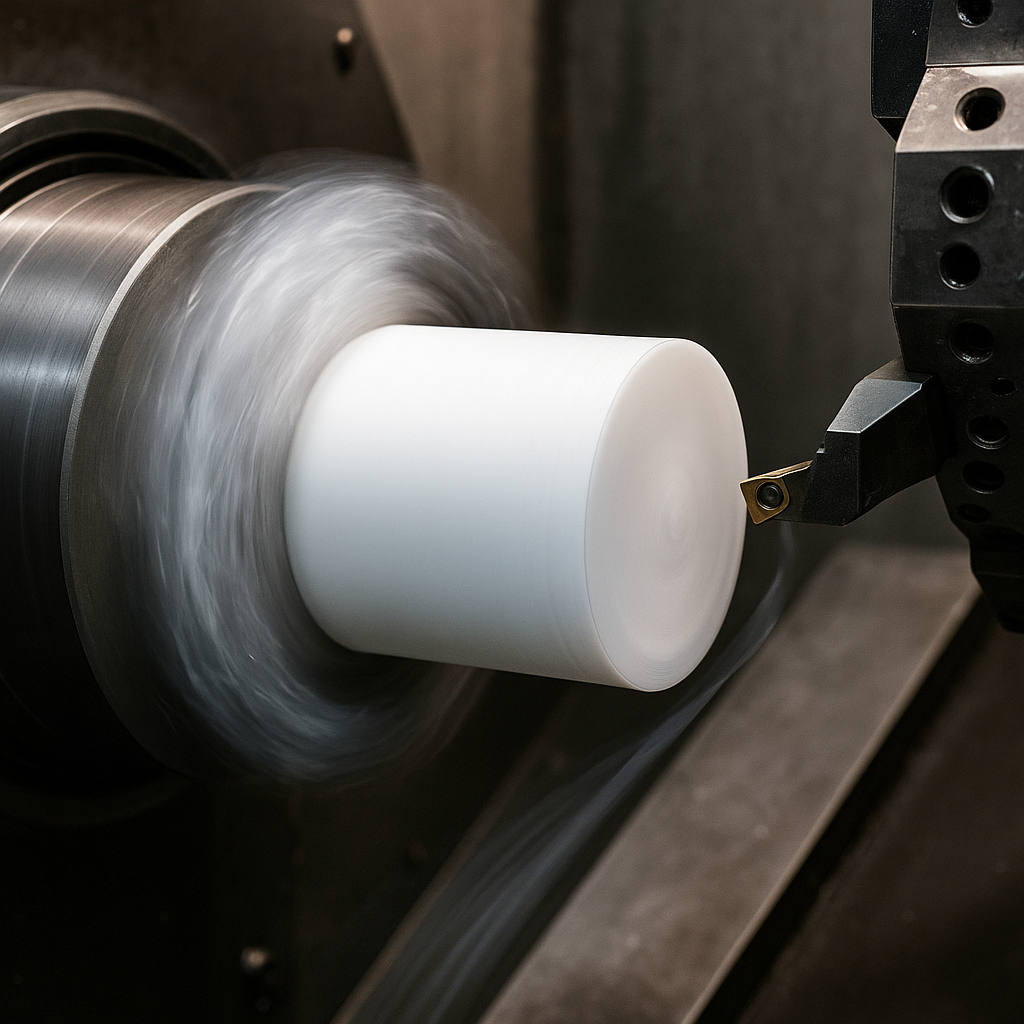

PEEK vs PTFE: CNC Machinability and Processing

Although both PEEK and PTFE are machinable thermoplastics but their machinability it different due to difference in properties. Some adjustments in machining settings and tool selection will yield good machining results.

Cutting Speed and Tool Wear Comparison

As PTFE is comparatively softer, a low cutting speed of around 30-60 m/min is advisable. Tool wear is very insignificant in machining of PTFE. PEEK is a bit rigid. Presence of fillers also moderately increase its hardness. So a moderate cutting speed of around 80-120 m/min can be adopted. Tool wear is higher in comparison to PTFE, but it's still not so much significant.

Workholding Solutions: Soft PTFE and Rigid PEEK

While PEEK is easy to clamp and machine, PTFE poses some dispositioning issue. For soft and slippery PTFE, use textured jaws and vacuum holding to avoid change in position.

Tolerance and Surface Finish

Due to the rigidity of PEEK, tight dimensional tolerance with a good surface finish is possible. PEEK being soft and slippery, gives a broad tolerance and machined surface appears to be waxy.

Advantages In CNC Machining Processing

PEEK:

- High dimensional accuracy

- Good edge definition

PTFE:

- Low tool wear

Disadvantages In CNC Machining Processing

PEEK:

- Higher tool wear specially with fillers

- Generates heat

PTFE:

- Poor dimensional stability

- Smears

- Difficult to hold and polish

PEEK vs PTFE: Industrial Applications

The high temperature performance and high strength of PEEK and non-stick and inert behavior of PTFE are the main reasons in the selection of these materials in industrial applications. The below table give some of the common industrial applications of these materials:

|

Industry |

PEEK |

PTFE |

|

Aerospace |

Brackets and bushings |

Wire insulation, seals etc. |

|

Medical |

Implants and surgical tools |

Catheters and gaskets |

|

Electronics |

Connectors, insulators etc |

PCB coatings, cable jackets etc |

|

Chemical Processing |

Pump parts, valve seats |

Linings, hoses |

|

Automotive |

Engine parts, gears |

Seals, fuel linings |

|

Food Processing |

bushings, wear strips |

Conveyor belts, non-stick liners |

Which One Is Cheaper in 2025?

PTFE is significantly cheaper than PEEK resin material. PTFE is estimated to be around 4-6 times more cost effective than PEEK. However, the material properties and parts durability become the key selection criteria. Even at place where PEEK is costly, but the application demands it, PEEK is selected over other materials.

Current Resin Prices per Kilo

In Asian markets, the per kilo price of PEEK resin is around USD 50-80, while the per kilo price of PTFE resin is USD 10-13. A bit of variation in prices results due to the percentage of filler component in resin, the origin of material and payment conditions.

Tooling Cost vs. Part Cost

The tooling cost of PTFE is low due to a very low wear of tool. However, the slow cutting speed and probably higher wastage scrap might increase the tooling cost. The part cost of PTFE is lower comparatively.

For PEEK, tooling cost can be a bit higher. The part cost is also high.

Recyclability Savings

PEEK is a highly a recyclable thermoplastic, whereas, PTFE is often difficult to detach from manufactured components. As a result, PTFE is often permanently wasted.

How to Pick the Right Plastic

Selection of the right plastic material largely depends on the desired material properties and cost effectiveness. In some critical applications like medical impacts or defense equipment, desired properties weigh more than the cost factor.

When to Choose PEEK or PTFE

PEEK is chosen in applications where mechanical strength, stiffness, wear resistance, and long-term performance in high temperature and/or high-stress environments is required.

PTFE is chosen in application which require chemical inertness, low friction, non- adhesiveness, or electrical insulation. It is often used in non-load bearing applications.

Main Drawbacks of PEEKvs.PTFE

PEEK cannot be easily injection molded due to its high melting point. It is prone to cracking in cold environments. PTFE is one of the most expensive thermoplastic polymer.

PTFE has a low dimensional stability and it has a low creep resistance.

Lower-Cost Alternatives to PEEK

- PPS (Polyphenylene Sulfide)

- PEI (Polyetherimide)

- PSU/PES (Polysulfone/Polyethersulfone)

- Phenolics

Conclusion

PEEK and PTFE are both high performance thermoplastics that are used in specialized applications. PEEK is known for its excellent mechanical strength, durability, high creep and fatigue resistance and a good chemical inertness. PTFE is used in applications which require chemical inertness and non-adhesion. The CNC machining parameters for both of these materials are technical and might need a good R&D for continuous development.

We at TUOFA CNC Plastic Machining strive to deliver the best quality parts made from high performance thermoplastics. To realize this goal, we put great efforts in R&D and continuously train our staff to bring about high-end quality parts for our cleints.

FAQ of PEEK vs PTFE

What is a substitute for PEEK material?

A common substitute for PEEK is PEI (Polyetherimide), which provides good strength and heat resistance at a lower cost.

Is PEEK better than Delrin for machining?

PEEK outperforms Delrin in strength and heat resistance, while Delrin is more affordable and easier to machine.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Least Conductive Metals: A Complete Guide

Least Conductive Metals: A Complete Guide