Is Carbon Fibre a Metal? - Properties & Metal Comparisons

Jun 05,2025

Jun 05,2025

You may be aware that carbon fibres are increasingly used these days. You frequently hear about the use of carbon fibres in the transition from the aircraft industry to the sports industry. Previously, metals were common in an aircraft's body. They are still in use, no doubt, but composite materials have replaced a significant portion of metals. You will study every aspect of carbon fibre in this article. At the end, you will be able to answer the question "Is Carbon Fibre a Metal?". So, let's begin with the introduction of what carbon fibre is.

Carbon Fibre in One Minute

It's a material, composed of thin filaments of Carbon, like a fabric. Carbon fibre is made of 99.99% pure carbon. It is commonly known for its excellent mechanical properties and its use in difficult conditions. In 1860, carbon fibre was used for the first time in the bulbs.

What Carbon Fibre Looks and Feels Like

If you see carbon in the above figure, it has a woven structure, proper texture and a matt finish. If you touch it, it feels like a rigid surface, but still a very lightweight material. If you look at it with a microscope, its thin fibres are strongly bonded in a resin matrix.

Why It's Often Mistaken for Metal

First, due to its metallic sheen and secondly, its mechanical properties are compared and maybe better than many metals, people mistakenly consider it as metal. But carbon fibre is completely different from metal.

Is Carbon Fibre a Metal or Not? Material Classification Explained

As we mentioned, there are some common reasons why people mistakenly consider carbon fibre as a metal. In this section, some important aspects of these two different materials have been discussed. We hope it will be helpful to understand the difference from the very basic concept.

Atomic Structure vs. Metallic Lattice

In the following table, you can read the difference between carbon fibre and metal according to their microstructural differences.

|

Feature |

Carbon Fiber |

Metals (e.g., Steel, Aluminium) |

|

Atomic Arrangement |

Aligned graphitic crystallites in a polymer matrix. |

Crystalline lattice with free-moving electrons. |

|

Bonding Type |

Covalent (strong directional bonds between carbon atoms). |

Metallic (delocalized electrons forming a "sea" of charge). |

|

Structural Order |

Anisotropic (properties vary with fibre direction). |

Isotropic (uniform properties in all directions). |

|

Defect Sensitivity |

Brittle: cracks propagate easily along fibre misalignments. |

Ductile; dislocations allow deformation without sudden failure. |

Bonding and Electrical Conductivity

Due to restricted movement of electrons, the electrical conductivity of carbon fibres is very low.

|

Property |

Carbon Fiber |

Metals |

|

Primary Bonding |

Covalent (strong, directional). |

Metallic (electron-sharing lattice). |

|

Electrical Conductivity |

Low (semiconductor along fibres, insulator perpendicularly). |

High (free electrons enable easy current flow). |

Why Carbon Fibre Is Classed as an Advanced Polymer Composite

Carbon fibres can't be used alone; to make them useful for applications, we use a resin matrix and make carbon fibre-reinforced polymer composites. These composites are hybrid materials offering excellent mechanical properties.

Microstructure & Chemical Composition

To differentiate between two materials, one of the most basic criteria is to examine and understand the microstructure and chemical composition of both materials. The following table shows the difference between the microstructure of metals and carbon fibre. the difference in chemical composition is discussed below in this section:

|

Feature |

Carbon Fibre |

Metals |

|

Structure |

Aligned fibres in a resin matrix |

Uniform crystalline grains |

|

Texture |

Anisotropic (direction-dependent) |

Isotropic (uniform in all directions) |

|

Defects |

Delamination risk |

Grain boundary dislocations |

How Carbon Fibre Is Made?

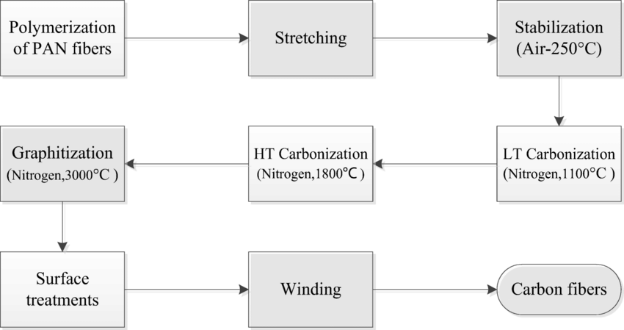

As the following figure shows:

- Precursors are prepared through polymerisation and then oxidised at 250 °C

- Non-carbon atoms are removed through the carbonisation process

- Graphitisation to align crystallites

- Fibre coating to enhance resin bonding

- Then the last step, weaving and composite formation

Graphitic Crystallites and Alignment

To form graphite crystallites, carbon atoms are arranged in a hexagonal graphene layer. Around 2500 °C, these crystals align in a better structure, increasing the strength and stiffness. These graphitic crystallites increase brittleness in the structure.

Resin Matrix Options

The following table can help you in quick decision-making for the respective applications.

|

Resin |

Pros |

Cons |

Best For |

|

Epoxy |

Low cost, easy to use |

Limited heat resistance |

Bikes, cars |

|

BMI |

Handles 200-250°C |

More brittle |

Aerospace |

|

PEEK |

Extreme heat/chemical resistance |

Very expensive |

Jet engines |

Effect of Fibre Volume Fraction on Performance

The most common volume fraction is 45-55% Vf and is known as the "production sweet spot". This volume fraction provides a balance between strength and resin adhesion.

- If it's <40%, it means weak and resin-dominated.

- >60% Vf causes poor bonding and is prone to cracks.

Key Mechanical & Physical Properties

This section presents a comparison of carbon fibre with metals in terms of mechanical and physical properties.

Strength-to-Weight Ratio

You can see carbon fibre is, although just 20% the weight of steel, but shows 5X higher strength than steel. Yes, compressive strength is a little bit lower.

|

Property |

Carbon Fiber |

Steel |

Aluminum |

|

Tensile Strength |

500-700 ksi |

50-300 ksi |

40-80 ksi |

|

Compressive Strength |

300-400 ksi |

Comparable |

Lower |

|

Density |

1.6 g/cm³ |

7.8 g/cm³ |

2.7 g/cm³ |

Stiffness (Modulus) and Fatigue Life

If you compare the stiffness of carbon with metal, i.e. steel is the same 30-50 MSi. Carbon fibres outperform metals in terms of fatigue life. In proper stress levels, carbon fibre has unlimited resistance to fatigue. That is the reason you can use carbon fibre in aircraft.

Thermal Expansion, Conductivity & Magnetic Response

Thermal Expansion

You will get almost zero thermal expansion if you use carbon fibre, but metals are good thermal conductors.

Conductivity

If you need directional electrical conductivity, you can use carbon fibres due to their anisotropic structure. Metals are good electrical conductors due to free electrons.

Magnetic Response

Carbon fibres do not respond to magnetic fields, which means they are completely non-magnetic. Some metals are magnetic.

Carbon Fibre vs. Metals: Steel, Titanium

We are comparing carbon fibre with steel, titanium and aluminium, etc. because these metals are considered high-strength materials. In this section, you will study how carbon fibre is better than these metals in many aspects.

Weight & Density Comparison: Who Is Lighter

You can see that carbon fibre is lighter than these metals still offer better mechanical properties.

|

Material |

Density (g/cm³) |

Weight Comparison |

|

Carbon Fiber |

1.5-1.6 |

Lightest (70% lighter than steel, 40% lighter than titanium) |

|

Aluminum |

2.7 |

60% heavier than CF |

|

Titanium |

4.5 |

Nearly 3x heavier |

|

Steel |

7.8 |

5x heavier |

Strength and Stiffness: Who Is Stronger?

As we mentioned earlier, carbon provides superior stiffness and tensile strength than these metals.

|

Property |

Carbon Fiber |

Steel |

Titanium |

|

Tensile Strength |

500-700 ksi |

50-300 ksi |

100-200 ksi |

|

Stiffness (Modulus) |

30-50 Msi |

29 Msi |

15-17 Msi |

Corrosion, Fatigue, and Impact Performance

Corrosion Resistance

Carbon fibre remains immune even in difficult conditions. Steel rusts while titanium offers excellent corrosion resistance.

Fatigue Strength

Carbon fibre can resist an unlimited number of cycles of proper load. Steel offers decent fatigue strength, but titanium is very best in case of fatigue failures.

Impact Performance

As you know, carbon fibres are brittle, so poor impact resistance. Metals excel for impact resistance.

Cost per kg: Who Is Cheaper?

According to the market rates, the manufacturing of carbon fibre is more expensive than metals. That is why this material is used only in critical applications.

|

Material |

Cost per kg (USD) |

|

Carbon Fiber |

$10-$30 |

|

Aluminum |

$2-$5 |

|

Titanium |

$30-$100 |

|

Steel |

$0.50-$2 |

Advantages and Disadvantages of Carbon Fibre

Advantages

Carbon fibre offers many critical advantages, such as:

- Highest strength-to-weight ratio, which is why they are used in sports and transportation.

- They remain immune to corrosion while metals corrode easily.

- Higher fatigue strength.

- Higher stiffness.

Disadvantages

- Brittle structure, so poor impact resistance

- Very limited recyclability

- Expensive manufacturing and machining

- Can't be repaired like metals

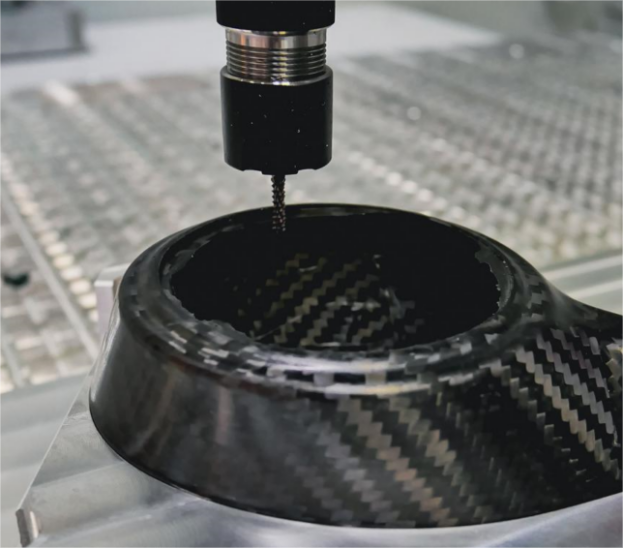

Carbon Fiber vs. Aluminum: CNC Machining Difference

In this section, you will specifically read about the machining differences of carbon fibre and aluminium because both are lightweight and used in the aerospace and automotive industries.

Machining Difficulty and Tool Selection

Aluminium is malleable and ductile, so it offers ease of machining. Standard carbide tools can be used for aluminium machining.

While in the case of carbon fibres, you need to use lower cutting speeds and diamond-coated tools.

Chip vs. Dust Evacuation

The machining of aluminium produces chips which can easily be managed. But Carbon fibres produce fine and hazardous dust particles, which can cause serious respiratory issues. So, you should use PPE and a vacuum for carbon fibre machining.

Achievable Tolerances and Edge Quality

Carbon fibres require very careful machining to achieve the desired tolerance.

|

Factor |

Carbon Fiber |

Aluminum |

|

Tolerances |

±0.005" (can fray) |

±0.001" (more precise) |

|

Edge Quality |

Risk of delamination |

Smooth, burr-free |

Post-Machining Finishes

Carbon fibres are sealed to avoid moisture absorption, while aluminium is anodised for corrosion resistance.

When to Choose Carbon Fibre Rather Than Metals?

The criteria are not so difficult for when to choose carbon fibre rather than metals. Some situations are:

- When weight reduction is important

- A higher strength-to-weight ratio and stiffness are required

- Good corrosion resistance even at elevated temperatures

Conclusion

This article concludes that carbon fibre material has evolved as one of the best materials and has gained importance for critical applications. The metals have served our requirements till now. But now, weight reduction, high strength, stiffness, speed, and fuel savings are in demand. To fulfil these requirements, carbon is best.

FAQs of Carbon Fibre

How much more expensive is carbon fibre than aluminium?

Carbon fibre is 10 times more expensive than aluminium if we talk about the machining of these materials.

Can carbon fibre corrode like steel?

No, not all. Carbon remains immune to corrosion or rust.

Is carbon fibre stronger than titanium?

Yes, if we say strength-to-weight ratio, but Ti shows better impact resistance and ductility.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Metal Replacement Guide: Metals to Advanced Polymers and Composites

Metal Replacement Guide: Metals to Advanced Polymers and Composites