SKD11 Tool Steel: Properties, Heat Treatment & Machining Guide

Jul 22,2025

Jul 22,2025

As a manufacturer if you are looking for a high-performance material with an excellent hardness, wear resistance and dimensional stability, SKD11 should be your material of choice. SKD has attained a high level of customers' satisfaction in applications like dies and punches that are require to withstand wear and repeated loads for long lasting durations. Due to the stringent quality requirements of the Japanese Industrial Standard with which SKD11 steel is complied, it shows an impressive microstructural cleanliness which enhances its durability. Let's explore more about it.

What Is SKD11 Material?

SKD11 material belongs to the tool steel family and it is compliant with the Japanese Industrial Standards (JIS). Due to the presence of a high percentage of chromium and carbon, SKD11 steel acquires high wear resistance, compressive strength, and dimensional stability. Vanadium acts as a micro alloy and facilitates in attaining a high hardness. With a proper heat treatment SKD 11 alloy steel can have a hardness value as high as 62 HRC.

What Makes SKD11 a “Cold-Work” Tool Steel

SKD 11 is typically used as die materials for cold working applications like blanking, forming, and shearing. A high chromium and carbon content in SKD11 steel helps the formation of carbides and a fine grained microstructure. It can be air hardened, thus, it evades and dimensional distortion. Dies and tools made od SKD 11 have tight dimensional tolerances.

International SKD11 Material Equivalent (D2, 1.2379, X153CrMo12)

Although the grades mentioned in the below table are equivalent but they are not entirely equal. There are small differences in chemical and mechanical properties arising due to differences in regional requirements.

|

Standard |

Region |

Steel Mill example |

Grade |

|

JIS |

Japan |

Nippon Steel |

SKD11 |

|

AISI |

USA |

Nucor Steel |

D2 |

|

GB |

China |

Bao Steel |

Cr12Mo1V1 |

|

DIN |

Germany |

ThyssenKrupp |

1.2379 |

|

EN |

Europe |

Arcelor Mittal |

X153CrMoV12 |

|

AS/NZS |

Austrailia |

BlueScope |

D2 |

Typical Hardness Range Before/After Heat Treat (HRC 58-62)

The below chart gives the hardness values of SKD11 steel in different heat treated conditions:

|

Condition |

Hardness |

|

Annealed |

HB 255 |

|

Normalised |

HRC 60 |

|

Tempered |

HRC 58-62 |

SKD11 Material Chemical Composition & Standards

Here is a comparative table of SKD11 and its equivalent grades highlighting the chemical composition of each grade:

|

Standard |

Grade |

C (%) |

Cr (%) |

Mo (%) |

V (%) |

|

JIS |

SKD11 |

1.4 - 1.6 |

11 -13 |

0.8 - 1.2 |

<0.5 |

|

AISI |

D2 |

1.4 - 1.6 |

11 -13 |

0.7 - 1.2 |

<1.1 |

|

GB |

Cr12Mo1V1 |

1.45 -1.7 |

11 -13 |

0.8 - 1.2 |

0.15 - 0.3 |

|

DIN |

1.2379 |

1.5 |

12 |

0.9 |

0.35 |

|

EN |

X153CrMoV12 |

1.53 |

12 |

0.9 |

0.35 |

|

AS/NZS |

D2 |

1.4 - 1.6 |

11- 13 |

0.7- 1.2 |

< 1.1 |

Chromium, carbon, molybdenum and vanadium are the most important chemical elements which affect the mechanical properties of these grades. The percentage of Cr, C and Mo are almost the same in all grades. But the percentage of vanadium varies slightly.

Full Element Breakdown (C, Cr, Mo, V)

In SKD 11 material, the presence of carbide forming elements like Cr, Mo and V along with a high percentage of carbon helps in the formation of carbides during heat treatment. It helps in attaining a high hardness and an excellent wear resistance. The presence of around 12% Cr content helps in attaining a mild corrosion resistance due to a build up chromium oxide layer over the surface.

JIS vs ASTM vs DIN Specs

What Is JIS, ASTM and DIN Standards?

JIS, ASTM and DIN are all international standards which are complied with in many regions around the world. JIS is a Japanese standard, ASTM belongs to the USA and DIN is a German standard. While the governing bodies of these standards are country specific, but they are used in many other countries around the world. As an example, although JIS is a Japanese standard but material complied with it can also be produced in China.

How They Differ from Others?

Steel grade equivalents compliant with JIS, ASTM or DIN standards are interchangeable. There are some insignificant and minute differences only. Actually, these standards are different only due to the presence of their governing bodies in specific countries. Otherwise, they are equivalent.

SKD11 Mechanical Properties

SKD11 steel is engineered in a way such that it withstands high impact forces while maintain a good dimensional stability. In applications like dies in cold working of sheet metal or various other tools, the material should withstand wear and cyclic loads. SKD11 has an excellent wear resistance and fatigue resistance.

Tensile & Yield Strength Data

SKD11 alloy steel is capable of maintaining an impressive hardness of 60HRC. At this level the ultimate tensile strength exceeds 2000 MPa. For comparison, the UTS of A2 steel is only 1800 MPa.

Impact Toughness vs Conventional D2

Although D2 steel is an equivalent grade of SKD11 steel, but as per general practice SKD11 shows a higher impact toughness than D2. It might be due to the stringent quality control that mills place when following Japanese standards. Detrimental elements like sulphur and phosphorus are minimized following an ESR process.

Dimensional Stability After Tempering

SKD11 steel shows an impressive dimensional stability after heat treatment. On a 100mm gauge it deviates only a ≤0.02 % after triple temper.

SKD11 vs Other Tool Steels

Quite often there is a choice of material when selecting it for a particular application. There are similar and equivalent grades in the tool steels family. However, for any specific application the choice should depend on factors like hardness, dimensional stability, toughness and most importantly the cost. Let's weigh some of the common tool steels against these factors.

SKD11 and SKD61

SKD11 and SKD61 are both tool steel. However, their scope of applications is entirely different. SKD11 is prized for its high wear and fatigue resistance and an excellent dimensional stability which makes it ideal for cold working applications. While SKD61 steel is used mainly in hot working applications due to its high thermal shock resistance, high toughness retention at high temperatures and high wear and oxidation resistance.

SKD11 vs D2

SKD11 has a bit cleaner and more uniform microstructure than the D2 grade. It's due to the difference in manufacturing process. SKD11 undergoes though an ESR (Electro Slag Remelting) process due to which detrimental elements are removed and carbide dispersions become finer. Due to the more stringent quality requirements of SKD 11 steel, it is a bit pricier than D2 steel.

Are D2 and SKD11 the same?

D2 steel and SKD11 are equivalent grades having comparable mechanical properties. However, SKD11 material is used in high quality application due to a refined microstructure.

SKD11 vs Cr12MoV

Cr12MoV is a low cost yet effective equivalent grade of SKD11 tool steel. It is compliant with the Chinese GB standards. Both SKD 11 and Cr12MoV steels can retain hardness till 200°C.

When to Pick SKD11 Over A2 or O1

Both A2 and O1 have higher toughness compared to the SKD11 steel grade. But, from the wear resistance and dimensional stability factors SKD11 is clearly the winner. So, SKD11 should be chosen in high performance applications when cost is not a limiting factor.

SKD11 Heat Treatment Process Flow

The real Skd11 properties can be ushered by a proper heat treatment. In the as manufactured annealed state, the SKD 11 steel is a bit soft. Thus, shaping operations like machining or forging as easier. Once, it attains a required shape, proper heat treatment becomes necessary to protect it against wear and dimensional changes.

Pre-Heat & Stress-Relief (650 °C, 2 h)

Actually, SKD 11 steel is austenitized in a temperature range if 1020-1040°C. But a pre heat schedule at an in-between temperature of around 650°C helps in relieving stresses accumulated during manufacturing. A direct heating from the room temperature to 1040°C can crack the material due to a steep temperature gradient between the surface and the core.

Hardening (1020-1040 °C, air/oil quench)

Quenching is the next step in heat treatment. The SKD 11 steel is heated to an elevated temperature of 1040°C and then it is either allowed to cool in air or it is quenched in oil. Oil quenching provides a steep thermal gradient, which can cause cracking in thicker sections and distortion in others. Air cooling gives moderate thermal gradient which is often more desirable. But oil quenching gives a hardness value of around 62 HRC while air cooling results in 60 HRC only.

Triple Tempering (520 °C × 3 × 2 h)

SKD11 is heated to a 520°C temperature for three cycles of 2 hours each. This tempering treatment relieves internal stresses, makes fine carbide dispersions, reduces brittleness and imparts toughness. The presence of Cr, Mo and V helps in increasing hardness through secondary-hardening effect. They react with carbon to form fine carbide dispersions.

Vacuum vs Salt Bath--Pros & Cons

|

Feature |

Vacuum |

Salt Bath |

|

Cleanliness |

Clean surface |

Needs cleaning |

|

Speed |

Moderate |

Fast |

|

Cost |

High |

Moderate |

|

Process Control |

Precise |

Low |

|

Shape |

Regular shapes |

Complex shapes |

|

Applications |

Precision dies |

Mass production |

The below link gives a general overview of heat treatment basics:

What's SKD11 Machinability? How to CNC Machine It?

CNC machining of SKD11 is comparatively difficult in the hardened state. However, most manufacturers prefer to machine SKD11 in the annealed state. Machining of heat treated SKD 11 steel is often done for fine tuning only. Some manufacturers use EDM technique to avoid hard-cutting.

Rough Turning in Annealed State

The annealed SKD 11 material has a relatively low hardness of HB 255. So, it does not require very stringent CNC settings. CNMG432 insert tool with a cutting speed of 160m/min and 0.3mm/rev feed rate is optimum.

Finish Milling After Hardening

CNC machining of hardened SKD 11 is a bit tricky. It requires CBN inserts. Sumitomo BNC2010 or Mitsubishi MB4020 are good tool examples. In comparison to carbide tools, CBN inserts show better edge. In numbers, CBN edge wear is only 15 microns while carbide shows an 85 microns edge wear.

Wire EDM for Complex Punch Shapes

Wire EDM is often a very desirable option for CNC as no hard cutting is required. Production speed increases with a high precision. It is specially good for large batch production of complex shaped parts.

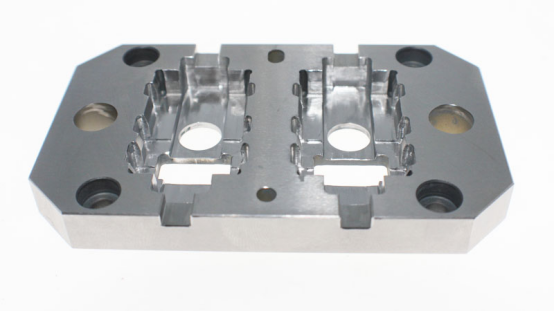

What Are The Typical Applications of SKD11?

When it comes to exceptional hardness and resistance while maintaining a good dimensional stability, SKD11 has no match. It is generally used in high performance applications in which cold working of metal is involved. Usual applications are dies and tools of many forms.

Blanking & Punching Dies

Blanking & punching dies made up of SKD11 steel show an excellent dimensional stability over repeated use. It is very unlikely to worn out or crack when punching or blanking sheet metal. As an example, thickness of around 0.8 mm Stainless Sheet can be handled very easiiy.

Cold Forging Inserts for Fasteners

An excellent combination of high compressive strength and resistance to chipping makes SKD 11 ideal for cold forging inserts. As an example, M6 hex bolt can be manufacturing using the same insert head tool for upto150 k cycles.

Plastic Mould Wear Inserts

High wear resistance against glass or mineral-filled resins while maintaining a tight tolerances makes SKD11 steel suitable for ejector sleeves, core inserts, and gate inserts in filled plastic injection moulds.

SKD11 Material Equivalents

SKD11 is a cold-work tool steel complaint with the Japanese Industrial Standard (JIS). It offers excellent wear resistance, high hardness after heat treatment, and good dimensional stability. Equivalent grades exist in other international standards and are often used interchangeably depending on availability and application requirements.

The most common equivalent: D2 Steel

The most common equivalent grade to SKD11 is AISI D2. Its specifications are mentioned in ASTM A681. Both grades have nearly identical chemical compositions. The primary difference between SKD11 and D2 is mainly in steel cleanliness. The ESR processing method gives a refined microstructure which can affect fatigue life and dimensional stability.

Other equivalent grades

Other than D2, SKD11 corresponds to DIN X153CrMoV12 in Europe and Cr12Mo1V1 China. These grades have similar composition and performance in cold work applications. However, variations in steelmaking and refining methods may influence toughness, surface finish, and tool life. Cr12Mo1V1 grade shows comparative results but the price is normally less than SKD11.

Conclusion

SKD11 steel is an excellent material for high performance applications that require a combination of wear resistance, toughness and dimensional stability. SKD11 needs hardening and tempering treatment for attaining a hardness value of 60-62 HRC. SKD11 has other equivalent grades in other standards but their performance varies slightly depending on the manufacturing route.

FAQs

Is SKD11 stainless?

No, SKD11 is not purely stainless. Although it has a 12% Cr content but, it is not available entirely to built a self healing corrosion protective Chromium Oxide layer.

What's the best tempering temperature for SKD11?

550oC temperature for 3 cycles of 2 hours each is optimum.

Can SKD11 be laser-hardened locally?

Yes, SKD11 steel can be locally laser-hardened to improve surface hardness.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What Is S235JR?-Complete Guide to the Most-Used Steel Grade

What Is S235JR?-Complete Guide to the Most-Used Steel Grade