Custom Sheet Metal Fabrication Service

Online sheet metal fabrication Service - Low-cost on-demand manufacturing, on-time delivery. Custom-formed sheet metal prototypes and production parts from China. If you want to find a cost-effective and rapid sheet metal prototyping solution for your manufacturing needs, Tuofa as a custom machining manufacturer can be a good choice for you. Based on extensive experiences and professional expertise, our sheet metal fabrication services are available for both prototypes and low to high volume production runs. We are also a 3D printing manufacturer.

- Get free a quote within 12 hours

- sheet metal custom 5-23 days lead time

Instant Sheet Metal Fabrication Quote

Trustworthy Custom Sheet Metal Fabrication Solution

Manufacturing Experience

As one of the best turning parts manufacturers, we have capabilities in fabrication, machining, and finishing enable us to offer one-stop shopping, our mechanical engineers have more than 17 years of processing and manufacturing experience.

Technical Support

Are you looking for precision milling parts manufacturers? Accurate dimensions and specifications based on your demands and a variety of instruments. Competitive prices and the highest standard quality provide the most economic solution.

Quality Control

Tuofa as a precision machining manufacturer have passed ISO9001 certification, and offer competitive sheet metal prices for low volume prototypes and cost savings for high volume production runs.

Our Sheet Metal Fabrication Capabilities

We provide instant online CNC quote in China. Sheet metal fabrication service supplies durable parts for prototype and end-use.

Tuofa provides a wide range of sheet metal capabilities, from high-quality metal stamping, punching, bending welding, to laser cutting services.

Metal Stamping

If you are looking for CNC machining parts manufacturer, you should also know that metal stamping (metal working or pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining.

Stamping area: Up to 4000 x 6000 mm

Material thickness: Up to 60 mm

Metal Stamping Instant Quote

Laser Cutting

Tips from your reliable machinery parts manufacturer: Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then the material either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish.

Cutting area: Up to 4000 x 6000 mm

Material thickness: Up to 60 mm

Instant Laser Cutting Quote

Plasma Cutting

Tuofa is the CNC machining parts supplier for you. Plasma cutting is a process that cuts through electrically conductive materials utilizing an accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass, and copper, although other conductive metals may be cut as well. CNC plasma cutting configurations:2-dimensional / 2-axis plasma cutting,3-dimensional / 3+ axis plasma cutting.

Cutting area: Up to 4000 x 6000 mm

Material thickness: Up to 40 mm

Plasma Cutting Instant Quote

Waterjet Cutting

OEM CNC milling parts manufacturer sing the principle of liquid pressurization, the mechanical energy of the power source is converted into pressure energy through a specific device. The water with huge pressure energy passes through the small hole nozzle, and then the pressure energy is converted into kinetic energy to form a high-speed jet. It can cut all kinds of materials using an extremely high-pressure water jet or a mixture of water and abrasive materials.

Maximum cutting area: Up to 3000 x 6000 mm

material thickness: Up to 350 mm

Instant Waterjet Cutting Quote

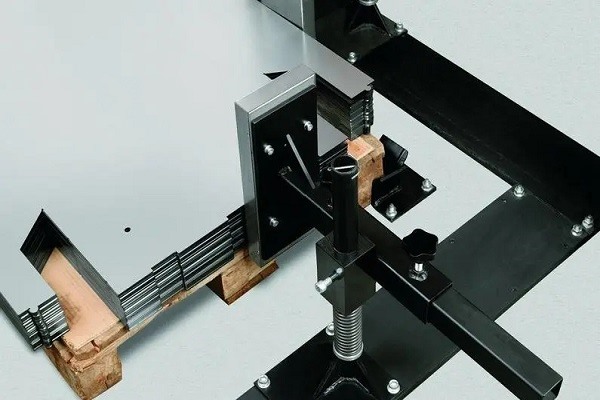

Metal Bending

Bending can process complex parts with less waste in the production process. The product has sufficient shape and dimensional accuracy, good interchangeability, and high surface quality. Get your instant CNC machining quote now.

Metal folding capacity: Up to 200 tons

Maximum bending length: Up to 4000 mm

Maximum thickness: Up to 30 mm

Instant Metal Bending Quote

Metal Welding

Sheet metal welding is to weld multiple parts together. The purpose of this is to achieve single piece seam welding and sheet metal processing, so as to increase its strength. You can also order custom 3d printed parts from us.

Instant Sheet Metal Welding Quote

Our experience in Sheet Metal Fabrication Service

|

|

|

|

| 500+ | 2M+ | 60+ | 17+ |

| Companies served | CNC parts produced | Countries shipped | Years in business |

Sheet Metal Materials Available at Tuofa

Metal |

Application of Metal |

|

Aluminum; Aluminum 6061, Aluminum 5052 |

Learn more about aluminum sheet metal |

|

Copper; Copper 101, Copper C110, Copper 260 (Brass) |

Learn more about copper sheet metal |

|

Bronze; Bronze 220, Bronze 510 |

Learn more about bronze sheet metal |

|

Stainless steel; Stainless steel 301, Stainless steel 304, Stainless steel 316/316L |

Learn more about stainless sheet metal |

|

Steel; Steel 1018 (Low Carbon) |

Learn more about steel sheet metal |

Available Surface finishes for Sheet Metal

Surface finishes are applied after machining and can change the appearance, surface roughness, hardness, and chemical resistance of the produced parts.

Name |

Description |

|

Sandblasting |

The main function is to remove the dirt and rust on the workpiece surface, increase the adhesion of the workpiece surface and prepare for the subsequent surface treatment |

|

Wire drawing |

Let the material pass through the upper and lower sand belts and pull out traces on the surface of the material |

|

Painting |

Liquid baking paint and self-drying spray paint are suitable for some precision products |

|

Products |

Electroplating is to attach a layer of other metals on the surface of the material to increase the corrosion resistance of the metal and achieve a certain beautifying effect |

|

Anodizing |

A dense protective film is formed on the surface of the workpiece to increase the corrosion resistance of the workpiece Generally, there are two methods: chemical oxidation and anodic oxidation |

|

Silkscreen printing |

the process of silk screen printing various marks on the surface of materials |

Sheet Metal Fabrication Standard

Compared with single sheet metal fabrication shops, we have the experience and the right sheet metal fabrication services necessary to bring your idea to life. Start to request your CNC turning parts quotes.

This includes services like high tolerance and wide thickness range laser cutting, bending capabilities, and other post-processing options. Try our metal laser cutting service.

Dimension Detail |

Tolerance |

|

Edge to edge, single surface |

+/- 0.005 inch |

|

Edge to hole, single surface |

+/- 0.005 inch |

|

Hole to hole, single surface |

+/- 0.005 inch |

|

Bend to edge / hole, single surface |

+/- 0.010 inch |

|

Edge to feature, multiple surface |

+/- 0.030 inch |

|

Over formed part, multiple surface |

+/- 0.030 inch |

|

Bend angle |

+/- 1° |

| By default, sharp edges will be broken and deburred. For any critical edges that must be left sharp, please note, and specify in your drawing. | |

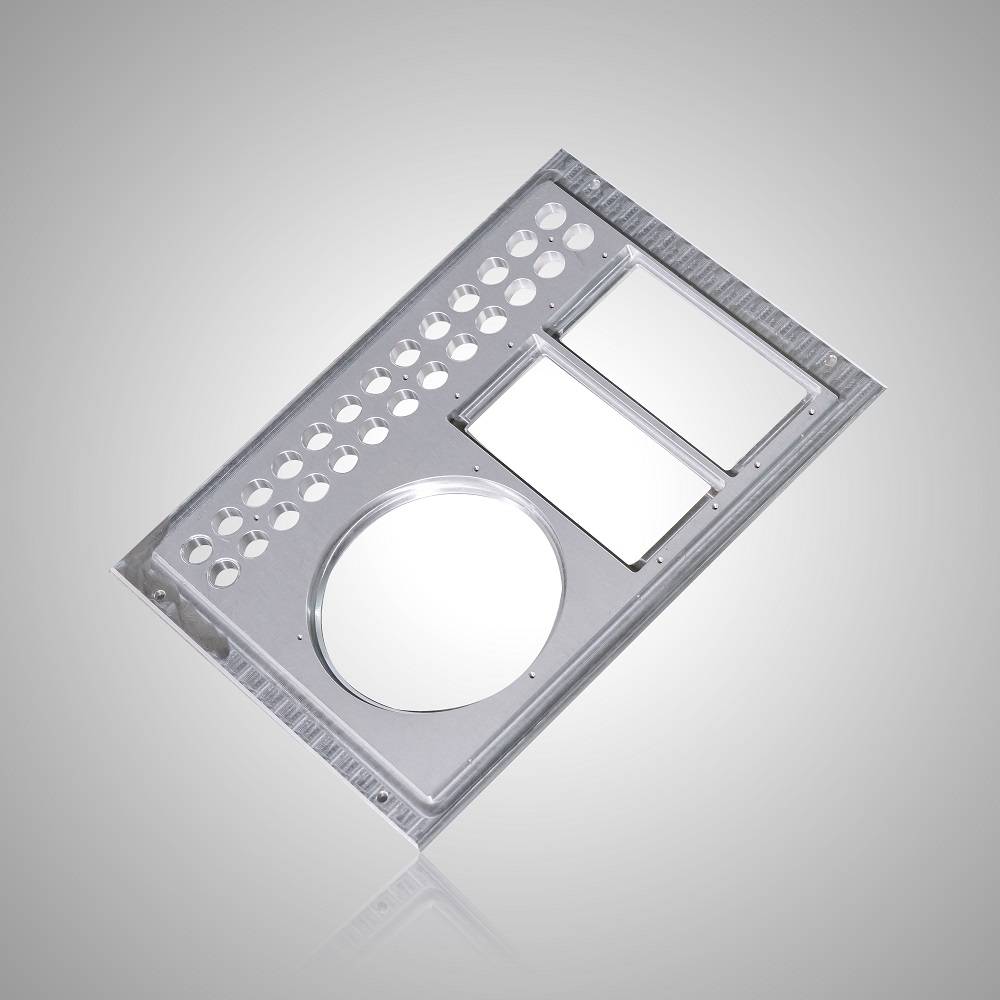

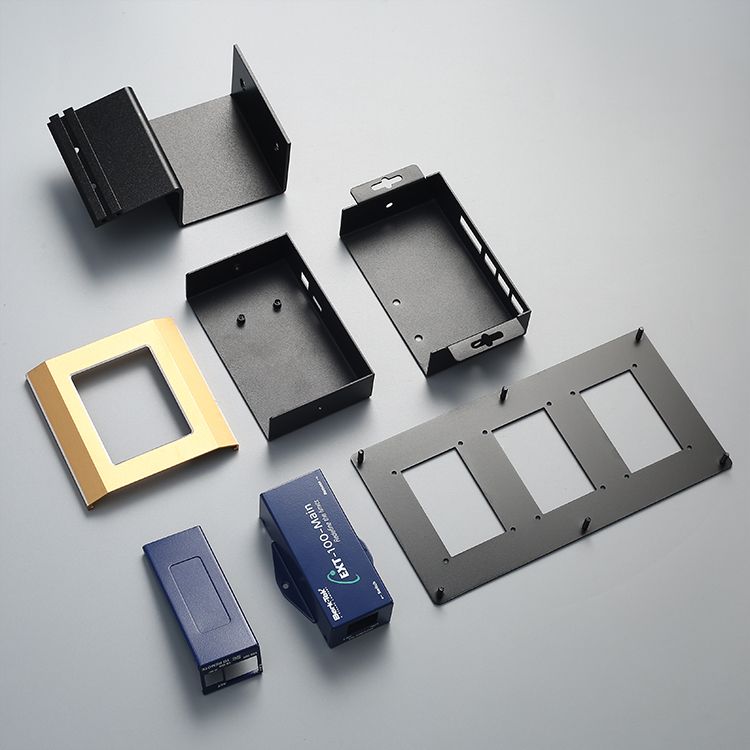

Custom OEM Sheet Metal

Are you looking for metal stamping companies? Sheet metal processing can be a cost-effective alternative to casting and machining. The process is also fast and produces minimal material waste.

Sheet metal processing is widely used in industrial and consumer parts, as well as automotive, aerospace, energy, robotics and other professional industries.

Electronic Industry

Medical Industry

Automotive Industry

Agricultural industry

Machine tool industry

Aviation Industry

Custom Metal Fabrication Services - Tuofa Precision Sheet Metal Fabrication

If you want to find a cost-effective and rapid sheet metal prototyping solution for your manufacturing needs, Tuofa can be a good choice for you. Based on extensive experiences and professional expertise, our sheet metal fabrication services are available for both prototypes and low to high volume production runs. Working with Tuofa, the most advanced fabrication machinery allows us to fabricate end-use sheet metal parts and products in high efficiency while maintaining premium quality, which saves money and time for our clients significantly. Take a look on mechanical parts online.

A wide range of materials and surface finishes enable us to make the best option for your project, the raw materials include but are not limited to stainless steel, aluminum, brass, copper, steel, plastic, etc. Polishing, painting, sandblasting, plating, anodizing, powder coating, and more finishing services bring better surface quality for your parts. Our custom sheet metal fabrication service provides durable and affordable sheet metal components that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.

Why Choose Custom Sheet Metal Fabrication Services at Tuofa?

- Efficient Sheet metal fabrication manufacturer for mass production rapid prototyping service

- Average 10 days turnaround time and 99.88% on-time delivery

- Multiple options of machining materials to meet specific properties.

- Fast free quotation within 24 hours after inquiry

- Have High customer satisfaction and loyalty

- Rich design and manufacturing experience

- If you are looking for quality sheet metal fabrication services near me, our low-cost custom metal fabrication will review the design, build your quote, assess the cost, and get your non-metal or metal fabrication parts into production orderly and efficiently.

As one of the best CNC sheet metal fabrication manufacturers in China, Online custom sheet metal service for 50 CNC machines, making it an excellent choice for rapid prototyping and low to high volume production runs, instant CNC parts quotes, low-cost on-demand manufacturing, 50+ materials Perfect & 10+ surface finishes for tolerances down to 0.01mm.

Instant Sheet Metal Fabrication Quote

What is Sheet Metal Fabrication?

Sheet metal processing is called sheet metal processing. Sheet metal processing includes traditional cutting, stamping, bending forming, and other methods and process parameters. Due to the difference in sheet metal parts, the sheet metal processing process may be different, but the total number does not exceed the following:

- Design and draw part drawings of sheet metal parts, also known as three views. Its function is to represent the structure of sheet metal parts through drawing.

- Draw an expansion diagram. That is to expand a complex part into a flat part.

- Parts are manufactured through the sheet metal processing process to complete surface treatment.

- Final assembly, combining multiple parts or components to make it a complete project.

Advantages of Sheet Metal Fabrication

Inexpensive but high-quality end-use sheet metal products.

Sheet metal custom parts have the advantages of being lightweight, saving metal materials, simple processing technology, reducing production cost, and saving production cost.

Strength and Durability

Sheet metal fabrication is strong and durable, and sheet metal parts are often able to withstand greater pressure and heat than those made with plastic.

Malleability

With the right equipment, it can be bent into numerous shapes, while still retaining its strength and structural integrity.

Replaceability

One of the biggest advantages of using sheet metal fabrication is that the parts are replaceable. If several metal parts are used to make an assembly, instead of making the whole part out of one substance, the individual components can be removed and replaced without having to replace the entire assembly. This can save money on repairs and even allow for modifications and upgrades.

Quality assurance Of Our Sheet Metal Fabrication Services

- Tuofa precision CNC machining shop has passed ISO9001 certification

- Inspection report included in every order

- Full dimensional inspection reports on request

- Material certifications and test reports available on request

- Batch inspection in concurrence with ISO285

- Strict NDA agreements with all buyers

- Low Cost On Demand Manufacturing, on-time delivery

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home