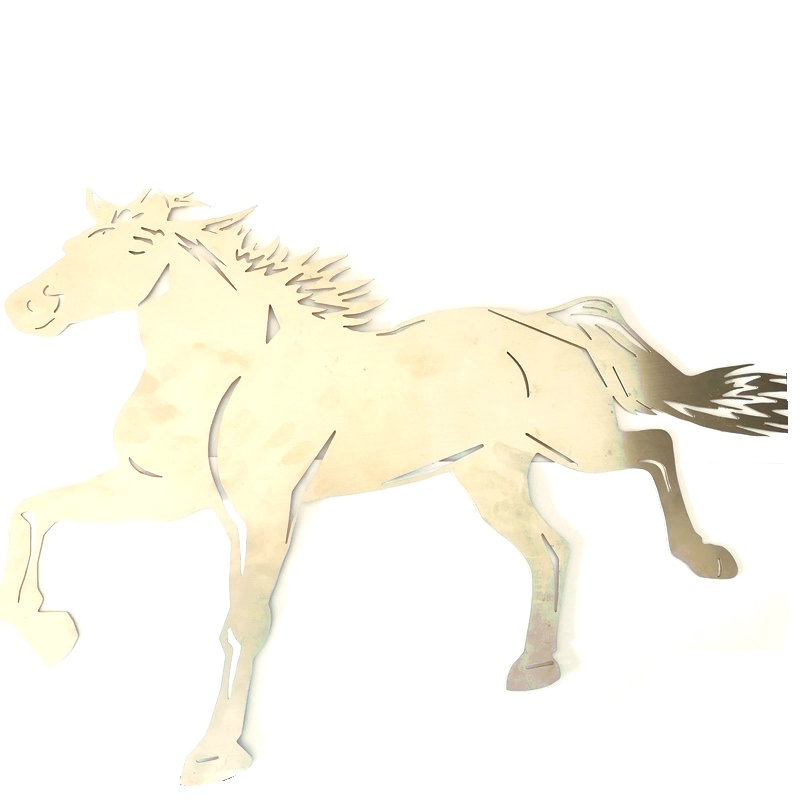

CNC Machining Manufacturer Custom Wire Edm Machining Services

China Shenzhen Tuofa's core team has more than 17 years of experience in the Wire Edm Machining industry. The 50,000-square-foot fabrication shop can produce complex prototypes and low-volume production of precision-machined parts in a wide range of 50 metals and plastics, as well as 10 surface treatments.

In tuofa-cncmachining.com, Wire Edm Machining is suitable for the production of precision parts and small batch products in quantities of 1 - 100,000. Tuofa provides you with free process consultation, modification and product proofing.

China Wire Edm Machining Services-Low Cost On Demand Manufacturing, On-Time Delivery

Are you looking for a reliable and fast Wire Edm Machining manufacturer? Then you have come to the right place. At Tuofa CNC Machining, we provide engineers, product developers and designers with custom CNC machining services, sheet metal fabrication and 3D printing services. Our immediate quotes and fast lead times can accommodate your customized high-quality parts, flexible production and development phases.

Our experienced engineers will combine CNC milling, CNC turning, Wire EDM, CNC cutting, surface treatment and more processes to complete your customized products, parts, and small batch production. These include the automotive industry, aerospace, medical instruments, complex machine parts, etc.

Our Experience in Numbers

|

|

|

|

| 2000+ | 2M+ | 60+ | 17+ |

| Companies served | CNC parts produced | Countries shipped | Years in business |

Precision Wire EDM Machining Services in China

Tuofa CNC Machining has the most senior 8 hardware mechanical engineers in Shenzhen, China, and is honored to be one of the leading manufacturers of machined parts in China. We operate a 24/7 CNC machine shop that is always in operation and produces high precision machined products without manual handling. Come and review our manufacturing capabilities now, we will be your most reliable outsourcing company.

We passed the ISO9001:2015 quality certification, which supports the long-term development of CNC lathe machining, CNC machining milling, CNC milling-turning, CNC cutting, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc. Take a look on our precision sheet metal fabrication service.

Tuofa professional CNC machining supplier involves CNC metal parts manufacturing, plastic CNC machining, and some difficult materials. Our CNC machining products can be utilized in a broad range of industries.

Tuofa CNC Machining Services Capabilities

As one of the fastest-growing precision CNC machining services China factory, the following machining capabilities at Tuofa are available to serve your needs of CNC machined parts, from rapid prototyping to precision parts and tooling machining, to end-use production.

- CNC Turning: a technology through which the material block is fixed on the CNC turning center or lathe rotating with high speed, while the cutting tool moving into the rotating axis to process the workpiece, to get CNC turned parts with exact sizes.

- CNC Milling: often regarded as the most common machining process, which refers to utilizing a CNC milling cutter to do circular motion and create milled parts with certain shapes and details in a stationary piece, including slots, holes, notches, grooves, etc.

- CNC Drilling: a cutting process in which the workpiece is fixed, aligning the cutter center with the hole center and rotating to produce round holes, can be done on lathes and mills.

- CNC Milling and Turning: a compound machining technology in which the cutting tool and workpiece are both rotating, to produce complex curved or special-shaped parts through designed multiple kinds of tasks.

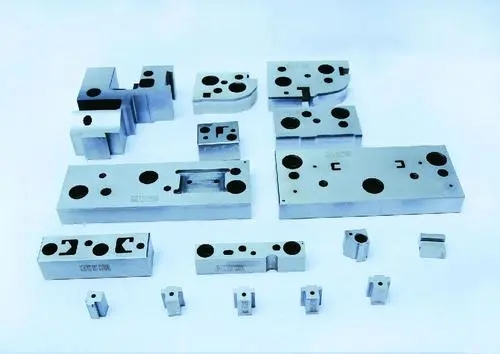

- Wire EDM Machining: EDM/OEM CNC parts from prototypes to full production with tight tolerance and complex construction.

Want to get the manufacturer's evaluation and suggestions on processing materials and surface treatment for newly designed products? The project sent out a quotation, but the supplier did not respond for a long time? Contact Tuofa now, you can get what you want.

Available Materials for CNC Machining

Aluminum

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

Brass

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

Plastics

CNC machining plastics material are also very popular option for CNC machining because of its wide choices, relatively lower price, and significantly faster machining time needed. We provide all common plastics for CNC machining services.

- POM

- Nylon

- ABS

- PEEK

- PTFE

- PC

- HDPE

- PVC

- PMMA

- PET

- PP

Metal |

Applications of Metal |

|

Aluminum; Aluminum 6061, Aluminum 5052 |

Learn more about aluminum CNC Machining |

|

Copper; Copper 101, Copper C110, Copper 260 (Brass) |

Learn more about copper CNC Machining |

|

Bronze;Bronze 220,Bronze 510 |

Learn more about bronze CNC Machining |

|

Stainless steel;Stainless steel 301,Stainless steel 304,Stainless steel 316/316L |

Learn more about stainless CNC Machining |

|

Steel;Steel 1018 (Low Carbon) |

Learn more about steel CNC Machining |

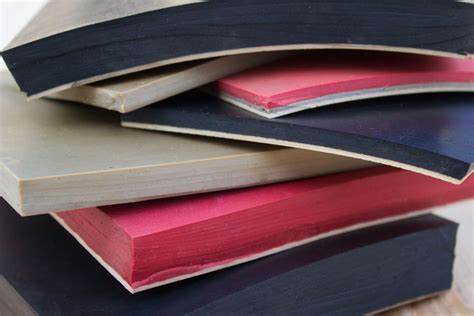

Available Materials for Wire Edm Machining

Get your precision machining components faster and at lower prices with Tuofa machining.

Ceramics

Glass

Metal

Plastics

Rubber

Wood

Available surface finishes for Tuofa Wire Edm Machining

You can choose a wide selection of metal surface finishing services after machining at Tuofa CNC machining manufacturer to improve the parts appearance, surface smoothness, corrosion resistance and other performance of your CNC machined parts.

- Painting: refers to an altering surface finishing process, spraying paint, pigment, or color to a solid surface as a colored protective layer, and can be done on metal or non-metal CNC machined components of any shapes, usually applied on aluminum, stainless steel, and steel alloy parts. The purpose is to improve aesthetic appearance and prevent corrosion or oxidation.

- Passivation: a common chemical surface treatment method for steel and stainless steel, to remove ferrous contaminants or use a light coat of protective material to create a shell for enhancing the corrosion resistance or reducing the chemical reactivity.

- Electroplating/Plating: a process of using an electric current to reduce dissolved metal cations so that they form a thin coherent metal coating on an electrode, to change the properties of the machining metal surface or build up thickness for undersized parts.

- Powder coating/Powder coat: a functional and decorative finish, which is applied as a free-flowing, dry powder, employs electrostatically and then cured under heat, to create a hard finish that is tougher than conventional paint. The main applications include household appliances, aluminum extrusions, drum hardware, automobile, motorcycle, and bicycle parts.

- Anodizing/Anodized: an electrolytic passivation process of forming a thin layer of aluminum oxide on the exterior of aluminum CNC machined parts to increase the thickness of the natural oxide layer and protect the metal, as the layer has higher corrosion and abrasion resistance than aluminum.

More Custom Metal Finishing Service For Presenting The Best Effect Of Your Parts

- Black oxide: also known as blackening, gun bluing, or hot blackening, a chemical process of forming a black conversion coating on stainless steel, copper and copper-based alloys, zinc, powdered metals, silver solder, and ferrous materials, to improve corrosion resistance and minimize light reflection.

- Conversion coating: also known as chromate conversion, the coating is used for metals converted to a protective layer through the chemical or electrochemical processes, primarily used as a corrosion inhibitor, decorative finish, or to retain electrical conductivity.

- Bead blasting/Bead blast: the process of removing surface deposits by applying fine glass beads at high pressure without damaging the surface.

- Abrasive blasting/sandblasting: the process or operation of propelling a stream of abrasive material composed of high-velocity sand-sizes particles against the metal surface under high pressure with blast equipment like air pressure system, to remove surface contaminants, clean metals, or increase a texture, then change the smoothness or roughness of a surface.

Manufacturing Standards for High-Quality Machined Parts

We ensure high quality machined parts. Every order includes our standard inspection report. Further reports and certifications are available on request. Submit an order to begin. Low-cost on-demand manufacturing, sheet metal stampings and on-time delivery are the standards of our CNC machining services.

Feature |

Description |

|

Maximum Part Size |

Milled parts up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm). Lathe parts up to 62” (1,575 mm) length and 32” (813 mm) diameter. |

|

Standard Lead Time |

3 business days |

|

General Tolerances |

Tolerances on metals will be held to +/- 0.005" (+/- 0.127 mm) in accordance with ISO 2768 unless otherwise specified. Plastics and composites will be +/- 0.010”. |

|

Precision Tolerances |

Tuofa can manufacture and inspect to tight tolerances per your drawing specifications including GD&T callouts. |

|

Minimum Feature Size |

0.020” (0.50 mm). This may vary depending on part geometry and chosen material. |

|

Threads and Tapped Holes |

Tuofa can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review. |

|

Edge Condition |

Sharp edges are broken and deburred by default |

|

Surface Finish |

The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote. |

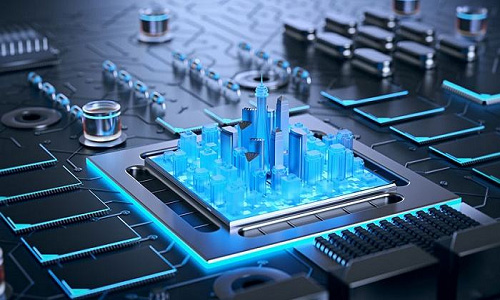

Industries of Wire Edm Machining Applications

CNC machining parts are all around you, they may be important components of your car and also can perform vital functions in your electrical equipment. Tuofa is an accomplished machined parts manufacturer that engaged in a broad range of CNC machining applications.

Electronic Industry

Medical Industry

Automotive Industry

Agricultural industry

Machine tool industry

Aerospace industry

Advantages of Tuofa Wire Edm Machining Services

- Efficient CNC machining factory for mass production rapid prototyping service

- Average 10 days turnaround time and 99.88% on-time delivery

- Multiple options of machining materials to meet specific properties.

- Fast free quotation within 24 hours after inquiry

- Have High customer satisfaction and loyalty

- Rich design and manufacturing experience

If you are looking for quality CNC machining services near me, our low-cost CNC custom machining will review the design, build your quote, assess the cost, and get your non-metal or metal fabrication parts into production orderly and efficiently.

Wire Cutt Machining Services – Wire EDM Shop & Electric Discharge Machining Manufacturer

Tuofa wire cut services of wire EDM machining & electrical discharge machining, Commercial wire EDM capability, and use have advanced substantially during 17 years. Feed rates have increased and surface finish can be finely controlled.

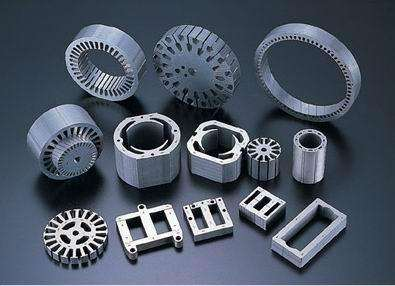

The EDM process is most widely used by the mold-making, tool, and die industries, but is becoming a common method of making prototype and production parts, especially in the aerospace, automobile, and electronics industries in which production quantities are relatively low.

Tuofa as one of the best CNC machining manufacturers in China is an ideal choice if you are seeking a CNC Machining Manufacturer or CNC Shop for the fabrication of small, medium, large-sized products in low volume or mass production. Our exceptionally trained and experienced employees fabricate components in accordance.

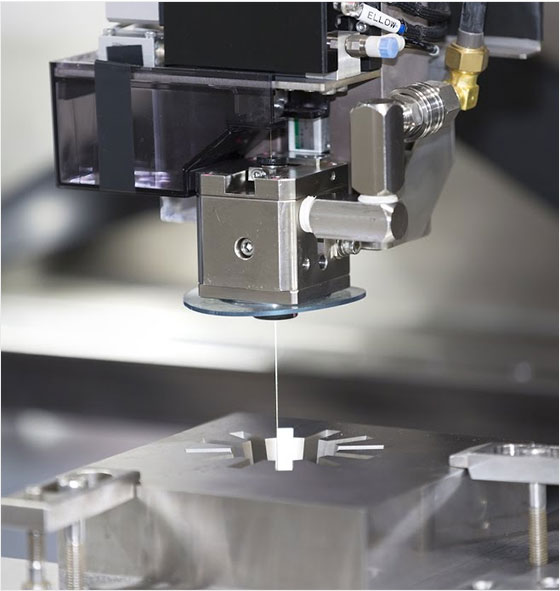

What is Wire EDM?

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning, or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks) Material is removed from the workpiece by a series of rapidly recurring current discharges between two electrodes, separated by a dielectric liquid and subject to an electric voltage.

How Does Wire EDM Work?

An electrically charged wire is used in the EDM process, which is the most significant characteristic of wire cutting. Then how does it work?

- First, put the workpiece to be processed on the workbench. You can cut it from the end of the workpiece, but at the beginning of wire cutting, the starting hole is usually connected to the material to avoid deformation due to the internal stress of the workpiece. When the worktable (or wire) moves in the XY direction (on the plane) according to the CNC data, machining is started.

- When the distance between the workpiece and the wire electrode in the insulating state in the working fluid is close to tens of microns, the insulation between them is damaged, and spark discharge occurs, resulting in the instantaneous flow of pulse current. In a high-density discharge state called an arc tower, a local high temperature of thousands of degrees is generated and the metal melts.

- In addition, the temperature of the working fluid around the arc column immediately rises and vaporizes, causing rapid volume expansion, resulting in an explosion between the workpiece and the electrode surface. This blows out metal debris.

- Then, when the pulse current is cut off and flows into the surrounding clean water, the molten metal cools and becomes fine debris. The debris is washed away, and the insulation between the electrodes is restored again, waiting for the supply of the next pulse voltage.

- In this way, the metal is melted and removed at each voltage pulse and repeated hundreds of thousands of times per second to cut the workpiece by wire cutting EDM.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home