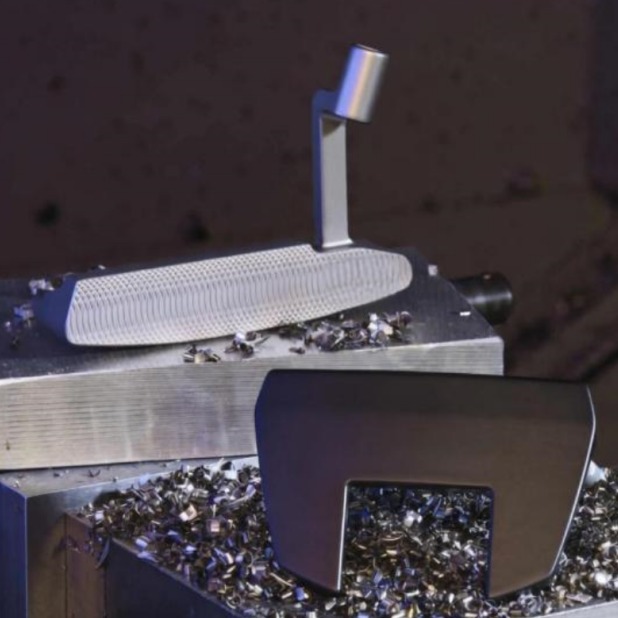

Golf Putters CNC Guide: Why Choose Milled Putters?

Golf is one of the most expensive games. It is not as common as cricket and football, but it is common in Europe. There are three essential pieces of equipment in golf: golf balls, a golf flag, and multiple types of clubs. Other accessories include tees,

Jan 08,2026

Jan 08,2026

2026 CNC Machining Trends: A Quick Outlook

CNC machining has modernized the manufacturing industry with advancements like automation, AI and robotics. Production of precise and complex parts has become easier and luckily; there's a lot more to come in CNC machine industry. Understanding the fu

Jan 07,2026

Jan 07,2026

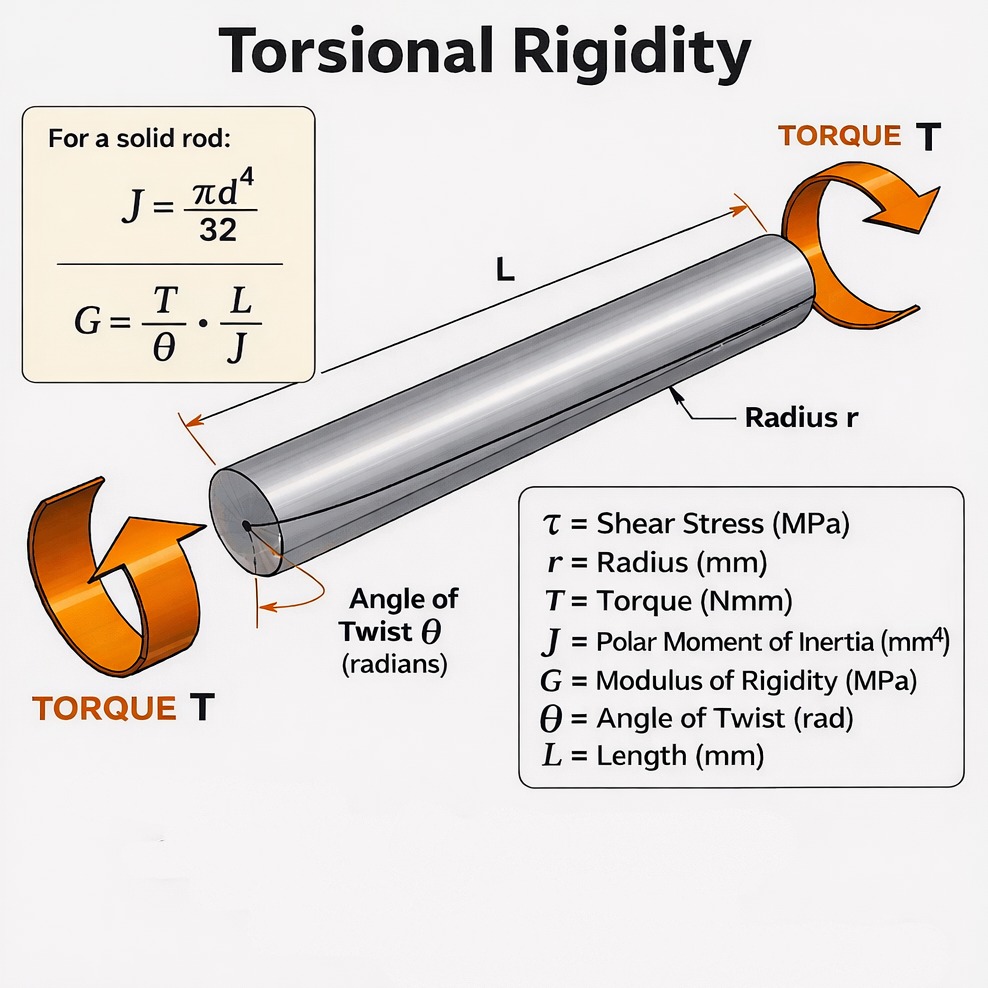

Torsional Rigidity in CNC Machined Parts: Design Methods

Torsional rigidity is an important engineering factor in CNC machined parts. In simple words, it is twisting rigidity and correct amount of rotational stiffness is crucial in engineering designs. For example, if rigidity is high, it makes part heavy and b

Jan 06,2026

Jan 06,2026

Titanium Cost Per Pound and The Cost of Titanium Machining

In the world of critical applications, where it is most important to avoid failure, Titanium stands tall with its excellent properties. Despite its excellent mechanical properties, Ti is not commonly used as other metals, such as stainless steel or alumin

Dec 31,2025

Dec 31,2025

What Is 40Cr Steel? A Complete Guide for You

Quite often a material is required that offer a high performance at a comparatively lower cost. 40Cr steel is one such option. Compared to its alternatives like 42CrMo4 steel or 4130 steel, it offers comparable strength at a low price. A slight addition o

Dec 31,2025

Dec 31,2025

Pipe Thread Types: Features, Differences, Applications & CNC Machining

You will have seen big joints in the big power plants, gas plants, and hydraulic plants. Sometimes, these joints are made using a welding process, sometimes using screws, and sometimes through the pipe threads. These threads are of multiple types. This ar

Dec 29,2025

Dec 29,2025

6063-T5 Aluminum: Temper, Properties, Weld & Machining

6063 T5 is a versatile aluminum alloy and famous across many industries due to its lightweight, workability characteristics and superior finish. Also, a balance of moderate strength and superior finishing makes it an ideal choice for decorative applicatio

Dec 27,2025

Dec 27,2025

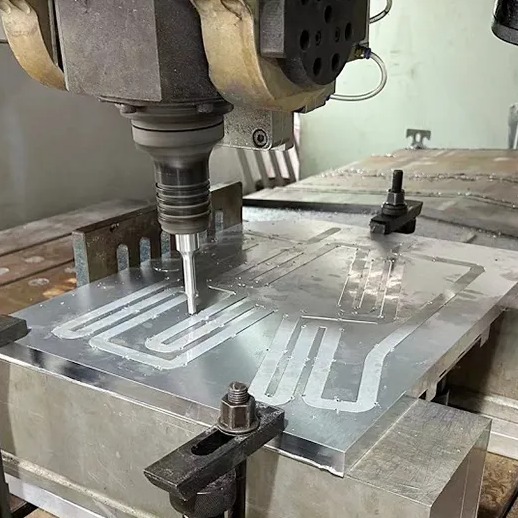

Liquid Cold Plates: Types, Applications & CNC Machining Guide

In this 21st century era, almost all systems around us are energy driven. Newer technologies are consuming enormous power. Designers see a lot of emphasis on compact designs. This huge power output in a constrained space difficult to be cooled by traditio

Dec 26,2025

Dec 26,2025

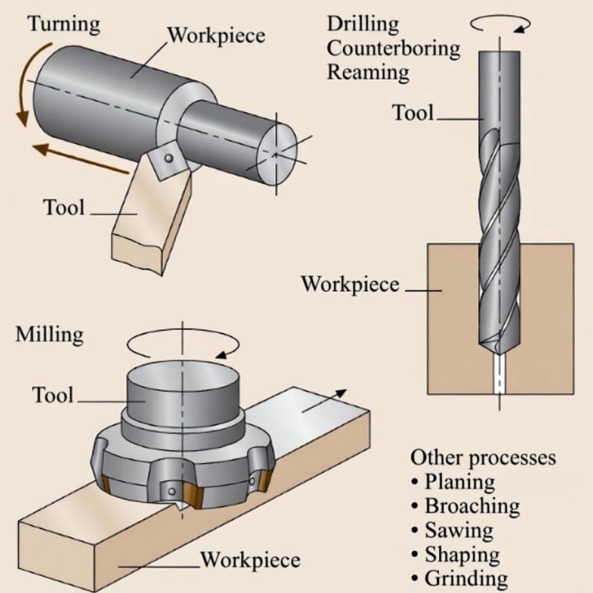

Types of Machining Operations You Should Know

In manufacturing industry, machining is a fundamental and essential part. Machining techniques have different types that can transform raw materials into a final product. So, what are these different types and how to know which one is suitable for any par

Dec 25,2025

Dec 25,2025

MIC 6 Aluminum: Properties, Machinability, and Best Uses

For applications such as vacuum chucks, tooling, or machine bases, materials with exceptional flatness and dimensional stability are required. This article presents a material that offers both flatness and dimensional stability, which makes it able to be

Dec 19,2025

Dec 19,2025

What Is Digital Manufacturing? Importance, Types, Tools & Advantages.

With the onset of the industry 4.0 era, manufacturing industry is witnessing such a high level of advancement that was unthought of in the past. Increasing demands for high quality and precision make traditional manufacturing difficult. Now, digital manuf

Dec 18,2025

Dec 18,2025

Nitriding Steel: Importance, Comparison, Applications & CNC Machining

Nitriding perfectly complements CNC machining by adding hard nitride layers on complex shaped steel parts. This creates superior and long-lasting parts for aerospace, automotive and tooling. However, some challenges occur in Nitriding steel like alloy sel

Dec 16,2025

Dec 16,2025

CuZn38Pb2 Brass: Composition, Properties, Machining

CuZn38Pb2 is a well-known brass alloy for its high machinability. This is one of the versatile copper and brass grades that has a unique balance of strength and durability. CuZn38Pb2 is highly valuable in precision engineering and manufacturing for its hi

Dec 11,2025

Dec 11,2025

A Complete Guide to Know Product Development Life Cycle

The product development lifecycle (PDLC) characterizes the step-by-step process to make a product. For example, an industrial company making a mechanical product from an idea to a ready-to-use shape for its customers. This process also includes the proces

Dec 10,2025

Dec 10,2025

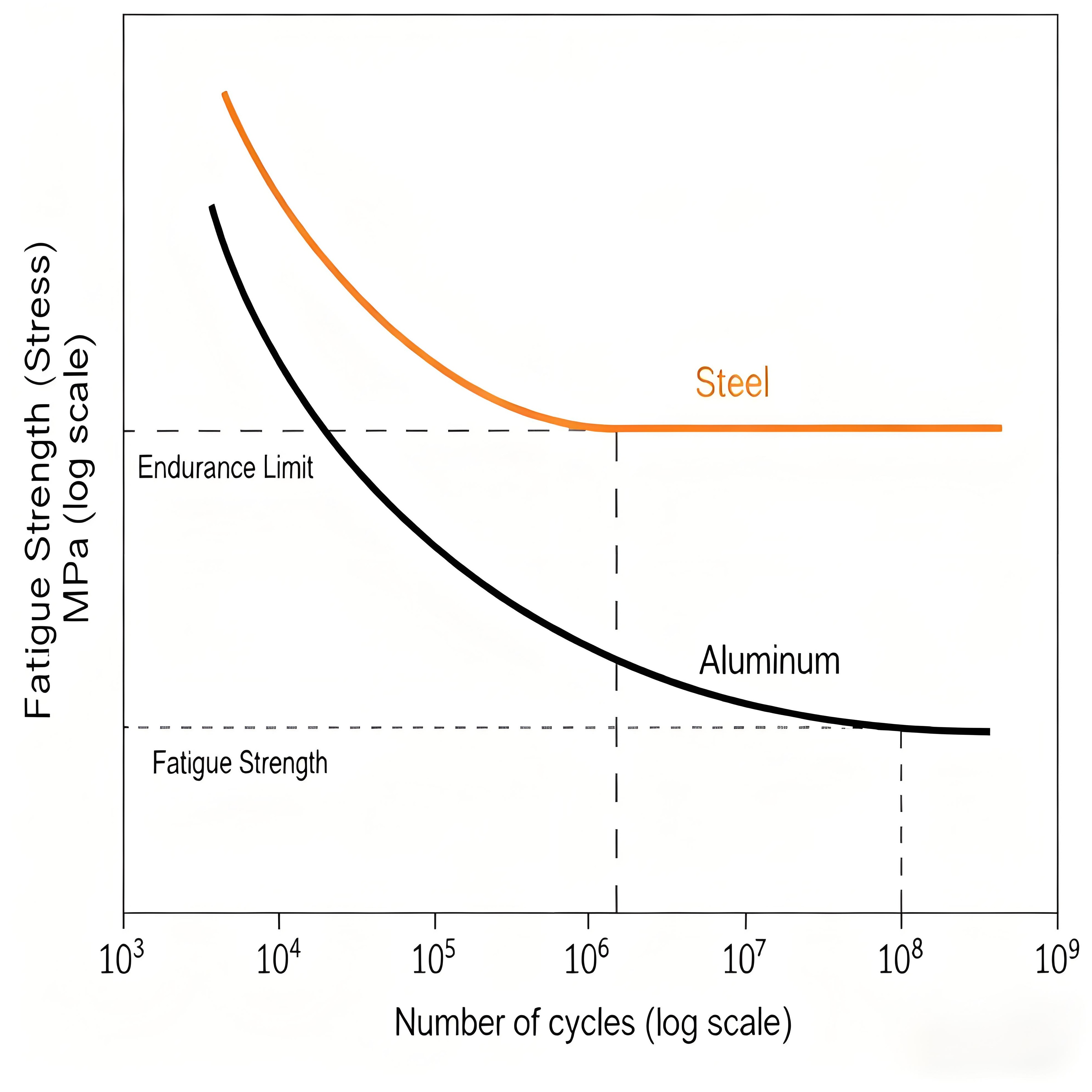

Fatigue Limit: Understanding Material Durability

The most important feature to consider when selecting the material is the service conditions of the application. These are determined by identifying fatigue limit of material like how much load a material can withstand before failure or by identifying loa

Dec 03,2025

Dec 03,2025

Nickel Plating in CNC Machining: A Complete Guide

Nickel plating has become quite famous in CNC machining for a huge range of products. Nickle plating not only enhances aesthetics but also increases the strength, hardness and durability of a part. It has a unique combination of high functionality and aes

Dec 02,2025

Dec 02,2025

Nitronic 60 Stainless Steel CNC: Properties, Process & Machinability

You would have noticed that when two metals are connected, wear issues arise, which further lead to failures or sometimes disasters. The wear issues arise when one of the two connected metals has poor wear resistance, and under friction, it becomes prone

Nov 29,2025

Nov 29,2025

65Mn Steel: Composition, Properties, Heat Treatment & CNC Machining

At times a strong and hard yet a tough material is needed for certain applications. Take an example of a survival knife. Even if the blade if sharp but it doesn't show flexibility, it's usage might get limited. 65Mn steel fits perfectly

Nov 28,2025

Nov 28,2025

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address