What Is Low Alloy Steel: Must-Know Properties, Grades,& Applications

May 27,2025

May 27,2025

We hope you know that Iron is the second most used material after aluminium. If you go into its history, iron has been in use since around 1200 BCE. Steel was introduced in 1856. Until now, we use hundreds to thousands of steel alloys in this world. These alloys are different based on composition, the way of strengthening them and their properties, etc. This article will familiarise you with low alloy steel, its properties, grades and applications. So, let's start with a brief introduction to low-alloy steel:

What Is Low Alloy Steel?

Low alloy steel means that this series contains a very low number of alloying elements, i.e. <5%. This steel comes with a balance between mechanical properties and cost. For instance, if you see stainless steel, which is a highly alloyed material, it is very expensive compared to this steel due to alloying elements, and so the mechanical properties. We will explore in detail how low-alloy steel is an important material in our world.

Composition of Low-Alloy Steel

After the extraction of iron from the blast furnace, alloying elements are used to make different steel alloys. As we mentioned earlier, low steel is composed of just 5% alloying elements and 95% Fe. This section presents comprehensive information on which alloying elements are used and why.

Key Alloying Elements and Their Roles

Low alloy steel contains only 0.1% to 0.3% Carbon. The other key elements include Cr, Mo, Ni, V, Ti, and W. Low C content in this steel makes it stronger and ductile. Let's figure out the role of other alloying elements in low-alloy steel:

Chromium, Molybdenum, and Nickel

Chromium

Low alloy steel contains 1% - 8% Cr, which is used for corrosion resistance and hardness in respective materials.

Molybdenum

Mo is added in the range of 0.1% - 0.7%. The role of this element is to increase hardenability and performance at high temperatures.

Nickel

In low alloy steel grades, Ni is added in the range of 0.8% - 3%, which increases toughness and corrosion resistance.

Vanadium, Titanium, and Tungsten

Vanadium

The role of V is to increase the strength and hardness of the low alloy steel. It is added in the range of 0.03% - 0.16% into different steel grades.

Titanium

Ti controls C/N and is used for grain refinement in the low alloy steels. Its percentage is 0.01% - 0.1%.

Tungsten

0.2% - 1% W is added in the grades of low alloy steel, which improves wear resistance and high-temperature strength.

Typical Composition Examples of Low Alloy Steel

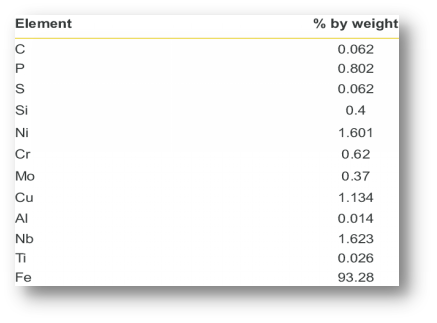

The following table represents different low-alloy Steel material grades with respective standards, composition and applications.

|

Grade |

Standard |

Composition (% by weight) |

Applications |

|

AISI 4140 |

ASTM A29 |

Cr (0.8-1.1%), Mo (0.15-0.25%) |

Gears, shafts, axles |

|

AISI 4340 |

AMS 6415 |

Ni (1.65-2.0%), Cr (0.7-0.9%) |

Aircraft landing gear |

|

42CrMo4 |

EN 10083 |

Cr (0.9-1.2%), Mo (0.15-0.3%) |

Heavy-duty machinery |

|

16Mo3 |

EN 10028 |

Mo (0.25-0.35%) |

Boiler pipes, pressure vessels |

AISI 4340 low alloy steel is one of the stronger materials, which is why it is used in an aircraft landing gear.

Key Properties of Low-Alloy Steel

The properties of any material are important to understand before bringing it to the applications. Alloying elements in any material greatly affect the mechanical properties of that material. This section presents a brief description of the mechanical properties of low-alloy steel material.

Mechanical Properties

Mechanical properties mean strength, toughness, ductility, etc. These properties are the basis for using the material for the respective applications. If a material has good mechanical properties, you can use it even in harsh conditions like a rocket nozzle, etc.

Strength

AISI 4340 steel is a grade of high-strength low alloy steel; its strength, i.e. 655MPa, outperforms carbon steel and is used in aircraft gears.

Toughness

Toughness means how much a material can resist stress before it fractures. Low alloy steels have good toughness, i.e. 40 – 100j due to the Ni content.

Ductility

We know that low alloy steel has good strength, but still, it shows moderate elongation (10-20%) under tensile loads.

Weldability and Formability

There is an issue of cracking during welding low-alloy steels, so it is wise to preheat the object around 150 – 200 °c to avoid cracking.

Different grades show different levels of formability. HSLA steel shows better formability than high-strength steel, e.g. 4340.

Resistance to Corrosion and Wear

- Since low alloy steel has Cr and Ni in its composition, it shows good corrosion resistance in normal conditions.

- Good wear resistance due to Mo and V alloying elements.

Common Types and Grades of Low-Alloy Steel

We categorise low alloy steels based on how they are heat-treated, which alloying elements have been used, their properties and applications, etc. There are many types and grades of low alloy steel; some of them are discussed below in this section.

High-Strength Low-Alloy (HSLA) Steels

These steels exhibit higher strengths, good formability and welding due to certain alloying elements such as V, Nb, Ti, etc. You can use these steels in structural components, automotive chassis, etc. ASTM A572 and ASTM A588 are the commonly used grades of this series.

Quenched and Tempered (Q&T) Low Alloy Steels

These steels come with a balance between strength (up to 1400 MPa yield strength), hardness and toughness due to the combination of quenching and tempering. You can use these steels in military army vehicles, oil and gas equipment. Its common grades include AISI 4140, 4340.

Chromium-Molybdenum (Cr-Mo) Low Alloy Steels

Due to Cr (0.5 – 1.5%) and Mo (0.1- 0.3%) alloying elements, these steels show good strength and creep resistance even at high temperatures. The common grades of this series include 4140 and 4130. You can use these steels in aerospace components, gears, boilers, etc.

Nickel-Chromium-Molybdenum (Ni-Cr-Mo) Low Alloy Steels

Alloying Elements

Ni (1–3%), Cr (0.5–1.5%) and Mo (0.2–0.5%)

Properties

These steels exhibit good fatigue resistance, toughness and hardenability.

Applications

You can use it in aircraft landing gear and heavy machinery components.

Grades

AISI 4340, EN24

Weathering Steel (COR-TEN Steel)

Alloying elements like Cu, Cr and P help these steels to achieve better corrosion resistance by making an oxide layer over the surface. Its common grades are COR-TEN A/B and ASTM A588. These steels are used in bridge construction and railway wagons.

Pros and Cons of Using Low-Alloy Steel Materials

Till now, we have been discussing the pros of low-alloy steel, like a balance between mechanical properties, but it also has some cons. We will figure out both the pros and cons of using this steel here:

Advantages of Low-Alloy Steel Materials

Its main advantages are:

Strength-to-weight ratio

Higher than carbon steel, so you can use it in structural and automotive applications.

Durability

Under cycling loading, these steels offer a longer life span, so lower maintenance costs.

Toughness

Alloying elements like Cr and Ni provide enhanced toughness and high impact resistance.

- These properties enable them to be used widely across multiple industries such as automotive, structural and aerospace.

Limitations of Low-Alloy Steel Materials

Low-alloy steel materials have the following disadvantages, which can limit their usage in certain applications:

- Low alloy steels do not have higher contents of Cr and Ni, so they can't be used in harsh corrosive conditions such as marine or high temperature.

- At high temperatures, susceptibility to creep is high.

- Not every low-alloy steel is weldable easily. Some grades, like 4140, can crack if they are not preheated. So, pre-heating around (150–300°C) is required before welding.

Manufacturing and Processing Techniques for Low-Alloy Steel

After alloying elements, manufacturing and processing techniques are responsible for the performance of respective materials in the applications. There are different techniques like rolling, forging, annealing, etc. These techniques or processes are used according to the desired properties of that material.

Heat Treatment Processes

If we talk about the low alloy steel material, the heat treatment processes include annealing, normalising, quenching and tempering. These heat treatment processes provide different hardness and strengths, so we need to be careful while choosing a specific heat treatment.

Annealing and Normalising

Annealing

If you need softness or machinability from low alloy steel, you need to perform annealing on that material. It refines grain structure.

Normalizing

Normalising causes an increase in strength and hardness, although very low, because it results in a fine-grain structure. This heat treatment results in uniform properties from the low-alloy steel part.

Quenching and Tempering (Q&T)

Quenching

Quenching results in a martensitic microstructure. We heat the product around 900 °c and then dip it in water or oil. It increases hardness and strength greatly.

Tempering

Quenching causes brittleness in the material. To reduce tempering, we heat the quenched part around 500oC then air cooling. It results in enhanced toughness but reduced hardness.

Machining Low Alloy Steel

There are many machining techniques which are used in manufacturing. some common techniques include milling, grinding and turning, etc. We choose a specific machining operation according to the required tolerance, precision and shape.

Recommended Cutting Tools and Techniques

Carbide and Cermet cutting tools can cut low-alloy steel without reducing the material's integrity.

Variable Helix End Mills and Trochoidal Milling technologies are commonly used for low-alloy steel.

Tips for Achieving Precision and Surface Finish

To achieve precision and good surface finishes, use the following tips:

- Use tools with rounded tips for smoother surface finishes.

- To avoid vibrations during machining, clamp the workpiece strongly.

- Use a coolant to keep the temperature low for tools and workpieces.

Typical Applications and Examples of Low-Alloy Steel Parts

Now, you will see how low-alloy steel is used across different industries in this section.

Automotive and Transportation Industry

AISI 4140 steel is used in chassis components and suspension parts in the automotive and transportation industry.

Aerospace and Aircraft Structures

In aerospace and aircraft structures, AISI 4340 steel is used in landing gear and structural frames.

Construction and Infrastructure

HSLA steels are used in bridges and structural beams in this industry.

Energy and Power Generation

16Mo3 steel is used in pressure vessels and piping systems in energy and power generation.

Comparing Low-Alloy Steel with Other Steel Types

As we mentioned earlier, there are more than 100 steel types in use today. We have compared low-alloy steel with some of the most common steel types in this section.

Low Alloy Steel vs. Carbon Steel

Medium carbon steels such as AISI 1045 are known as carbon steels. Low-alloy steel (AISI 1040) outperforms carbon steel in terms of strength.

Is Low-Alloy Steel the Same as Low-Carbon Steel?

No, both are different in terms of alloying elements, properties and applications. Carbon steel is cheaper than low alloy or mild steel, but not recommended.

Differences in Strength and Applications

|

Property |

AISI 4140 (Low Alloy) |

AISI 1045 (Carbon Steel) |

|

Tensile Strength |

850-1000 MPa |

585 MPa |

|

Impact Resistance |

Excellent |

Moderate |

- Low-alloy steel is used in landing gears and construction beams, etc.

- Carbon steel is used in dies and cutting tools, etc.

Low Alloy Steel vs. Stainless Steel

It is easy to weld stainless steel as compared to low-alloy steel, while it is easier to machine low-alloy steel grades.

Low-alloy steel grades show strong magnetism, but stainless steel does not exhibit this.

Differences in Corrosion Resistance and Cost

Stainless steel, e.g. AISI 304, exhibits excellent corrosion resistance as compared to low-alloy steel, e.g. 42CrMo4. The reason is the passive layer of Chromium Oxide in stainless steel.

Low Alloy Steel vs. High Alloy Steel

In this section, the difference between low-alloy and high-alloy steel is provided.

Alloying Element Levels and Usage Differences

The following table shows a clear difference between low-alloy and high-alloy steel based on alloying elements and usage.

|

Characteristic |

Low Alloy Steel |

High Alloy Steel |

|

Alloy % |

1-5% |

5-50% |

|

Typical Cost |

Moderate |

Very High |

|

Special Properties |

Better strength |

Extreme heat/corrosion resistance |

|

Examples |

4140, 4340 |

Tool steels, superalloys |

How to Choose the Right Low-Alloy Steel Grade for Your Project

There are always some criteria behind the selection of any material for any project. The following are some guidelines so you can choose the right low alloy steel grade for your project.

Identifying Project Requirements

First, you should know the level of strength you need in your project, then the operating environment and finally your budget.

Weldability and Machinability

During the construction or machining of the components, weldability and machinability are important properties. Choose that alloy which offers ease of weldability and formability during construction or machining.

CNC Machining Solutions from Tuofa

Toufa is a China-based company which stands tall with its capabilities of producing highly precise and accurate components. Our advanced machines and experienced workers will provide you with tight tolerances for your critical objectives. We will deliver on time and at the lowest prices relative to the market.

Conclusion

Finally, it is concluded that low-alloy steels are an important part of our world because of their applications in construction, aerospace and automotive industries. Low alloy steel grades provide a balance between strength and ductility with acceptable corrosion and wear resistance. Since many low-alloy steel grades, you should select the required grade according to your operating environment, strength, weldability and formability properties and finally your budget limit.

FAQs

What is the difference between alloy steel and low-alloy steel?

If any alloy steel contains less than 5% of alloying elements, we call it a low alloy steel and vice versa.

Can low-alloy steel rust easily?

Fe reacts with oxygen very quickly. We know that low alloy steel contains less than 10% Cr content, which makes it susceptible to rusting and corrosion.

Is low-alloy steel suitable for high-temperature applications?

Yes, some low alloy steel contains Mo up to 1%, which helps perform well under high temperatures.

Is 4140 or 4340 low alloy steel?

Yes, both are low-alloy steel and contain Cr and Mo.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Is Carbon Fibre a Metal? - Properties & Metal Comparisons

Is Carbon Fibre a Metal? - Properties & Metal Comparisons