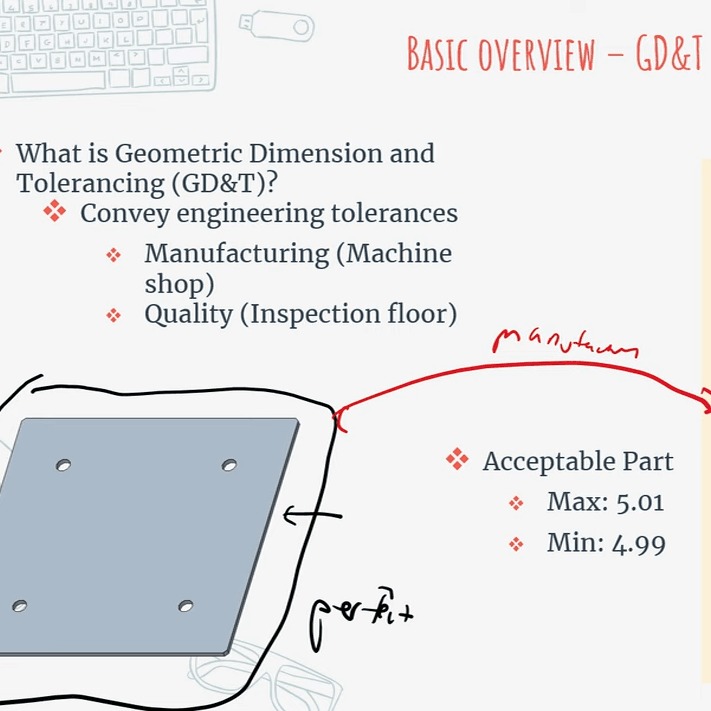

What is GD&T? Purpose and Rules

Geometric Dimensioning and Tolerancing (GD&T) is a vital aspect of engineering design and manufacturing, offering methodical approach to defining and communicating admissible limits of variation in a part's geometry. The purpose of GD&T is to

Sep 06,2024

Sep 06,2024

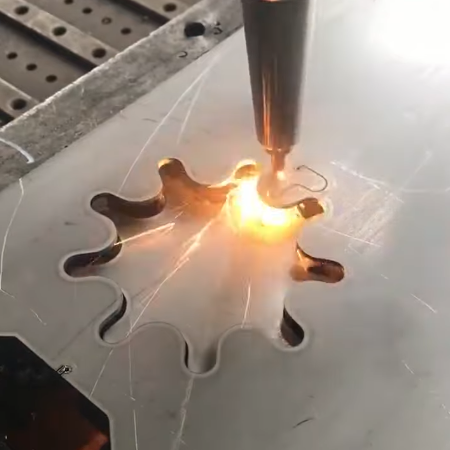

11 Ways to Cut Titanium | Cutting Guide 2025

The aerospace, medical and automotives industry all employ titanium, which is light weight and has good corrosion resistance. It also has high strength to weight ratio. Machining of titanium is not a simple task because of its high hardness value and it i

Jul 24,2024

Jul 24,2024

Aluminum 6061 T6 vs T651 vs T6511: What is the Difference?

Aluminum alloys are available in many grades and it is not an easy task to differentiate between them. This article provides you with a comparison of two of the most used tempering processes being used for aluminum alloys. These tempered alloys have the s

Jul 23,2024

Jul 23,2024

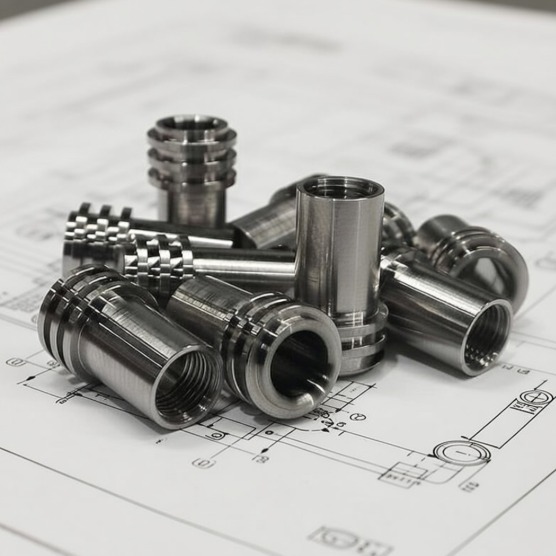

A Method for Calculating the Cost of Turned Parts

Cost of turning parts

Due to the development of science and technology, the machinery for turning parts and components has changed a lot. From the traditional manual ordinary turning machinery (referred to as "ordinary lathes") to a

Jul 24,2024

Jul 24,2024

Surgical Steel vs Titanium: Deep into the Properties, Piercings, and Suitability

You surely know that the strongest metal is titanium, and the alloy is steel that we frequently use in our daily lives. Both are superior in their perspective because having excellent chemical and physical properties. But their alloys are totally differen

Jul 24,2024

Jul 24,2024

Anodized Titanium: The Definitive Guide

Anodizing is a famous electrochemical technique to develop colours on different metal and alloys. Anodizing of titanium is different than aluminum anodizing as it doesn’t involve any dye. An electrochemical process is implied and colour variation is

Jul 23,2024

Jul 23,2024

6061 vs 6082 Aluminum Comparative Guide

Aluminum is a very demanding material in engineering applications because of being strong and lighter in weight. By adding alloying elements in Al alloys and providing heat treatment, its mechanical properties like shear strength and toughness further inc

Jul 24,2024

Jul 24,2024

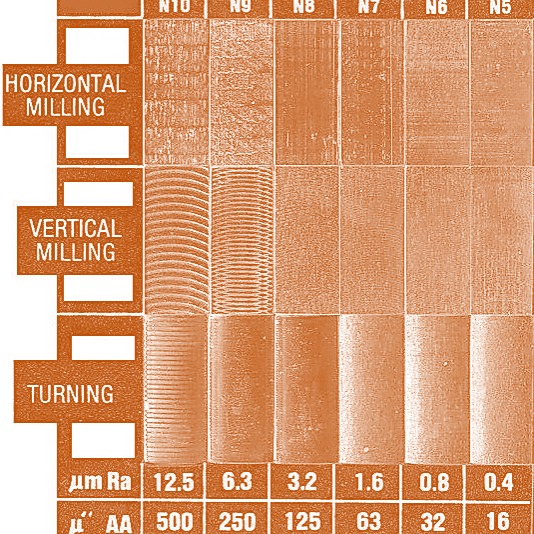

Surface Finish Chart: The Complete Guide

Metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. In addition to physical properties like strength, ductility or toughness etc. surface provides material an overall appearance. A smooth surfac

Jul 24,2024

Jul 24,2024

3Cr13 Steel: The Complete Guide

3Cr13 martensitic stainless steel has intrinsic metallurgical properties. These properties decide the category of the 3Cr13 item. One has to understand the edge retention and corrosion behavior of a knife. Edge retention decides the life and maintenance o

Jul 24,2024

Jul 24,2024

How to Clean Oxidized Aluminum: 4 Ways

Cleaning oxidized aluminum and making it stain free The versatility of aluminum metal made it durable and the most commonly used metal for vast applications ranging from household items like kitchen utensils to industrial level products. This special meta

Jul 24,2024

Jul 24,2024

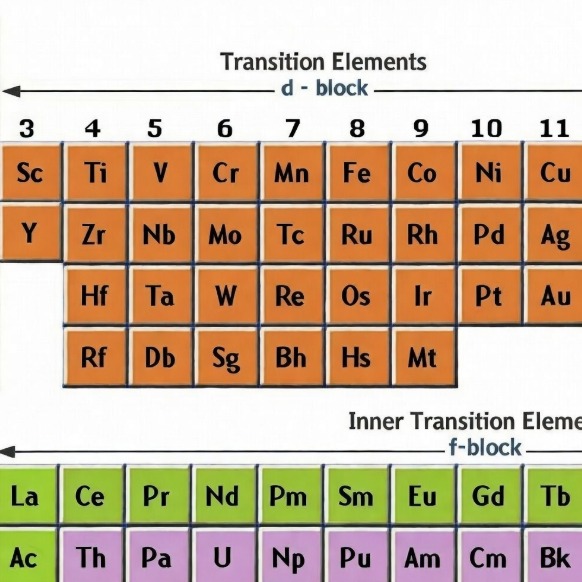

What Are Transition Metals? Definition, Properties, and Uses

Transition metals are from the various chemical elements that possess valance electrons. These elements are present in the middle portions of periodic table. The term “transition” is not related to any specific chemical significance. But it is

Feb 27,2026

Feb 27,2026

The Most Common Titanium Alloy: Ti-6Al-4V (Grade 5/TC4) CNC Tips

In Titanium alloys, Ti-6Al-4V is the most commonly used alloy as a custom CNC machining part material. This alloy is common for critical applications for aerospace and medical implants. A complete guide is provided in this article, which covers each aspec

Feb 22,2026

Feb 22,2026

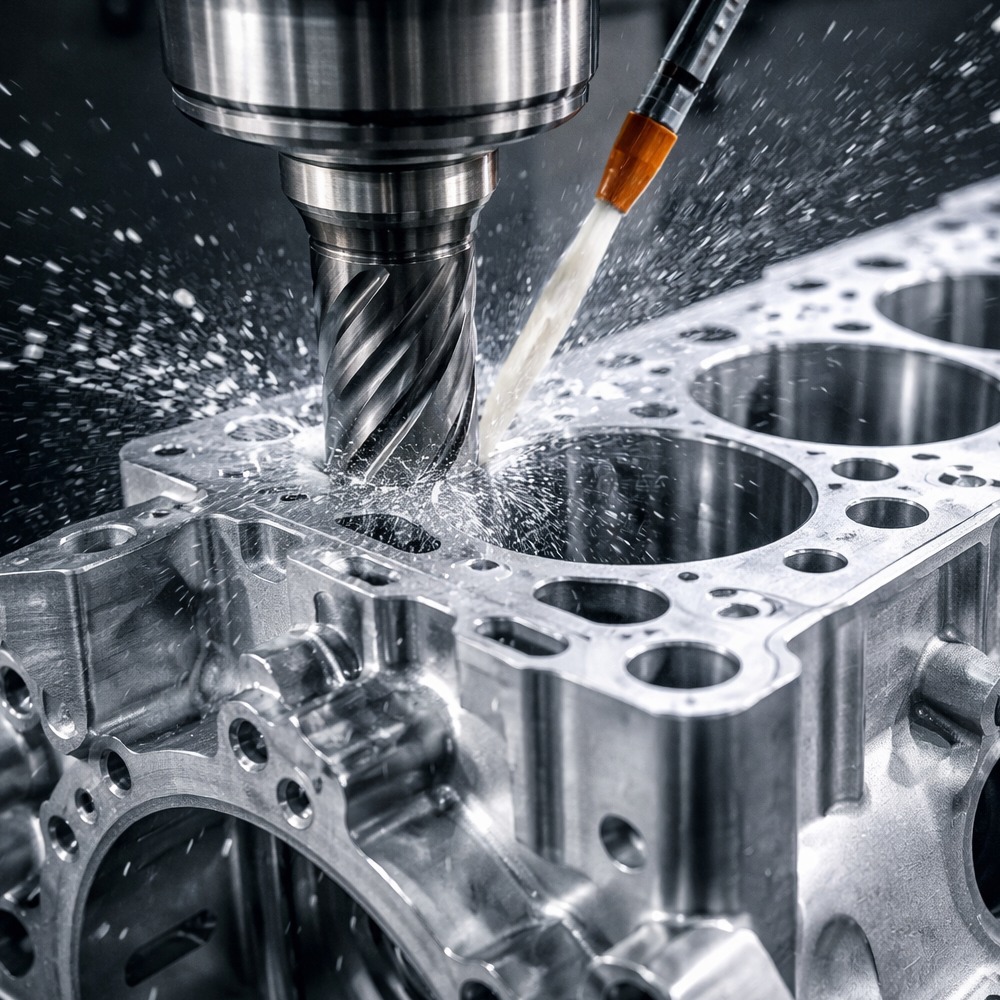

Aluminum Block Machining: Guide for CNC Milling Projects

CNC milling always been a highly reliable solution when it comes to precision, repeatability and accuracy. Aluminum block machining is being widely used to manufacture parts like engine blocks. The stringent tolerance and dimensional accuracy requirements

Feb 18,2026

Feb 18,2026

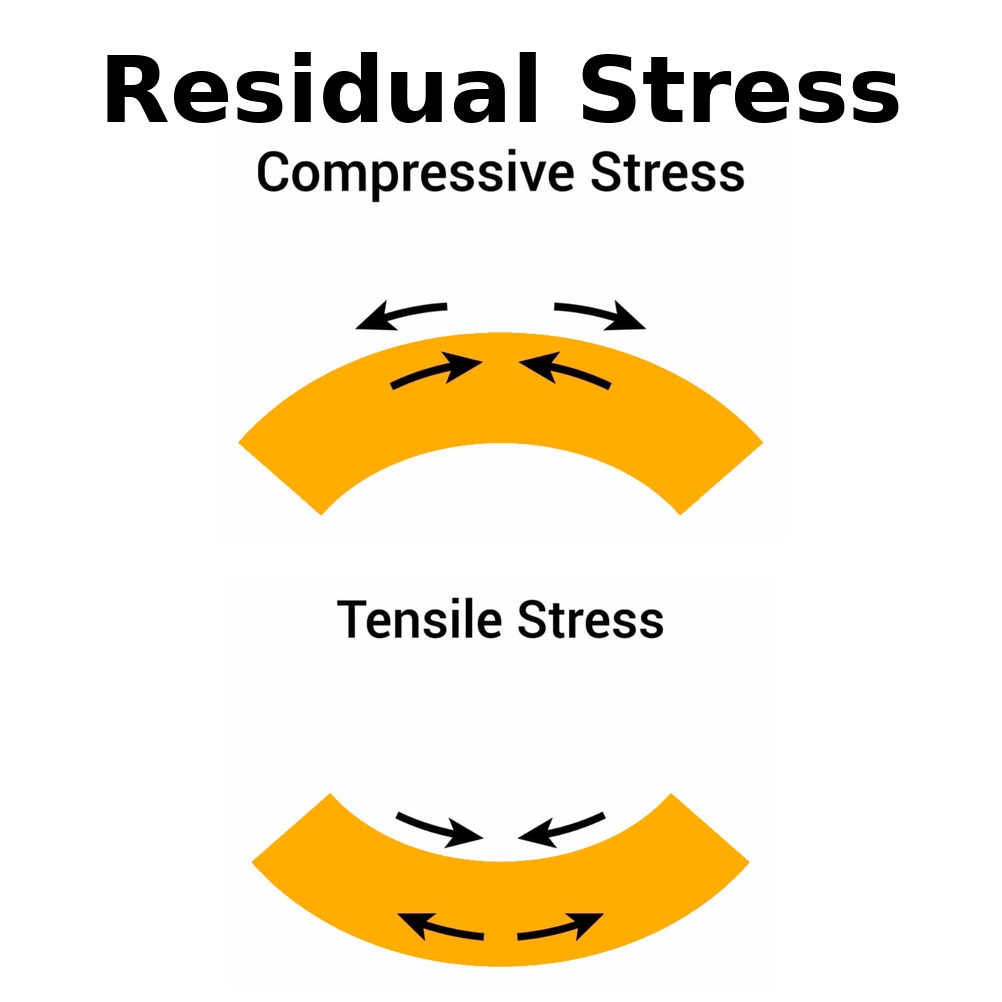

What Is Residual Stress? Causes, Types & Measurement

Residual stress is the silent force hidden within your components. It may change dimensions, reduce the life of components, and disrupt delivery schedules without giving any noticeable warning or indication. In many manufacturing projects, distortion, rew

Feb 14,2026

Feb 14,2026

What Is Titanium Used for? Machined Parts & Applications

Titanium is a strong and versatile metal. Its remarkable mechanical strength, corrosion resistance and lightweight features make it highly demanding in many industries. Furthermore, it is biocompatible and non-toxic. Because of these distinctive propertie

Feb 12,2026

Feb 12,2026

Vapor Polishing: An Important Guide to Plastic Parts

Your project needs a flawless and glossy finish on plastic parts but do not know what to do? Then vapor polishing is your thing. It is an effective method to have a smooth and transparent surface without visible surface imperfections. This article will gi

Feb 16,2026

Feb 16,2026

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address