Vapor Polishing: An Important Guide to Plastic Parts

Your project needs a flawless and glossy finish on plastic parts but do not know what to do? Then vapor polishing is your thing. It is an effective method to have a smooth and transparent surface without visible surface imperfections. This article will gi

Feb 16,2026

Feb 16,2026

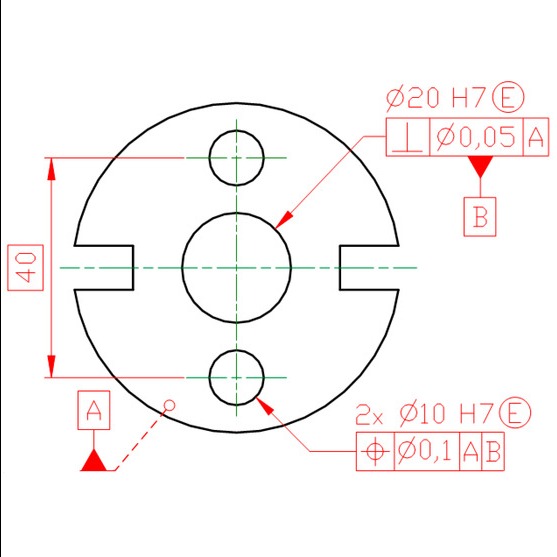

Geometric Tolerance: What, Why and How to Use?

The very first stage of creating a part is drawing, where its dimensions are decided. This geometry is then used to produce the part after selecting the raw material, machining processes, and machining. To avoid any undesirable variations from the basic d

Feb 20,2026

Feb 20,2026

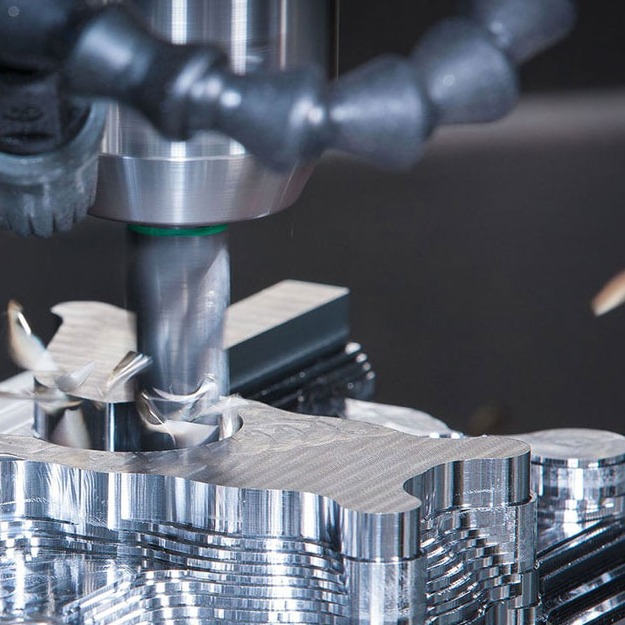

What Is Slot Milling? The Newest Guide for You in 2026

CNC machines are among the most important tools in the manufacturing field. Every CNC milling operation has different types that are used for different applications. This article particularly focuses on the milling operation type, i.e., Slot Mil

Feb 07,2026

Feb 07,2026

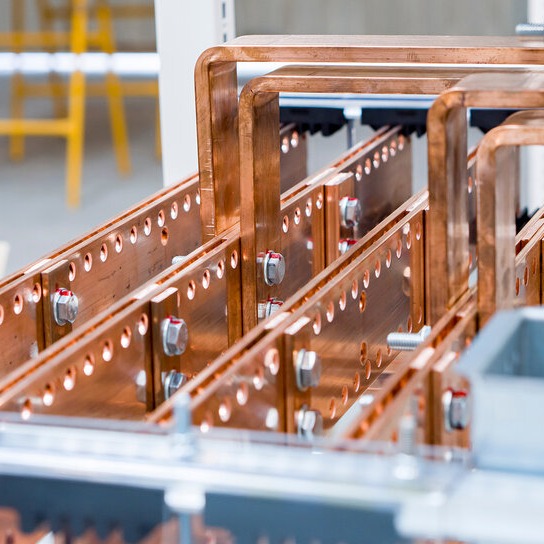

What Is An Electrical Bus Bar? A Complete Engineering Guide 2026

Electrical bus bar is a metallic conductor used in electrical systems to transmit electric current. It reduces electrical interference, increases current transmission, reduces power losses and provides more reliability. In some demanding situation, bus ba

Feb 05,2026

Feb 05,2026

Standard Tolerance Grades IT5-IT8 in CNC Machining

In designs, geometry, or manufacturing, dimensions are everything. A little in any dimension can affect the efficiency or accuracy of the product to be employed in any application. Tolerances are defined to limit these changes to a certain value. Internat

Feb 04,2026

Feb 04,2026

Contract Manufacturing: How It Works and How to Find One

Contract manufacturing has a vital role in global supply chains. It helps those businesses to collaborate with other companies in order fulfilling which may not have sufficient resources or funds to invest in heavy machinery. Contract manufacturing operat

Jan 30,2026

Jan 30,2026

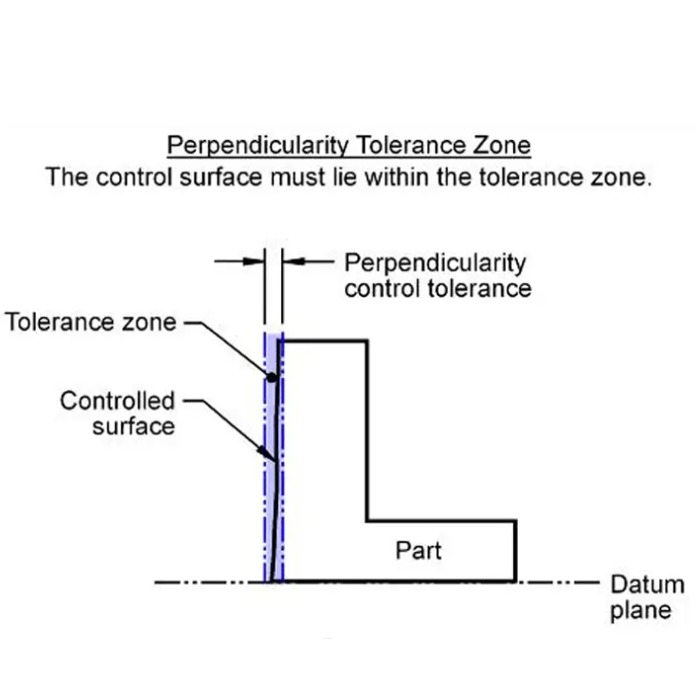

Perpendicularity in GD&T: Important Geometric Tolerance Symbol

In drawing and manufacturing, GD&T(Geometric Dimensioning and Tolerancing) is mainly used. Multiple terms are used in a drawing to show different dimensions. Perpendicularity is one of these terms to verify if a dimension is close to 90°. This art

Jan 29,2026

Jan 29,2026

Guide for Custom Bumper Latches: Types, Functions & CNC Machining

Bumper latches are one of the most significant aftersales auto parts for modified vehicles. They not only secure bumpers in place but also provide it the flexibility of quick release. Whether it is the quick replacement of bumpers for aesthetic purposes o

Jan 28,2026

Jan 28,2026

Strength of Plastic: 2026 Complete Guide for Materials Selection

In recent times, plastics are progressively replacing materials like steels, aluminum alloys, and ceramics. One of the common reasons is the durability and strengths of high-performance plastics. However, a wide range pf plastic can make someone confused

Jan 27,2026

Jan 27,2026

On-Machine Inspection in CNC Machining: A Mechanical Inspection Guide

On-machine inspection is a contemporary method to test parts in a machine whereby parts are still under process in the CNC machine. It ensures that the parts are with very small quality deviations before the next manufacturing process. In modern super-fas

Jan 24,2026

Jan 24,2026

Spring Sheet Metal: CNC Machining & Applications

As you know, automotive and industrial suspension are the common uses of spring steel. These steels have very high yield strength which helps them to return to their original shape. Spring sheet metal is a sheet or plate form of spring steel and used to m

Jan 21,2026

Jan 21,2026

What Is Duralumin Material? Know Its Properties & Applications

Duralumin is an incredible aluminum alloy when it comes to high specific strength and light weight. While it has one of the lowest densities out of all structural metal, its strength is really impressive. Since its discovery in 1909m, duralumin is highly

Jan 20,2026

Jan 20,2026

What Is Oxygen Free Copper? A Complete Guide for You

Copper contains traces of impurity depending on its sources, including oxygen. The content of oxygen is very small, however, it‘s still enough to possibly cause damage with time. Therefore, the projects where durability and conductivity are co

Jan 16,2026

Jan 16,2026

What is 41Cr4 Steel? Everything You Should Know

41Cr4 steel is a strong alloy that beats many steels like C45 in hardening. It also possesses remarkable mechanical properties, making it suitable for machineries manufacturing. Other technical and mechanical aspects of 41Cr4 alloy steels are discussed in

Jan 13,2026

Jan 13,2026

Leaded Brass: A Properties, Grades, and Machining Guide

Huge numbers of metals and metal alloys are used in this world in multiple applications. At the end of the 18th century, Brass (Cu-Zn alloy) was commonly used in different applications. At the start of the 19th century, leaded brass was introduced because

Jan 12,2026

Jan 12,2026

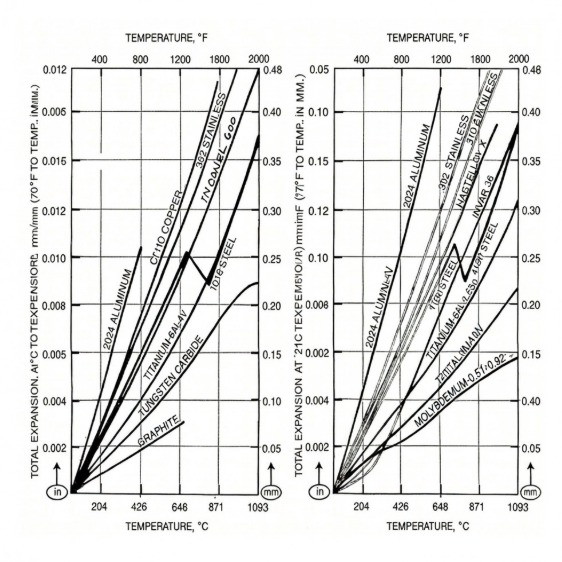

Does Metal Expand When Heated? Understanding Thermal Expansion

At times, a conflict might occur between the CNC manufacturer and the client regarding dimensional accuracy. The CNC manufacturer makes parts as per CAD given by the client. But still dimensions deviate from the design. The client wonders: “does met

Jan 09,2026

Jan 09,2026

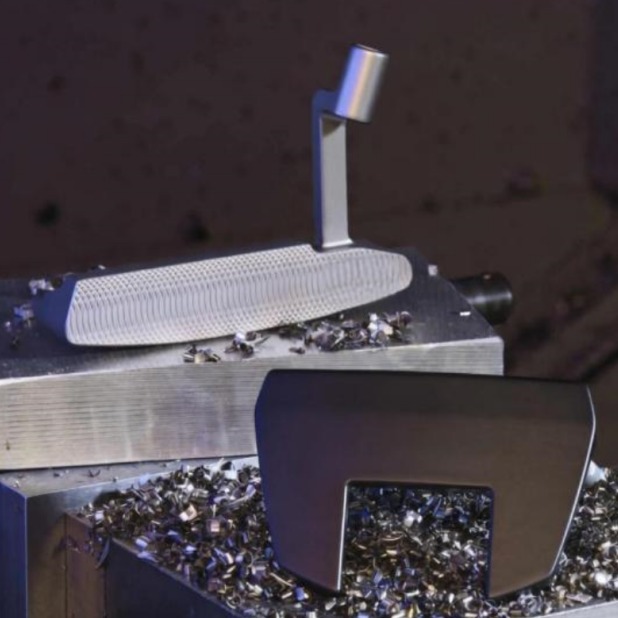

Golf Putters CNC Guide: Why Choose Milled Putters?

Golf is one of the most expensive games. It is not as common as cricket and football, but it is common in Europe. There are three essential pieces of equipment in golf: golf balls, a golf flag, and multiple types of clubs. Other accessories include tees,

Jan 08,2026

Jan 08,2026

2026 CNC Machining Trends: A Quick Outlook

CNC machining has modernized the manufacturing industry with advancements like automation, AI and robotics. Production of precise and complex parts has become easier and luckily; there's a lot more to come in CNC machine industry. Understanding the fu

Jan 07,2026

Jan 07,2026

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address