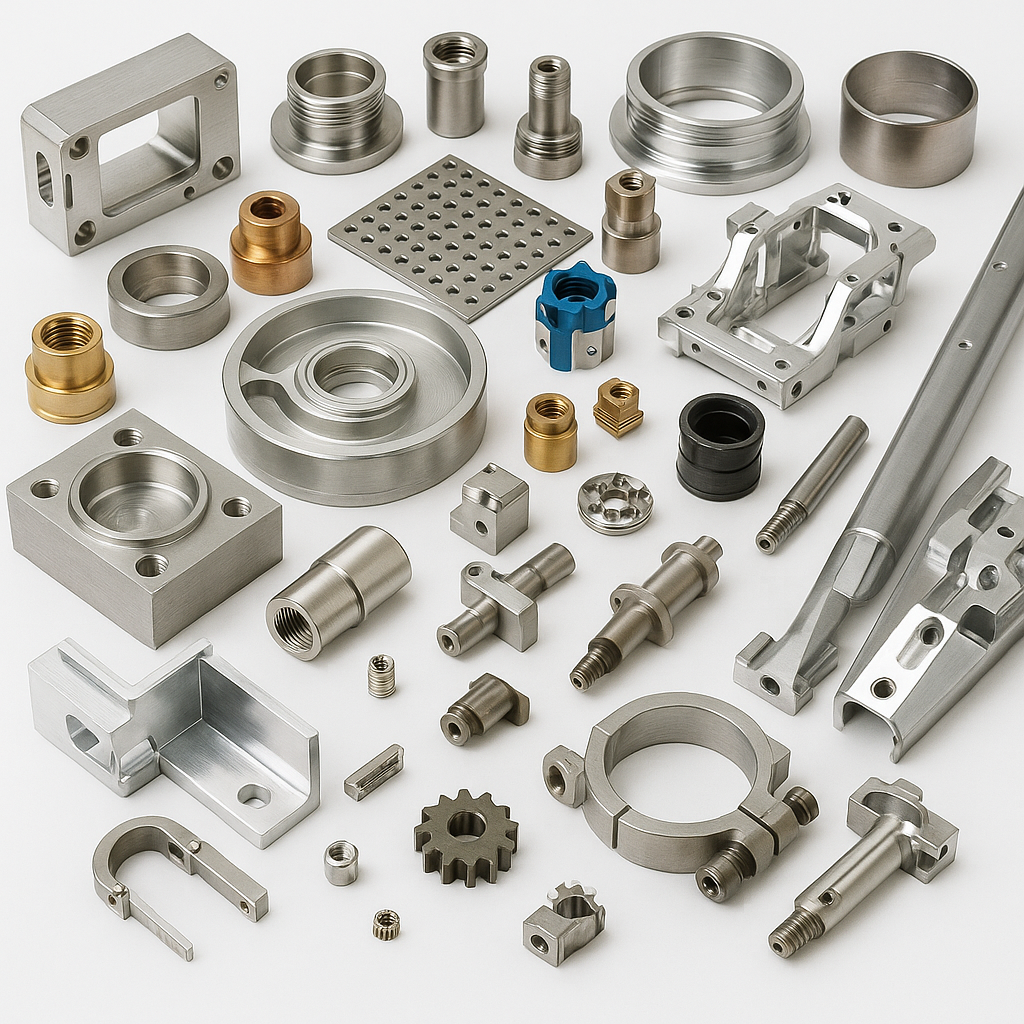

Types of Metal Fabrication: Processes and Custom Metal Parts

Dec 15,2025

Dec 15,2025

Metal fabrication has been in use for thousands of years; however, technological advancements have increased the number of fabrication processes, though. To manufacture any component, from a washer to a huge bridge, metal fabrication is required. This article represents comprehensive information about different fabrication processes, their applications, and suitable materials for metal fabrication.

What Is Metal Fabrication?

When a metal is converted into a product, let's say, a nut is made out of a steel rod, it is called metal fabrication. In simple words, metal fabrication processes just convert the raw metal into a desired product.

Basic Definition of Metal Fabrication

Metal fabrication can be simple, precise, and advanced. Let's figure out some important differences between them.

Basic Metal Fabrication

Basic metal fabrication can be considered as a first-level manufacturing work. Through basic metal fabrication, simple parts or structures are made by cutting, forming, or bending.

Precision Metal Fabrication

When tolerances in the dimensions or surface roughness become critical, then precision metal fabrication comes into the field. In this type of fabrication, advanced manufacturing machines, such as CNC milling, drilling, etc., are used to manufacture very precise parts. This type of fabrication is mostly used in aerospace, automotive, electronics, and medical industries.

Advanced Metal Fabrication

Advanced metal fabrication uses automation, robotics, CNC machines, etc., to manufacture highly-precise parts in large volumes.

Types of Metal Fabrication by Process

There are many metal fabrication processes used in daily life. Some of the most used processes are discussed here:

1. Casting Metal

This is one of the oldest metal fabrication processes. In this type, first the raw metal, such as Aluminum, is brought into a liquid state and then it is solidified in a mold of the required design. Engine Cylinder Block is a common product of aluminum material manufactured through casting metal.

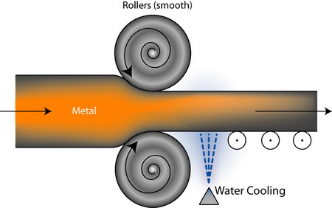

2. Forming and Deformation

Forming is the simplest type of metal fabrication process because it does not involve any kind of cutting. Simple, a force is applied, and due to deformation, the raw metal is converted into the required product. The common example is a bracelet of a steel sheet made through simple bending.

3. Forging and Hot Working

In this type of metal fabrication, a hammer having a die of the required design hits the raw material. The design of the die is formed on the raw material. For instance, for a gear, first the blank of raw metal in a red-hot state is placed under a hammer; after thousands of tons of force, this blank is converted to the required design of the gear.

4. Machining Processes

After giving the initial shapes to the products, some machining processes are used to add necessary features or remove useless features.

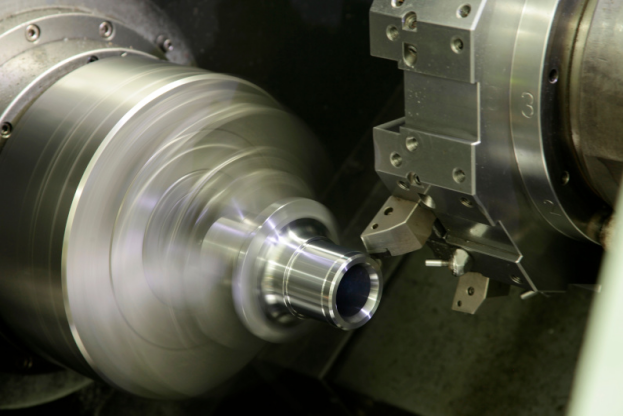

Precision Turning

To make a cylindrical part by removing excessive material, the turning process is used. It can be performed using a lathe machine or a CNC machine. Shafts, bolts, etc., are manufactured using this process.

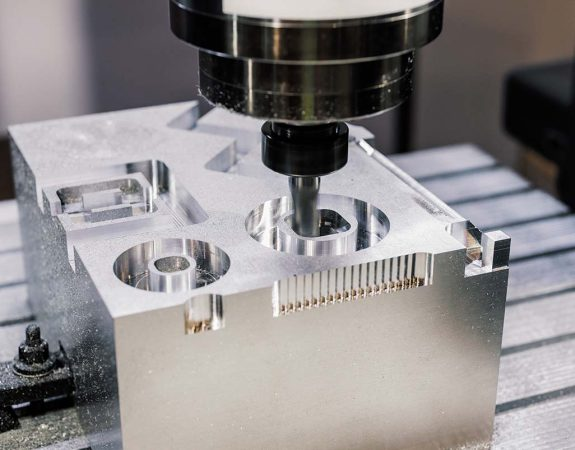

Precision Milling

Milling is used to machine complex-designed components by removing excessive material. The rotating cutting tools perform the cutting action on a stationary workpiece. Engine blocks, slots, etc., are produced through this process.

Precision Drilling

To make holes in the parts, the drilling metal fabrication process is used. The most common example of the product is nuts.

CNC Machining for Custom Metal Parts

If the design of the part has to fit non-standardized functions, then custom CNC machining is required. Specific tools are used for such requirements. For turbine blades, it is often used.

Types of Metal Fabrication by Parts

Let's understand the types of metal fabrication by parts in this section.

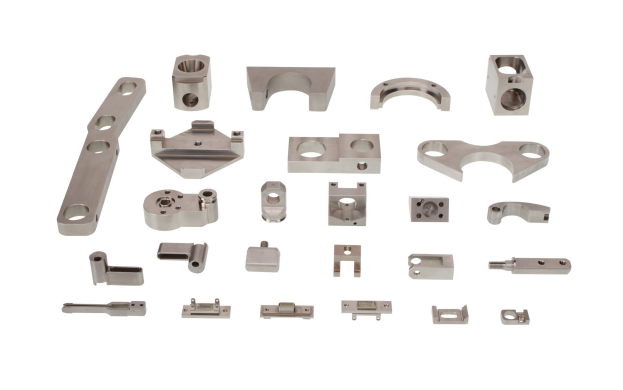

Metal Fabricated Parts

Types of metal fabrication by parts mean that different parts have different sizes, shapes, or functions. So, the fabrication process or the equipment is selected accordingly. The purpose of this metal fabrication by parts is to manufacture structural parts, industrial parts, etc.

1. Heavy Fabrication

For huge parts, such as bridges, heavy fabrication is required. For this purpose, heavy, large sheets are cut, rolled, welded, and machined on a large scale.

2. Sheet Metal Fabrication

When thin metal sheets are converted into parts, sheet fabrication is used. For this purpose, cutting, bending, stamping, or punching processes are used. For instance, CNC punching and bending are used to make server racks.

3. Precision CNC Metal Parts

Small parts, such as brackets, spacers, and mounting plates, require tight tolerances in the dimensions. To meet these dimensional accuracies, traditional tools cannot be used, which is why precision CNC machining is performed.

4. Custom Prototype Fabrication

Prototypes machining means manufacturing a sample to prove and validate its design, functionality, and feasibility before large-scale production. For rapid prototyping, CNC machining is commonly used.

What Metals are Commonly Fabricated?

A single metal fabrication process cannot be used for all metals with the same efficiency. Different processes or methods are used for these metals.

Ferrous Metals Fabrication

Ferrous metals include carbon steel and alloy steel. These metals are mostly used in structural or general-purpose applications.

Best for:

Ferrous metals are considered best for forging, rolling, welding, and heavy-duty cutting because of their strength, toughness, and heat resistance.

Stainless Steel Fabrication

The most commonly used grades of stainless steel are 316, 304, 410, and 430. The reason for their commonality is their corrosion resistance with their high strengths.

Best for:

The fabrication for stainless steel grades is a little tricky because of the risk of reduction in corrosion resistance, and it work hardens quickly. It is best for forming and deformation, machining, welding, and joining.

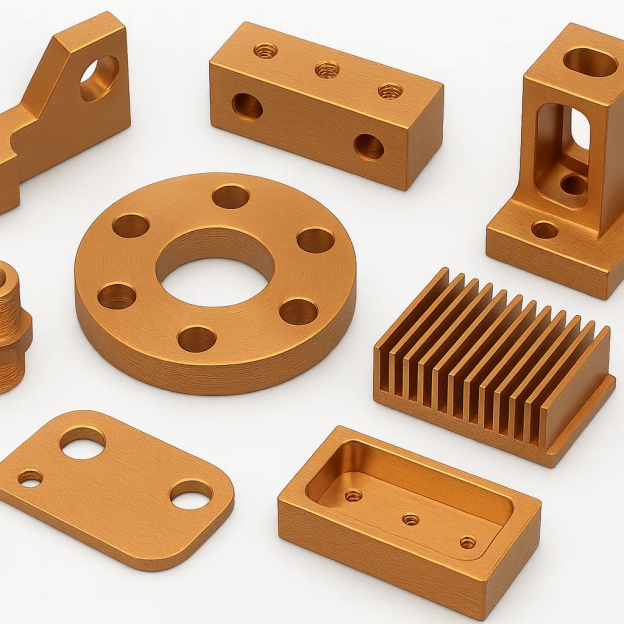

Aluminum Alloys Fabrication

1100, 2024, 3003, 6061, and 7075 are the commonly used Al grades in metal fabrication. These grades are selected based on the requirements of strength, corrosion resistance, and fabrication method.

Best for:

The fabrication of Aluminium is relatively easier than ferrous alloys. The common fabrication processes include extrusion, casting, TIG or MIG welding, and brazing.

Copper, Brass, and Bronze Fabrication

Copper and copper alloys, like brass and bronze, are used in fabrication mainly for their electrical conductivity and corrosion resistance, with moderate strength.

Best for:

For Copper: Sheet forming, machining, welding, or brazing

For Brass: Casting, Forming, Soldering, and Machining

For Bronze: casting, machining, and brazing

Specialty Alloys and Hard Metals

For extreme conditions, such as in high temperatures, special alloys, such as Inconel or Ti alloys, are made. They offer excellent mechanical properties but very poor machinability, due to which specific tools are used for their machining.

Best for:

These special alloys are best for fabrication processes, such as additive manufacturing, investment casting, or CNC machining.

Metal Fabrication Process Flow

Metal fabrication is a complete process that starts with designing. It takes multiple steps from the design stage to deliver the products.

1. Design and Engineering Stage

The very first step in the metal fabrication process is designing. In this step, multiple drawings, 3D models, and different software are used to make an accurate design of the product. The most common software at this stage of metal fabrication is AutoCAD.

2. Rapid Prototyping Test

Once the design of the part is completed, the stage of prototype testing comes. In this step, a sample or model is manufactured to validate its design, functionality, and fabrication method.

3. Plan for Production Fabrication

After a successful design and prototyping test, the plan for final production is designed. In this plan, the processes, machines, number of people in labour, and inspections are selected for smooth production.

4. Quality Inspection

To ensure the quality of the products, quality inspection is done at multiple stages during the metal fabrication process. First, the raw material is inspected, then during the fabrication, and then the final inspection in the lab is carried out.

5. Packaging and Delivery

Packaging depends mainly on the type of products and transportation methods. For ground transport and sea voyage, the packaging is different.

One-Stop Custom Metal Fabricators

For big projects, like in the automotive industry, metal precision fabrication or machining of existing metal parts is required. For such projects, the best reliable metal fabricators are required. We, TUOFA, offer the best services for metal precision fabrication due to advanced machines and expert labour. We will provide services from raw material to deliver your specified destination in due time at the best prices. For all the services at one stop, visit TUOFA.

Choosing the Right Metal Fabrication Process

The metal fabrication process depends on many factors. Some of discussed in this section.

Part Geometry and Design

The most important criteria are the geometry and the design of the part. The factors, such as the shape of the component, thickness, and level of complexity in the geometry, affect the selection of the metal fabrication process. For instance, if the raw material is a thin sheet and the required product is a bracelet, then simple forming will be enough.

Tolerances and Surface Finish

If the tight tolerance and very smooth surface finish, i.e., mirror-like surface finish, are required, then precision machining will be required to meet these specifications.

Volume of Production

For a small volume of production, simple manual machines work best. But for the large volume of production, advanced automated machines are used. This is how metal fabrication processes change with respect to the volume of production.

Design Tips for Custom Metal Parts

- Choose the suitable material wisely

- Avoid unnecessary tight tolerances

- Keep the thickness with respect to the application requirements

- Try to avoid sharp edges in the design. They become stress constraints later.

CNC Machining vs. Welding for Custom Metal Parts

CNC machining and welding are commonly used metal fabrication processes. Let's figure out the advantages and disadvantages of both processes:

CNC Machining Advantages and Disadvantages

Advantages

- Tight Tolerances: In industries like aerospace or medical, tight tolerances are required to avoid any errors in the dimensions. These accurate dimensions make the part more valuable.

- No Human-Error: Since the machining process is controlled by a computer, the chances of errors during machining are negligible.

- Less Labour: Due to automated working, less labour is required, which saves both time and money.

- Large Volume Productions: Due to automated features, the large productions in short times are easy in the case of CNC machining.

Disadvantages

- Cost: The costs of CNC machining per piece arehigher compared to traditional cutting tools.

- Expert Operators: The CNC machine operators must be well-trained to avoid any errors in the programming and machining.

Welding Advantages and Disadvantages

Advantages

- Quick Metal Joining Process

- Produces strong permanent joints

- No holes or fasteners are required

- Commonly used for complex-designed shapes

- Good electrical and thermal conductivity

Disadvantages

- Causes residual stress

- Heat-affected zones weaken the component

- Heat, fumes, and electrical shock are safety hazards

- Requires skilled labour

Industries Where Metal Fabrication is Used

Metal fabrication is used in almost every field. The most common fields are briefly discussed in this section.

Automotive Parts

To make automotive parts more reliable, metal fabrication processes, such as welding and CNC, are commonly used. From the frame of a car to a nut or fastener, different metal fabrication processes are used.

Electronics and Consumer Product

In electronics and consumer products, the common metal fabrication processes include brazing, soldering, precision CNC machining, and welding. These processes make these components easy to use.

Industrial Equipment and Machinery

Metal fabrication processes also have great importance in industrial equipment and machinery fields. In these fields, the common fabrication processes include heavy machining, CNC machining, and welding. Industrial equipment, like a pressure vessel, requires metal fabrication.

Conclusion

Metal fabrication processes are an important part of this world because of their usage from a nut to make a giant bridge. Metal fabrication processes make our lives easier because of the production of any product, irrespective of its design. Metal fabrication involves many processes, such as forming, welding, CNC machining, etc. Metal fabrication processes are selected based on the material, geometry, and level of precision in the surface or the dimensions.

FAQs About Types of Metal Fabrication

What are the 7 base metals?

Base metals are common, non-precious metals used widely in manufacturing and fabrication. They are less expensive than precious metals and form the foundation of most industrial metal applications.

- Iron

- Copper

- Zinc

- Nickel

- Aluminium

- Lead

- Tin

What are the six most common types of metal working?

- Casting

- Forming

- Machining

- Joining

- Heat treatment

- Surface finishing

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What Is Digital Manufacturing? Importance, Types, Tools & Advantages.

What Is Digital Manufacturing? Importance, Types, Tools & Advantages.