Steel Sleeve Machining: Types, Applications & Process

Dec 09,2025

Dec 09,2025

During applications, any component of the product, exposed to the environment faces harsh conditions. That component, which is exposed to harsh conditions, becomes more vulnerable, or its chances of failure increase compared to parts inside. Applications can be engines, hydraulic systems, industrial machinery, etc. Their failure becomes even more important to avoid if these components are expensive or critical. In cases like that, steel sleeves are used as protective parts. Comprehensive information regarding steel sleeves, their machining, types, etc., is given in this article.

What Is a Steel Sleeve?

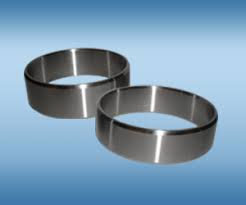

It is a type of guard that is wrapped around another part to protect it from harsh conditions. The design of this sacrificial part is a tube, which faces difficulties, but the inner component remains safe.

How to Define Steel Sleeve

In engineering and practical terms, it is a cylindrical insert, used in protecting, restoring, or reinforcing another component. It is like a cover for a shaft or pin, or a replaceable lining inside a softer housing.

Common Steel Sleeve Geometries

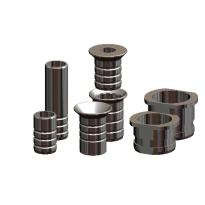

These are the common geometries of steel sleeves, used in practical industries.

- Straight Steel Sleeve

A Straight sleeve is used when the requirement is to protect or restore a shaft or a bore. It has the same thickness and parallel sides throughout its length. The perks of its geometry include straightforward machining and precise fits.

- Flanged Steel Sleeve

The following table provides insights into flanged steel sleeve:

|

Feature |

Description |

|

Sleeve Type |

Steel sleeve with rim/collar at one end |

|

Rim/Collar |

Extended geometric part forming a flange |

|

Function of Flange |

Acts as positive end |

|

Benefits |

Provides uniform load distribution |

|

Ensures secure axial positioning in housing/bore |

- Split Steel Sleeve

A longitudinal cut is present along the length of a steel sleeve. The purpose of this geometry is to flex open or compress slightly for easier installations. It is used over shafts or into bores without full disassembly.

Technical Sleeve vs Bushing vs Liner

In general, a technical sleeve is used for protection or reinforcement, a bushing steel sleeve is used as a bearing, and the liner steel sleeve is used as an inner protective layer. Let’s read their differences in detail:

Feature Differences

The following table shows the differences between geometric and other features.

|

Feature |

Technical Sleeve |

Bushing |

Liner |

|

Main Purpose |

Protects/extends housing bore |

Reduces friction + wear |

Provides inner protective layer |

|

Geometry |

Straight cylindrical tube |

Short, thick-walled ring |

Thin-walled cylindrical insert |

|

Load Handling |

Light–medium |

Medium–high |

Light |

|

Motion Type |

Mostly static |

Rotational/oscillatory shafts |

Static protection (no motion) |

|

Wall Thickness |

Moderate |

Thick |

Thin |

|

Fitment |

Slip-fit or press-fit |

Press-fit |

Slip-in or shrink-fit |

|

When Used |

To restore bore size |

For shaft support & smooth motion |

To protect internal surface from wear, heat, or corrosion |

Function Differences

These are the functional differences among these functional types of steel sleeve:

|

Item |

Technical Sleeve |

Bushing |

Liner |

|

Main Purpose |

Protect shaft/rod surface |

Reduce friction + absorb load |

Protect housing bore from wear |

|

Wear Role |

Wear takes place on sleeve |

Bushing itself is sacrificial |

Liner is sacrificial layer inside bore |

|

Movement Type |

Mainly sliding protection |

Supports rotation and oscillation |

Static protection of bore |

|

Replacement Logic |

Replace to restore shaft surface |

Replace due to friction wear |

Replace when bore wears out |

Manufacturing Differences

The following table briefly and precisely explains the manufacturing differences among these steel sleeves. Many manufacturers will heat treat the steel sleeves to ensure maximum hardness and durability.

|

Item |

Technical Sleeve |

Bushing |

Liner |

|

Typical Manufacturing |

Simple turning from tube/bar stock |

Precision turning + optional flange machining |

Deep-drawn, rolled, or thin-wall machined |

|

Material Removal |

Minimal (simple ID/OD turning) |

Higher (thicker wall, tighter tolerances) |

Very low (thin-wall finishing) |

|

Tolerances |

Moderate |

Tight (fit + bearing clearance) |

Moderate to tight depending on application |

|

Heat Treatment |

Rare |

Common (hardened bearing-grade materials) |

Rare unless high-wear material |

|

Surface Finish |

Basic finish |

Very fine finish for friction reduction |

Smooth inner surface to prevent bore wear |

|

Complexity Level |

Low |

Medium–High |

Medium |

Applications of Machined Steel Sleeves

Till now, the discussion has been general. This section offers multiple real-life, important applications in which machined steel sleeves are used.

Bearing and Guide Sleeves

- Bearing Sleeves

A shaft rotates inside a housing or bore, like in car engines. During the rotation, it is important that the surface remains smooth and resistant. Bearing sleeve is used inside the engine so that shaft can rotate without damaging the boring or housing.

- Guide Sleeves

Guide sleeves prevent wobbling and reduce wear on the surrounding component by keeping the pins or rods aligned. Guide sleeves simply guide the rods or pins.

Engine Block Liners

Engine block liners, used in internal combustion engines to form cylinder walls. The design and cooling system decides the type of liners.

- If contact with the coolant is not required, then dry engine block liners are used.

- Wet engine block liners remain in direct contact with the coolant.

Shaft Repair and Wear Sleeves

- Shaft Repair

As the name itself shows, this sleeve is used in restoring a damaged shaft. In this way, the requirement to replace a damaged shaft is fulfilled.

- Wear Sleeves

If there is sliding or rotation in the application, then these thin wall wear sleeves are used to shafts or housings.

Hydraulic and Pneumatic Liners

The piston slides or rotates inside a hydraulic cylinder for efficient fluid sealing and reducing leakage. Steel sleeves are used inside these hydraulic cylinders to avoid any wear on the surface.

The same is the case in air-driven systems(pneumatic cylinders). Steel sleeves are responsible for providing a smooth bore for the piston to move.

Custom Design Sleeves

If the design of a housing or a bore is different than the standard design, then the customization of the sleeve design is required. These custom design sleeves can have customized grooves, flanges, or stepped diameters.

Common Steel Sleeve Materials

Different materials have different properties, so they are chosen based on a proper criteria which is discussed in this section.

Material Selection Criteria

Choose the material which:

- Offers high wear resistance

- Excellent corrosion resistance

- Has high strength and hardness

- Offers good thermal resistance

- Easy to machine

- Should be economical and easily available

52100 Bearing Steel

- Has high carbon

- Known as chromium alloy steel

- Properties include high hardness, excellent wear and fatigue resistance

- Used in bearing sleeves, engine liners, and shafts

4140/42CrMo4 and 4130

4140/42 CrMo4 and 4130 are used to make steel sleeves because:

|

Material |

Main Purpose / Application In Steel Sleeves |

Key Features / Notes |

|

4140 / 42CrMo4 |

High-strength, wear-resistant sleeves for high-load applications and heavy-duty shafts, gears |

Excellent toughness, good hardenability, high fatigue strength |

|

4130 |

In automotive or aerospace components, sleeves where moderate strength and good machinability are needed |

Easier to machine, good corrosion resistance, moderate strength |

420/440C and 316L Stainless

- 420/440C

It is used in manufacturing flanged, wear, and bearing sleeves. If the focus is on high hardness and wear resistance, then 420/440C steel grade is used after heat treatment.

- 316L Stainless Steel

If the environment is aggressive for steel sleeves, where the corrosion resistance must be higher, this stainless steel is used to make steel sleeves.

Heat Treatment for Steel Sleeves

The material used for manufacturing steel sleeves is passed through some heat treatments because the most important requirement is to achieve high hardness and wear resistance. For this purpose, mostly quenching followed by tempering is performed on the material. For instance, for 420/440C steel, first quenching followed by the tempering process, and sometimes nitriding is performed.

Steel Sleeves Manufacturing Process and CNC Strategies

This section explains manufacturing processes for steel sleeves.

Main Manufacturing Process

These are the main manufacturing processes:

Blank Preparation

First, the raw material sheet is placed in a press machine. The die of this machine contains the design of the required steel sleeve. This process produces a steel sleeve of rough surface finish.

Thin-Wall Fixturing

Blanking produces a steel sleeve with a little more than the required thickness. To make it precise, its wall thickness is reduced using different processes, like turning or grinding, etc.

Precision Boring

It is done to increase the size of existing holes on the lathe or CNC machines.

Steel Sleeves Machining Challenges

Steel sleeves are not easy to machine because of many reasons, such as:

- Tight dimensional tolerances

- Heat generation

- Tool deflection

- High hardness

- Thin-wall sections

- Chips evacuation

Machining Tips

Use the following tips for an enhanced machining experience of steel sleeves:

- Use carbide or ceramic tools

- Low feed and moderate cutting speeds

- Use a steady setup

- Use appropriate coolant or lubrication

- Control chips evacuation properly

- Rough passes for bulk material removal

- Finish passes for minimal material removal

What Ra Is Recommended for a Honed Sleeve Bore?

Surface roughness is an important factor for the performance of steel sleeves. The steel sleeves having rough surfaces face more friction and ultimately cause failures in the applications. The common Ra for most steel sleeves is 0.2 microns to 0.8 microns.

CNC Honing Steel Sleeves

Through precise stroke, pressure, and abrasive choice, it refines the steel sleeves. Two other parts of this process include:

- To manage high hardness, CBN stones

- To prevent glazing, Coolant

Produced sleeves have a low-friction and dimensionally consistent surface.

CNC Grinding Steel Sleeves

In this process, after the grinding process, the surface of the steel sleeve is stain-level clean. The workpiece remains stationary while the grinding paper remains rotating.

Surface Finish Targets (Ra, Rz)

Surface Roughness (Ra)

Ra shows how smooth the surface is. It is the height of microscopic peaks and valleys.

Rz (Mean Peak – Valley Height)

- Distance from the highest peak to the deepest valley

- Gives an idea about the surface texture

Generally, Surface finish targets remain:

- Ra: 0.2 microns to 0.8 microns

- Rz: 1.5 – 6.0 microns

Factors to Consider When Choosing Surface Treatment

There are certain factors on which the surface treatments are performed, regardless of whether they are painted or galvanized steel sleeves. These surface treatments are only related to the surface. These factors include:

Wear Mode

First, it is analyzed how the material is being removed from a steel sleeve. For instance, if it is due to sliding, then the nitriding surface treatment is performed.

Corrosion Exposure

Corrosion exposure means the kind of environment in which the steel sleeve is being used. For instance, if the environment is marine or saltwater, strong barrier coatings, such as duplex PVD, are applied.

Dimensional Build

Dimensional build means the change in thickness of the steel sleeve. Surface treatments often increase the overall thickness. For instance, for precise fits, PVD coatings are used because they are ultra-thin (1-5 microns).

Design for Manufacturability of Steel Sleeves

To make machining of steel sleeves easy, sometimes design for manufacturability (DFM) is required. This DFM includes:

Materials Selections

Select material wisely because every material has its own properties, like high hardness or low corrosion resistance. Select material based on the environment in which the steel sleeve will be used.

Geometry Designs

Do not add unnecessary tolerances in the design of steel sleeves because these tolerances make machining difficult. Try to round the corners because sharp corners in a steel sleeve are stress constraints, cause failures.

Manufacturing Process Considerations

- During the manufacturing process of steel sleeves, you should have:

- A rigid setup for machining

- Proper system of chip evacuation

- Availability of coolant and lubrication

- Suitable tools according to the material of the steel sleeve

- Optimum feed rate and cutting speed

One-Stop Custom Solutions

TUOFA is the right solution for you if your team is searching for one-stop custom machining solutions. We deliver one-stop machining solutions from the raw material to surface treatments of the steel sleeve. We have advanced blanking presses, CNC machines, and facilities for surface treatment. We will complete your machining project at the best prices and possible shortest delivery times.

How to Ensure the Machined Steel Sleeves Quality?

For a high-quality steel sleeve, it is important to do an inspection first of the raw material. Then, quality inspection during and after the production of steel sleeves ensures quality. For quality inspection, these tools are used:

- Coordinate measuring machine (CMM)

- Surface roughness tester

- Rockwell/Vickers hardness test

- Micrometers

- Bore gauges

- Height gauges

- Non-destructive testing

Conclusion

To keep parts protected from wear and tear issues, steel sleeves are important for manufacturing parts. Sometimes, these sleeves are selected based on functionality, and sometimes based on their geometry. High hardness and wear resistance are the core required properties for a material to be used in manufacturing a sleeve. Sometimes, surface treatments, such as nitriding, are performed to achieve high hardness. Its manufacturing starts with blanking and then CNC machining to achieve tight tolerances. During and after the production of steel sleeves, inspection tools are used to ensure the quality of the steel sleeves.

FAQs

What hardness is typical for 52100 sleeves?

- In annealed condition:

15-20 HRC

- After quenching:

60-66 HRC

- After Case-Hardening:

60-65

How do you prevent distortion in thin-wall sleeves?

By using:

- Steady setup

- By minimizing the cutting forces

- By clamping and fixturing

- Using a proper sequence of machining

Do sleeves require honing after heat treatment?

The heat treatments, such as quenching, always distort the dimensions of a steel sleeve; that is why honing is always required after a heat treatment.

Can I hone or grind after coating steel sleeves?

If the coating is very thin, then honing is not safe to do because it will damage the coating. For thick coatings, yes, grinding or honing can be performed.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Types of Metal Fabrication: Processes and Custom Metal Parts

Types of Metal Fabrication: Processes and Custom Metal Parts