Types of Machining Operations You Should Know

Dec 25,2025

Dec 25,2025

In manufacturing industry, machining is a fundamental and essential part. Machining techniques have different types that can transform raw materials into a final product. So, what are these different types and how to know which one is suitable for any particular project? This article will give you a deep insight into machining processes and their types.

What Is Machining?

Machining is a subtractive manufacturing process that transforms raw materials like metal, plastics or wood into precise finished parts. The process is done by controlled removal of excess material using cutting tools, often with machines like lathes and mills. The aim is to achieve specific dimensions, forms, and smooth finishes in parts for industries like automotive, construction or aerospace.

Why Machining Matters for Manufacturing?

Machining in manufacturing is critical because it turns raw materials into precise, complex, and customized parts with tight tolerances. These parts have reliability and functionality in critical industries like aerospace, medicine, and automotive. Detailed machining allows for innovation and are cost-effective by reducing waste and rework through high-accuracy CNC methods.

Different Types of Machining Operations

Traditional machining operations remove material from a workpiece using cutting tools, with common processes like turning, milling, drilling, planing, shaping, grinding, sawing and broaching. Each method creates specific geometries like cylindrical shapes, flat surfaces, holes, or complex internal features. The features of general machining process are distinct from advanced non-conventional methods like EDM, laser beam, plasma arc or ultrasonic machining methods. Non-conventional methods use energy and remove material without direct contact.

Turning Machining

Turning is a basic soft machining process to remove material from a rotating workpiece with a cutting tool. It can create cylindrical shapes with a machine called lathe. And widely-used CNC turning has become the most popular way to create parts with tight tolerance.

Types of Turning Process

Turning operations are done with tools on manual or CNC lathes to shape parts with precision. Different types of turning processes are:

- Facing: creates a flat surface perpendicular to the workpiece's axis.

- Parallel Turning: turns the workpiece to a uniform diameter along its length.

- Taper Turning: creates a conical shape with a gradual change in diameter.

- Threading: cuts helical grooves for fasteners

- Boring: enlarges an existing internal hole.

- Parting: cuts a finished piece from the raw stock.

- Knurling: creates a textured pattern like diamond or straight for better grip

Advantages of Turning

We have understood what is turning, to know why it is widely preferred in manufacturing, we should explore its unmatched advantages:

- Good surface finish: smooth and precise surfaces can be attained.Turning can achieve surface roughness as low as Ra 0.4-0.8 µm for some materials like steel and aluminum.

- High precision: tolerances can be held very closely with CNC tools.As for machined parts, turning machining can achieve tolerance within ±0.01 mm.

- High productivity: Turning can create precision partslike cylindrical and conical parts quickly with consistent quality.

Applications for Turning Process

Turning technique is always considered a good choice for machining metal parts that require high tolerance or complex designs. Below are some applications:

- Machined parts: for various industries.

- Automotive and machinery parts: drive shafts, crankshafts, engine shafts and other essential

- Knurled handles: For tools, machinery, and equipment.

- Medical implants: High-precision parts for surgical devices

Milling Operation

In milling, a rotating cutting tool removes material from a workpiece and forms desired features. It is also one of popular and common machining techniques. And now computer is used to control milling machine, which is called CNC milling.

Milling Process Types

There are different types for milling process, which create different features:

- Face milling:forms flat faces with cutters that work on the top of the parts.

- Slab milling:removes material across the side (periphery) of the workpiece and makes flat top surfaces.

- End milling:has an end mill to cut slots, contours, and pockets

- Side milling:uses two cutters to mill parallel surfaces simultaneously.

- Slot milling:cuts grooves, keyways, or channels.

- Gang milling: has multiple cutters on an arbor to machine several features at once.

Advantages of Milling

Milling operation is the best selection for manufacturing parts with complex designs. That is why it is widely used in many industries. Explore the its following advantages for your projects:

- Flexible machining:Milling can make diverse geometries from simple to complex. It allows small-batch according to customer's specific custom requirements.

- Complex parts:Milling can create intricate profiles, pockets, and free-form surfaces.

- Good surface finish:Milling can create smooth, accurate surfaces, especially when using CNC milling machines with optimized cutting parameters.

- Tight tolerances:Achieves high dimensional accuracy (±0.02~±0.05 mm) for precision engineering applications.

Common Milled Parts

Common machining products made from milling include machined parts for aerospace, medical or for automotive industries.

Aerospace Components

Milling creates high-precision brackets, engine components, structural parts need strength and light weight.

Medical Parts

Surgical tools, orthopedic implants like hip or knee implants and device housings needing biocompatibility and accuracy are made from milling.

Automotive Parts

Milling creates fasteners, engine parts like pistons, connecting rods, gears, shafts, and housing for different vehicle systems.

Drilling Operation

Drilling creates cylindrical holes in workpiece with the help of a rotating tool. This tool can ream, counterbore, countersink and tap for different applications.

Types of Drilling Process

These refine a basic drilled hole:

- Core Drilling:is the fundamental process of making a cylindrical hole with a drill bit.

- Reaming:Sizes and finishes an existing hole to a precise dimension.

- Counterboring:enlarges the opening of a drilled hole and makes a flat-bottomed recess

- Countersinking:creates a conical and sloped enlargement at the hole's end

- Tapping:creates internal threads into a drilled hole.

- Spot Facing:creates a flat surface around a hole's opening

Advantages of Drilling

Drilling can bring the following advantages because of its simple tools and efficient operation. The advantages of drilling are:

- Lower costs:efficiently removes material by keeping production expenses low.

- High productivity:Fast operation and high-volume manufacturing.

- Wide material applicability:handles metals, plastics, wood, and rock.

- Good foundation for finishing:prepares surfaces for following processes like threading.

What Can Drilling Be Used for?

The purpose of drilling is creating holes, which are common in many industries. It can drill holes on metal materials. Many parts are made with holes for assembly and connection or any other purposes. Here are some application of drilling:

- Engine blocks:to create precise passages for coolant, oil, and cylinders.

- Fuel Injector nozzles:to make fine, precise holes for fuel delivery.

- Medical implants:to make biocompatible components with tight tolerances.

Planing in Machining

Planing creates flat, straight or sculpted surface on large workpieces. The workpiece moves linearly against a stationary single-point cutting tool. It is worth noting that planing is not ideal for small precision parts.

Types of Planing Process

Planing process has types like:

- Horizontal planing:The tool head moves vertically, and the table moves horizontally.

- Vertical planing:The tool head moves horizontally, while the table moves vertically

- Angular planing:is done by tilting the tool head or workpiece to machine angled surfaces

Importance of Planing

Planing is suitable for large workpieces or massive items like beds, frames, and large structural components that other methods cannot make. It produces highly precise and smooth flat surface that is important for alignment and fitting in machinery. Another great feature of planing is cutting slots, keyways and grooves on large parts.

Applications of Planing

Planning is used in creating grooves, keyways between shafts and gears, channels for fluid, and T-slots for modular workholding systems. It is used for making flat surfaces on large structural parts for shipbuilding, aerospace, and heavy equipment.

Shaping

Shaping uses a single-point cutting tool on a back-and-forth ram to cut a stationary workpiece. It removes material during the forward stroke and lifts the tool on the return stroke. This is ideal for general machining and contours on large workpieces.

Types of Shaping Process

The types of shaping process are:

- Horizontal shaping:The most common type and is used for flat surfaces and general purposes.

- Vertical shaping:tool moves vertically to machine internal shapes and slots.

- Inclined shaping:Tool post is angled to cut bevels and angled surfaces.

- Grooving shaping:cuts grooves, keyways, or slots.

- Dovetail shaping:makes dovetail joints and slide.

Advantages of Shaping

The advantages of shaping are:

- Lower costs:lower investment cost than complex CNC machines for simple work.

- Flexible operation:Versatile for various shapes like flat, angled, or internal with one machine.

- Simple setup:easy to set up and less skill needed for basic work.

Typical Shaping Applications

Shaping is normally used for:

- Machining flat surfaces and to create smooth and flat planes.

- Cutting grooves, slots, keyways, and T-slots.

- Internal features like internal gears, splines, and curved surfaces can be made from shaping

- Angular Surfaces on parts are achievable from shaping

Grinding Machining

In grinding, a rotating abrasive wheel removes small amounts of material for fine finishes and precise dimensions on hard materials.

Types of Grinding

Grinding has different types like:

- Cylindrical Grinding: creates tapers for external cylindrical parts like rods using plunge.

- Internal Grinding:Grinds the inside the diameters of workpieces like bushings.

- Surface Grinding:makes flat surfaces on parts with a rotating wheel on a rotary table.

- Centerless Grinding:Grinds cylindrical parts without centers.

- Tool & Cutter Grinding:Specialized machines for sharpening and shaping cutting tools.

Advantages of Grinding

Grinding is a machining method often used to achieve preferred surface after primary machining operations like turning or milling. The advantages it can offer include:

- Superior surface integrity with low surface roughness on precise geometries.

- Removes materials lowly and has minimal workplace distortion.

- Excellent for Hard Materials like hardened steels and ceramics.

Applications for Grinding Technique

Due to its advantages, grinding is commonly used to for applications that require high precision. As you can find below:

- Cutting tools like sharpening drills, end mills, and blades.

- Precision shafts and components, engine parts, aerospace components, and automotive gears.

- Measuring tools like calipers, gauges, and precision tooling.

Sawing

Sawing uses toothed blades for part machining of wood, metal, and plastic. It is essential in machining for preparing raw stock and cutting structural shapes.

Types of Sawing

Sawing machining process has types like:

- Power Hacksaw:has a reciprocating blade for mitered cuts on metal stock.

- Band Sawing:has a continuous and flexible toothed band stretched between wheels that makes straight cuts, curves, and intricate shapes.

- Circular Sawing:uses a rotating toothed disc, "cold saw," for precise and fast cuts in metals

- Abrasive Sawing:uses a rotating abrasive wheel to cut tough materials./li>

Advantages of Sawing

Sawing has advantages like:

- A cost-effective way to cut materials with minimal chip production.

- Easy to operate tasks that are difficult or slow with hand tools.

- High Portability and has flexibility.

- Versatile with materials like wood, plastics, composites, and metals

What Is Sawing Used for In Machining?

Sawing has many uses in machining like cutting raw materials and making large stock into manageable sizes. It is also useful for preparing precise bricks for later operation, can for cutting structural shapes like angles or channels. Furthermore, bandsaw is a primary tool for complex part shaping.

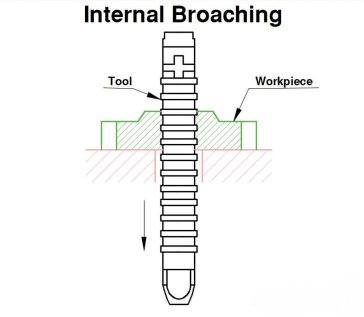

Broaching

Broaching metalworking is done with a tool with progressively shaped cutting teeth to shear away material. it produces precise and complex forms in one continuous stroke.

Types of Broaching

The types of broaching are:

- Internal Broaching: creates holes, keyways or splines by pulling or pushing the broach through a hole.

- External Broaching machines the outer surface to form contours or flats.

- Rotary Broaching uses a rotating broach in a lathe to form non-circular shapes.

Advantages of Broaching

Broaching operation offer outstanding advantages for creating complex internal profiles with high consistency. The benefits of broaching are:

- Creates excellent Surface Finish in one pass

- Superior part consistency with high dimensional accuracy and repeatability

- Long Tool Life

- Simple Operation and can integrate in multiple machining steps like roughing or finishing

What Are the Main Applications?

Because of the mentioned advantages, broaching is commonly applied to many applications with internal and external features. Broaching is used in making:

- Keyways with a precise cut slot for keys in shafts.

- Internal profiles like squares, hexagons, or complex internal contours.

- Splines on shafts for gears and couplings.

Turning, milling, drilling, and grinding are the fundamental machining processes. They can be performed manually for basic tasks as well as with CNC machines. CNC machining dramatically enhances precision, repeatability, complexity, speed, and automation. It is best for tight tolerances and mass production.

|

Machining Operation |

Major Types |

Key Tools |

Advantages |

Applications |

|---|---|---|---|---|

|

Turning |

Facing, Taper Turning, Threading, Boring |

Lathe, cutting tools (carbide, HSS) |

Good Surface Finish, High Precision and Productivity |

Shafts, bolts, customs and auto parts. |

|

Milling |

Face, Slab, End Milling, and Side Milling |

Rotating cutters |

Versatile and tight tolerance |

Engine blocks and aerospace parts |

|

Planing |

Horizontal, Vertical and Angular Planing |

Single point cutting tools. |

Handles very large workpieces |

Grooves & slots and creates flat surfaces |

|

Drilling |

Core Drilling, reaming, counterboring and countersinking |

Drill bits, multi-spindle drills |

Lower costs and high productivity |

Engine blocks and fuel injector nozzles |

|

Grinding |

Cylindrical, internal, surface and centerless grinding |

Grinding wheels (abrasive grains) |

Superior surface integrity and minimal workpiece distortion |

Cutting tools, precision shafts |

|

Shaping |

Horizontal, vertical, inclined, grooving and dovetail shaping |

Horizontal and vertical shaper |

Lower costs And flexible operation |

Cutting grooves and internal gears |

|

Sawing |

Power hacksaw, band, circular and abrasive sawing |

Saw blades |

Low cost and easy operation |

Cutting raw materials |

|

Broaching |

Internal, external and rotary broaching |

Broaches (multi-point cutting tool) |

Excellent surface finish and part consistency |

Splines and keyways |

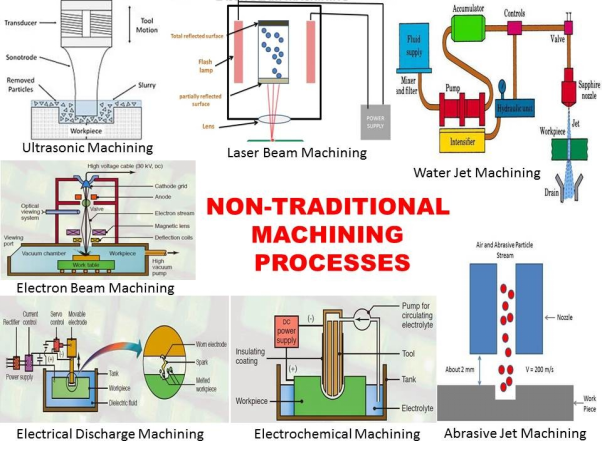

From above multiple machining types, we can find easily that geometric dimension and tolerances is the key elements of modern machining. After exploring conventional methods, we now turn to Non-Conventional Machining processes. These are advanced machining processes that are used where traditional tools fail and offer supplementary and high-tech solutions for complex geometries.

Non-Conventional Machining Operations

Non-conventional methods work without direct tool-workpiece contact and use energy sources like electricity, lasers, or chemicals. These are best for intricate shapes and hard materials.

Electrical Discharge Machining (EDM)

It uses controlled electrical sparks between an electrode and workpiece in a dielectric fluid to melt and vaporize the material. It is used for complex contours and blind holes.

Electrochemical Machining (ECM)

It is an anodic dissolution process where a shaped tool acts as a cathode. An electrolyte flows through a gap and removes metal ions electrochemically. This method is best for shaping hard or complex parts without mechanical and heat stress.

Laser Beam Machining (LBM)

It has a focused laser beam which vaporizes material and creates high-precision cuts and holes. It is used for engravings in materials and used in electronics, medical devices, and aerospace parts.

Plasma Arc Machining (PAM)

In PAM, a high-velocity and high-temperature plasma jet melts and blows away material. It is ideal for cutting thick and conductive plates.

Chemical Machining (CHM)

In CHM, chemical etchants selectively remove material and create complex contours or thin-walled parts. It relies on precise masking to control material removal.

Ultrasonic Machining (USM)

In USM, a tool vibrates at ultrasonic frequencies and drives abrasive slurry against hard materials. The vibration fractures them to create precise shapes, used for intricate holes and molds.

Traditional Machining vs Non-Conventional Machining

Traditional machining operations use mechanical force and a harder tool to cut material. These are for bulk removal in common materials. while the non-conventional methods use energy sources for high precision. It has little to no physical contact and minimal tool wear. A brief comparison of these two methods is explained below for better understanding.

|

Feature |

Traditional Machining |

Non-Conventional Machining (NTM) |

|---|---|---|

|

Energy Used |

Mechanical |

Electrical, thermal, chemical, or light, |

|

Tool-Workpiece Contact |

Direct contact |

No direct contact |

|

Material Removal |

Chips |

Ions, molten or vaporized particles, |

|

Tool Wear |

High |

Minimal to none. |

|

Applications |

Bulk material removal, simpler shapes |

Hard materials, complex shapes, high precision. |

|

Cost |

Lower |

Higher |

|

Examples |

Turning, milling, drilling, grinding. |

EDM, LBM, or EBM |

Conclusion

Machining processes remove material to shape parts. These are categorized as Conventional and Non-Conventional methods. Conventional manufacturing methods used mechanical force for bulk removal and form chips by machining. Examples are Turning, Milling, Drilling, Grinding, Planing, Shaping, Sawing and Broaching. Non-Conventional methods are energy-based and have no direct contact with workpiece. Examples are EDM, Laser Cutting, Waterjet, ECM, Ultrasonic Machining.

FAQ

What are the three most common machining operations?

Milling, turning, and drilling are the most common machining operations.

What materials can be CNC machined?

CNC machining can handle variety of materials like metals, plastics, wood, foams, ceramics and composites.

What is precision machining?

It is a high accuracy manufacturing process that uses CNC machines to remove material. It creates complex parts with extremely tight tolerances and precise dimensions.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Liquid Cold Plates: Types, Applications & CNC Machining Guide

Liquid Cold Plates: Types, Applications & CNC Machining Guide