10 Types of Turning Operations: Knowing Operations on Lathes

Nov 03,2025

Nov 03,2025

Turning operations play a crucial role in the manufacturing of high-precision mechanical components for various CNC machining industries. A number of turning operations are utilised to process raw material into desired shapes, such as sleeves, gears, and more. Knowing about these lathe operations is essential for deciding which process will yield the target results. That's why, here in this guide, we are going to explore 10 types of operations on a lathe machine, from straight turning to face operations. Stay with us and explore more about these CNC turning operations in depth.

What Is Turning Operation?

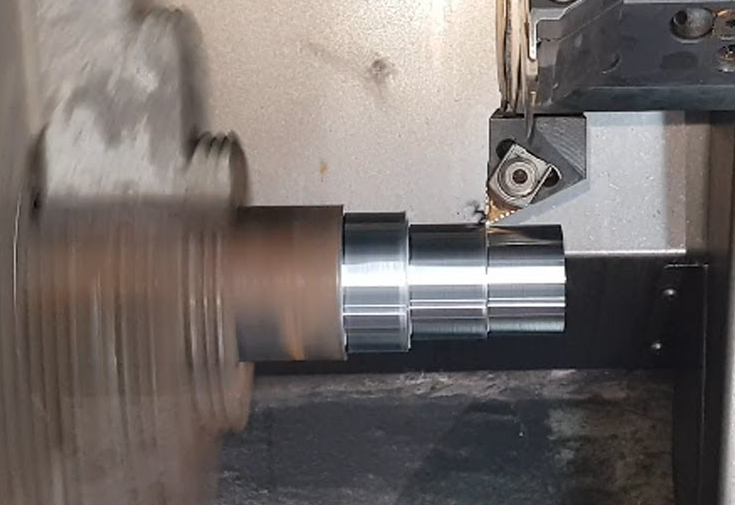

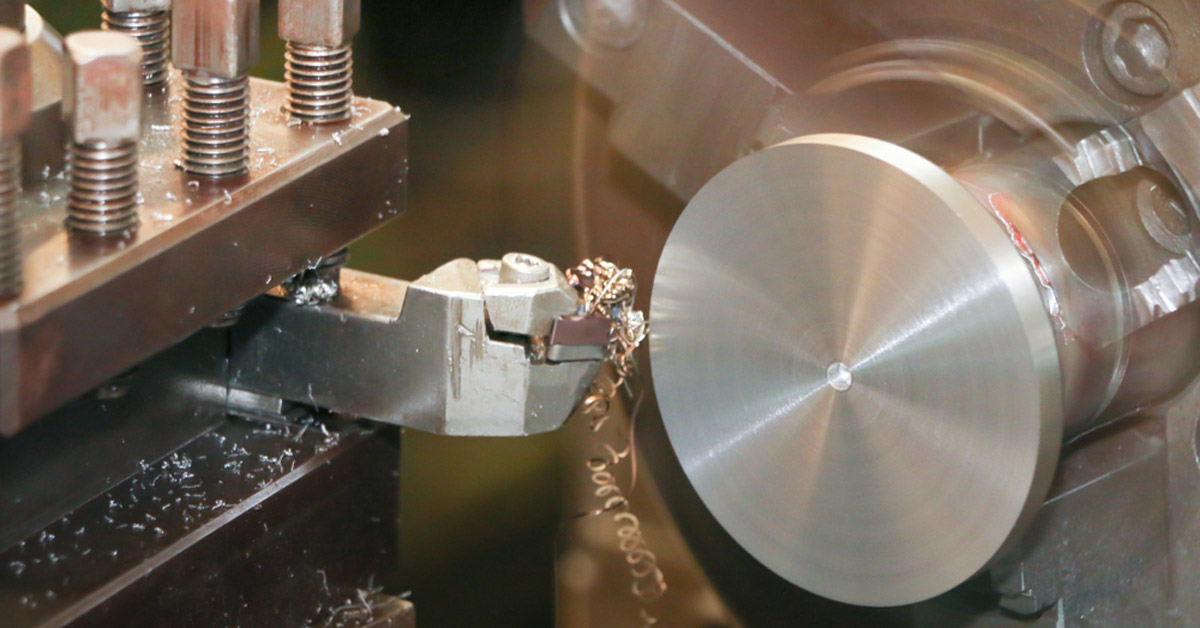

Turning is a well-known manufacturing process where components with remarkable surface finish are obtained by using a lathe and a single-point cutting tool. Lathes are rotating machines that make the workpiece rotate around its axis while a cutting tool removes material. Turning can be both manual or CNC-assisted for enhanced precision and repeatability. It is used in industries where precision, strength and repeatability are the key to components such as for aerospace, automotive and industrial machinery.

What Is The Difference between Milling and Turning Operations?

To select the proper machining process between milling and turning, it's essential to understand the differences between the two. You should consider the product's geometry, cost, and production needs. Basically, both process differs from the production process:

In tuning, the workpiece is clamped on a lathe, which rotates, and a linearly moving cutting tool removes material to achieve the desired shape. In milling, the workpiece remains stationary or moves linearly, while a rotating multi-point cutting tool (milling cutter) performs the cutting.

We have compiled the information about Turning Vs Milling for your ease to understand the fundamental differences in both processes so you can select which is suitable for you:

|

Factor |

Turning |

Milling |

|

Basic Principle |

The workpiece rotates while a stationary single-point cutting tool removes material. |

A rotating multi-point cutting tool removes material from a stationary or slowly moving workpiece. |

|

Typical Shapes Produced |

Cylindrical, conical, or round. |

Prismatic or flat parts. |

|

Machine Type |

CNC lathe or turning centre. |

CNC milling machine (vertical, horizontal, or 5-axis). |

|

Tooling |

Single-point tools or inserts. |

Multi-point cutters such as end mills, face mills, and drills. |

|

Workpiece Movement |

Rotates along the machine’s spindle axis. |

Remains stationary or moves slightly while the cutter travels along multiple axes. |

|

Precision & Tolerances |

Excellent concentricity and roundness (±0.001–0.002 in typical). |

High-dimensional accuracy across multiple planes. |

|

Surface Finish |

Smooth spiral finish |

Step-pattern finish |

|

Suitable Stock Shape |

Bar or rod stock. |

Plate, block, or cast stock. |

|

Tool Wear & Cost |

Lower tool cost; predictable wear on inserts. |

Higher tool cost; wear is distributed across flutes, but more frequent tool changes are required. |

|

Production Volume |

Best for medium-to-high volume runs with repeatable parts. |

Suited for low-to-medium volume or complex, multi-feature components. |

|

Automation Potential |

High |

Moderate to high |

|

Multi-Axis Capability |

2-axis standard; 3-axis or Y-axis with live tooling. |

3-, 4-, and 5-axis configurations common for advanced shapes. |

|

Material Range |

Ideal for round metals and plastics. |

Compatible with metals, plastics, and composites in block or plate form. |

|

Cycle Time Efficiency |

Faster for simple, rotational parts. |

Slower for simple parts; excels at complex surfaces and multi-face machining. |

|

Typical Applications |

Shafts, rollers, pulleys, and threaded parts. |

Brackets, moulds, engine blocks, and enclosures. |

How Does Turning Work?

During a turning process, the workpiece is clamped on a lathe and rotated at a specified speed while moving linearly along one or more axes to remove material from the rotating workpiece. The tool follows the outer contour until the desired diameter and geometry are achieved. CNC (Computerised numerical control) turning is operated automatically using pre-programmed instructions for precision and repeatability. However, manual turning requires an expert operator to control the rotational and cutting speeds according to the desired shape and geometry.

1. Straight Turning

Straight turning is one of the fundamental turning processes in which typically long, thin and cylindrical-shaped components are manufactured. In plain turning the cutting tool moves in the longitudinal direction of the element for cutting to reduce its diameter until a required constant diameter is obtained.

Typical Straight Turning Parts

Straight tuning is specifically used for manufacturing cylindrical components, such as shafts, pins, rods, sleeves, supports, axles, and spindles, through lathing.

Main Features

Cylindrical turning uses a longitudinal turning process where a single-point cutting tool bit is placed at 900 of the centre of the workpiece. The spinning lath chunk is moved forward until a desired thickness is obtained. Here, the speed rate, depth of cut and feeding rate are set according to the desired diameter.

Straight Turning Advantages

- External turning offers smooth surface finished parts with minimal or no secondary machining required.

- It is known for producing components with tight tolerance and high precision.

- One of the remarkable edges is that it can process components made with various materials, either metals or composites.

- When combined with CNC, it can manufacture high-precision components on a large scale.

- Considered ideal for long, simple round shapes.

2. Step Turning

Step turning, which is also known as shoulder turning, is used for manufacturing shafts with sharp shoulders, perfect for fitting bearings and gears. These parts fit only on exact diameters, so each step must be perfectly sized.

Typical Step Turning Parts

- Spacer: Typically applied in assemblies to maintain exact gaps between parts

- Washer: Used in load distribution, bearing seats, and precision fittings

Main Features of Shoulder Turning

In step turning, a straight cutting or parting tool is used for removing material in order to get a smaller diameter. It produces shafts with multiple precise diameters. The perpendicular step transitions between diameters assure accurate positioning of mating parts.

Pros of Step Turning Operations

- Step turning is considered suitable for producing long components due to its efficiency when combined with CNC.

- Shoulder turning can produce complex and high-precision diameter shafts suitable for various equipment such as motors, engines and gearboxes.

- Step turning is faster and cheaper than grinding for prototypes or short runs.

3. Taper Turning

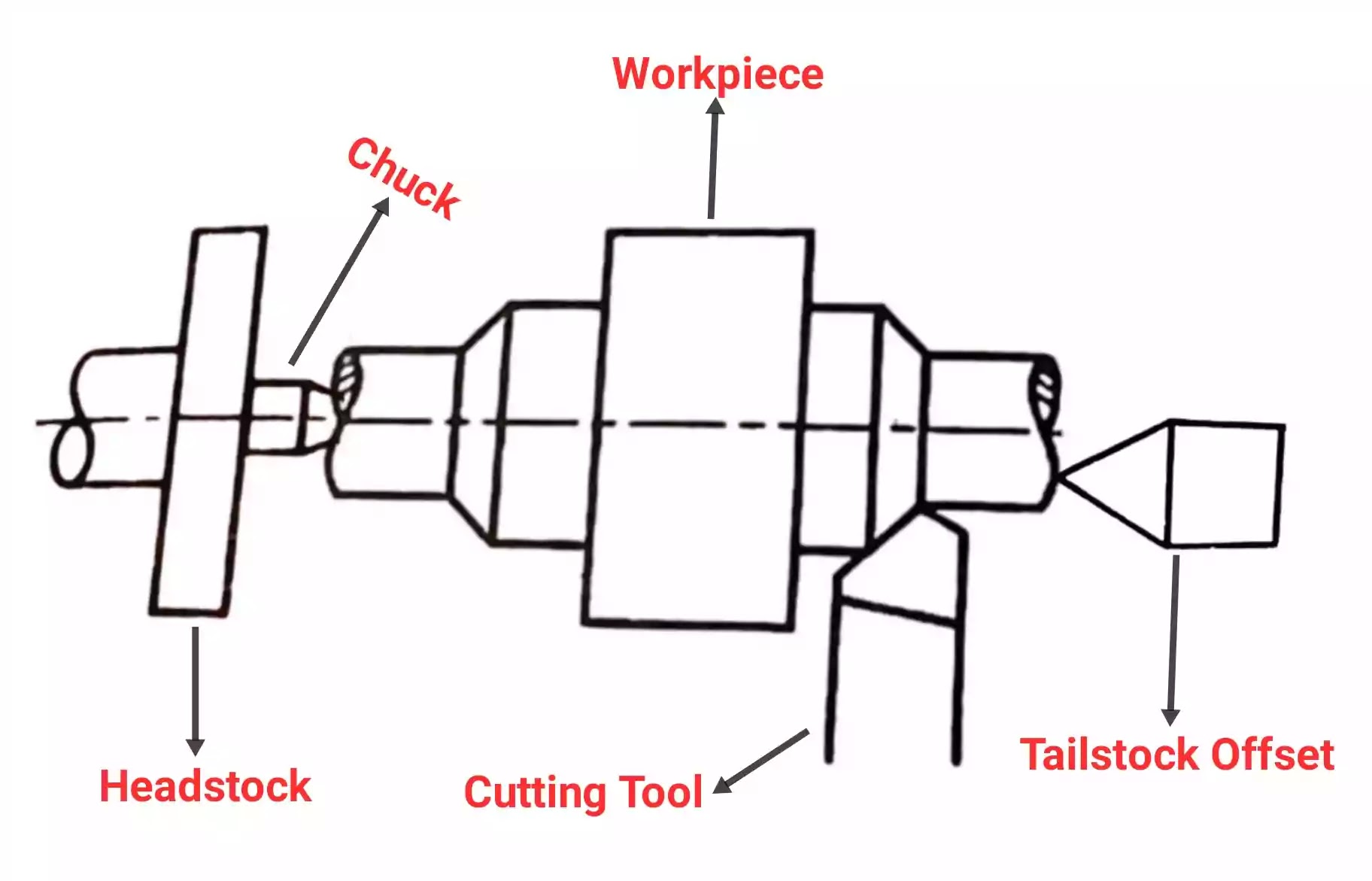

Taper turning is typically used for producing cylindrical components with a conical structure with varying diameters. It requires a unique tool and setup compared to other turning operations it can be performed in various ways:

Tail stock offset: In this method, the tailstock is moved sideways to form an angled axis. It’s an easy method but less precise, mainly used on manual lathes to produce long tapers.

Compound Rest Method: Here, the tool post is subjected to rotation at a specific taper angle; in this way, the cutting tool follows a particular angle of cutting. It is suitable for small tapers, such as for socket joints.

CNC tapered turning: Works on a programmed interpolation method.

Typical Applications on Shafts

Tapper turning finds its application in constructing tools such as holders, connecting shafts, and mould parts in the aerospace, automotive, and energy equipment manufacturing industries.

Main Features

- Produces a gradual change in diameter along the length of a cylindrical part, forming a conical surface.

- The cutting tool moves at a specific angle to the axis of rotation.

- Can be performed by offsetting the tailstock, using a compound slide, or employing a taper attachment.

Taper Turning Advantages

It assures dimensional accuracy and enhances the long-term performance of assembled parts. Not only this, but the tailstock offset method is simple and suitable for quick, non-critical work. Another remarkable advantage of CNC taper turning is the production of high accuracy and consistency, which is ideal for industries requiring tight tolerances.

Step Turning vs. Taper Turning

Since step turning and taper turning both involve cutting the tool along its diameter to obtain varying diameter components. That's why sometimes we get confused with each other. Here is a concise table highlighting the main difference between them:

|

Aspect |

Step Turning |

Taper Turning |

|

Geometry |

Produces stepped cylindrical sections with distinct shoulders. |

Forms conical surfaces with a gradual diameter change. |

|

Tool Movement |

The tool moves parallel to the workpiece axis. |

The tool moves at an angle to the workpiece axis. |

|

Operation Complexity |

Simple linear cutting process. |

Requires precise angular setup and control. |

|

CNC Programming |

Basic linear commands. |

Involves angular interpolation. |

|

Applications |

Shafts, spacers, and stepped components. |

Morse tapers, valve seats, and conical fittings. |

4. Profile (Form) Turning

Profile turning uses a specialised tool named “form tool”, removing the material from the workpiece until the desired contour or profile is obtained. Form turning can be done on internal, face and external diameters of the part. That's why it is divided into three types.

Types of Profile Turning

- Internal profile turning:It is used to form a complex shape inside the bore.

- External Form tuning:In this form, the external parts of components are shaped by removing excess material.

- Face profile turning: The component's face is machined to achieve the desired geometry.

Typical Profile Turning Parts

With the help of taper turning, manufacturers can produce shafts requiring complex contours as well as flanges, collars. Numerous manufacturers also prefer profile turning for developing high-precision custom fittings and mechanical components.

5. Facing Operations

Face-turning or facing machining is used to machine the end surface of a workpiece to create a flat, smooth face. The facing operation turning is most probably used for flanges and components requiring precise surface ends.

Main Features of Facing

In this process, the cutting tool moves perpendicular to the workpiece axis. This process is known for obtaining an accurate surface finish and controlled diameter.

Typical Face Turning Parts

Face turning is adopted in order to produce cylindrical parts that require precise surface ends. These components include sleeves, discs, shafts and especially fangs.

What are the Advantages of Face turning?

These processes are well known for offering high precision, improved surface quality, and efficient material removal for end-face finish.

6. Parting and Grooving

Parting and grooving are specialised turning operations in which a considerable part of the workpiece is cut off, separating it from the remaining stock.

Main Features of the Parting and Grooving Process

The main features of both processes are their specialised tools performing required operations, such as in parting, narrow slots are created on the workpiece down to its centre. However, in grooving, small grooves are engraved on the internal or external diameters of components, such as retaining rings and O-ring seats.

Types of Parting

|

Type of Parting |

Diameter Range |

Recommended Solution |

Benefits |

|

Shallow Parting |

≤ 12 mm (0.47 in) |

3-edge inserts |

Used for economical parting in mass production. |

|

Medium Parting |

≤ 40 mm (1.57 in) |

Screw-clamp or spring-lock holders with 2-edge inserts |

Provides a good setup for medium-depth cuts. |

|

Deep Parting |

≤ 112 mm (4.41 in) |

Blade with a stable spring clamp and single-edge insert |

Ensures insert stability under high cutting forces. |

Applications of Parting and Grooving

These lathe operations are applied to shafts, pins, collars and rings. These process helps in accurate groove creation, efficient part separation, and offer minimal material waste.

7. Threading and Tapping

Threading

Threading is basically known for creating high-precision helical grooves on the cylindrical component. This can be either internal or external. It is used for manufacturing screw threads for fasteners. Threading ensures an accurate fit and reliable fastening in mechanical assemblies.

Features of Threading

In a typical tapping turning, threaded holes are created in the workpiece to allow engagement with machine screws, bolts, or other threaded components.

Benefits of Threading

Some advantages of threading are:

- Produces precise and strong helical grooves for reliable fastening.

- Enables secure mechanical connections in assemblies.

- Suitable for internal or external threads on a variety of components.

Tapping

The tapping process uses a tap, a hard screw-like tool with straight or helical flutes that provide cutting edges to form threads. To ensure secure, strong, and functional threaded connections, precision is key, as threaded components must withstand shear forces from fasteners.

Why Choose Tapping?

Engineers and manufacturers adopt tapping because of :

It offers reliable threaded connections

It creates clean and accurate threads

Threading is suitable for both manual and automated operations

Typical Threading and Tapping Parts

Threading: Bolts, screws, nuts, threaded shafts, fasteners, studs

Tapping: Machine blocks, flanges, housings, components requiring threaded holes for screws or bolts

8. Boring (Internal Turning)

Boring or internal tuning is performed to make the already formed hole more precise and larger for smothering surfaces.

How and When to Bore Parts?

In this process, a boring bar is placed in a pre-formed hole, and initially, a large part of the material is removed to reach the desired diameter. Now the bore bar is placed inside the rotation component to give it a final smooth finish. It is performed when the standard bit is not capable of producing the required precision.

Benefits of Boring Parts

Boring ensures the precision, length and width of the hole are according to the requirement.

Compared to other processes like drilling, it offers better control over hole precision and results.

Application of Boring

Holes produced by drilling and casting are finished to high quality through boring.

9. Drilling and Reaming on the Lathe

Drilling and reaming are also lathe operations that create holes and provide the required finishing to a preformed hole. Drilling forms the initial hole using a drill bit, whereas reaming enlarges and smooths the hole to achieve a precise diameter and surface finish.

When to Use Drilling and Reaming?

When a precise hole is required for assembly or fastening.

To enlarge an existing hole while improving dimensional accuracy.

For creating holes that require tight tolerance and smooth finishes.

Benefits of Using Drilling and Reaming

These processes produce accurate, consistent hole diameters and improve the surface finish inside the hole. Using these methods reduces the need for secondary finishing.

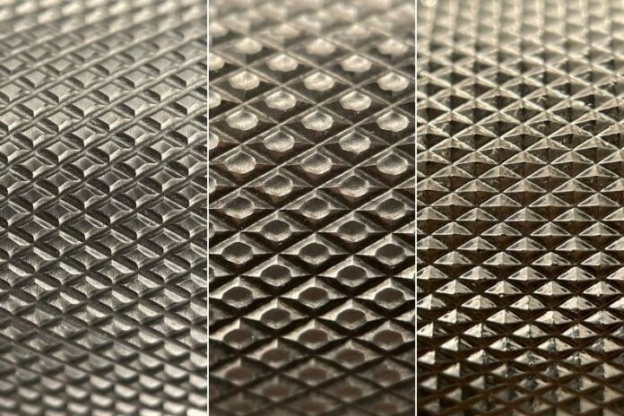

10. Knurling Operations

Kurnling is a finishing process that is applied to develop various patterns on the surface of cylindrical components or even on flat surfaces. In this process, the tool wheel is pressed on a rotating workpiece to displace material and create the required pattern. There are three common types of Knurling Patterns.

Types of Common Knurling Patterns

Diamond

Diamond knurling involves crossed diagonal lines forming a crisscross pattern. It offers stronger grip over handles, creating friction between hands and the surface.

Straight

Straight knurling possesses parallel lines along the axis. It is considered ideal for press-fit applications.

Spiral

It creates a helical pattern around the surface, combining aesthetics and functional grip.

Where to Add Knurled Patterns

Knurled patterns are typically added to handles, knobs, shafts, and hand-operated components where enhanced grip or friction is required.

Looking for Custom Turning Service?

Custom Turning Solutions

At TUOFA CNC Machining, we provide custom CNC turning services. We work with your existing designs to manufacture precise components. We ensure high-quality results for both prototype and production needs.

How to Choose Turning Materials

Choosing the right turning material typically depends upon the mechanical requirements, machinability, and end-use applications. According to our experts:

Metals like stainless steel, aluminium, and brass are common for their strength and ease of machining. At the same time, you can choose plastic-based materials for lightweight or corrosion-resistant parts.

At TOUFA, we offer professional guidance throughout your custom turning project. Not only this if we find that your design is not feasible for processing, we will provide practical suggestions to optimise manufacturability and functionality. Contact us today to get started with your custom CNC turning solution.

Conclusion

In short, Turing is an essential process for producing high-precision components. It can handle a variety of materials, including metals, ceramics, and plastics. Understanding the types of turning helps you manufacture components that meet specifications. Advanced techniques, including CNC turning, have further enhanced precision, repeatability, and productivity.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What Is Rapid Prototyping? Methods, Materials, and Steps

What Is Rapid Prototyping? Methods, Materials, and Steps