Precision vs Accuracy in CNC Machining: A Practical Engineer’s Guide

Jul 14,2025

Jul 14,2025

If a component serves for decades in any application, it is due to the accuracy and precision in the machining of that component. It means you need precision and accuracy collectively to get 100% efficiency from any component. To achieve precision and accuracy during CNC machining, very careful machining is required. This article is based on those important points or factors which affect precision and accuracy in CNC machining. You will learn the difference between precision and accuracy and their related factors.

What are Precision and Accuracy

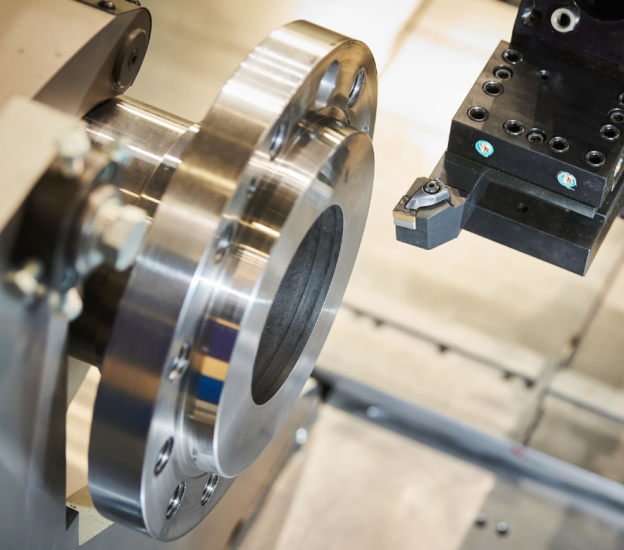

Precision and Accuracy are common terms in CNC machining, so first, you should understand what CNC machining is. CNC machining is basically a manufacturing process which uses computer-controlled tools to remove material from the workpiece to get the desired shape. In this section, you will study what precision and accuracy are in CNC machining terms.

Precision: Repeatability of Results

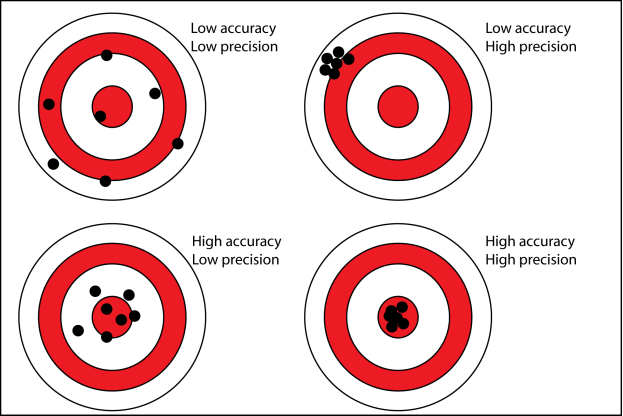

If you produce the same kind of measurements as required through the same processes repeatedly, it is called precision. It is a difficult task in batch production. For instance, if you are supposed to manufacture 100 brackets through CNC machining, then if you make the same brackets, it is called precision. Precision is called repeatability of results in CNC manufacturing.

Accuracy: Closeness to Target Value

If the result is close to the required dimension of the part or it is the same as required, it is called accuracy. Accuracy shows the level of your skills in CNC machining. Precision and accuracy both provide the basis for the successful application of that component or product.

Why the Two Often Get Confused

People often get confused between accuracy and precision because both are related to quality, but in different aspects. People think precision is accuracy, but it is different. A machine can be precise, but at the same time inaccurate. For instance, a machine like screw gauge consistently provide wrong results, we will say it is precise due to repeated results but it is inaccurate. Accuracy means how many true results are produced, and precision is the repeatability of an action.

What Is The Difference Between Accuracy and Precision in Machining?

If you are still confused about precision and accuracy in CNC machining, no worries, we are here to make it clear for you. In this section, you will study the complete difference between accuracy and precision with some practical examples:

Accurate & Precise in Machining

For precision machining and accurate machining, you will need extra care during machining for precision machined parts. But both of these, i.e. accuracy and precision, make sure the successful use of the component. It means both are crucial to attain in CNC machining.

What Is Considered Precision Machining?

As you studied earlier, precision is the name of repeated actions to produce parts of the same design. For instance, through CNC machining, turbine blades are produced in the aerospace industry. They need extremely careful CNC machining to meet aerodynamics requirements. Other examples include hardened ball-screw nuts, custom robotic-arm join brackets, etc., which need precision machining.

Precise but Not Accurate

If you remain unable to produce accurate parts after CNC machining, and these failures occur repeatedly, then it will be called precise but not accurate. For instance, during CNC tapping, if a drill consistently makes holes 0.1mm off-centre due to a misaligned fixture, the holes are precise but not accurate.

Accurate but Not Precise

If a skilled worker averages the correct depth, and each hole varies slightly due to manual inconsistency, it will be called accurate but not precise.

Neither Accurate nor Precise

Simply, if you are producing parts sometimes accurately but not repeatedly, it is neither accurate nor precise. This dimensional instability in production leads towards waste of money as well as material. That's a skill worker is always required in CNC machining.

What Will Affect Precision and Accuracy in Machining

These are the factors which affect precision and accuracy in CNC machining:

|

Factor |

Effect on Precision |

Effect on Accuracy |

|

Machine Tool Quality |

Ensures repeatability. |

Poor calibration leads to errors. |

|

Tool Wear |

Causes inconsistent cuts. |

Changes part dimensions. |

|

Cutting Parameters |

Wrong settings increase variation. |

Incorrect speed/feed deviates from design. |

|

Workholding Stability |

Loose fixtures reduce consistency. |

Misalignment shifts part position. |

|

Measurement Tools |

Low resolution lowers repeatability. |

Uncalibrated tools give wrong readings. |

How Tolerance Fits into the Picture

In engineering, tolerance is the most important thing because it's a pass/fail gate for the approval of many parts. Tolerance means how much error is acceptable. These are decided while drawing and then executed in CNC machining. If your part needs a tight tolerance, often tight tolerances are required in the aerospace industry, i.e. turbine blades, then there will be a very narrow gate for the approval of that part. In simple words, the chance of error is very small, so you will need to be very careful while machining that part.

Bilateral vs Unilateral Tolerances

Bilateral tolerance means that deviation in two directions from the nominal dimension is acceptable. For instance, 50 ± 0.1 mm. Bilateral tolerances are mostly used in our industries.

Unilateral tolerance means that deviation in only one direction from the nominal dimension is acceptable. Such as 50 +0.2/−0.0mm. These tolerances are used in only critical situations, such as while machining a shaft, etc.

Geometric GD&T Call-outs That Drive Cost

GD&T stands for Geometric Dimensioning and Tolerancing; it controls orientation, form and position beyond basic size dimensions. Some solid GD&T requirements are:

- Flateness (−):Extremely flat surface

- True Position (֍):Forces precise alignment

- Perpendicularity (↗):Requires exact 90֯ angle to a datum

- Runout (+):prevents wobble in rotating parts

What Breaks Precision & Accuracy: Common CNC Error Sources

This section is very important for precision and accuracy aspects because you will read about those factors which are sources of common CNC errors. Let's discuss how these factors affect precision and accuracy while CNC machining:

Machine Wear and Backlash

Backlash and machine wear badly impact CNC machining accuracy and precision because they cause dimensional errors and a poor surface finish.

Thermal Drift in Long Runs

In long runs, thermal drift is a common issue in which temperature fluctuations cause errors in dimensional accuracy and precision in CNC machining.

Tool Deflection and Runout

Tool deflection results in defective dimensions, and runout causes variations in chip load, which result in a rough surface and reduced tool life.

Operator & Programming Errors

These are human errors. An unskilled person or errors in programming result in reduced accuracy and precision in CNC machining.

Measurement Tools for Precision vs Accuracy

This is an interesting section of this article, as you will learn different techniques which are used in measuring accuracy and precision during and after the CNC machining. These tools make sure that the dimensions of the parts are exactly as required. Let's learn some of the advanced measurement techniques in this section:

Micrometres and Bore Gauges

You can read the basic differences between these tools in the following table:

|

Feature |

Micrometer |

Bore Gauge |

|

How It Works |

Uses a calibrated screw mechanism to measure the distance between the anvil and spindle. The thimble rotation translates into precise linear measurement. |

Uses spring-loaded contacts (2 or 3 points) that expand inside a bore. The displacement is measured via a dial, digital readout, or transferred to a micrometre. |

|

Why Use It? |

- Extremely precise (±0.001mm or better) |

- Designed specifically for internal diameters (ID) |

|

Best For |

- Shaft diameters |

- Cylinder bores |

CMM & 3-D Scanning Systems

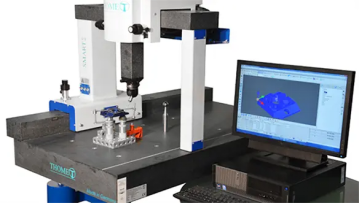

A Coordinate Measuring Machine (CMM) is an advanced measuring tool which collects 3D data of the part's surface first by using a probe. Then, software such as PC-DMIS analyses GD&T, form and position tolerances.

- You can use it for complex geometries, high accuracy, i.e. up to 0025mm and automated inspection.

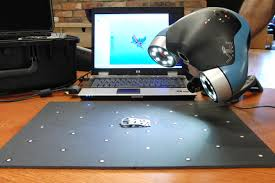

A 3-D scanning system is an even more advanced measuring tool, uses a laser to capture millions of data points. Then it converts these data points into CAD-compatible models to compare with the original design and dimensions.

- You can use it for fast digitisation of complex shapes; it is portable and best for organic designs.

In-Process Probing on CNC Machines

Advanced CNC machines are now equipped with built-in probes which keep on recording the surface dimensions and machine if any deviations are made.

Quantifying Precision & Accuracy with Cp/Cpk Metrics

If you want to assess process capability and measure how well a manufacturing process conforms to predefined specifications, you will need statistical Cp/Cpk indices. These metrics are often used in Six Sigma methodologies to identify and address process deviations, which ultimately result in reduced errors and increased precision and accuracy.

How to Calculate Cp/Cpk Step-by-Step

Let's do a step-by-step accuracy calculation through Cp/Cpk indices:

- 1.Define Specifications & Collect Data

To define specifications, first, you will determine the upper specification limit (USL) and the lower specification limit (LSL). These specifications are the customer's target values. After defining the specifications, you will collect data from at least 30 points to ensure the sample data is representative.

- 2.Verify Data Stability & Normality

You will need to verify the process stability before you rely on process capability analysis such as Cp/Cpk. The process stability means average and deviations remain consistent throughout analysis like no sudden jumps in the pattern, etc. Secondly, you will also need to confirm the normality of the data by checking if it follows a normal bell curve distribution.

- 3.Calculate Cp and Cpk Values

To calculate Cp, find:

- USL: upper specification limit

- LSL: lower specification limit

- σ: estimated standard deviation of the process

To calculate Cpk, find:

- USL: upper specification limit

- LSL: lower specification limit

- μ: process mean

- σ: estimated standard deviation of the process

- 4.Interpret Process Capability

To interpret process capability, you will need to understand Cp and Cpk values. For instance,

- Cp value>1: process capable of meeting customers' requirements

- Cp<1: Process deviation will not be within tolerance values

In case of Cpk:

Cpk=1: the process is well-centred within specification limits

If the Cpk value is negative, the output of the process will be beyond specification limits

In the range of 0-1, higher Cpk values mean better process capability

And if Cp=Cpk, the process is perfectly centred between the specification limits.

Interpreting a Capability Histogram

To interpret a capability histogram, you will need:

- Visual examination of the data spread in the histogram

- Normality Assessment

- Process centring

- Process Stability

Setting Acceptance Criteria for High-Value Parts

It is easy to set acceptance criteria now. For instance, for higher-value parts, the acceptance criteria are:

Target Cp and Cpk values of ≥ 1.33

And for the critical part, the acceptance criteria are target Cp and Cpk values of 1.67.

Precision vs Accuracy in Different Industries

In this section, you will see what is the practical difference between precision and accuracy concerning different industries:

Aerospace: Turbine Blade Root Slot ±0.01 mm

As you know, the highest safety standards are in the aerospace industry, which is why there is the lowest tolerance provided for the parts. As the tolerance is only ±0.01 mm, which means it requires very careful CNC machining.

Medical: Bone Plate Hole Location ±0.05 mm

In the medical industry, especially in orthopaedic surgery, the bone plate hole location is extremely important for successful results. To maintain accuracy and precision, the provided tolerance is only ±0.05 mm.

Automotive: EV Gearbox Cpk ≥ 1.67

Highly accurate and precise EV gearboxes require a Cpk of 1.67 or greater, forged accuracy, and micron-level CMM validation for optimal efficiency.

Custom Projects—Prototype to Production

Precision custom machining bridges the prototype to production flawlessly. Our CNC and CMM processes guarantee ±0.01 mm accuracy, ensuring your custom parts meet exact specifications from the first sample through full-scale manufacturing. Start your project today.

How to Improve Both Precision and Accuracy

Here is how you can improve both precision and accuracy:

1. Pre-Production Setup

- Verify machine capability

- Conduct Measurement System Analysis (MSA)

- Calibrate all measurement gauges

2. In-Process Control

- Use in-machine probing for real-time adjustments

- Implement statistical process control (SPC)

- Monitor tool wear and thermal effects

3. Post-Production Verification

- Perform final inspection with CMMs

- Validate against GD&T requirements

- Document results for continuous improvement

Conclusion

Every electronic machine is shifting towards AI-driven processes. The future trends in CNC machining include AI-driven process optimisation, IoT-enabled real-time monitoring and adaptive machining with closed-loop feedback. Other technologies, such as predictive maintenance, will increase accuracy and precision in CNC machining by providing tighter tolerances, smarter manufacturing and faster production.

FAQs

Does precision equal accuracy?

No, precision means the repeatability of the results, while accuracy means how close the result is to the required dimension.

Does higher precision always raise cost?

Yes, higher precision means tighter tolerance, etc. To achieve a tighter tolerance, we need more advanced tools and extra careful machining, so yes, cost will rise.

Can additive and CNC achieve the same accuracy?

No, because CNC can achieve the accuracy of up to 0.001mm, which is more than additive manufacturing (0.005mm).

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Rest Machining in CNC CAM: Definition, Strategies & Best Practices

Rest Machining in CNC CAM: Definition, Strategies & Best Practices