What Is Hard Turning for Precision Parts-A Complete Guide

Sep 05,2025

Sep 05,2025

As we all know that it is difficult to do machining through the conventional methods, when the material being turned has a higher hardness of material. This higher hardness is achieved due to heat treatment processes done on the material. Therefore, the manufacturer brings a method that gives high precision and surface finishing.

Figure 1: Hard Turning

What is Hard Turning

When we talk about machining, hardness is the headline—especially with heat-treated steels and other difficult materials. Here we will dive deep into hard turning in sections below. Let's learn something new together!

Hard Turning Meaning and Hardness Range

What is hard turning? If we took the word Hard from it, it refers to materials having a hardness >45HRC (Rockwell hardness scale). What is turning? Turning is a process where to achieve dimensional accuracy, the sample is rotated on a small motor, and a tool removes the excess material from it. For example, materials like titanium have a hardness range between 45-75HRC, and are categorized as hard materials.

Differences between Hard and Conventional Turning

The major differences between hard and conventional turning are as below:

- Tools which are used to remove excess materials from hard materials must also be made from hard materials themselves. In conventional turning, high-speed steel is used as it is a less hard material.

- Hard turning provides good dimensional accuracy and surface finishing as compared to conventional turning.

- In conventional turning, machining is done on materials that are annealed or normalized. While in hard turning, the machining is done on materials having their higher hardness due to quenching.

Is Hard Turning Really that Hard?

Till now, we have discussed the basics of hard turning. But is hard turning really that hard? There are many factors involved in this process, like choice of tool material, machine, angle of cutting. So now, we will discuss this in detail:

What are Hard Materials

In this section, you will see what the hard milling materials are. Hard materials, as is evident from their name, are resistant to wear and tear, especially at extreme temperatures, because of their high hardness and low toughness. Examples of hard materials include Inconel 718 and titanium alloys like Ti-6Al-4V; it is difficult to do machining of these materials through conventional machining methods.

Why Is It so Difficult to Hard Turning?

In hard milling/turning, if your parameters are slightly off and the tool is less rigid as compared to material to be cut. These things will lead to heating up and losing structural integrity of the material.

Devices Limitation

Some manufacturers lack modern machining equipment to cut hard materials such as titanium. But TUOFA has the latest machines that can cut these hard materials, like titanium, and provide dimensional accuracy with smooth finishing.

Advantages of Hard Turning

Till now, we have discussed the basic concept of hard turning, and it is difficult to do a hard turning operation. The section below will give you an idea about the importance of accurate hard turning:

1) It reduces the time and cost due to one-line operation.

2) Complex geometries can be formed and shaped compared to conventional methods.

3) It gives more dimensional precision and a smooth surface.

How Hard Turning Works on a CNC Lathe

Did you ever think about how a CNC lathe gives more precision as compared to other methods? The section below will explain how CNC works step-by-step.

Step-by-Step Process Flow

The following process flow should be followed while doing the hard turning:

1) Workpiece: Select a suitable material and then do heat treatment according to the application to make it hard between 45-70HRC.

2) Fixing the workpiece: Fix the workpiece tightly into the chuck to avoid vibration.

3) Tool selection: The tool material hardness should be greater such as CBN than workpieces.

4) CNC programming: Set the speed of the tool and, depth of cut according to the application.

5) Cutting and inspection: The CNC machine cuts the material according to your set depth of cut. Inspect the dimensions of the workpiece and cut further if needed.

Finish and Accuracy Targets You Can Expect

From my perspective, the results of CNC are better compared to conventional machining methods. A CNC machine can give good surface finishing comparable to grinding, especially in cylindrical parts. It gives ±2-3 microns dimensional accuracy and more consistency for production.

Coolant Strategy in Hard Turning

Is there is requirement for coolant during machining, and how much?

Is coolant used in CNC machining, and if so, how much is used? As you know, the type and amount of coolant used is dependent on the workpiece material.

- Dry machining: It is used for materials that are sensitive to thermal shock. In this process no coolant is used.

- Flood Coolant: In flood coolant, a large amount of coolant continuously falls on the workpiece to avoid the heating of the material.

- Minimum Quantity Lubrication: In minimum quantity lubrication (MQL), a very small amount of coolant is used.

Tooling for Hard Turning: CBN and Ceramic Inserts

If you want to get a smooth surface, then you need to focus on a parameter of hard turning. Out of them, one is a tool material. The tool material should be harder than the workpiece. These tool materials should have high hardness and a greater ability to withstand temperature. Some tool materials are discussed below:

CBN Hard Turning Inserts

Cubic boron nitride (CBN) is the second hardest material after diamond. That is why it is most used as a tool for hard turning.

Ceramic Hard Turning Inserts

As you know, ceramic is hard and brittle. So, that is why it is used as a tool for the hard turning process. But it can break if the load is applied more than UTS.

TiAlN Coatings

Coating on materials is a common choice these days, such as Titanium Aluminum Nitride coating. Their attractiveness in industries is due to long-term tool life and temperature resistance.

Toolpath and Lead Angle

Is it enough to use the more rigid material compared to the workpiece? I think not, the tool path and lead angle play a vital role in getting precision and finishing. A positive lead angle provides excellent surface finishing as compared to a negative lead angle.

Types and Features of Hard Turned Parts

The section below will give you an idea about the types and features of hard turned parts:

Bearing Rings and Shaft Journals

Bearing rings and shaft journals require dimensional accuracy and surface finishing.

Gear and Transmission Bores

Gear and transmission bores need high dimensional accuracy to avoid wear with other parts. That is why hard turning is applied to them.

Cooling and Wear Components

The dies, holder, and rings are common components to use in cooling and wear components. These components are used outside, which is why they need a highly smooth surface finishing to avoid creep and a low service life cycle.

Material & Heat Treat: What Affects Hard Turning

The following section will help you to identify which factor affects more on hard turning manufacturing process, the Material or the Heat treatment? From my perspective, it is good to understand the common hardened steels and Heat treatment method to identify which one affects the hard turning.

Common Hardened Steels

Table 1 shows the common hardened steel used in different application with their hardness.

Table 1: Common Hardened Steel

|

Material |

Typical Hardness (HRC) |

Common Applications |

|

H13 Tool Steel |

~50 HRC |

Dies, molds, hot-work tools |

|

52100 Bearing Steel |

60-64 HRC |

Bearings, rings, rollers |

|

440C Stainless |

~58 HRC |

Aerospace, surgical tools |

Case-Hardened vs Through-Hardened Parts

Case-hardened parts have a hard skin and a soft core. You need to change the depth of cut strategy if the case depth changes. If the depth of cut (DOC) is deep, then you should need to cut the hardened layer towards the softer core. As you go from the hardened layer towards the softer core, this will also change its surface finishing due to the hardness difference. While in through hardened part, the hardness is the same throughout the component.

Heat-Treat Growth (Dimensional Change)

During heat treatment processes, an increase or decrease in dimension can be done due to sudden heating or cooling. It is not a good option to rely on the final size after heat treatment, especially where high precision in dimensions is required.

Stock to Leave for Finish Hard Turning

It is good to leave the stock and then do hard turning manufacturing process for proper dimensional accuracy. This will lead to getting the proper dimensional (hard turning) and mechanical properties (from heat treatment).

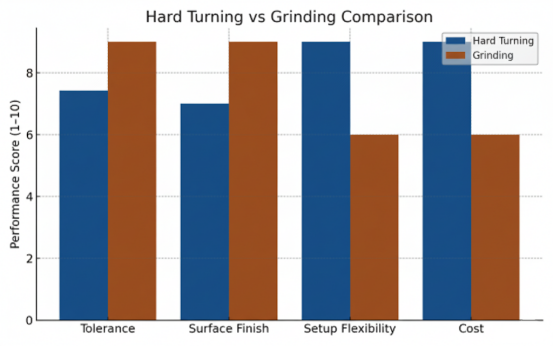

Hard Turning vs Grinding: Which Wins?

If we compare which one is good between turning vs grinding, the choice is totally dependent on the application. Grind machining is excellent in ultra-precision cases, while hard turning manufacturing process gives good efficiency and productivity. The following are some factors that will help you to decide which one is better:

Tolerance and Roundness

CBN grinding gives tight tolerances and roundness as compared to hard turning.

Surface Roughness

Grinding machining gives the surface roughness of < 0.1 µm, while hard turning gives the roughness range between 0.2-0.4 µm.

Part Geometry Limits

CBN Grinding or general grinding is still better for complex profiles at thin parts, while hard turning is good at cylindrical features in a single setup.

Low Cost

If we compare the cost of hard turning vs grinding. Multiple setup operations in grinding lead to higher costs as compared to hard turning. Hard turning is done in one operation with good finishing.

Hard Turning for Precision Parts

If you want to do machining on cylindrical parts, then hard turning is the best option to get high precision and productivity.

Figure 02: Comparison of hard turning and grinding operations

To get more knowledge about this, you can watch this video:

Process Planning: Hard Turning vs Soft Turning

The process planning is necessary to choose between hard turning and soft turning. Process planning indicates to you which process should be done first during the machining operation.

What is Soft Turning?

Soft turning means machining the material having a hardness of less than 35HRC. These materials are often annealed, normalized to achieve this hardness.

Best Order of Operations from Roughing to Finish

Here is the best order of operation you can follow from roughing to finishing:

1) Soft turning: Remove the bulk materials, which means if your workpiece has a dimension around 4mm and your requirement is 2mm, then you need to cut the material up to 2.5.

2) Heat treatment: Do the treatment such as annealing, normalizing, and quenching according to your requirements.

3) Finishing operation: Now, remove the material to get the dimension according to your requirements.

When to Leave Stock for Hard Turning or for Grinding

Always leave the little stroke before final finishing. It is because heat treatment can increase or decrease the dimensions of the material. It is good to leave the 0.2-0.4mm per side for hard turning and for grinding, leave the 0.1-0.2mm per side.

Hard Turning vs Soft Turning

The key differences between soft and hard turning is given below:

Table 2: Soft Turning vs Hard Turning

|

Aspect |

Soft Turning |

Hard Turning |

|

Material Hardness |

< 35 HRC (annealed/normalized) |

> 45 HRC (hardened) |

|

Purpose |

Bulk removal |

Finishing/semi-finishing |

|

Cutting Tools |

HSS or uncoated carbide |

CBN, ceramic |

|

Surface Finish |

Moderate |

Near-grinding finish |

|

Tool Wear |

Lower |

Higher |

The Truth About Hard Turning-4 Tips

It is a truth that hard turning cannot totally replace grinding. Hard turning is best for cylindrical features, but if you want to apply hard turning on every shape, then this is not possible. Here are four tips that you must follow:

Tip 1: Pick the Right Insert

For the hard materials, you can use CBN grinding material. It will give excellent wear resistance and withstand high temperatures.

Tip 2: Set Parameters for Chip

If you want the little chips and good surface finishing, set the consistent speed and depth of cut.

Tip 3: Clamp and Clock

The harder material requires more alignment (clocking in), chucking and tailstock support to avoid the vibration.

Tip 4: Leave the Right Stock

During the heat treatment process, the material undergoes thermal shock, and it can expand or contract. That is why, leave the 0.2-0.4mm thick material before heat treatment processes.

Conclusion

Hard turning is for hard materials, and it saves cost and time. It replaces the conventional machining methods, especially in cylindrical features. However, grinding is still best under complex profiles and ultra-fine finishing requirements. If you are looking for precise shaping, then TOUFA is for you. They use a setup consisting of modern machines that can shape the hard materials like Titanium with accurate dimensions and surface finishing.

FAQs

Which inserts/tools are best for hard turning?

Inserts and tools like Carbon Boron Nitride (CBN) and ceramic tools are best for hard turning, as their hardness is higher compared to tools used in conventional turning.

Which is a common challenge of hard turning?

Tool wear and usage of coolant are common challenges of hard turning. This occurs when the tool is not selected according to the workpiece or coolant is not used appropriate to the material being turned.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

8 Key Precision 2025 CNC Machining Trends

8 Key Precision 2025 CNC Machining Trends