Ceramic CNC Machining: Materials, Processes, and Alternatives

Oct 28,2025

Oct 28,2025

This article provides you with a machining guide of very useful material in real-life applications, but extremely hard to machine. This material is called ceramic. It shows higher yield strength and stiffness compared to steel, excellent corrosion resistance, but is very brittle, so difficult to machine. A single crack of >10 microns can cause failures. For instance, in the 2000s, SiN4 valves catastrophically failed in car engines. The reason behind their failures was inaccurate machining. Not good surface finish and machining-induced microcracks caused premature failures. That is why it is important to study its machining. So, let's begin.

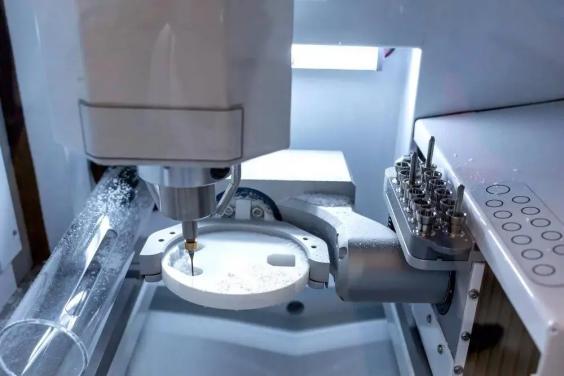

What Is Ceramic CNC Machining?

Ceramic machining is the same as we machine metals. It means in ceramic machining, we remove extra material from the ceramic workpiece through grinding, polishing, etc., methods to get the final shape. Ceramics are extremely hard and brittle materials, so very difficult to machine compared to metals.

Ceramic CNC Machining Explained

Ceramic machining starts with the raw material. As raw forms of metals like rods or plates are machined further into final designs, in the same way, ceramics raw form is powder after sintering or densification. The ceramic raw form is powder, but not rods or sheets like metals, because they are very brittle and can't be plastically deformed. So, ceramics machining starts with fine powders. Then this powder is molded or pressed into the required shape. After getting into shape, ceramics are taken into further processing, such as drilling holes or grinding etc.

Pros and Cons

The pros and cons of ceramics machining are given in the following table:

|

Pros |

Cons |

|

Excellent wear resistance, so longer tool life |

Brittle, so cracks easily during cutting |

|

High-temperature stability, so ideal for hot environments |

Hard surface, so difficult to machine precisely |

|

Corrosion-resistant, so suitable for harsh conditions |

Causes high tool wear, so frequent tool changes |

|

Retains hardness under load, so dimensional accuracy maintained |

Machining costs high, |

What Ceramic Materials Can You Machine?

Let us tell you that there are hundreds of ceramic materials, such as carbide, nitrides, silicates, borides, etc., but not every ceramic material can be machined. There are some criteria through which we can understand that this ceramic material can be machined. You can check hardness, thermal conductivity, microstructure, etc., to understand the machinability of the respective ceramic material. Let's study some ceramic materials and evaluate how these materials are machinable.

1. Alumina (Al2O3)

Alumina ceramic is extracted from bauxite ore and is called Alumina Oxide. It is so chemically stable, hard, and wear-resistant that it is second only to diamond and silicon carbide.

It is very difficult to machine in fully sintered form; that's why its machining is preferable in green (unsintered) form.

The properties given in the following table show why it is difficult to machine.

|

Property |

Typical Value |

|

Hardness |

15–20 GPa |

|

Thermal Conductivity |

25–35 W/m·K |

|

Toughness |

3–4 MPa·m¹ᐟ² |

- The high hardness of Alumina after sintering causes tool wear during machining

- Very low thermal conductivity results in local overheating and thermal cracks

- Due to low fracture toughness, it cracks easily under cutting forces

For a sintered Alumina workpiece, use diamond cutting or laser cutting.

2. Zirconia (ZrO2)

Zirconia is a white crystalline ceramic with a monoclinic crystal structure. Its important properties related to machinability are given below:

- Hardness:12-14 GPa

- Fracture Toughness:6-10 MPa·m¹ᐟ²

- Thermal Conductivity:2-3 Wm/K

It is tougher than Alumina, so it is easy to machine as compared to Alumina, but still its hardness is very high, and thermal conductivity is very low, due to which thermal cracking is common during machining.

3. Silicon Carbide (SiC)

Silicon carbide is the most used ceramic in the aerospace field. It is an extremely hard ceramic than others, so extremely difficult to machine.

- Hardness:25-28 GPa

- Fracture Toughness:3-4 MPa·m¹ᐟ²

- Thermal Conductivity:120-200 Wm/K

It has one major advantage in terms of machining, which is thermal conductivity, i.e., 120-200 Wm/K, so no thermal damage in its case. But its fracture toughness is poor, and its hardness is extremely high.

4. Silicon Nitride (Si3N4)

Silicon Nitride is a non-oxide ceramic; Si reacts with Nitrogen and makes covalent strong bonds. It is commonly preferred over other ceramics where thermal shock absorbance is a primary requirement.

- Hardness:15-17 GPa

- Fracture Toughness:6-8 MPa·m¹ᐟ²

- Thermal Conductivity:20-30 Wm/K

It is more difficult to machine compared to Alumina and Zirconia because of its higher hardness, lower fracture toughness, and poor thermal conductivity.

5. Aluminum Nitride (AlN)

Non-oxide ceramic, known for excellent electrical resistance, is preferably used in electronics.

- Hardness:11-12 GPa

- Fracture Toughness:3-4 MPa·m¹ᐟ²

- Thermal Conductivity:170-200 Wm/K

It is easier to machine than Silicon Nitride because of its good thermal conductivity and lower hardness.

6. Boron Nitride

You will find boron nitride in two different forms because of the different crystal structures. For instance, hexagonal is a soft ceramic, and cubic BN is an extremely hard ceramic.

Hexagonal BN is commonly used in the world, its machining-related properties are given below:

- Hardness:1-2 GPa

- Fracture Toughness:5-1 MPa·m¹ᐟ²

- Thermal Conductivity:30-60 Wm/K

In the world of ceramics, it is easily machinable.

How to Select a Ceramic Grade

The basic criteria to select a ceramic grade are the application. For instance, if the application is related to electrical resistance, then go for Alumina Nitride. If it requires thermal shock absorbance, as in aerospace, Silicon Nitride is an ideal choice.

Green Machining vs Fully Sintered Machining

Green or pre-sintered ceramics are different than fully sintered ceramics, so the machining routes for both are different. Let's study how.

What “Green” and “Bisque” States Mean

If the ceramic powder is just transformed into shape, like you fill a mold of a cup, but not sintered, it is called in the green state.

If it is partially sintered to get some hardness, it is called the Bisque state.

How They Differ?

In terms of temperature, green means the powder is just transformed into the mold shape at room temperature. It has lower hardness and excellent machinability.

Bisque is a state of high hardness because of the partial sintering process. Partial sintering is done at a lower temperature than sintering temperature.

When to Machine Before vs After Sintering

The following table shows when to machine before and after sintering a ceramic product:

|

Machine Before Sintering (Green/Bisque) |

Machine After Sintering |

|

For complex shapes |

For tight tolerances or finish |

|

When the material is soft |

After shrinkage correction |

|

To reduce tool wear and cost |

For minor finishing cuts |

|

For large material removal |

For small final adjustments |

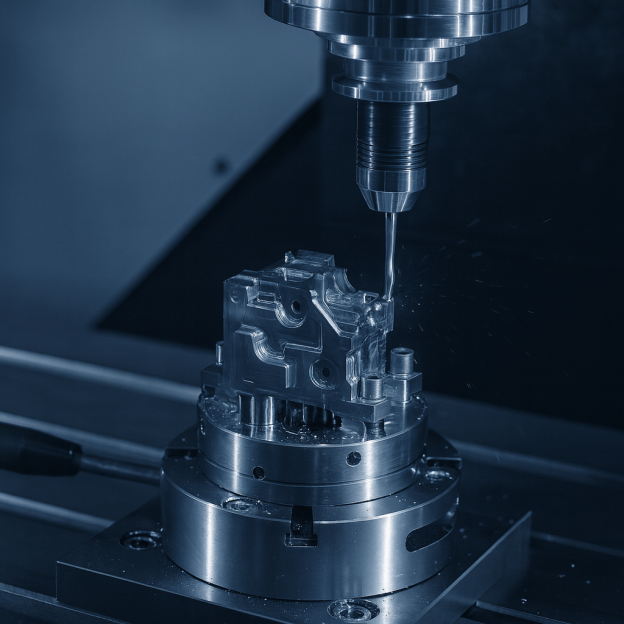

Ceramic CNC Machining Operations

By using conventional cutting tools, it is not possible to machine a ceramic product. Its machining is quite difficult because of its hardness, brittleness, and lower thermal conductivity; that is why advanced CNC operations are used for this purpose. This section will provide you with important CNC operations that are used for ceramics machining.

Precision Grinding and Lapping

During grinding and lapping operations, machining speeds and feeds are dependent on ceramics' nature. For instance, during the grinding of Zirconia:

- Machining speed: 25 – 40 m/s

- Feed rate: 0.5 – 3mm/min

During the lapping operation of Zirconia:

- Speed: 20 – 60 rpm

- Pressure: 0.05 – 0.5 MPa

For hard materials, slow speeds and lower feed rates are preferred.

CNC Milling for Ceramics

For ceramics in the green state, the speeds and feeds for the milling operation are:

- Spindle speed: 10,000 – 30,000 rpm

- Feed rate: 100 – 500 mm/min

But if for sintered ceramics, slow speeds and feed rates are used.

- Speed: 15 – 25 m/s

- Feed rate: less than 100 mm/min

Drilling and Core Drilling

Diamond-coated drilling tools are used in drilling and core drilling processes.

During the drilling operations

- Speed: 10,000 to 60,000 rpm

- Feed rate: 0.01 – 0.1 mm/min

During the core drilling operation

- Speed: 2000 – 15,000 rpm

- Feed rate: 0.02 – 0.2 mm/min

Dicing, ID Slicing, and Sawing

Dicing Process

- Used for semiconductor wafers and substrates

- Tool: Diamond Dicing Blade

- Speed: 20,000 – 40,000 rpm

- Feed rate: 1 – 10 m /s

Inner Diameter (ID) Slicing

- Used for cutting ceramic wafers and optical substrates

- Speed: 15 – 35 m/s

- Feed rate: 0.1 – 2 mm/s

Sawing

- Used for rough shaping of large parts

- Speed: 20 – 40 m/s

- Feed rate: 1 – 50 mm/min

Laser Machining

- Mainly used for slots and microfeatures

- Common Lasers: CO2 laser, Nd: YAG laser

- Power: 10 – 500W

- Feed: 1 – 50 mm/s

- Assistant Gas: Air, oxygen, or nitrogen

What's The Main Challenges of Machining Ceramic Materials

Till now, the main challenges regarding the machining of ceramic materials have been just mentioned. Now is the time to delve into the depths of these challenges.

High Brittleness of Materials

The biggest challenge during the machining of ceramic material is its hardness and brittleness. It means it is not possible to plastically deform them. Without warning, ceramic products can fracture during machining.

Thermal Shock and Heat Cracks

Ceramics are porous materials, so heat gets confined in them. They have very low thermal conductivity, due to which heat gets trapped within the structure and causes thermal cracks during machining.

Chatter on Thin Sections

If ceramic products have thin sections, then during machining, the common issue is chatter on thin sections. The cutting tools start to vibrate due to the lack of rigidity of the surface, which further leads to poor surface finish.

Metal vs. Plastic vs. Ceramic Machining Differences

This section comprehensively covers how ceramics are different than metals and plastics in terms of machining.

Material Machinability

The base of easy or difficult machining is the hardness and toughness. If a material has lower hardness and high toughness, it is easy to machine, and vice versa. Thermal conductivity is another issue, but it can be solved using proper lubrication during machining.

Machining Metal

Different metals show different machining behavior. It depends on the nature of the metal. For instance, it is easy to machine Aluminum 6061 T6 because it is ductile, so it can easily be transformed into any shape. The chips easily get removed from the surface.

On the other hand, titanium is a stronger and harder metal. It is very difficult to machine in the world of metals.

Machining Engineering Plastics

A general plastic is not easy to machine because of its lower strength and melting points. But some engineered plastics, such as Polyoxymethylene is an engineered polymer and has suitable strength for the machining process and maintain its shape.

On the other hand, Polytetrafluoroethylene is a very soft plastic. It doesn't retain its shape during machining.

Thermal Behavior

Thermal behavior is very important in terms of machining. Metals are the best thermal conductors compared to ceramics and polymers. Ease of conduction of heat makes a material retain its shape during the machining process. Polymers do not conduct heat, so they melt. Ceramics confine the heat, which results in thermal cracks.

Who Is Cheaper?

In terms of machining, polymers are easy to machine and can be transformed into desired shapes with conventional tools, so polymers are cheaper in terms of machining costs. The machining costs for metals are between those of polymers and ceramics. Ceramics have the highest machining costs.

Design for Manufacturability (DFM) for Ceramics

The design of the workpiece is very basic when it comes to machining. It is not possible to machine every design because of the sometimes more complex requirements than those required in the design. This section provides information about DFM in this section.

Design Purposes

CNC machines are automated machines. The cutting tools follow the design of the workpiece during machining. A poor design or one with extra complexity can lead to breakage of the workpiece and cutting tool, which is why it is very important to understand the design of the workpiece in the best possible way to avoid challenges during the machining process.

How to Avoid Breakage?

To avoid breakage of the workpiece or the cutting tools during CNC machining, follow the following tips:

- Change sharp edges with rounded corners

- Avoid thin sections

- Make large fillet radii at intersections

- Try to reduce the maximum number of holes, notches, or threads

- Prefer symmetrical designs

How to Make It Simple?

You can turn the complex shape of a workpiece by following these steps:

- Break the design of the workpiece into simple segments

- Avoid deep cuts or undercuts

- Simply the curves into arcs or lines

- Reduce the number of holes

- Use standard shapes, such as cylindrical, conical, or flat

- Try to match the design with available machining options

Ceramic Machining Tools Considerations

Since the ceramic material is very hard, it is extremely difficult to machine. In this way, you have to be very cautious while choosing the right tools. The preferred tools for such hard materials are diamond milling and diamond turning tools. These tools can withstand the heat and load given by the machining of ceramics.

Can I Use Other Alternative Materials?

If you can choose alternative ceramic materials, it all depends on the application requirements. Let's see the properties that help us find an alternative.

Alternatives to Similar Functions

Many materials can have similar functions to each other. For instance, polymers and ceramics have a similar function, i.e., electrical resistance. If two materials have similar functions, it means they can replace each other sometimes (it depends. If you want an accurate answer about whether them can be replacement or not, you can try to send a quote to TUOFA team, which is happy to help to make your custom project to success.)

High Wear and Abrasion

When an application has two primary requirements of high wear and abrasion, then you can use Tungsten Cobalt (WC) as an alternative. It is relatively easier to machine compared to ceramics.

Electrical Insulation

If the primary requirement at the room temperature is electrical resistance, then even plastics such as PTFE or an engineered polymer, like PEEK, can be an alternative to ceramics. The polymers are cheaper, lightweight, and easier to machine.

High Temperature Strength

For applications that need strength at high temperatures, you can use an alternative to ceramics, which is Inconel 625. It is a Ni-alloy which is lighter than ceramics, easier to machine, and does not fail catastrophically.

Get Custom CNC Machining Solu1tion from TUOFA

Are you facing difficulties in finding the best machining facility? No worries because TUOFA is here to help you. We can provide you with the best machining results with an excellent surface finish for various materials. We are equipped with the most advanced CNC machines and with highly professional experts in operating these machines.

If you need consultation in figuring out the best alternative of ceramic material for your application, come to us. We will help you to find the best alternative and then transform it into the final shape at competitive prices and with the shortest possible delivery terms.

Applications in Various Industries

Here are some applications of ceramics in the real world.

Medical Components

- For knee and hip joints, sockets, and dental implants, Alumina and Zirconia are widely used.

- Hydroxyapatite is used as a coating for metallic implants

- Piezoelectric ceramics are used in ultrasonic and pressure sensors

Semiconductor and Optics

Semiconductor

- Alumina and Silicon Nitride are used in substrates and packages due to their extremely good electrical resistance.

- Ceramics are used to make insulators and spacers for vacuum and high-voltage semiconductor equipment.

Optics

- Sapphire and Spinel ceramics are used in lenses and laser components

- ZnS and ZnSe are used in IR sensors, missiles, and thermal imaging

Aerospace and Energy

Aerospace

- Ceramics are used as thermal barrier coatings for turbine blades and nozzles

- SiC and SiN are used in turbine rotors and combustor liners

- Alumina and Silicon Nitride are used in transparent radomes

Energy

- Uranium dioxide and boron carbide are used as fuel and neutron absorbers in nuclear reactors

- Alumina and silica are used in furnaces and reactors for thermal insulation

Conclusion

Ceramics are an important material in our daily life applications, from medical to aerospace and electrical to energy sectors. These ceramics have some limitations, such as brittleness and high hardness, which make them difficult to machine. For its machining, special cutting tools are required, such as a diamond milling tool or a diamond turning tool.

To make the machining of ceramics easier, you can make changes in the designs or replace them with an alternative one.

FAQs

Why is so hard to machine ceramics?

Ceramics have the highest brittleness compared to metals, composites, or polymers. During machining or serving the application, even a microcrack can lead to catastrophic failure of ceramic products, which is why ceramics are so hard to machine.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

How to Manufacture Water Blocks? -Custom PC Cooling Solutions

How to Manufacture Water Blocks? -Custom PC Cooling Solutions