Tight Tolerance Machining: Guide to A Better Machined Part

Aug 14,2025

Aug 14,2025

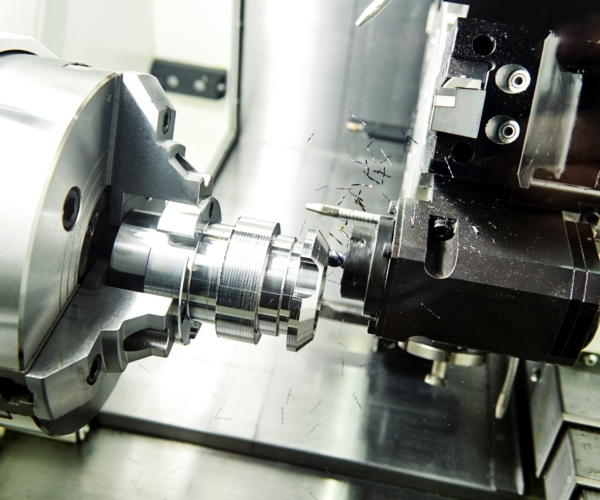

Tight tolerance is the foundation of precise machining in manufacturing processes. Accuracy is not only a necessity but the essence of quality and performance. It helps parts to fit properly and flawlessly and to perform under server conditions like aerospace, space, or medical devices applications where the margin for errors is kept in microns. This article will help you to understand all the essential details about tight tolerance and how to achieve it with all the available machine tools in your shop.

What is Tight Tolerance?

Tight tolerance means a very narrow range of permitted variation in the dimensions of a component. It is a relative term that means the criteria of low tolerance can vary with industrial standard tolerance, global norms, and the capabilities of the machining method. But the point to notice is that part must have a high degree of accuracy and high functionality.

Is .001 a tight tolerance?

Yes, .001 mm or +/- 0.001 mm is normally taken as tight tolerance in manufacturing. It lies within the range associated with very precise tolerance.

Typical “Tight” Numbers by Industry

Standard machining tolerances are crucial in industries like aerospace, medical or high precision electronic parts. Aerospace requires tolerances of ±0.001 mm or less, medical devices require ±0.005 mm, high precision optics require in the range of ±0.001 mm or less and for general machining, it is 0.001 mm or less.

5 Tolerance Types You Must Know

You must be aware of the 5 tolerances in manufacturing and engineering that are discussed below. They explain variations in size, form, and geometric relationships of components.

Limit Size Tolerances

It explains the maximum and minimum acceptable limits for a dimension in a permissible range for a part's size. For example, a hole might be 10.00mm-0.05mm, implies the part in this range is acceptable.

Unilateral Size Tolerances

It allows variation in only one direction from a definite dimension. For example, a shaft is allowed to be 0.02mm undersized but not oversized. It is used when a part has to be smaller than the nominal dimension, but not larger.

Bilateral Size Tolerances

It allows variation in both directions. The low tolerance zone is distributed on either side of the nominal dimension. For example, a shaft is allowed to be 0.01mm undersized or 0.01mm oversized with a symmetrical tolerance zone.

Geometric Tolerances (GD\&T)

It uses symbols to control the form, orientation, and location of part's features. It has a specified language to define precisely the tolerance and for its proper assembly and functionality.

Surface & Flatness Tolerances

Flatness shows how flat a surface needs to be. It's a geometric tolerance to control the variation from a perfect plane for a sealing or mating with other parts.

Fast Guide to Global Tolerance Standards

These standards act as a framework for you for consistent part dimensions and geometric tolerances for different countries. Core principles remain the same but specific tolerance values are different based on the region. It is due to the past manufacturing practices, material, and required performance levels. It is essential to know these variations for proper fit and functionality of your part.

ISO 2768 IT Grades

It is used for general low tolerances on linear and angular dimensions. It has classifications like f" (fine), "m" (medium), "c" (coarse), and "v" (very coarse) tolerances. Sub-grades of this standard are:

- ISO 2768-1 for general linear and angular tolerances.

- ISO 2768-2 for geometric tolerances like straightness or flatness,

What is the golden rule of tolerance?

The "golden rule" is the design for the loosest possible tolerance that makes the parts still functional and also balances cost, manufacturability, and performance.

ASME Y14.5 GD\&T Basics

This is another commonly used standard machining tolerances in North America, for geometric dimensioning and tolerancing (GD&T).

7 Hidden Factors That Affect Your Tolerances

There are some factors that can be predictable or less obvious but can affect your tolerances in a workshop setting. These are as:

1.Material Behavior

Every material has its own response to machining processes. Properties like hardness, ductility, and thermal expansion coefficient have a direct impact on part's behavior during and after machining and thus affecting final tolerances.

2.Tooling in Machining

The type and condition of cutting tools have a great influence on dimensional accuracy. Factors like tool material, shape and sharpness affect the final part's tolerance.

3.Coolant Temperature Control

Material behavior during machining like thermal expansion and contraction when heat applied can lead to dimensional errors. That is why it is essential for you to use coolants for heat management and to control temperature fluctuations.

4.Machine Calibration

Regular calibration helps to maintain the alignment of machine axes and other parts. Inaccurate calibration can cause deviation in the programmed path and in the part's tolerance.

5.Tool Wear & Life

Tool wear can change the cutting-edge geometry changes that can cause dimensional inaccuracies. Tool wear monitoring and their timely replacement can maintain consistent tolerances.

6.Humidity & Temperature

Change in temperature and humidity in workshop can cause expansion and contraction of machine components and workpieces which can change dimensions.

7.CAM Settings (Tolerance & Smoothing)

CAM used to set tolerances and for smooth parameters. These settings control the precision of the generated toolpaths. Fine-tuning helps to achieve the desired tolerances.

7 Design Tips to Improve Tight-Tolerance Parts

Design optimization is important to improve the quality of tight-tolerance parts. There are few tips to consider, from the start of machining to the final step to resolve the potential issues.

1.Prefer Standard Fits

It is suggested for the manufacturers to use standard fits rather than creating custom ones. This will simplify your machining process.

2 Do not Make Over-Tight Specs

Avoid tighter tolerances that affect functionally. This increases the costs and lead times.

3. Space for Tool Access

Leaver space for access for machining tools and to have smooth machining processes.

4.Stable Materials

Choose materials with less chance of deformation. This increases dimensional stability. So find a professional machining engineering team to get accurate CNC machining material advice.

5.Leave Clearance for Probes

When you are designing measurements, leave a good enough space for inspection probes. This can help to easily assess the part.

6.Manage Heat Flow

Measure the heat generation and its impact on dimensional stability and design specs.

7.Talk to the Machine Shop Early

Contact machine shop earlier to identify potential issues and prevent pricey reworking. Whether you're making a prototype or placing a large volume order, the helpful advice often comes from those who actually provide precision machined parts.

What's Better, Tight or Loose Tolerance?

There isn't a single "better" tolerance. It is based on your specified application and the engineering principles. Tight tolerances are required for precision components but are expensive and difficult to form. While the loose tolerances are cost-effective but have less accuracy for some of your applications.

Which Tolerance Is Most Difficult to Machine

Tight tolerances are difficult to machine in terms of position tolerances. The reason is that tighter tolerances require greater precision in machining, tooling, and inspection processes.

Where Tight Tolerances Are Non-Negotiable

Tight tolerances are important in your applications that need precise fit, functionality, and reliability, like aerospace parts like jet engines, senor mounts, medical implants like hip implant and bone plates, and automotive parts like bearings and shafts.

When to Compare Tight and Loose Tolerance

Critical applications need tight tolerances due to requiring precise fit like medical and aerospace industries, applications requiring consistent performance like sensors or critical engine components. Loose tolerances are used in less critical applications that allow some variation in dimensions. Their main focus is low-cost or assembly flexibility.

Tight Tolerance Machining and Hard-Metal Alloys

Hard metals like titanium and Inconel are difficult to get tight tolerance. It is because they have high strength, work hardening, and low thermal conductivity. This can cause heat build up, tools wear, and poor surface finish.

Why Hard Metals Push Tolerance Limits

Hard metals are more resistant to machining which increases the cutting forces and tool wear. They also have low thermal conductivity and high chemical reactivity that reduces tool life.

Titanium in Tight Tolerance Machining

Titanium alloys, like Ti-6Al-4V, are difficult to machine with tight tolerances. They have high strength, low thermal conductivity, and tendency to work harden. For precision machining of hard metals, contact a specialized manufacturer experienced in handling these challenging materials like TUOFA. We provide expert guidance and make sure that your components meet the tightest tolerances.

Inconel in Tight Tolerance Machining

Inconel 718 is frequently used in tight tolerance machining for aerospace and other industries demanding applications. Its machining is challenging due to its strength, work hardening tendencies, and high temperatures generated during cutting.

Tight Tolerance Machining and Engineering Plastics

Tight tolerances in plastic machining are difficult due to thermal expansion, creep, and moisture absorption. Engineering plastics like PEEK, PPS, Torlon®, and Acetal are more suitable than general-purpose plastics, for getting tolerances as tight as ±0.01 mm.

Why Is It Difficult to Achieve Tight Tolerance in Plastic

Plastics have higher thermal coefficients of expansion and can deform under loading conditions. This makes machining problematic and can cause dimensional accuracy. Another challenge is moisture absorption which can swell or wrap the plastic and affect dimensional stability.

Thermal Growth and Creep Constraints

High thermal expansion than metals in plastics makes them expand or contract more with temperature changes. And the plastics can undergo creep which is the deformation under sustained loads which can deviate them from the required dimension over time.

Best Polymer Choices for Tight Tolerance

Best polymers for tight tolerance are PEEK which has good mechanical properties, chemical resistance, and thermal stability. PPS is known for its dimensional stability, high heat resistance, and chemical resistance. Delrin is also a strong, rigid thermoplastic with good dimensional stability and low friction.

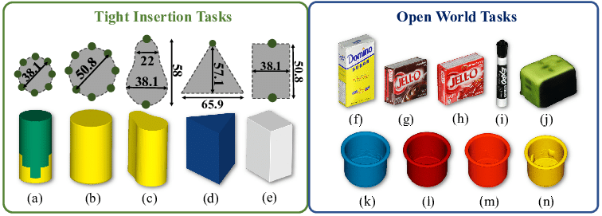

Tight Tolerance Machining and Components

Tight tolerance machining is important in many parts. For example, threaded holes, precision shafts, and engine features. They require dimensional accuracy to have good functionality and performance.

Threaded Holes & Fasteners

The standard screws and threads often have some flexibility. Tight tolerances are required for specialized applications or when precise torque and fit are critical.

Precision Shafts, Pins, and Bolts

These parts need precise dimensions to do proper function and prevent binding or excessive looseness, particularly in movable joints (like clevis pins) or with specific ID/OD needs.

Engine & Power-Train Features

Engines and power trains parts require extremely tight tolerances for maintaining proper alignment, minimizing friction, and optimal performance.

Business Benefits of Tight-Tolerance Machine Shops

Tight-tolerance machining has many business advantages. The primary one is its ability to have better product quality, efficiency, and reduce costs.

Process Capability (Cp, Cpk)

Process capability indices (Cp and Cpk) show the ability to maintain tight tolerances, and part consistently meets design specifications. This results in fewer defects and less rework, with overall higher quality.

Faster Turnaround

Faster turnaround is possible by advanced CNC technology and automation and quicker delivery times.

Customization and Precision

Tight tolerance helps in creating parts with higher complexity and customized parts with intricate features. This results in innovation and tailored solutions for specific customer needs.

Conclusion

Tight tolerance machining produces parts with very small permissible variations in dimensions, shape, or position. These tolerances are challenging to achieve and require careful attention to the factors like machine quality, material selection, tooling, and environmental control. Standard machining tolerances are crucial in industries like aerospace, medical or high precision electronic parts. Few tips to get tight tolerances are to use high-precision tools, choosing right materials, control cutting forces, controlling environmental factors and to use proper workholding.

FAQs

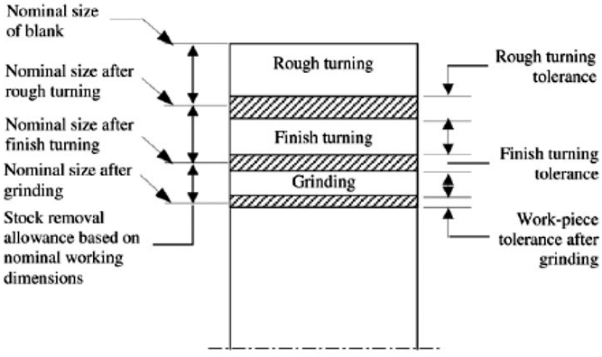

What is the difference between roughness and tolerance?

Roughness is the fine irregularities on a surface and tolerance is the acceptable range of variation in a part's dimensions. Roughness is about the texture of the surface, and tolerance is about the size of the part.

How tight can a modern 5-axis mill hold?

Modern 5-axis CNC mills can hold extremely tight tolerances up to micron level. Tolerances can be held down to about ±5-10 µm in 3+2 and ±10-25 µm in simultaneous cutting under stable conditions.

Why does shop temperature matter so much?

Shop temperature affects tight tolerance due to thermal expansion and contraction of materials. Small temperature variations can cause production delays, increased costs, and potential product failure.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Undercut Machining: A Comprehensive CNC Guide

Undercut Machining: A Comprehensive CNC Guide