Undercut Machining: A Comprehensive CNC Guide

Aug 21,2025

Aug 21,2025

You would have seen very small holes for fasteners in the components where a normal tool can't operate. These small holes are intentionally made undercuts, which perform multiple operations. This article will make you familiar with each aspect of undercut, like how they are made or functions and their types, etc.

What Is Undercut Machining?

The process to manufacture these areas, these undercuts, is called undercut machining. And in this machining, standard tools are not the most advanced tools to do the job, like by using a Computer Numerical Control (CNC) machine.

What is Undercut in Machining?

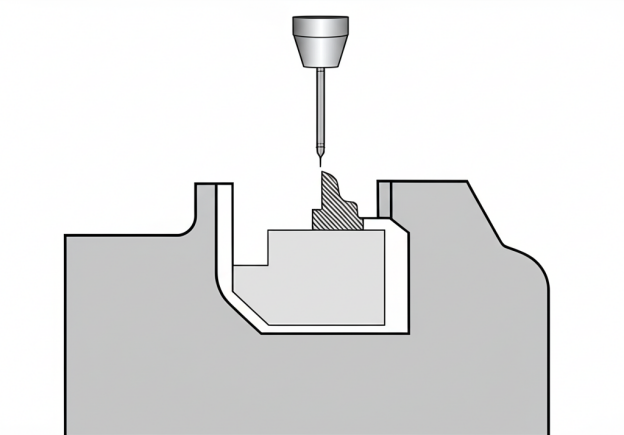

The following figure has many undercuts:

Figure1 Face Mill Cutter

You see, those hidden areas in the component, these are undercuts and are not accessible to standard tools are undercuts. A CNC machine is used to machine an undercut because a simple tool which operates vertically cannot machine these areas.

Key Purposes of Undercutting

For many reasons, you may need undercuts in your component or workpiece:

- Weight reduction

- Housing for O-rings

- For assembly, to interlock joints, snap fits, etc.

- To make designs on the workpiece to give an aesthetic appearance

Undercut vs. Standard CNC Operations

Here is the table for a comprehensive information regarding Undercut vs. standard CNC operations:

Table1 Comparative Analysis for Undercuts vs. Standard CNC Machining

|

Feature |

Standard CNC Operations |

Undercut Machining |

|

Tool Access |

Direct vertical/horizontal access |

Blocked by overhanging material |

|

Tools Used |

Standard end mills, drills, face mills |

Lollipop cutters, T-slot mills, custom tools |

|

Complexity |

Straight cuts, simple geometries |

Complex recessed features |

|

Example Operations |

Facing, pocketing, drilling |

Internal grooves, dovetails, undercuts |

|

Machine Requirements |

3-axis CNC sufficient |

Often requires 5-axis or multi-side setups |

|

Setup Difficulty |

Simple, single setup |

May require flipping or special fixtures |

ISO / ASME Relief Standard

You can take guidance from ASME B94.6 & ISO 3859 standards to make undercuts of optimum dimension for tool clearance and stress relief in thread sparts.

How Does Undercut Machining Work?

Perform these 3 steps to machine an undercut on a workpiece:

- Tool selection, based on the geometry of the undercut.

- Machining Approach

- Finishing

7 Major Types of Undercuts in CNC Parts

You can categorise various types of undercuts based on geometric and functional requirements. For instance:

1. Radial Annular Undercuts

- In cylindrical parts such as piston rings or bearing seats, you will need these circular shapes of undercuts.

- Bear retention and fluid sealing.

- T-slot turning machining

2. Axial Side Undercuts

- Responsible for part assembly

- Use Lollipop Milling or Lollipop Cutting

- Gears, Couplings, etc.

3. Stepped Undercuts

- Serves a structural purpose in applications

- reduction in the weight of the part

- Engine blocks and frames, etc

- Layer Milling process

4. Sealing Undercuts

- Seal leak-prone areas

- Pump housing or valves.

- Precision Turning process

5. Locking Undercuts

- Secures fasteners

- Bolts and threaded shafts

- Wire EDM

6. Relief Undercuts

- Reduces stress within the component

- Brackets and shafts

- Standard End Milling

7. 3D Contoured Undercuts

- Enable smooth fluid flow within the system

- Impeller blade roots and turbine blades

- 5-Axis Simultaneous Milling

What Special Tooling is Needed for Undercutting

As mentioned earlier, undercuts are never easy to make using general or standardised tools; that's why you will need to use CNC machining to machine these undercuts. In CNC machining, you can use only specified CNC undercut tools based on the respective material for a specific undercut.

Lollipop (Undercut) End Mills

This tool has a ball-nose or flat end with extended, tapered necks. It is used when recessing grooves behind edges is required, for instance, in internal O-ring snaps. In case of Al 6061 material, you can use this tool by using these parameters:

- RPM: 12,000 - 18,000

- Feed Rate: 0.08 - 0.15mm/tooth

- Neck Ratio: 4:1 (L:D) max

- The tool will be made of carbide material with TiAlN coating

T-Slot and Keyseat Cutters

You can use T-slot and keyseat cutters for machining internal grooves and keyways in mechanical components. Staggered-tooth and straight-tooth cutters are the common types.

Table2 Staggered-tooth vs Straight-tooth

|

Staggered-Tooth |

Straight-Tooth |

|

Cuts T-shaped grooves |

Machining of straight keyways |

|

Cuts on the side and bottom |

Side cutting for keyways |

|

Used in machine tables, fixtures, etc. |

Shafts, pulleys, gears |

Dovetail Cutters

- You should use 45°cutters for faster machining speeds and high feed rates. You can make machine tool slides through these Dovetail Cutters.

- Use 60o cutters if you are going to machine an undercut for a highly precision application, say, aerospace fixtures. They use slower cutting speeds and careful chip evacuation but provide increased load-bearing capacity.

Custom Form Tools and Inserts

You will need custom form tools and inserts if the design of the respective undercuts is unique or when it is not standard. To machine such undercuts, you will need your tools, which can cost you from 500$ - 1500$, depending upon the type of material, design or coating, etc.

CNC Milling Strategies for Undercuts

Undercut machining is not like simple machining of other workpieces; you will need proper strategies to manufacture a perfect undercut in a workpiece. These are some useful strategies for precise undercut manufacturing:

3-Axis Indexed Undercutting

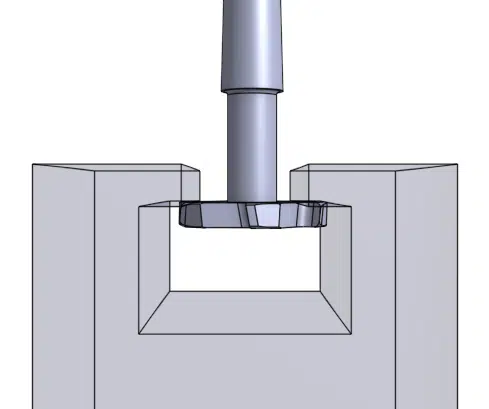

You can easily manufacture parts like flange sealing grooves through this strategy because of the undercut machining through three different angles. The CNC mill rotates in 3 axes (X, Y, Z), but the workpiece is moved manually.

5-Axis Simultaneous Toolpaths

The tools operate on 5 axes during machining, so, no need to position your workpiece manually. Everything operates automatically, which is why it is one of the most advanced manufacturing methods. You can use this ultra-precision machining method for making turbine blades, which must be near-perfect in shape.

Tips for Improving Surface Finish Undercuts

You want improvement in the surface finish of the undercut. Not a big issue if you follow these tips:

- Appropriate tool selection

- Reduced Feeds

- Climb Milling

- Torchoidal Milling

- High-pressure coolant

CNC Turning and Mill-Turn Undercuts

You have been using CNC turning for circular designs and milling operations for flat or complex-shaped components separately till now. But now the time has changed. Both of these operations can be used simultaneously now.

Applications:Landing Gears, Implants, etc.

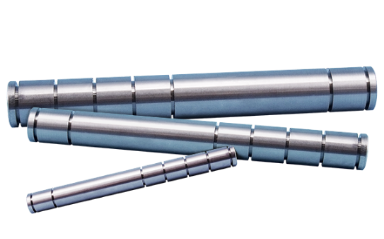

External Shaft Grooves

Do you know how these grooves in the following figure are made in snap rings, seals or bearings? You just need to use the Standard Lathe operation efficiently.

Standard lathe process uses T-type tools. If your workpiece is Al 6061 grade, then use these parameters:

- RPM: 2500 - 5000

- Feed Rate: 0.1 - 0.2 mm/rev for rough surface and 0.05 - 0.1 mm/rev for finish

- DOC: ≤60% of insert width

- Mill-Turn

You can use a tool of 2-6mm end mill or lollipop cutter to make such grooves. Use the following parameters for better machining.

- RPM: 8000 - 15000

- Feed Rate: 0.05 - 0.15 mm/tooth

- DOC: ≤30% of cutter diameter

Internal Bore Reliefs

O-ring grooves, assembly clearance or threading grooves need internal bore reliefs to handle stresses. You can use two CNC operations, as given below in the table:

Table3 Parameters for Al and steel materials undercut machining

|

Parameter |

Aluminum (6061-T6) |

Steel (AISI 1018) |

|

Tool Type |

Internal grooving blade / End mill |

Internal grooving blade / End mill |

|

Insert Width (mm) |

1.5-4 mm |

1.5-4 mm |

|

RPM (Lathe) |

2000-4000 |

800-1500 |

|

RPM (Mill-Turn) |

6000-12,000 |

2000-5000 |

|

Feed Rate (mm/rev - Lathe) |

0.03-0.08 |

0.02-0.05 |

|

Feed Rate (mm/tooth - Mill-Turn) |

0.05-0.12 |

0.03-0.07 |

|

Depth of Cut (Axial - Milling) |

≤1× cutter Ø |

≤0.5× cutter Ø |

|

Depth of Cut (Radial - Grooving) |

≤50% insert width |

≤40% insert width |

One-Setup Side Grooves (Mill-Turn)

As the name is giving you the idea, these grooves are produced using a one-setup process like Mill-turn. If your workpiece is an aluminium valve body, Al 6061, use the following parameters to achieve ±0.02mm accuracy:

- Speed: 10,000 - 20,000 RPM

- Feed Rate: 0.1 - 0.25 mm/tooth

- Depth: 1.5X of the tool diameter

You will need to perform the first turning operation for straight grooves, and then lollipop cutters will be required to machine deep undercuts.

How to Design Manufacturable Undercuts

How to design undercuts? Here, you may use these guidelines for better undercut machining or to make it easily manufactured. Let's figure out some strategies:

Eliminate or Minimise Where Possible

You may face some scenarios where the elimination or minimisation of undercuts becomes a better option than machining them. That is how it's done:

- If you can replace an undercut, use chamfers or radii

- Using snap grooves instead of grooves

- Mating part geometry to eliminate undercuts

The common application of this strategy can be found in snap rings, such as replacing a groove with a shoulder + threaded retainer.

Keep Features Shallow and Accessible

- Do not increase depth over 2X width

- Use radii ≥0.5mm

- Use open-side access for standard tools

Plan Tool Access and Fixturing Clearance

- Ensure tool approach. For instance, you should use tools with six times diameter of the end mills.

- Avoid tool collisions

- Leave ≥5mm clearance for around clamps

What Are the Main Applications of Undercut Machining?

As you know, undercuts have specific purposes for any application, like can be made for structural or functional purposes. In this section, you will be familiarised with those applications which use undercuts.

Aerospace: Shafts, Grooves

Aerospace, the most critical industry in terms of safety, uses threaded relief undercuts to prevent stress concentration at thread runouts. These undercuts are made in the turbine blades made of Ti-6Al-4V alloy. You will need advanced manufacturing operations to create such threads perfectly. For instance, Wire EDM and Lollipop Finishing are used to achieve a very tight tolerance of ±0.005mm and surface finish of Ra 0.8μm.

Automotive: Engine & Transmission Parts

In the automotive industry, the undercuts are made to serve functional purposes in the application. For instance, you will need a radial angle of 0.5 mm - 1 mm depth in Aluminium piston grooves because these undercuts are responsible for securing piston rings at 300°C+ operating temperatures. The suitable machining method is CNC turning with ceramic inserts. Use an optimum speed of 1500 RPM and a 0.1mm/rev feed rate.

Medical: Implant Recesses

3D contoured locking features are required to serve the purpose of Osseointegration via bone ingrowth textures. CoCrMo femoral knee implants use these undercuts. Use a 5-axis micro-milling process to achieve a surface finish of Ra ≤ 0.5μm.

Quality Control for Undercut Features

Timely quality and inspection of any component guarantees its performance in the respective applications. If you want enhanced reliability in your components, you need to use these quality control measurements:

CMM and Optical Scanning Methods

The advanced tiny probes or laser scanners perform the primary task of eliminating errors in the undercuts.

Working Mechanism

- Takes a very precise 3D picture of the undercut

- Checks if the picture is exactly according to the standards or not

- Provides efficiency up to 0.005mm in measuring details

The aerospace and medical industries use this quality control method because a small error can lead to disasters.

In-Process Probing

Isn't it amazing that you don't need to stop production and then pick a sample to inspect the quality? Yes, you can inspect while producing the components due to the automation feature in advanced CNC machines. In-process probing does this job beautifully. Let's see how:

Working Mechanism

- The prob gently pokes the undercut

- It informs the machine right away to fix the respective issue

Surface Integrity Checks

- Smoothness is checked out through a very sensitive finger

- Tiny cracks using special dyes

- Hidden damage using powerful microscopes

Conclusion

This article was focused on undercuts and their related concepts, such as how they are manufactured, their types, etc. Advanced one-setup manufacturing process and in-process probing, etc., are used now for fast and precise manufacturing of undercuts. TUOFA can help you with one-stop custom solutions. Equipped with the most advanced CNC machines and expert operators, we offer you support from prototype to production of the critical component at cost-effective and fast delivery times.

FAQs on Undercut Machining

Does an undercut weaken a shaft?

Yes, but you can recover strength by increasing the shaft diameter near the under, using fillets to reduce stress concentration, etc.

Can undercuts be machined in hard metals like titanium?

Yes, but you will need specialized tools such as Wire EDM, Trochoidal Milling, and Laser machining.

What is the difference between undercut and overcut machining?

In undercut, recess is hidden behind material, assemble/seal along with lollipop mills and T-slot cutters; whereas in overcut, excess material stays beyond the edge and it provides decorative edges or weight reduction along with ball end mills and chamfer tools.

|

Undercut |

Overcut |

|

Recess is hidden behind material |

Excess material beyond the edge |

|

Assembly/sealing |

Decorative edges or weight reduction |

|

Lollipop mills, T-slot cutters |

Ball end mills, chamfer tools |

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Ultra Precision Machining: Processes, Performance, and Applications

Ultra Precision Machining: Processes, Performance, and Applications