2026 CNC Machining Trends: A Quick Outlook

Jan 07,2026

Jan 07,2026

CNC machining has modernized the manufacturing industry with advancements like automation, AI and robotics. Production of precise and complex parts has become easier and luckily; there's a lot more to come in CNC machine industry. Understanding the future and trends of CNC machining is vital and that's what we will explore in this article.

What Is the Current State of CNC Machining?

The current state of CNC machining reflects significant progress by implementing advanced manufacturing practices and advanced CNC technologies. Modern CNC machining is designed to incorporate high-speed operations with multi-axis machining and to produce complex parts across different materials.

The emphasis on sustainability and intelligent resource utilization while maintaining the high standards of precision has reduced waste and improved operational efficiency. Most importantly, the adaptation of industry 4.0 technologies by integrating smart sensors, Internet of Things (IoT) connectivity, and data analytics has revolutionized the production environments.

These advancements have overall improved product quality, production flexibility, and behaved smartly with dynamic market demands.

CNC Machining Market in 2025

Th global CNC machining market has exhibited strong growth from 95.29 billion in 2024 to USD 101.22 billion in 2025, according to recent report by Fortune Business Insights. And it is expected to grow to USD 195.59 billion by 2032 with a CAGR of 9.9%. This massive increase is driven by the increasing demands from the industries like aerospace, aviation, automotive and etc. Key approaches like using Computer-Aided Manufacturing (CAM) and Computer-Aided Design (CAD) technologies have further streamlined the machining process.

Opportunity & Challenge of CNC Machining

CNC machining has revolutionized with a lot of opportunities like integrating AI, machining learning, IoT improves precision and production quality. Similarly, smart machines and sensors allow manufacturers to maintain and optimize performance. Most importantly, mass production and customization of unique products become feasible and help manufacturers to meet diverse customer demands proactively.

However, manufacturers must encounter a few challenges also. For example, high capital costs, difficulty in finding skilled operators, intense competition and constant need of capital for advanced CNC technologies to compete can be technically demanding.

Trends of CNC Machining in 2026

As CNC machining demands increase for complex and high-precision parts, smart manufacturing and automation technologies are likely to be adopted more in 2026. According to market prospects report, among the top trends for CNC machining in 2026, digitalization of CNC machining with industry 4.0 will trend with data analytics and cybersecurity to improve efficiency would become more common. Smart tool holders and tool management are becoming more important in CNC machining. While, automation and robotics, AI, machine learning and sustainability are already being implemented in many industries.

2026 CNC Machining Market Forecast

The forecast for CNC machining for 2026 shows a strong market driven by AI and automation. Modernization across different industries like aerospace, automotive, medical, defense and etc. are expected to shift towards industry 4.0 standards. The key roles are to improve quality, complex parts manufacturing, reduce production time for specialized applications like EVs, medical or aerospace parts.

|

category |

Detail |

|---|---|

|

Market Size |

Approx. $115-129 billion (estimated from 2025-2035 forecasts) |

|

CAGR |

Approx.;7-8% (from 2025-2035 forecasts) |

|

Market Drivers |

Automation and precision manufacturing up to 57%. |

|

Market segmentation |

Milling 45%. Turning 34% Electrical discharge machining (EDM) 21% |

|

Regional Share (Approx. %) |

Asia-Pacific: Over 50% of global machine tool production (leading countries China, Japan, South Korea with 55.32% market share (estimated from 2024 data). |

|

Key Industries |

Automotive & Transportation (EVs included). |

Increasing Demands for CNC Machining

Increasing demand for CNC machining is resulting from reshoring trends, EV growth, and aerospace needs. All are making use of CNC's precision for automation and flexibility for complex parts.

Reshoring Initiative

The trend of reshoring and nearshoring is supported by the need to reduce dependence on overseas manufacturing. Companies are bringing production closer to home to increase flexibility, timely delivery, and to reduce overall risks and production costs

Key Industries

As mentioned above, the key industries in CNC machining are automotive, aerospace, and defense.

Auto Industries

CNC machining is featured in producing precise and complex parts from challenging materials like titanium that are essential for custom EV batteries. Precision machining has also made easy high-volume production for Ev and other auto parts like chassis or drivetrains with robotics with consistency, speed and operation efficiency.

Aerospace & Defense

Aerospace parts like engine parts especially require superior precision and high-strength alloys like titanium or exotic alloys. CNC multi axis machining can produce intricate parts tight tolerances consistently. Furthermore, the evolving defense needs benefits from CNC's flexibility for prototypes and large production runs.

In this important field, choosing a manufacturer who can provide parts with tight tolerance up to ±0.001mm and complex geometries is important, and Tuofa CNC is one of the best options.

Small-batch Customization Demands

CNC machining has becoming smarter and evolving with customer needs. Consumers and businesses demand customized products and emphasize to be offered with tailored solutions. CNC machining can easily complex and short run projects with strict quality standards. Fast CNC machining is specialized to meet unique needs across high-stakes industries and moving beyond mass production to customized parts.

Higher CNC Machining Technology

Higher CNC technologies are multi-axis machines, hybrid machining, mill-turn centers and AI-assisted operations for efficiency with cutting tools that are needed for complex tasks.

Hybrid Machining

Hybrid machines integrate turning, milling and sometimes drilling in one setup and create multitasking machines. These are also called mil-turn centers and can produce complex geometries in a single setup. Hybrid machines increase accuracy, efficiency and reduce machining time. Aerospace, automotive and medical devices are normally produced from these machines and driving industry 4.0 trend towards smart manufacturing.

AI-Assisted CNC Operations

AI improves CNC operations by predictive maintenance and data analysis for process optimization and better quality control. Furthermore, smart tool path generation helps to make these machines smarter and more autonomous.

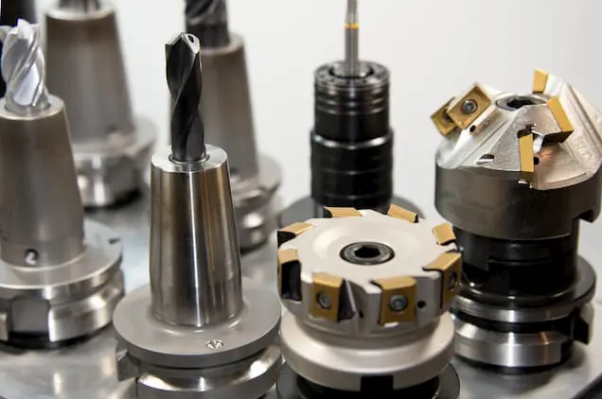

Advanced Machining Tools

The demands of advanced machining like 5 and 6-axis machines are growing and making easier to produce parts like turbine blades and aerospace parts in single setups. Tuofa's 5 axis machining center can help machine parts with complex designs at a time.

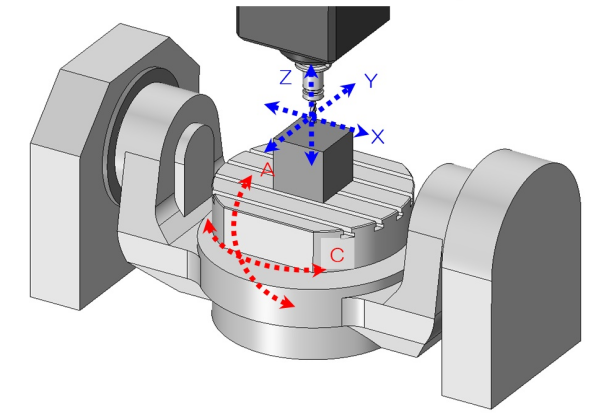

Multi-Axis CNC Machines

The trend of shifting from 3-axis to 5-axis or 6-axis machines increases efficiency and accuracy by reducing setup and minimizing errors. It allows for simultaneous movement on linear (X, Y, Z) and rotary (A, B, C) axes and creates precision parts with quality standards. It is expected that The International Manufacturing Technology Show (IMTS 2026) will feature these innovations and will show how manufacturers are achieving the "impossible" with next-gen tech.

Advanced Cutting Tools

Development of specialized cutting tools like high-performance end mills and drills for multi-axis applications, maximizes the material removal rates and tool life. These cutting tools and advanced coating are essential for maximizing speed, accuracy, and tool life in these demanding hybrid environments.

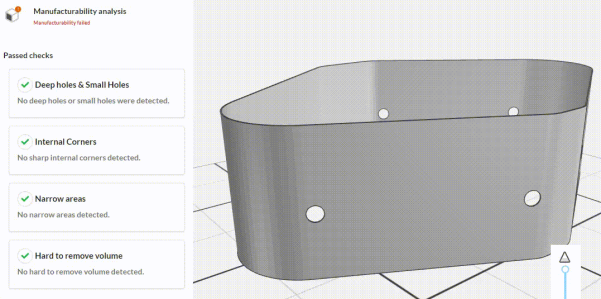

Automated Quoting

The key areas where automated quoting systems for manufacturing and businesses are expected to improve in 2026 are as:

AI-Power Quoting System

AI continues to grow with accuracy and intelligence of online quoting systems. AI algorithms can better control huge data like parts geometry, material, machine type and provide accurate and data-driven cost as lead time estimations. AI will smartly differentiate high-value or urgent Request for Quotes (RFQs) and streamline the sale process.

Refined Quotation Process

The automated validation for product configurations will allow streamlined, transparent, and user-friendly processes. Customers can generate instant and no-error quotes for standards parts and will reduce the workload for internal teams. It will improve customer satisfaction, win rates, response time and consistency in machining process.

Digital Analysis of CAD for DFM

Digital analysis of CAD files can provide valuable insights early in the process. And AI integration will assist in automated feedback on design choices at earlier stages. Compatibility with a huge variety of CAD file types will improve like STEP (Standard for the Exchange of Product model data), STL (Standard Tessellation Language), IGES (Initial Graphics Exchange Specification) and others like Parasolid, SAT, 3DM, etc.

Rapid & Transparent Costing

Costing will be faster and more accurate with AI automation. Quotes will be adjusted with real-time data like raw material costs, machine availability, volume etc. AI can help machining services to offer better pricing with transparent breakdown of costs that aligns with market conditions.

Industry 4.0 & Smart Manufacturing

Industry 4.0 & Smart Manufacturing operated with IIoT, Automation, AI, and Big Data. They create interconnected and intelligent factories for real-time efficiency and quality control. Moreover, integrating green manufacturing principles can reduce waste and optimize energy.

IIoT & Machine Connectivity

IIoT is the backbone and allows systems to communicate to share real-time data. They allow remote monitoring and control for better visibility and transparency.

Automation & Robotics Integration

Autonomous robots and automated systems work alongside human operators. They improve speed, precision, and safety and a way to move from fixed automation (Industry 3.0) to intelligent systems.

Real-Time Quality Control

Sensors and AI can analyze live data streams for immediate defect detection. They can perform anomaly identification with consistent product quality and reduce scrap.

Green Manufacturing

Using Industry 4.0 technologies like energy monitoring, waste tracking, predictive maintenance is a very smart way to achieve sustainability. It can meet green initiatives with minimal environmental impact and optimized resource use.

Market Opportunities for Future Precision Machining

Future precision machining for medical devices is expanding. The industry is driven by demand for smaller and high-precision parts in surgical tools and optical devices. The key growth areas in 2026 for medical and optics are explained below.

Medical Device Machining

The major trend is creating smaller and intricate parts with micro level tolerances. Demands for machining advanced alloys like nitinol or composites for biocompatibility and strength in implants are increasing. 61% of companies are exploring micro-machining for catheters, guidewires, and surgical instruments. The growth areas are orthopedic implants, microfluidics, and health monitoring devices.

Optical Instruments

Advancements in sensor tech and demands for non-invasive diagnostics & continuous monitoring make precise optical components. It is crucial for accuracy and function in devices like endoscopes or imaging tools. The optical devices like optical housing, lens mounts and frames require tight tolerance for alignment, image quality and strength, respectively, that can be achieved with advanced CNC machining.

Challenges for CNC Machining Service Providers

There are a lot of challenges that CNC machining service providers face. These are related to advanced machines, operating staff and production batch.

Lack of Advanced Machines

Advanced multi-axis machines can be expensive and create barriers to entry and upgrade. The need for constant upgrades can be challenging while balancing precision with cost-effectiveness. The best way is to optimize toolpaths and maintenance and invest strategically in automation.

Lack of Highly Trained Operators

Operators need specialized training in CAD/CAM, programming and other skills that are short in supply. The more advanced machines require trained-well operators. It is required to invest heavily in ongoing training to cover the gap and add costs.

Production Batch Stability

Consistent quality for complex parts and extreme tolerances demands robust quality systems and process documentation. Custom machines parts like aerospace parts require 2 microns or less dimensional accuracy. Maintaining consistent quality across large or small batches can be clanging and need rigorous process control.

How Can CNC Machining Suppliers Prepare for 2026?

To prepare for 2026, CNC suppliers must invest in advanced methods like 5/6-axis machines and Industry 4.0 for automation. It helps to boost efficiency, precision, and handle complex demands.

Invest in Tools & Machines

Using multi-axis machine reduces setup and cost for precision parts like aerospace, medical and automotive. Furthermore, advanced cutting tools made from carbide, ceramic, PCD, and CBN can efficiently machine superalloys.

Automated Manufacturing

Integrating machines with IoT for real-time data can enable predictive maintenance and optimizing workflows. Moreover, implementing digital twins for virtual testing and simulation of machining processes can improve efficiency before physical production.

Enhance Quality Control

Integrating sensor and measurement tools into machining cycle for immediate feedback can detect error early. And advanced inspection systems and optical metrology for non-contact allows high-speed inspection of surface finishes and defects.

Choose Tuofa as Your Outsourcing Partner

Choose Tuofa for your next machining project if you want to stay competitive. We offer CNC machining services with advanced capabilities like cutting-edge tech and skilled talent for complex parts. We will help you to concentrate on innovation, not on manufacturing logistics.

Conclusion

CNC Machining industry outlook trends focus on industry 4.0 with smarter and sustainable operations by 2026 and later. The trend is supported by AI, digital twins and predictive maintenance that allows hybrid manufacturing, ultra-precision and smart tool and automation with a focus on sustainability.

FAQ

What is a 6 axis CNC machine?

6-axis CNC machine has two additional rotational axes (A, B, or C) to the standard three linear axes (X, Y, Z),

Will CNC machinists be replaced by AI?

No, rather than replacing CNC machinists, the combination of CNC technology with AI empower human will make production cycle easier and optimized.

What is industry 5.0?

Industry 5.0 focuses on human-centric, sustainable, and resilient models. This prioritizes worker well-being and planetary limits.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Golf Putters CNC Guide: Why Choose Milled Putters?

Golf Putters CNC Guide: Why Choose Milled Putters?