8 Key Precision 2025 CNC Machining Trends

Sep 18,2025

Sep 18,2025

CNC machining is transforming with new technologies and rising demand for high-precision multi-axis centres. In 2025-29, CNC machining tools market is projected to expand by $21.9 billion with a CAGR ~5.4%. This article highlights eight key precision trends, from AI-driven programming to on-demand manufacturing networks. How businesses can boost parts accuracy, reduce waste, and stay competitive in manufacturing.

What is the Current State of CNC Industries?

A strong understanding of the current state of CNC machining enables manufacturers to adopt new technologies and stay competitive. Here is breakdown of best CNC 2025 market growth:

|

Category |

Key Insights (2025 Data) |

|

CNC Market Size & Growth |

USD 115.41B in 2025, expected to rise upto USD 244.59B by 2035, CAGR 7.8% |

|

Key Drivers |

Aerospace demand (61%), Automotive (55%), Medical devices (48%) |

|

Major Restraints |

High equipment costs (43%), Skilled labor shortage (37%), Maintenance complexity (29%) |

|

Emerging Trends |

Automation (57%), IoT-enabled CNC (49%), Additive manufacturing integration (41%) |

|

Regional Leadership |

North America (46%), Europe (39%), Asia-Pacific (35%), Latin America (22%) |

|

Market Segmentation |

Milling (45%), Turning (34%), EDM (21%) |

|

Competitive Landscape |

Top 5 players control (58%), Regional manufacturers (25%), Small-scale workshops (17%) |

|

Recent Developments |

CNC upgrades surged (52%), Partnerships grew (47%), Precision tooling adoption (38%) |

|

Key Players |

MNB Precision (UK), Nidec Corp (Japan), Sanmina (US), Ascentec (US), Swiss Precision Machining (US) |

Data within the table provides an insight on the latest market growth, key drivers of controlled CNC machining and its rising global demand.

1.How AI Work in CAM and CNC Programming?

A number of software are being used in CNC causing its rapid developments, such as CNC Autodesk and CAM. Introduction of CAM in cnc has significantly decreased the need for manual programming, enhancing the production rate through automation. As a result, it makes the manufacturing process more productive, fast and precise. The next major leap in CNC industries comes through automation and robotics.

Automation and Robotics

Introduction of automatics and robotics in cnc machining is increasing with the passage of time to ensure the reliability and productivity of the process. Now using automated systems has become easier than ever, as they don't need that much expertise or long-term training.

Manufacturers can develop components with complex and detailed designs with tight tolerances through the use of robotics. Considering their effectiveness, manufacturers like Tuofa are always looking to stay up to date with technology to make their production smooth.

AI Toolpaths

In traditional cnc the pre-programmed tool paths were adopted, which were not that much effective when it comes to complex geometries. The introduction of AI-assisted toolpaths changes the way the manufacturing AI tool itself builds an operational plane. AI can analyse part geometry, material type, and machine capabilities to minimise tool wear and reduce cycle time. Many CNC software platforms now include adaptive AI toolpath optimization for greater accuracy and less manual input.

In-Process Feedback

In-process feedback is one of the advanced methods adopted in cnc machining. It provides real-time feedback for geometry and superior detailing of components during manufacturing. Here analysis is done by introducing tools like probes, lasers, infrared sensors and other software. Such systems can detect vibration, tool wear, and temperature fluctuations during production.

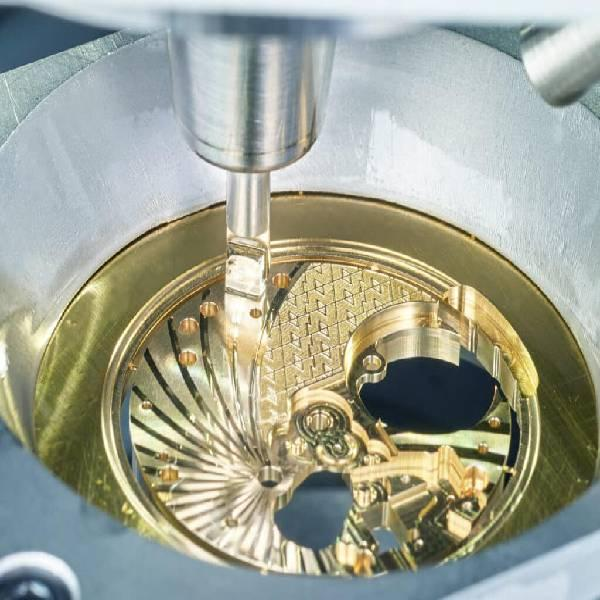

2.Multi-Axis & Turn-Mill Trends

Multiaxis machining and turn-mill machining both are gaining the attention of manufacturers with their exceptional results. These advanced methods enable the production of components with:

- Exceptional accuracy

- Economy in mass production

- Reduced cycle time

Owing to their advantages, these are adopted in aerospace, automotive and medical device development.

5-Axis vs. Mill-Turn Machining

5-axis machining allows a cutting tool to move across five different axes simultaneously. This enables the creation of complex and fine-tuned parts with fewer setups. Whereas in mill-turn machining the component is rotated or the tool moves as needed to perform cutting and shape the geometry. Rotation of components allows the manufacturing of components within one step, making the process time-saving and delivering the highly accurate component. Both processes produce highly detailed components.

At Tuofa CNC Precision, we specialise in 5-axis and mill-turn machining solutions. We are here to help you achieve faster production, tighter tolerances, and cost savings. So contact us today to discuss and get the instant quote for your project needs.

Complex Geometries Parts Machining

Complex shape components like turbine blades, impellers and orthopaedic implants are produced through 5-axis machining. Parts demanding fine detailing require multi-axis control to achieve smooth surfaces, accuracy, and productivity in fewer setups.

Thin-Walled and Intricate Components

Mill-turn and multi-axis machines are used to produce lightweight, thin-walled parts. They are especially valuable for creating highly detailed components in aerospace structures and medical devices.

3.The Rise of Micromachining and Nanofabrication

The modern manufacturing technologies like micromachining and nanofabrication are rapidly evolving as a result of the rising demand for smaller, lightweight and advanced design parts. Micromachining is used for interacting features in the range of 1–500 µm in multiple equipment. Nanofabrication works with products whose size is in the range of nanoscale. Here is a glance at market growth of both:

Nanofabrication Market: The nanofabrication market is forecasted to reach USD 39.85 billion by 2032, growing at a CAGR of 14.2%.

Micromachining Market: Analysis showed that micromachining market is expected to grow at a CAGR of 7.3% from 2020 to 2027.

Challenges of Micromachining

Tooling and Spindle Requirements

- High-Precision Tools:Micromachining utilizes ultra-fine carbide or polycrystalline diamond (PCD) end mills. These mills typically range from 0.1–0.4 mm, with specialised coatings like TiAlN or diamond-like carbon. In order to succeed in micro-scale cutting operations, reducing wear and maintaining the required detailing are essential.

- Spindle Requirements: Air-bearing or hydrostatic spindles operating at speeds between 50,000–150,000 RPM. High speed is necessary to ensure minimal runout (<1 µm) to prevent tool deflection and breakage during high-speed micro-milling processes.

Applications of Micromachining and Nanofabrication

Micromachining Applications

- Fabrication of medical devices and surgical instruments:

- Micro-scissors

- Vascular stents

- Implantable sensors

- Manufacturing aerospace and defence components:

- Fuel injector nozzles

- Turbine cooling channels

- MEMS-based inertial sensors

Nanofabrication Applications

- Creation of thin films and nanoscale layers for:

- Semiconductors

- Sensors

- Microelectromechanical systems (MEMS).

- Integration of nano-scale structures in:

- Biomedical devices

- Chemical microreactors

- High-performance electronics.

4. Innovations in CNC Machining Materials

New CNC Machining Materials

Modern CNC machining increasingly incorporates advanced materials such as high-performance composites and technical ceramics. While this category of materials are less common in traditional turning

Composites: Machining composite materials requires managing abrasive fibres and minimizing delamination.

Ceramics: Compared to other cnc materials ceramics are hard and brittle. Rigid cnc setups are required for machining such materials to avoid cracks or chipping during the machining process.

Hard-to-Machine Materials

Inconel: Nickel based super alloys like inconel are resistant towards machining out of their exceptional durability and corrosion resistance. It generates substantial thermal stress and cutting forces during machining. While machining inconel machining tool may lead to wear and deflection because of the thermal stress.

Titanium (Grade 5): Titanium also falls in the category of hard to machine materials resulting from its low thermal conductivity, strong mechanical properties, and tendency to bear stress.

Tips for Machining These Materials

To machine such materials it is necessary to utilise appropriate tooling which can handle such hard materials. Cutting speed and feed rates must be adjusted according to the material’s properties. For materials like inconel which generate heat stress, effective cooling techniques should be applied.

CNC Machining in 2025 Trends

Over the past six months, the CNC industry has been undergoing constant changes. Let's take a look at some of the following trends:

5.Lights-Out for High-Mix Work

It's the use of automated robotics and software to handle the manufacturing of complex parts through CNC machining. It supports 24/7 production without human intervention, increasing throughput. Still it requires advanced automation and monitoring systems, which can be costly.

6.API-Driven Instant Quotes

Instant quotes allow customers to get instant pricing for CNC parts through online platforms. Despite it saves time and improves customer experience, many API driven platforms are not fully mature. That is why it can give inaccurate quotes compared to expert teams like TUOFA.

7.In-Machine SPC Monitoring

In CNC in-machine SPS monitoring is also in high demand, as It uses sensors and software inside the machine to monitor quality in real-time. Though it requires investment in equipment and training, it helps reduce defects and ensures consistency in the manufactured components.

8.On-Demand Manufacturing Networks

Manufacturing on demand (MOD) networks connect customers with many manufacturers who can produce parts as per their requirements. MOD is more flexible and reduces inventory costs.

2026–2028 Outlook CNC Machining Industry

The CNC machining industry is expected to have a broader outlook in 2026-28 thanks to its flexibility and consistency. CNC is becoming a one-stop customisation solution for many industries, including motorcycle and bicycle, and robotics. The specified eight key precision trends in cnc highlights CNC machining’s growing role in enabling rapid prototyping, small-batch production, and highly tailored manufacturing solutions. Explore our custom CNC machining services at Toufa for reliable and precise production.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Look Back on 2024 CNC Technology Trends-What’s Changing?

Look Back on 2024 CNC Technology Trends-What’s Changing?