Knurling: A Complete Guide for Process, Types & Patterns

Jul 21,2025

Jul 21,2025

Knurling is a key manufacturing process that introduces patterns to the surface of a workpiece. It is commonly found in many machined parts, especially in custom projects. It improves grips which are essential in applications which require secure handling. It also adds texture, and visual appeal in tools, handles, fasteners and other parts that need friction. However, knurling is not a straightforward technique. It has various types and applications that everyone who is related to manufacturing must know. This article will provide you with all the essential details on how to navigate this technique easily for your project. So, let's get started.

Knurling 101-What It Is and Why It Matters

knurling machining is a deformation process that doesn't remove material, but it displaces material from a pattern. This pattern can be straight, angled, or diamond-shaped, depending on the desired applications. Knurling manufacturing is commonly performed on a knurling lathe, but you can also do it easily on even surfaces.

What Is the Purpose of Knurling? - Main Functions

Knurling serves the basic purpose of adding grip for your parts like handles, knobs, and fasteners. Some other common purposes of knurling are as follows:

- Grip Knurling

It enhances friction and improves the grip on an object. This makes holding and manipulating easy for objects which are slippery or wet.

- Decoration Knurling

You can do it on a range of surfaces to improve appearance and to increase surface wear and scratch resistance.

- Press-Fit Knurling

It creates a textured surface on a component, typically metal. This creates more secure and reliable press fit, or interference fit, between two parts.

Machine Knurling vs. Hand Knurling

Machine knurling is normally done on a knurling lathe, as mentioned earlier, and is a faster and more precise method. You can use cutting tools to form the pattern in machine knurling. While hand knurling uses a hand tool. It is a simpler and suitable process for smaller projects and relies on pressure to create indentations.

Knurl vs Serration vs Engraving

These all are surface finishing techniques, but have different purposes, process, and resulting appearance. Knurling creates a textured surface for grip. Serrations are typically used for cutting edges. And engraving creates decorative or informative markings.

|

Differences |

Knurl |

Serration |

Engraving |

|

Purpose |

enhances grip on handles and knobs. |

used on cutting edges, like knives and saws to improve grip |

Creates permanent, decorative, or informative markings |

|

Appearance |

raised, textured pattern, |

notched or saw-toothed edge |

recessed lines, patterns, or text |

|

Materials |

steel, aluminum, and brass. |

steel or other metals. |

metals, plastics, wood, and glass. |

How Knurling Works on Lathe & CNC Machines

The knurling process is done on lathes and on knurling CNC machines with specialized knurling tools. In the knurling operation, a pattern is impressed into the material rather than cutting it away.

Form-Roll Knurling Cycle

In these knurling methods, hardened steel rollers having inversed desired pattern are pressed against the workpiece while rotating. The material is displaced and creates knurled patterns. During knurling 6061-T6 aluminum at 30 m/min, zero chips are produced. because it is not a cutting process but a forming process.

Cut-Type Knurling Cycle

These knurling methods use a cutting tool to create the knurled pattern. It is suitable for harder materials and gives finer finish than form-rolling. This method is suitable for your stainless steel 304 project due to its ability to handle harder materials.

CNC Knurling Code-G76 Knurl Macro

G76 knurl macro is a basic code used in CNC knurling. It uses G01 (linear interpolation) to create the knurled pattern. You can adjust specific parameters (X, Z, R, F) based on the desired knurl pattern and material.

Main Knurling Pattern Types: When to Use These Patterns?

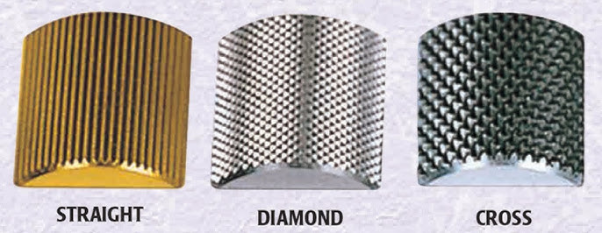

The most common knurling patterns are Straight, diamond and diagonal(left/right) patterns. There are a few other patterns that are covered in the following section.

1.When to Use Straight Knurling

It is also known as linear knurling. Straight knurling methods are ideal for optical focus rings requiring a tactile grip and precise alignment. The created parallel grooves increase grip for fingers and give accurate adjustments for fine-tuning or precise movement control.

2.When to Use Diamond Knurling

This method is chosen for maximum hand torque applications in accordance with ISO barbell standard which is 90-degree diamond pattern and 1.5 mm pitch. It provides a superior grip compared to straight knurling and improves friction and prevents from slippage during heavy loads.

3.When to Use Helical/Annular Rings

Helical or annular components are used in seals for various reasons. This is primarily to improve performance, retention, and sealing. Helical rings are used with oil seals for shock absorbers to enhance oil retention. While the annular rings are used as backup rings to prevent seal extrusion under pressure.

4.When to Use Right/Left-Handed Knurling

Right-hand knurling is used when the knurling tool is fed from left to right. And the left-hand knurling is used when the tool is fed from right to left. The feed direction and resulting pattern is determined by the rotational direction of tool and the workpiece.

5.When to Use Concave/Convex Knurling

Convex knurling provides a more effective grip due to its raised surface. This also improves friction and reduces slippage, for example in screwdriver handles. While Concave knurling is less common for handles than convex because it offers less surface contact and grip of your part.

6.When to Use Square Knurling

Square knurling is used to increase grip and torque resistance. for example, medical device knobs which need a strong, secure hold. It is also used to add visual markings dots or lines to indicate direction or position in medical device knobs.

How to Knurl on a Lathe?

Knurling on a lathe is done by impressing a pattern onto a workpiece's rotating surface. The speed of setup and part volume are key factors in the selection of the right tool. Common knurling tools and their comparison are as follows:

|

Features |

Single-Wheel Knurling Tool |

Dual-Wheel Knurling Tool |

Cut Knurling |

|

Setup Speed |

Relatively fast |

Moderate |

Fastest setup |

|

Part Volume |

low to medium volume production |

medium to high volume production |

high volume production |

|

Advantages |

Simple and easy to set up |

consistent knurl pattern |

finer knurling patterns |

|

Disadvantages |

Not suitable for harder materials |

complex setup |

Most difficult and complex setup |

Scissor vs Straddle Holders

Straddle holders provide support and reduce deflection, especially beneficial for smaller diameters and longer parts. Scissor holders are also known as quick-acting clamp-type knurl holders. It uses a scissor-like mechanism to apply pressure from both sides and give precise and clean knurl patterns.

Quick-Change Insert Wheels

Scissor holders are known for their compact design and ability to access tight spaces. However, straddle holders offer better flexibility in application and can take up less storage space on machinery.

Cut-Knurl Tools for Hard Alloys

Cut-knurl tools with TiAlN-coated wheels are suitable for hard alloys like 45 HRC steels. TiAlN coating on knurl tools enhances the tool's wear resistance and heat resistance which are ideal features for machining harder materials.

Process Parameters That Make or Break a Knurl

To get optimized results of your knurling process, optimize the process parameters such pitch selection or feed rate.

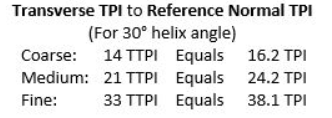

Pitch Selection Chart (DP & TPI)

Knurl TPI (teeth per inch) selection is crucial to get the desired knurled surface. Lower TPI knurls are generally better for larger workpieces, coarser, more aggressive pattern is needed. While higher TPI knurls are used for smaller, finer, more delicate patterns are desired.

Speed-Feed Window: 20-50 m/min, 0.1 mm/rev

Knurling without using optimal speed-feed window can cause material damage. A very low speed can cause tearing, and very high speed can cause glazing. The knurl depth should be approximately 50% of the knurl pitch.

What are The Best Materials When Knurling

Knurling is used on steel and brass, because both undergo plastic deformation that rolled knurling requires. Knurling of steel tooling components create knurled patterning of the molded parts that the tool produces.

Best Metals That Knurl Cleanly

Metals can deform easily and create raised ridges or a patterned surface that enhances grip or provides aesthetic appeal.

Al 6061

Aluminum 6061 is a softer material and is a popular choice for knurling. It can deform under pressure and create clean and well-defined patterns.

Brass 360

Brass generally outperforms aluminum in knurling due to its higher strength and has higher wear resistance.

Hard Steels-Pre-Heat-Treat vs Post-Heat-Treat

Knurling gives the best results after the heat treatment of hard steel. It gives better control over precision and final dimensions and surface finish. This is because material is hardened and dimensionally stable after heat treatment. If knurling is done before heat treatment, it can lead to cracking, warping, and can be difficult to achieve the desired pattern due to high hardness and brittleness.

Surface Prep: Turn to Ra ≤ 1.6 µm

The instruction "Turn to Ra ≤ 1.6 µm before knurling" means that the surface roughness of workpiece should be machined to 1.6 micrometers or less (Ra ≤ 1.6 µm). it gives a smoother surface and better grip with a more consistent pattern.

Common Knurl Defects and Quick Fixes

Common Knurling defects like double tracking, poor definition, and chatter marks can be fixed by adjusting tool alignment, pressure, and speed.

Double Tracking

- Symptom:

This occurs when knurling tool re-engages the workpiece on a subsequent pass at offset positions. This creates a duplicated or blurred pattern.

- Root Cause:

- Misalignment of the knurling tool.

- incorrect pressure application.

- Improper initial contact with the workpiece.

- Quick Fix:

- Use proper tool alignment.

- Adjust the feed rate.

- Make the initial contact on the end of the part before feeding axially.

Poor Definition

- Symptom:

The knurled pattern is shallow, uneven, or incomplete.

- Root Cause:

- Insufficient pressure applied by the knurling tool.

- Dull or damaged knurling wheels.

- Using the wrong tool for the material.

- Quick Fix:

- Increase the pressure.

- Replace or sharpen the knurling wheels.

- Make sure the tool is appropriate for material hardness.

Chatter Marks

- Symptom:

The knurled surface is rough and uneven and has chatter marks.

- Root Cause:

- Heavy vibration caused by a loose tool setup.

- High spindle speeds.

- Inadequate tool support.

- Quick Fix:

- Secure the tool setup.

- reduce the spindle speed.

- use proper tool support.

Custom Tool Path for Complex Knurl Patterns

To get knurling custom patterns like tapered parts or one-pass spirals, you will have to use specific toolpaths and potentially custom programming in CNC knurling lathe.

Knurling on Tapered Parts

Knurling on tapered parts needs careful consideration of the toolpath's geometry. It requires using a tool that can adjust to the changing diameter.

One-Pass Spiral for Long Helix

It is essential to have a continuous helical motion with a specific feed rate and depth of cut for one-pass spirals.

One-Stop Custom Solution on TUOFA

TUOFA, as a professional machining shop, has a one-stop solution for all your custom parts, like complex patterns, knurling on tapered parts, and one-pass spirals for long helixes. To learn more and get a knurling custom solution for your custom parts, please visit the TUOFA Machining or contact our team. As a machining one-stop solution provider, TUOFA will get back to you soon once you upload your parts technical drawings (2D & 3D in STEP/STL/IGS format).

Conclusion

Knurling is a commonly used manufacturing process that is utilized in many industries. It creates a textured pattern on a workpiece, like a metal part with the help of knurling tools. This pattern has various shapes like straight, diagonal, or diamond-shaped ridges, which improve grip, aesthetics, and help in assembly. Knurling process is mostly done on cylindrical parts like handles, knobs, and tool grips. It also adds visual appeal to tools, handles, fasteners and other parts that need friction.

FAQs and Quick Reference

What's the fastest way to calculate knurl TPI?

To calculate knurl TPI (teeth per inch) quickly, you can use a simple formula:

Can you knurl plastic parts?

Yes, plastic parts can be knurled. However, metals are more commonly knurled.

What is the ideal lubricant for cut knurling?

Cutting oil is generally recommended for steel cut knurling and for aluminum and brass, cooling emulsion is recommended.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Bilateral vs. Unilateral Tolerance: A Guide for Precision Engineering

Bilateral vs. Unilateral Tolerance: A Guide for Precision Engineering