What Is 40Cr Steel? A Complete Guide for You

Dec 31,2025

Dec 31,2025

Quite often a material is required that offer a high performance at a comparatively lower cost. 40Cr steel is one such option. Compared to its alternatives like 42CrMo4 steel or 4130 steel, it offers comparable strength at a low price. A slight addition of Chromium in 40Cr steel elevates its performance level way ahead of plain carbon steels. Here is complete guide for 40Cr steel. Lets learn more!

What Is 40Cr Steel?

40Cr steel is a chromium steel alloy complied with the Chinese standard GB/T 3077 40Cr. The addition of chromium in 40Cr Steel offers an excellent balance of strength, toughness, and machinability. Chromium forms stable carbides which impart hardness, strength, wear resistance, and corrosion resistance in 40cr material. Thus, it can endure high stress and repeated loading. Due to these properties 40Cr steel is extensively used in precision machined automotive parts and machinery components.

What Are Chemical Composition of 40Cr?

40Cr is a medium carbon alloy steel. The chromium content of 0.8-1.10% in 40Cr steel distinguishes it from plain carbon steels. It attains a good hardenability and high hardness after quenching and tempering. Chemical composition of 40Cr steel is given in the below table:

|

Element |

Content (%) |

Key Role |

|---|---|---|

|

Carbon (C) |

0.37-0.44 |

Strength and hardness |

|

Chromium (Cr) |

0.80-1.10 |

Hardenability and wear resistance |

|

Manganese (Mn) |

0.50-0.80 |

Strength and toughness |

|

Silicon (Si) |

0.17-0.37 |

Deoxidation |

|

Phosphorus (P) |

≤ 0.035 |

Controlled impurity |

|

Sulfur (S) |

≤ 0.035 |

Controlled impurity |

Is 40Cr Steel Important for Manufacturing Parts?

40Cr steel is highly important in the manufacturing of durable parts. As it can withstand fatigue and high stress environments, 40Cr steel is highly suitable for dynamically loaded components. 40Cr alloy steel is commonly used in the manufacturing of:

- Shafts, spindles, and axles

- Gears and gear shafts

- Bolts, studs, and fasteners

- Couplings, pins, and sleeves

Properties of 40Cr Steel

40Cr steel offer a good combination of strength, toughness, and cost effectiveness. It's properties can be adjusted through heat treatment. Generally, the most important characteristic of this chromium steel alloy is its hardenability and fatigue resistance. Some of the dominant characteristics of 40Cr steel are discussed below.

Characteristics of 40Cr Steel

In addition to the properties of 40Cr, it also has key characteristics that influence the applications. The Characteristics of 40Cr steel include corrosion resistance, heat resistance, hardening ability, and machinability.

Corrosion Resistance

40Cr steel offers only a moderate corrosion resistance. Although its corrosion resistance is better than plain carbon steels but it does not match stainless steel. The performance of 40Cr steel is satisfactory in mildly corrosive environments. But plating or coating can further enhance the service life.

Heat Resistance

40Cr steel can maintain mechanical properties at moderately elevated temperatures. During service 40Cr steel can withstand frictional or intermittent heat thermal loads.

Hardening Ability

In terms of hardenability, 40Cr steel is an excellent choice. It responds well to quenching and tempering. It can harden to impressive depths of around 20mm in oil quenching and more in water quenching. Normally, core is desired to be soft, high surface and core hardness.

Machinability

40Cr steel has a good machinability in annealed or normalized condition. It makes turning, milling, and drilling operations easy. After machining, components made up of 40Cr steel can be heat treated to the desired hardness.

Mechanical Properties of 40Cr

As with all common metallic alloys, mechanical property values change with heat treatment. This effect is predominant in 40Cr steel. Since, the finished parts are mostly in the quenched and tempered state, values of the Q&T state are given in the below table:

|

Property |

Values in Tempered condition |

Advantages |

Main Functions |

|---|---|---|---|

|

Tensile Strength |

850-1000 MPa |

High load-carrying capacity |

Resists breaking under tension |

|

Yield Strength |

800-950 MPa |

Excellent elastic stability |

Prevents permanent deformation |

|

Hardness |

32-36 HRC |

high wear resistance |

Protects surfaces from abrasion |

|

Fatigue Limit |

450-500 MPa at 10^6 cycles |

Long service life |

Withstands cyclic loading |

Great Tensile Strength

As compared to plain carbon steels, 40Cr steel offers a great tensile strength in a range of 850-1000MPa, depending on the heat treatment. It therefore allows 40Cr steel parts to operate in high stress environments.

Good Yield Strength

Yielding indicates the permanent deformation of a part under stress. Having yield strength in the range of 650-800MPa, 40Cr steel can endure a high level of stress without permanent deformation.

High Hardness

40Cr steel can easily attain a hardness in a range of 50-55HRC. Hence it can prevent abrasion of material in harsh service environments.

High Fatigue Strength

Parts like gears and shafts can have a way longer service life compared to plain carbon steels. Parts made from 40Cr steel have a high fatigue limit of 450-500MPa at 106 cycles.(quenched and tempered state)

Physical Properties of 40Cr Steels

The physical properties of 40Cr steel are almost the same other alloys of irons. Alloying additions does not have a significant effect on the physical properties. On the other hand, alloying additions significantly change the mechanical properties which affect machinability. The below table shows the physical properties of 40Cr alloy steel.

|

Property |

Typical Value |

Notes |

|---|---|---|

|

Density |

7.85 g/cm³ |

Comparable to most carbon and alloy steels |

|

Melting Point |

1420-1460 °C |

Varies with composition |

|

Thermal Conductivity |

42 W/m·K |

Lower than pure iron due to alloying |

|

Specific Heat Capacity |

460 J/kg·K |

Affects heating and cooling rates |

|

Electrical Conductivity |

1.4-1.9 MS/m |

Much lower than copper or aluminum |

|

Magnetism |

Magnetic |

Ferromagnetic in all common conditions |

What Are Equivalent Materials of 40Cr Steels?

40Cr steel is governed by the Chinese standard GB/T 3077 40Cr. It has its equivalents in other standards systems like AISI, DIN, JIS etc. Finding a strict equivalence in other standards is often difficult. There can be minor variations in alloying additions which can slightly affect the mechanical properties. Here, we'll be discussing the equivalent material like AISI 5140 / DIN 41Cr4 and JIS SCr440.

AISI 5140 Steels

The 51xx alloy steels in the AISI standard systems have approximately 0.8-1.3% Cr content. The last two numerical digits indicate the carbon content. As an example, in 5130 steel the carbon content is 0.3%, in 5140 it is 0.4% and so on. AISI 5140 steel closely matches the 40Cr steel in composition and properties.

DIN 41Cr4 Steels

DIN standard system was developed in Germany. With the evolution of a single standard systems in the EU, DIN 41Cr4 steel is now also designated as EN 1.7035. DIN 41Cr4 steel matches 40Cr steel in the German standard system.

JIS SCr440 Steels

JIS stands for “Japanese Industrial Standards”. In this standard system, 40Cr steel is approximately equivalent to JIS SCr440 Steel.

40Cr Heat Treatment

Normally, 40 Cr steel is mostly subjected to a quenching and tempering heat treatment. The material is soft in annealed condition. Machining is easily performed in this stage. After the components attain the final shape, it is subjected to a Q&T heat treatment. The main objective remains to improve the surface hardness and tensile strength while maintaining a soft core.

Purpose of Heat Treatment

Heat treatment unlocks the true potential of 40Cr steel. It tailors the 40Cr material to the desired mechanical properties. Heat treatment enhances hardenability, refines the microstructure and relieves internal stresses. It tailors a balance between surface hardness and core toughness making the material suitable for the desired applications. Typically, high wear resistance, high fatigue resistance and high load bearing capacity is imparted by heat treatment.

Heat Treatment Methods

The below table give a general overview of the various heat treatment processes for 40Cr steel:

|

Heat Treatment Method |

Process Conditions |

Characteristics |

Applications |

|---|---|---|---|

|

Annealing |

830-860 °C, furnace cooling |

Reduces hardness, improves machinability |

Forgings, pre-machined parts |

|

Normalizing |

850-880 °C, air cooling |

Grain refinement, uniform structure |

Structural and general parts |

|

Quenching |

840-870 °C, oil quench |

High hardness and strength |

Gears, shafts |

|

Tempering |

500-650 °C, air cooling |

Improves toughness, relieves stresses |

Load-bearing components |

|

Quench & Temper (Q&T) |

Quench followed by tempering |

Balanced strength and toughness |

Automotive, machinery parts |

|

Surface Hardening (Induction/Flame) |

Local heating + rapid quench |

Hard surface but tough core |

Shafts, gear teeth |

Comparison Between 40Cr & Other Steels

40Cr steel has a few alternatives in market. A comparison is drawn between the common alternatives to find suitability based on factors like strength, hardenability, toughness and cost. The below table draws a comparison between 40Cr steel and its common alternatives:

|

Steel Grade |

Main alloying element |

Performance Level |

Cost |

Typical Selection Reason |

|---|---|---|---|---|

|

40Cr |

Cr |

Balanced strength &andughness |

Medium |

Standard choice for machinery parts |

|

1045 / 45# |

Plain Carbon |

Lower hardenability |

Low |

Cost-driven, light-duty parts |

|

4130 |

Cr-Mo |

Better toughness but lower hardness |

Medium |

Good weldability, moderate loads |

|

4140 / 42CrMo4 |

Cr-Mo |

Higher strength & fatigue resistance |

High |

Heavy-duty, higher temperatures |

|

5130 |

Cr |

Lower strength than 40Cr |

Medium |

Carbon level-dependent use |

|

SCr440 / 41Cr4 |

Cr |

Similar to 40Cr |

Medium |

Direct equivalents |

40Cr Steels vs 1045 Steels

1045 steel is a plain carbon steel having a 0.45% carbon content. On the other hand, 40Cr steel is a chromium steel alloy. 1045 steel too offer a high strength and hardness combination, but its hardenability is limited. 1045 is often chosen for cost-sensitive or low-stress applications. While 40Cr steel is preferred for shafts, gears, and components subjected to dynamic loads.

4130 vs 40Cr Steels: What Are Differences?

4130 steel is a chromium-molybdenum alloy steel. The addition of molybdenum in 4130 steel enhances toughness and weldability. Although a lower hardness and strength is achievable after heat treatment, 4130 favors toughness and fabrication. But it a is bit expensive than 40Cr steel. When it comes to strength and wear resistance 40Cr steel performs better than 4130 steel.

40Cr Steel vs 4140

Similar to 4130 steel, 4140 steel is also a chromium-molybdenum alloy steel. It has a higher hardenability, better toughness, and improved performance at elevated temperatures. It is more expensive than 40Cr steel. 4140, can serve as an alternative to 40Cr for industrial parts. Customers opting for 40Cr typically prioritize cost, whereas customers choose 4140 steel for improved toughness and higher service temperatures.

45# vs 40Cr Carbon Steels

45# steel is similar to the AISI 1045 steel. It is plain carbon and has limited hardenability. It is more cost effective than 40Cr steel. But, 40Cr steel provides better strength, hardness and fatigue limit than 45# steel.

Applications of 40Cr Structural Steels

Due to the ability of 40Cr steel to be tailored to the desired properties with heat treatment, it is used in a number of applications. Manufacturers of precision steel parts value 40Cr steel for its strength, hardenability, and machinability. Alloy steel machined parts with tight tolerances can be machined out of 40Cr steel.

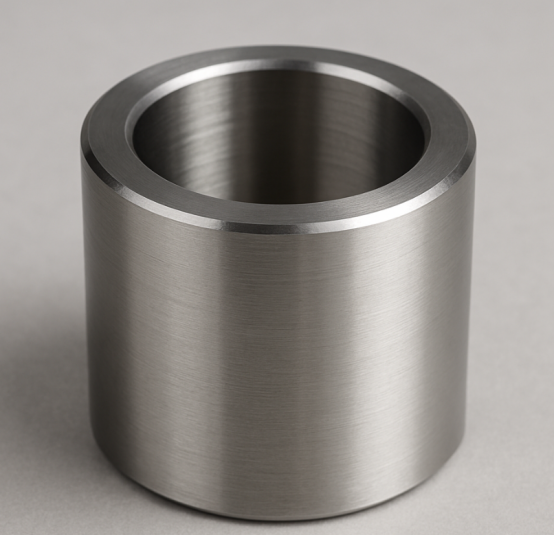

Steel Mechanical Parts

Parts for industrial equipment and power transmission systems like shafts, gears, bushings and pins are made up from 40Cr steel. It provides a hard wear resistant surface with a tough core inside.

Auto Components

Auto parts that are subjected to continuous cyclic loading and vibration need a high fatigue strength and dimensional stability. 40Cr steel provides an excellent fatigue resistance and incredible dimensional stability for automotive applications.

Aerospace Components

40Cr steel has the ability to provide extremely tight tolerances for aerospace components. It is perfect match for strength and precision. 40Cr steel provides a cost-effective solution for aerospace parts like landing gear components, structural fasteners and fittings.

When Choosing 40Cr Materials for Your Project?

40Cr steel can be an ideal choice where a balance between performance, reliability, and cost. It is valued by many different industries based on performance indicators like strength, viability in operating environments and cost effectiveness.

Mechanical Properties

40Cr is the great choice for components that require high stress, bending, or impact resistance. Quenching and tempering heat treatment cycle enhances the mechanical properties. A lot of alloy steel machined parts and precision steel parts are made out of 40Cr steel.

Application Environment

40Cr low alloy steel can handle high stress environments where load nature is cyclic. It offers a better corrosion resistance than plain carbon steels but it is not suitable for highly corrosive environments. It can endure moderately elevated temperatures. But for very high temperatures superalloys may be preferred over 40Cr steel.

Budget & Costs

40Cr offers an excellent performance-to-price ratio. It is more affordable than Cr-Mo alloy steels like 42CrMo4. But performance indicators for 40Cr steel must match the desired applications. Its performance definitely better than carbon steels. In short, 40Cr steel is preferred where cost control is important without compromising mechanical reliability.

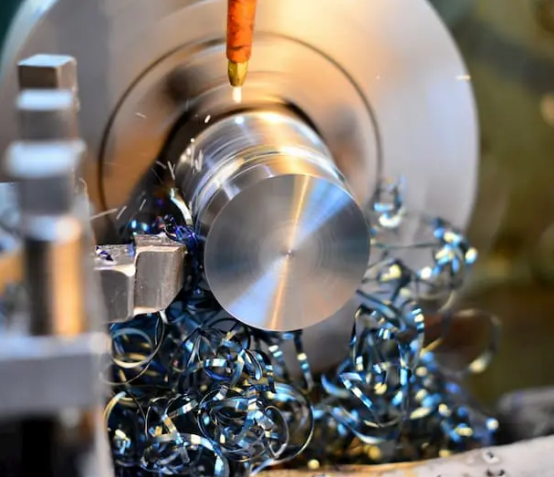

CNC Machining for 40Cr Steel

A question may pop up in our readers' minds: Can 40Cr steel be machined? The answer is yes. As already discussed, 40Cr steel has a lot of applications in many industries. Normally, 40Cr steel is machined in the annealed or normalized state where machinability is high. The heat treatment state directly affects the tool selection, cutting speed, cutting force and machining method. So, 40Cr steel is quenched and tempered afterwards.

Drilling Techniques

Drilling is commonly done in the pre-hardened state to prevent rapid tool wear. Use carbide or high-speed steel (HSS-Co) drills enhance tool life and accuracy of drills. Moderate cutting speeds and sufficient coolant also increase the drilling performance.

Thread Cutting

Thread cutting is performed before final heat treatment. Coated tools improve surface finish and dimensional accuracy. Proper lubrication reduce friction and overheating during tapping and threading operations.

CNC Turning

40Cr steel shows a stable cutting behavior during CNC turning. So, axis symmetrical components like shafts can be easily made out of it in the annealed state. Carbide inserts with wear-resistant coatings allow higher cutting speeds. Feed rates can be fine tuned to attain a good surface finish.

CNC Milling

In the annealed or normalized state, end mills and face mills made from coated carbide are suitable for 40Cr steel.

Tuofa Climb milling technique increases tool life and surface finish while prevention overheating and friction. Lower cutting speeds and rigid setups are preferred to get a good machining quality.

Conclusion

40Cr steel is versatile material that can be fine tuned to the correct hardness during a quenching and tempering cycle. It's high hardenability and cost effectiveness makes it suitable for many industrial parts that require high dimensional stability. It can withstand high fatigue resistance that make it suitable for cyclic loads. In short, it performance is better than plain carbon steels but lower than Cr-Mo steel alloys. Given its price which is lower than other alternatives, 40Cr steel is preferred in cost control situations.

FAQ

How durable is 40cr steel?

After quenching and tempering treatment, 40Cr steel is very durable because of its high fatigue resistance, high wear resistance and high strength.

What is 42crmo4 steel?

42CrMo4 is a chromium-molybdenum alloy steel. The addition of Mo in steel enhances the hardenability, toughness, and performance at elevated temperatures.

What is medium carbon steel?

Medium carbon steels have a carbon content in the range of 0.30-0.6%. Plain carbon steel has carbon as the main alloying element. In contrast to it, 40Cr steel has Cr as the main alloying element. So, it is not ordinary medium carbon steels. It is medium-carbon alloy structural steel.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Titanium Cost Per Pound and The Cost of Titanium Machining

Titanium Cost Per Pound and The Cost of Titanium Machining