6063-T5 Aluminum: Temper, Properties, Weld & Machining

Dec 27,2025

Dec 27,2025

6063 T5 is a versatile aluminum alloy and famous across many industries due to its lightweight, workability characteristics and superior finish. Also, a balance of moderate strength and superior finishing makes it an ideal choice for decorative applications. If you deal with construction and manufacturing projects, knowing about 6063 T5 can help you select the right material from the beginning and save you from making costly mistakes.

What Is 6063-T5 Aluminum Alloy

6063-T5 aluminum is a heat-treatable alloy. It is a versatile alloy with medium strength and is used where looks and durability are needed like architectural frames, windows, doors and decorative purposes.

Alloy 6063

6063 aluminum alloy contains magnesium and silicon as primary alloying elements. These elements help to increase its strength after heat treatments. It is mostly supplied in tempered state like T5 or T6 to increase strength, formability and weldability. That also implies it has good machinability and can easily be cut to any shape with a standard tool. The combination of these properties makes it suitable for decorative and structural applications.

6XXX Series Aluminum

6XXX series aluminum contains Magnesium and Silicon as primary elements. They form magnesium silicide Mg2Si which increases the corrosion resistance, formability, extrudability, machinability and weldability. Common alloys in the 6xxx series are 6061 known for its strength and 6063 for good machinability with smooth finish and extrudability.

Meaning of Temper T5

T5 is a temper designation that depicts the heat treatment of aluminum alloys after shaping. T5 temper specifically means the alloy was cooled and then artificially aged after hot extrusion. As mentioned above, tempering creates a good balance of medium strength and excellent surface finish and workability. This resultant finish is also great for further treatments like anodizing.

6063-T5 Standards and Designations

Equivalent standards point to similar alloys with similar properties and use. For 6063 T5, equivalent standards and designations are:

|

standards |

grades |

|

UNS no |

A96063 |

|

ASME/ASTM |

B210, B221, B241, B345, B361, B429, B483, B491 |

|

ISO |

AlMgSi |

|

BS |

H9/HE9/HE19 |

|

DIN |

3.3206 AlMgSi0.5 |

*These grades are approximate only. The list shows the functionally similar materials not as a schedule of contractual equivalents. Exact equivalents must be consulted with experts from Tuofa CNC machining.

6063-T5 Chemical Composition

The chemical composition of 6063-T5 primarily contains aluminum with other elements magnesium, silicon, iron, copper and titanium. T5 is the tempering state, it does not alter the chemical composition but precipitates fine particles of Mg2 Si in the microstructure.

Main Alloying Elements in 6063

The main elements of the aluminum 6xxx series are Magnesium and silicon, which are also present in 6063, as mentioned earlier. These elements contribute to the major properties of 6063 like strength and corrosion resistance, moderate machinability, excellent extrudability and finishing.

6063-T5 Composition Range

To know the quantities of each element in 6063-T5 composition, the table below is presented:

|

Elements |

Percentage |

|

Aluminum |

Balanced,97%. |

|

Magnesium |

0.45–0.9% |

|

Silicon |

0.2–0.6% |

|

Iron |

≤ 0.35% |

|

Copper |

≤ 0.1%. |

|

Manganese |

≤ 0.1%. |

|

Chromium |

≤ 0.1%-0.05% max |

|

Zinc |

≤ 0.1%. |

6063-T5 Mechanical and Physical Properties

Aluminum 6063-T5 is demanded in architectural applications due to its strength-to-weight ratio, moderate strength and corrosion resistance. other prominent mechanical and physical features of 6063-T5 are as:

6063-T5 Density

Aluminum alloys have lower density mostly. 6063-T5 density is 2.7 g/cm3.

Strength and Hardness of 6063-T5

Aluminum 6063-T5 has moderate strength. Typical tensile strength is around 186MPa and 6063-t5 yield strength is 145MPa. A moderate hardness of 60(HBN) or 70HV have been observed in 6063-T5.

Ductility and Formability of 6063-T5

6063-T5 has good ductility. T5 temper provides enough elongation for shaping and creates a good balance between flexibility and strength. While the formability and extrudability is excellent in both hot and cold conditions. And 6063-T5 can easily be formed into complex and precise shapes.

|

Mechanical properties |

Values |

|

Ultimate Tensile Strength |

186 MPa |

|

Yield Strength |

145 MPa |

|

Elongation |

12% |

|

Modulus of Elasticity |

68.9 GPa |

|

Shear Strength |

~117 MPa |

|

Hardness (Brinell) |

60HBN |

6063-T5 Thermal Properties

6063-T5 aluminum has excellent thermal performance for architectural uses. It offers high thermal conductivity and a moderate coefficient of thermal expansion.

|

Thermal properties |

Values |

|

Thermal conductivity |

~209 W/m-K |

|

Coefficient of Thermal Expansion |

~23.4 µm/m-°C |

|

Specific Heat Capacity |

~0.9 J/g-°C |

|

Melting point |

616 – 654 °C |

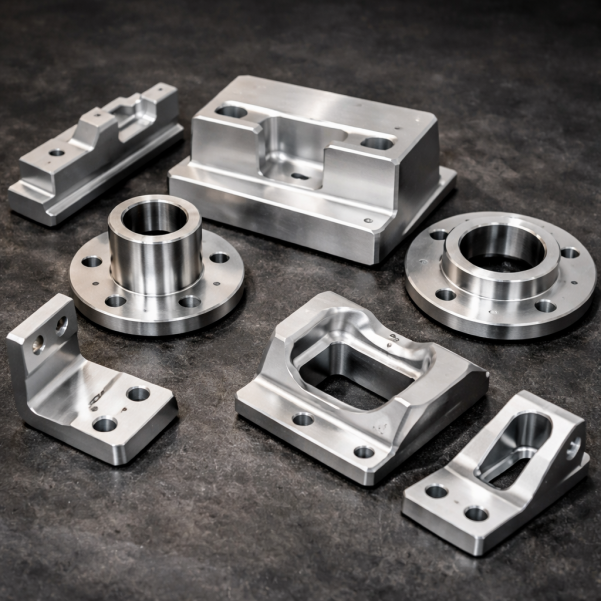

CNC Machining 6063-T5 Process

Aluminum alloy 6063-T5 is a common material used for CNC machining. It is CNC machined especially for light structural components due to its favorable properties and process characteristics.

Machinability of 6063-T5

6063-T5 has good machinability and is relatively ductile. The chips produced during machining are long and continuous. However, the material can cut edges and lead to built-up edge which increases tool wear.

CNC Milling 6063-T5 Process

High-speed steel or carbide tool are used as milling tool for 6063-T5 milling. TiN coated drills can improve material removal rate and optimized spindle speed, feed rate, and depth of cut gives best surface roughness. However, deep holes require internal coolant tools to manage heat for longer runs.

CNC Turning 6063-T5 Process

Turning process is similar to CNC milling. It requires appropriate speeds and feeds for good chip breaking to form clean and precise parts. However, it is challenging to maintain accuracy on intricate profiles and to prevent tool wear

Custom CNC Machining 6063-T5 Solutions

If you are looking for supplier who offers custom machining services for your next 6063-T5 aluminum project, then Tuofa offers solutions for all your problems. Tuofa offers engineering support with design of manufacturability and strict quality control during and after production. Contact us today for expert solutions and a fast quote!

Is 6063 Good for Bending?

Yes, 6063 aluminum is very good for bending. It provides excellent formability and requires smaller bend radii than harder metals. It can easily adapt any complex shapes because softer tempers like 6063-O or -T5 bend better than harder temper like 6063-T6.

Is 6063 Easy to Weld?

Yes, 6063 aluminum is easy to weld. It gives excellent performance in TIG and other arc welding processes. Good weld quality and minimal deformation make it ideal for use where aesthetic matters. However, welding reduces strength in the heat-affected zone, but it can often be restored with post-weld heat treatment.

6063-T5 Welding Process

Welding 6063-T5 aluminum is common in architectural and structural uses. It primarily uses MIG (GMAW) or TIG (GTAW) with ER-5356 filler. It needs thorough cleaning to remove oxidation, argon shielding gas, and careful heat control due to high thermal conductivity of aluminum. Welding often uses AC for TIG to break the oxide layer and DC for MIG to have good fusion and to retain strength in joints.

Common CNC 6063-T5 Parts & Applications

6063-T5 are commonly used in automotive, structural and electronics parts. because they offer high surface finish, good corrosion resistance, easy extrusion, a medium strength and lightweight alloy.

Automotive Parts

6063-t5 is used in heatsinks for LED lighting, engine cooling system and radiator. It has lightweight supports for various components like brackets and mounts.

Structural Components

The most common application of 6063-T5 is architectural parts like window frames, door frames, curtain walls, railings and decorative trims. It is also utilized in solar panel frames and furniture like shelf brackets or frames. 6063-t5 is used in irrigation tubing too due to its corrosion resistance.

Electronics and Consumer Products

High thermal conductivity makes it suitable for use in heat sinks for dissipating heat in electronics. Consumer products like device casing and housing and other electronics that need a good finish. 6063-T5 is also used for custom parts for lighting, appliances, and high-end goods.

6063-T5 vs 6063-T6 vs 6061-T6

6063 alloys are better in aesthetics, and 6061 are great for structural use but are more expensive. A brief comparison among 6063-T5, 6063-T6 and 6061-T6 are as:

6063-T5 vs 6063-T6 Properties

The difference between T5 vs T6 in their:

Processing: T5 is cooled from high temperature and artificially aged, while T6 is solution heat-treated or quenched and then artificially aged at higher temperatures.

Strength: T6 is stronger in strength than T5 and is harder. While T5 offers better formability and easy machining. T6 is hard to machine.

Surface: T5 is preferred for aesthetics but T6 also has good surface quality.

6063-T5 vs 6061-T6 Performance

6063 and 6061, both are Al-Mg-Si alloys but 6061 has higher levels of magnesium, silicon and copper (Cu). This makes it harder and more expensive but difficult to extrude than 6063.

Strength: 6061-T6 is stronger than 6063-T5.

Machinability: 6061-T6 have higher machinability due to higher hardness.

Extrudability: 6063 is easier to extrude into complex shapes than 6061.

Cost: 6061-T6 is more expensive due to higher alloying elements.

|

Features |

6063-T5 |

6063-T6 |

6061-T6 |

|

Strength |

Lower |

Medium |

High |

|

Extrudability |

Excellent |

Very Good |

Difficult |

|

Surface Finish |

Excellent |

Very Good |

Good |

|

Machinability |

Good |

Moderate |

Excellent |

|

Applications |

Architectural, decorative |

Higher strength architecture |

Structural |

When to Choose 6063-T5

6063-T5 is used for architecture, heat sinks, piping, and furniture frames. It is chosen because of high surface quality, superior anodizing, extrudability, and corrosion resistance. However, it has lower strength than 6061.

6061-T5 and 6061-T52

6061-T5 is artificially aged for good strength and balanced properties. While 6061-T52 is naturally aged at room temperature. The biggest difference is that T5 has better strength and T52 has potentially better ductility. But they're very close and often interchangeable in many structural roles.

What Is the Difference between 5052 and 6063-T5?

5052 is a magnesium alloy and is non-heat treatable. It has better corrosion resistance, formability, and fatigue strength than 6063.

6063-T5 is silicon-magnesium alloy and is heat-treatable. It has higher extrudability, surface finish, but lower corrosion resistance than 5052. But both alloys have lower strength than 6061.

Design Tips for 6063-T5 Aluminum Parts

6063 is selected where a combination of formability, corrosion resistance, and aesthetic appeal is required. It has moderate strength, so not suitable for high-stress parts.

Wall Thickness and Corner Radius

Minimum wall thickness can be achieved in 6063-T5 is 1.5-3mm for general parts. thick section must be consistent to reduce stress and machining challenges. Thicker walls have better rigidity for machining and holding the part.

Internal corner radii must be at least the radius of end mill being used. This avoids stress risers and hard cutting. Largest radius 3-6mm or larger is better for tool life, chip evacuation, and strength.

Features for CNC Machining

Some tips for common CNC machining features:

For holes (tapped) thread depth of 1.5-2x thread diameter and thread class 2B is used. Use heli-coils are for deeper or high-cycle threads.

Add chamfers to edges and holes to ease assembly and prevent burs catching.

Design tabs, pockets, or dowel pin holes to precisely locate parts during assembly.

Features for Assembly and Joining

6063 has good weldability and brazeability. Consider these for permanent joints if machining is not the only method.

What Surface Finish Can You Choose for 6063-T5?

6063-T5 can be surface finished with mill finish, anodizing (silver, black, bronze, gold, custom), hard anodizing, brushed, polished (mirror/bright), powder coating, and wood grain effects.

Affecting Factors

Common affecting factors for aluminum alloy 6063-T5 are aesthetics, durability, corrosion resistance and application.

- For aesthetics, anodizing offers a range of colors options and polishing gives high gloss.

- Anodizing and electroless nickel plating also offers high corrosion resistance.

- For higher durability, hard anodizing offers high wear resistance and best for functional parts.

- For architectural applications, anodizing and for high-wear hard anodizing is used.

Anodizing 6063-T5 Aluminum

Anodizing is an electrochemical process that improves the aluminum's natural oxide layer with higher durability and finishes. It can be different type: natural, colored and hardcoat. Anodizing offers corrosion and UV resistance, scratch resistance with wide color options for 6063-T5.

Electroless Nickel Plating 6063-T5 Parts

Electroless nickel plating is a chemical decomposition of nickel-phosphorus alloy layer. It forms a uniform coating even on complex shapes to increase hardness, wear resistance, corrosion protection in 6063-T5 parts.

Other Surface Treatments for 6063-T5

Other treatments for 6063-T5 are powder coating with dry powder, polishing or buffing to make reflective and mirror-like finish, bead and sandblasting for matte or textured surface and chemical brightening before anodizing for a brighter, clearer finish.

Conclusion

6063-T5 aluminum has high extrudability, corrosion resistance, and smooth finish. 6063-T5 has fair machinability and is prone to built-up edge. It has most of the applications for architectural parts where appearance matters due to smooth surface after extrusion and anodizing.

FAQs about 6063-T5

Is 6063 T5 strong?

Yes, aluminum alloy 6063-T5 has medium strength with a good balance of lightweight and moderate structural integrity.

Is 6063 good for bending?

Yes, 6063 is good for bending and is preferred over harder 6061 alloy due to its excellent formability.

What is the strongest grade of aluminum?

The strongest aluminum grades are present in the 7xxx series. For example, 7075 is widely recognized for its exceptional strength.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What Is 40Cr Steel? A Complete Guide for You

What Is 40Cr Steel? A Complete Guide for You