Nitriding Steel: Importance, Comparison, Applications & CNC Machining

Dec 16,2025

Dec 16,2025

Nitriding perfectly complements CNC machining by adding hard nitride layers on complex shaped steel parts. This creates superior and long-lasting parts for aerospace, automotive and tooling. However, some challenges occur in Nitriding steel like alloy selection, distortion control or corrosion resistance. To know more about nitriding steel for your next project, this article will give you deep insights into the topic. So, let's dive in!

What Is Nitriding Steel?

Nitriding steel refers to specialized alloy steels that form hard nitrides when surface-hardened by diffusing nitrogen into them. Commonly used steels, for nitriding, are heat-treatable and have nitrogen absorbent elements like Al, Cr, Mo, and V. The resultant steel is called nitrided steel after this nitriding process.

Nitriding Steels and Nitridable Alloy Steels

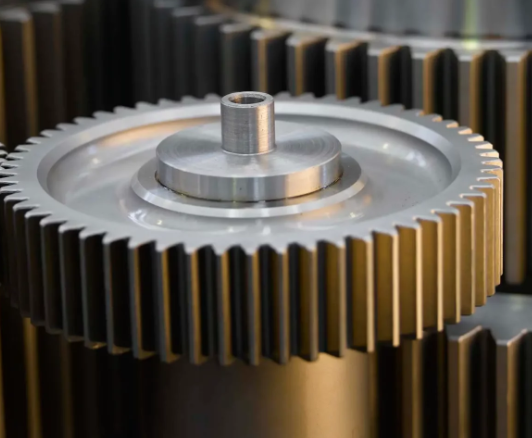

Key grades of nitriding steel are 15CrMoV, Nitralloy steels, and 4140 steels. Nitirided steel has an extremely hard, wear-resistant case layer with a tough core. The purpose of the nitriding process is to increase hardness, fatigue, and corrosion resistance for parts like gears, shafts, and dies. While nitridable steels are broader and include tool steels, stainless steels, and cast irons that can also undergo nitriding to improve their performance.

Why Nitriding Steel Matters in Machined Parts?

Nitriding steels matter in machined parts because they have a super-hard, wear resistant case on their surface. This improves durability, fatigue life and corrosion resistance without distorting parts' precise dimensions. Nitriding steels are perfect to make precision parts like shaft, gears and molds for automotive, aerospace, and tooling industries.

Advantages of Nitriding Steels

After learning about the importance of nitriding steels, we also need to explore the advantages of them, which are key considerations for engineered components. Nitriding steel offers major advantages like high hardness and fatigue resistance. Following are main benefits of nitriding steel after the nitriding process:

Superior Surface Hardness

Nitriding dramatically increases the surface hardness up to 900-1200HV. It forms hard nitrides like Fe₄N and Fe₂-₃N by diffusing nitrogen into the surface. This creates a hard case layer while maintaining the core's toughness. And in turn, it enhances the hardness of nitrided steel and creates a strong and resilient component.

Great Abrasive Resistance

The drastic increase in the hardness of nitrided steel directly transforms into remarkable wear and abrasion resistances. They become ideal for high-friction applications like gears and bearings.

High Fatigue Strength

Nitriding introduces beneficial compressive residual stresses in the surface layer of nitriding steels. This increases the fatigue life of components by up to 50%. And steel can survive cyclic loadings without failure.

Resistant to Deformation

Nitriding is done at relatively low temperatures at 480-580°C. This range is below the steel's transformation temperature. Therefore, it causes minimal or no distortion and dimensional changes to the component.

Disadvantages of Nitriding Steel

There are few drawbacks associated with Nitriding steel that make it not ideal for all the applications. These drawbacks are:

Brittle Nitrided Layer

The outermost compound layer has hard (ε) nitride phase. This is very brittle in nature, having low impact toughness and prone to spalling under impact. It also increases the surface roughness which needs extra polishing steps.

Low Productivity

Nitriding of steel can take many hours like 10-100+. This makes it slower and costly than the other surface treatments like carburizing. This overall lower the productivity of the process

No Aesthetic Appearance

The resulting dark and matte finish of nitriding steels due to hollow cathode effect, especially in plasma nitriding. This is not suitable for decorative parts. This limits the nitride steel use where appearance is critical.

Not Suitable for Welding

Ater nitriding, the steels cannot bear the high temperature. And high temperatures during welding can temper the hardened case or cause cracking. Therefore, nitride steel requires careful post-weld heat treatment or avoidance.

Nitriding Steel Grades Comparison

As mentioned above, nitriding alloys contain elements like Al, Cr, Mo, V, Ti. These elements are present different in content which alter the properties of steel like surface hardness, wear resistance, and fatigue strength. These features are crucial for precision parts in CNC machining. Details about nitridable steels are mentioned below

Common Nitriding Steel Grades

Common nitriding steels grades are 34CrAlNi7, 31CrMoV9, and Nitralloy 135M/N. They all have different properties via nitrogen hardening and depending on specific grades.

- 34CrAlNi7

This is a common European nitriding steel with Chromium, Aluminum, and Nickel. It has high hardness, wear resistance, and good core strength through nitriding. Common applications for 34CrAlNi7 are gears, crankshafts, and automotive parts.

- 31CrMoV9

It contains Chromium, Molybdenum, and Vanadium. Nitriding increases its strength, toughness, and wear resistance. 31CrMoV9 is ideal for heavily stressed parts like gears, shafts, and crankshafts.

- Nitralloy N,1,2

These are aluminum-containing steels and Nitralloy has small amounts of Vanadium. These are designed for maximum surface hardness and fatigue life. Nitralloys are perfect for tools, dies, aerospace parts, and high-wear automotive parts.

|

Grades |

Key Alloying Elements |

Primary features |

Hardness (HRC) after nitriding |

Common Applications |

|---|---|---|---|---|

|

31CrMoV9 |

Cr, Mo, V |

High Strength & Toughness, Wear Resistance. |

50-60 |

Gears, Shafts, Crankshafts, Heavily Stressed Parts. |

|

34CrAlNi7 |

Cr, Al, Ni |

Excellent Wear, High Surface Hardness. |

55-65 |

Automotive Parts, Dies, Tools, Gears. |

|

Nitralloy N |

Cr, Al, V, Mo |

Extreme Surface Hardness, High Fatigue Strength. |

55-65 |

Aerospace, Dies, Tools, High-Wear Parts. |

|

Nitralloy 135M |

Cr, Al, Mo |

Good Toughness with High Hardness. |

50-60 |

Gears, Crankshafts, Camshafts. |

Nitridable Alloy Steels Grades

Nitridable steel is a broader term that is used for alloy or non-alloyed steels that can react with nitrogen during the process. Tool steels, stainless steels are common materials that can be nitrided. Common nitridable alloy steels are 31CrMo12, 41Cr4, 42CrMo4 and others explained below:

- 31CrMo12 Steel

It is a general-purpose nitriding steel containing Cr and Mo. It has good wear resistance and core toughness which is useful for various machine parts.

- 41Cr4 Steel

It is chromium-based steel, suitable for nitriding. It has high wear resistance and is commonly used in shafts and gears.

- 42CrMo4 Steel

It is very common steel with good core strength and toughness. 42CrMo4 is widely used for gears, shafts, and spindles.

- 20CrMoS4 Steel

It is a sulfurized version of 20CrMo. 20CrMoS4 has improved machinability for complex parts that still need nitriding.

- 20NiCrMo2-2 Steel

It is a Nickel-Chromium-Molybdenum steel which has high hardenability and toughness. 20NiCrMo2-2 is mostly used for gears and critical components.

|

Grades |

Key Alloying Elements |

Primary Properties |

Hardness HRC After Nitriding (Approx.) |

Common Applications |

|---|---|---|---|---|

|

31CrMo12 |

Cr, Mo |

High strength, good machinability, toughness, wear resistance |

58-63 HRC |

Plastic injection moulds, die casting dies. |

|

41Cr4 |

Cr, Low Mo |

Good strength, hardenability, wear resistance |

54-59 HRC |

Gears, shafts, automotive parts, tools. |

|

42CrMo4 |

Cr, Mo |

High tensile strength, fatigue strength, impact resistance |

57-61 HRC |

Crankshafts, gears, axles, bolts, heavy machinery parts. |

|

20CrMoS4 |

Cr, Mo, S |

Enhanced machinability, good wear, strength |

50-55 HRC |

Gears, splining shafts, high-wear components. |

|

20NiCrMo2-2 |

Ni, Cr, Mo |

Excellent core toughness, good wear resistance, ductility |

57-61 HRC |

Gears, bearings, shafts |

Key Factors for Choosing Nitriding Steels

From the above content, we can know that nitriding steels have many different grades. Then which material is your best choice? Actually, the right selection of Nitriding steel based on applications needs, mechanical performance, environmental resistance and machinability of steel.

Machining Requirements

When choosing nitiriding steels, difficult to machine or not is an important factor. Dimensional accuracy and component complexity should be considered as well. Nitriding steel 4140 is known for good machinability before nitriding. Low temperature in nitriding reduces warping as compared to what happens in case hardening. But precise parameters are important for consistent results in large geometries.

Application Requirements

The application requirements are based on mechanical properties and functionality of nitriding steel. for example, for high wear resistance, steels with Al, V like Nitralloy N, 31 CrMoV9 forms hard nitride increase surface hardness and resistance. Similarly, for high fatigue and impact strength Nitralloy 135M is suitable. Another important feature is high-temperature operation. Specific alloys like Nitrodur can retain its surface hardness up to ~500-550°C.

Environmental Factors

Corrosion and temperature are the most important environmental factors. Common Nitriding steels need extra protection in moist environments. Stainless nitriding steel can perform in humid places. And temperature decides nitriding process and operating limits. For example, standard gas nitriding is performed at 500-580°C, while soft nitriding is at even lower temperatures to minimize part distortion.

Budges and Costs

It includes total cost of nitriding process, which is material cost, processing time (long for gas nitriding), and life-cycle benefits (low maintenance due to wear resistance).

Applications for Nitriding Steels

Nitriding steels are commonly used in different industries for parts needing extreme hardness, wear resistance, and fatigue strength.

Mechanical Parts

Nitriding alloys are widely used in shafts, gears, cams, heavy-duty machine elements due to overall better strength, hardness, and service life.

Automotive Parts

Nitriding steels are used in gears, crankshafts, camshafts, valve parts, injectors, clutch components. They increase wear resistance and reduce engine maintenance of automotive parts.

Aerospace Components

Nitriding steels are used in landing gear parts, fasteners, and critical shafts. They improve fatigue life and safety under extreme loads in aerospace parts.

Industrial Equipment

Nitriding alloys are used in extrusion screws, plastic molding tools, forging dies, machine slides, spindles, shafts. They maintain dimensional stability and precision at high temperatures and stresses.

How to Machine Nitriding Steels?

Nitriding steels are widely used in many industries as mentioned. Therefore, cnc machining is indispensable technology for create nitriding steels parts.

Nitriding provides exceptional surface hardness. But, nitriding of steel at high temperature operation around 500-540°C and gaseous environment causes slight distortions and material changes. This means it is difficult to achieve final dimensions after hardening through simple cutting. Therefore, CNC machining of nitriding steel is divided into two stages:

- pre-nitriding machining for roughing out features,

- post-nitriding precision machining, for grinding and honing.

This is done to achieve final tolerances and surface finish on the hardened case.

Select Suitable Nitriding Steels

Choosing steel for nitriding like 4140 (Cr-Mo) or specialized steels like Ovako's Hybrid Steel that contain nitride formers like Al, Cr, Mo and V is the key step for desired case depth and hardness.

Define Machining Requirements

Define the requirements, for example, for roughing, machine to near-final dimensions. This will leave a slight stock allowance of 0.1-0.3 mm for post-nitriding grinding on critical surfaces. Before nitriding, create threads, keyways, holes, and sharp corners to avoid brittleness and can affect case growth.

Choose Suitable CNC Machining Methods

Common CNC machining methods used for nitriding steels are CNC milling and turning. Standard carbide and coated tools are used to remove material. drilling and boring are used to make holes. After nitriding, post treatment like grinding with CBN or diamond grinding wheels and honing are done to achieve final dimensional accuracy.

Surface Treatment

Normally, surface is cleaned and protective coatings of oil or passivation are applied to prevent the now-hardened surface from rusting before final assembly.

Choose Tuofa One-Stop Solution

A key step of customizing nitriding steel parts is to find a reliable supplier. Tuofa offers one-stop solutions from expert guidance to material selection, design optimization, rapid prototyping, precision CNC Machining to final surface treatment for your Nitriding steels project. We ensure your parts are highly optimized for performance and manufacturability.

Conclusion

Nitriding is a critical surface treatment for CNC machined parts. It diffuses nitrogen into steel to create a super hard layer that further increases the wear and fatigue resistances. It also improves corrosion resistance without significant dimensional change which is important for aerospace, automotive, and tooling applications. Nitriding occurs at lower temps (500-580°C) as compared to case hardening. This preserves the core properties and excels in dimensional stability which is ideal for complex and precision parts. Post-nitriding precision machining is applied to steels to increase dimensional accuracy and extend part's life significantly.

FAQ

What is nitriding stainless steel?

Nitriding stainless steel are those that can diffuse nitrogen into their surface at high temperatures to increase hardness, wear-resistance and corrosion resistance.

Is 4140 considered a nitriding steel?

Yes, 4140 steel is a very common nitriding steel. its chromium and molybdenum content promote the formation of hard nitride layers and improve surface hardness, wear resistance, and fatigue life.

Can 1018 steel be nitrided?

Yes, 1018 steel can be nitrided. But it is a low-carbon steel and cannot achieve the extreme hardness of high-alloy steels.

How to nitride steels?

To nitride steel, heat the alloy steel parts in a nitrogen-rich environment (like ammonia gas or plasma) between 500-600°C for hours. It allows nitrogen diffusion into the surface and form extremely hard metallic nitrides. These nitrides increase wear-resistant but causes minimal distortion.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

MIC 6 Aluminum: Properties, Machinability, and Best Uses

MIC 6 Aluminum: Properties, Machinability, and Best Uses