Standard Tolerance Grades IT5-IT8 in CNC Machining

Feb 04,2026

Feb 04,2026

In designs, geometry, or manufacturing, dimensions are everything. A little in any dimension can affect the efficiency or accuracy of the product to be employed in any application. Tolerances are defined to limit these changes to a certain value. International Standardization Organization (ISO) defines these tolerances. Various tolerance grades, used in designing and manufacturing, are discussed in this article.

What Are Standard Tolerance Grades IT5–IT8

IT5 – IT8 tolerance grades are defined by ISO, which allow permissible variations in the dimension. For instance:

- IT5 tolerance grade means a very low permissible variation in the dimension

- IT6 means high precision but relatively loose tolerances compared to IT5

- IT7 provides loose tolerances for general applications

- IT8 provides a greater range in the allowed variations

Engineering Tolerance Explained

Tolerance in engineering is all about how much variation is acceptable in any dimension. How well a part fits in the application and performs all depends on the engineering tolerance.

What Are Standard Tolerance Grades Mean?

These standard tolerance grades mean the level of permission given to make variations in the dimensions. The smaller the tolerance grade, the tighter the tolerance, e.g., IT8 means more allowed tolerance compared to IT5.

Tolerance Grade vs Dimension Size

Tolerance grade specifies the maximum allowable variation in the dimension. For instance, ± 0.01 mm is a tolerance value guided by a tolerance grade.

Dimension size is simply the size of the part in the design, such as 1.5 mm thickness.

IT Grades in the ISO 286 System

ISO 286 is an international standard that defines a system of limits and fits. It is mainly used in mechanical engineering. IT grades are defined by ISO 286, which further defines the permissible variation in the dimensions of the parts.

How to Calculate Machining Tolerances IT Grades?

Tolerance IT grades are made by ISO. In specifying these tolerance grades, proper calculation is performed. Let’s understand the calculations used in machining tolerance IT grades.

Important Terms

During calculations, these important terms are used:

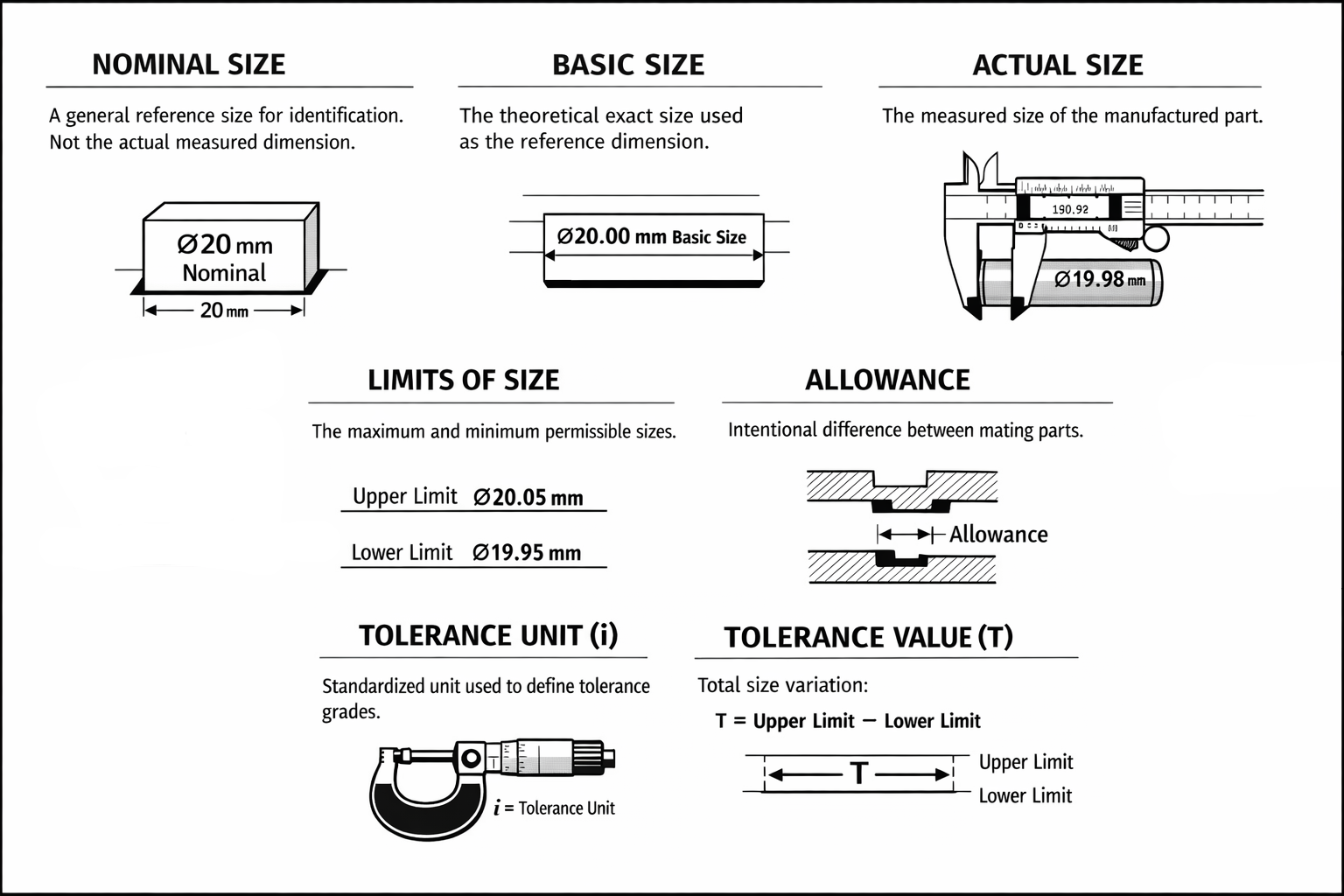

1. Nominal Sizes

A nominal size is a typical value of a dimension in engineering or drawings of a part. It is like 10 mm width is a nominal size, but the actual size can be 9.8 mm.

2. Basic Sizes

This is the initial size of a dimension in engineering or at the design stage, but it is the exact value based on which tolerances are specified.

3. Actual Sizes

The actual size of the part or a dimension is the final size, which is calculated after the manufacturing. For instance, if a shaft is manufactured and its diameter is 10 mm, it is the actual size.

4. Limits of Size

Limits of size in engineering or while specifying the dimensions mean the maximum size and minimum size a part should have. For instance, the diameter of a shaft should not exceed 10.2 mm, but should not be less than 9.9 mm.

5. Allowance

Allowance means allowed variation in the dimension of a part. For instance, 0.2mm in upper and lower sides is an allowance.

7. Tolerance Unit (i)

Tolerance unit can be in mm or µm, depending on the actual size of the part. For instance, ±0.1 m for a 10 m length.

8. Tolerance Value (T)

Tolerance value is the actual difference between the upper and lower limits of the dimension of a part. For instance, if:

10/+0.01 mm

10/-0.02 mm

- So, the tolerance value is 0.03 mm.

Calculation of Standard Tolerance Unit i (in µm)

ISO 286 formula for calculation of standard tolerance unit i in µm:

i = 0.45 * ∛D + 0.001 * D

Where:

- i= standard tolerance unit in µm

- D= geometrical mean dimensionin mm (for shafts/holes: √(D_max × D_min))

Example (quick calculation):

If D=50mm:

- ∛50=3.6

- 45×3.684=1.658

- Add linear term:001×50=0.05

- Sum: i=1.658+0.05=1.708 μm

Result: i=1.71 μm

From IT Number to Numeric Tolerance

Every IT number has a different numerical tolerance. If the IT number is IT7, then the numeric value will be 0.025mm. The smaller the tolerance number is, the higher the required precision.

IT5–IT8 Tolerance Values by Size Range

Tolerance grades IT5 to IT6 refer to a specific permissible variation range in the basic dimensions. Let’s figure out size ranges for these IT numbers based on different applications.

Typical IT5 and IT6 Ranges

For instance, a hole in the aerospace industry would require higher precision, so here, IT5 and IT6 tolerance numbers are employed.

|

Nominal Size (mm) |

IT5 (µm) |

IT6 (µm) |

Applications |

|

3 – 6 |

2 |

3 |

Precision shafts, small holes |

|

6 – 10 |

2.5 |

4 |

Small bearings, dowel pins |

|

10 – 18 |

3 |

5 |

Machine pins, bushings |

|

18 – 30 |

4 |

6 |

Medium shafts, housings |

|

30 – 50 |

5 |

8 |

Gears, pulleys |

|

50 – 80 |

6 |

10 |

Shafts, accurate couplings |

Typical IT7 and IT8 Ranges

IT7 and IT8 tolerance numbers provide higher permissible variation in the dimensions compared to IT5 and IT6. For instance, a tolerance value in machine frames.

|

Nominal Size (mm) |

IT7 (µm) |

IT8 (µm) |

Example Applications |

|

3 – 6 |

6 |

10 |

General holes, Standard shafts |

|

6 – 10 |

7 |

12 |

Pulleys, Bushings |

|

10 – 18 |

8 |

14 |

Housings, Shafts |

|

18 – 30 |

10 |

18 |

Cylinders, Medium gears |

|

30 – 50 |

12 |

21 |

Guide rails, Machine frames |

|

50 – 80 |

15 |

25 |

Couplings, Shafts |

IT5–IT8 Grades and Fits in Hole–Shaft Systems

ISO has designed a system of limits and fits for holes and shaft assemblies. For clearance, transition, and interference fits, the tolerance grades IT5, IT6, IT7, and IT8, etc., are used.

Common Fits Types

Three major fit types are:

- Interference fit

- Clearance fit

- Transition fit

These tolerance grades control the level of precision for each fit type. IT5-IT8 tolerance grades are essential to define precision. The position of the hole and the shaft tolerance zone define the fit type.

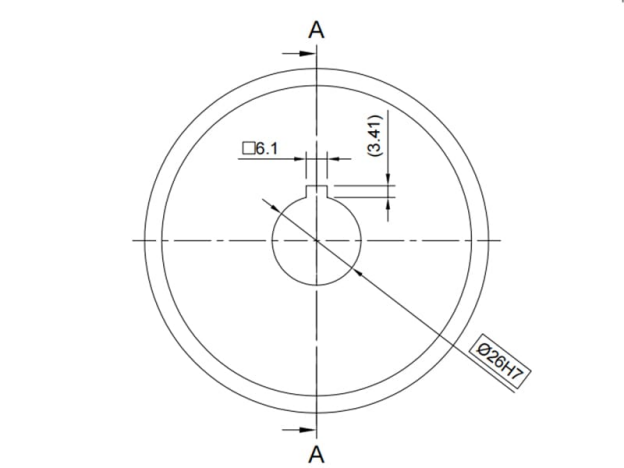

Common H7/h6, H8/f7, and Similar Pairs

H7

- H= hole system with respect to lower deviation= 0

- 7 means IT tolerance grade.

While h and f are shaft tolerance letters.

|

Fit Pair |

Hole |

Shaft |

Fit Type |

Typical Use |

|

H7/h6 |

H7: Hole, lower deviation = 0, IT7 |

h6: Shaft, upper deviation = 0, IT6 |

Close clearance/line fit |

Accurate location, sliding with minimal play |

|

H8/f7 |

H8: Hole, lower deviation = 0, IT8 |

f7: Shaft, negative deviation (shaft always smaller), IT7 |

Clearance fit |

Easy assembly, smooth rotation, or sliding |

Fits for Rotating and Sliding Parts

H-based fits with IT tolerance grades provide:

- Acceptable manufacturing cost

- Smooth motion

- Controlled clearance

That’s why they are used for rotating and sliding parts.

- H7/g6:

- It is a transition fit, which may result in slight clearance or slight interference, depending on the actual dimension.

- Applications include hubs, gears, and couplings

Machining Processes vs IT5–IT8 Capability

The tolerance grades have a great impact on the machining processes because they directly control the required precision of a part. For instance, if the IT5 tolerance grade is employed, it means ultra-high precision is required.

Turning, Milling, and Grinding

Common CNC/Lath machines processes include milling, turning, and grinding. For instance, to manufacture a shaft, the turning process is used. IT5 – IT8 tolerance grades are used during these processes according to the required precision. For instance:

IT5 Machining

IT5 grade tolerance means the ultra-high precision is required and is used in applications, such as instrument parts, high-accuracy shafts and holes, and bearing tips, etc.

IT6 Machining

The range of permissible variations in sizes is higher than IT5 in this tolerance grade, so the level of precision in machining is relatively lower than IT5. It is used for:

- Gear bores and gear shafts

- Pneumatic and hydraulic components

- Bearing seats

IT7 Machining

The level of precision in machining is relatively lower than IT6, so the higher permissible variations in the dimensions. It is used in:

- General machine parts

- Pump and motor components

- Automotive mechanical parts

IT8 Machining

In ISO tolerance grades, this IT number offers the highest range of sizes in tolerance. Its general applications include:

- Fabricated and welded assemblies

- Agricultural machinery parts

- Commercial mechanical assemblies

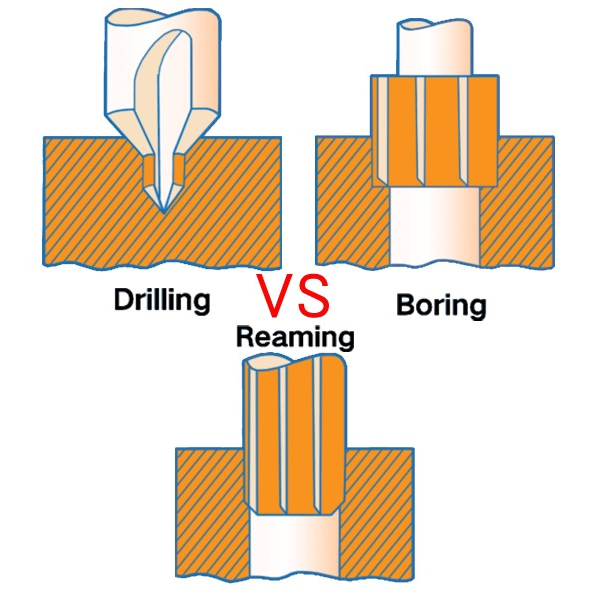

Reaming, Boring, and Honing

- Reaming: For finishing pre-drilled holes to achieve high precision

- Boring: To enlarge the existing holes

- Honing: To produce a cross-hatch surface pattern for oil retention

All these processes use tolerance grades (IT5 – IT8) to meet precision requirements.

When You Need Grinding to Reach IT5

Grinding can be used to reach IT5 tolerance grade, e.g.

- For hardened materials where other cutting operations are not effective

- Tight control over geometric accuracy is required

- Stringent surface finish requirements

International Tolerance in Different Industries

IT6, IT7, and IT8 are used to achieve higher accuracy of automotive parts during precision CNC machining.

IT5, IT6, IT7, and IT8 tolerance grades are used when ultra precision is required, e.g., medical parts.

IT7 and IT8 tolerance grades are used in industrial machinery components because, instead of precision, these components are more important for functional fit and durability.

IT6 and IT7 tolerance grades are commonly used for motion-critical robot parts, such as joint shafts, bearing seats, gearbox/reducer bores, couplings, transmission components, and end-effector interfaces in precision CNC machining. These tighter grades help control clearance and concentricity, reduce backlash and vibration, and improve repeatability after assembly. For non-motion structural parts (frames, covers, mounting brackets, guards), IT7 and IT8 are often enough because the priority is stable fit, durability, and fast assembly rather than ultra precision.

Choosing Between IT5, IT6, IT7, and IT8

Generally, it depends on the application in choosing between IT5, IT6, IT7, or IT8. The main difference in these grades is the level of precision achieved after a machining process. For instance, IT5 is related to ultra-high precision.

Main Affecting Factors When Choosing IT Grades

These are some important factors that affect when choosing an IT number during the design and manufacturing:

Functional Role

If the application is very critical, like an implant, then IT5 is fundamental to choose. So, the functionality is the fundamental role in choosing IT grade.

Fit and Assembly Type

If the fitting and assembly type is in the aerospace field, it means high-precision machining is required. So, either IT5 or IT6 tolerance numbers are used.

Material and Machining Process

Some materials, such as cast iron, are very difficult to machine with ultra-high precision, so the IT grade is chosen accordingly. Same for the machining process.

Other Custom Features

The custom features mean the design of the part is a little bit different from the standard design. For such features, custom machining is required.

For your projects, whether they need standard or custom features, TUOFA will provide you with technical improvements in the design and the best machining services. There are fully advanced machines at TUOFA with its expert operators. So, TUOFA is capable of providing ultra-high precision parts at the best prices and with the shortest delivery times.

Recommended IT Grades for Typical CNC Parts

The functionality of a part is critical when choosing the IT grade during the machining process. For instance:

|

CNC Part |

Typical IT Grade |

Functional Reason |

Impact of the Looser Tolerance |

|

General mounting holes |

IT7–IT8 |

Clearance fit, easy assembly |

Misalignment, uneven load |

|

Shaft for bearing fit |

IT5–IT6 |

Proper bearing seating |

Bearing creep, reduced life |

|

Sliding fit shaft |

IT6–IT7 |

Smooth motion, controlled play |

Vibration, noise |

|

Press-fit shaft |

IT4–IT5 |

Interference, no slip |

Slippage, loss of torque |

|

Gear bore |

IT5–IT6 |

Concentricity, load transfer |

Runout, gear wear |

|

Hydraulic/pneumatic bore |

IT4–IT5 |

Sealing, pressure retention |

Leakage, pressure loss |

Design Tips for Using IT Grades on Drawings

Certain factors, like where to use IT grades and direct limits, should be understood before designing or machining a part. These factors play an important role in achieving high-precision parts.

Where to Use IT Grades vs Direct Limits

When manufacturing is specified in a standardized way, especially if it is for fits or mass production, then it is important to choose IT grades in drawings.

When the parts are not standard or of unique design, and the quantity is low, direct limits are used in the drawings.

Combining with ISO 2768 and GD&T

IT grades alone cannot control the level of precision in machining. So, they are always combined with ISO 2768 and GD&T in drawings. For instance:

- IT grades control size variation

- ISO 2768 gives general tolerances for dimensions

- GD&T controls form, orientation, location, and runout

Design Tips for Your Custom Projects

When you customize your projects, focus on these factors:

- Know the function of parts in your project

- Use tolerance grades in a hierarchy

- Instead of naked IT grades, use standard fits

- Choose the IT grade with respect to the process capability

- Clearly define basic sizes, limits, and grades

TUOFA, which is best in providing components machined with tight tolerances, also provides a feasibility check before machining based on technical drawings within 24 hours.

The Tighter The Better?

Yes, a tighter tolerance means the part will be manufactured exactly according to the required drawing. There are no machining flaws that enhance the efficiency of the parts. So, compared to loose or relaxed tolerances, the tighter tolerances are more valuable.

Why Tight Tolerance Is Better? When Not?

Tight tolerance in every design does not increase the efficiency of the part. Tighter tolerance demands more careful, time-consuming, and advanced machining, which increases the expenses a lot.

Tight tolerance helps when you must control fit, alignment, interchangeability, and stable performance, especially for critical interfaces like bearing seats or press fits where the interference range matters. But it is not worth it for non-critical features: it can force extra setups, slower machining, higher scrap, and more inspection. The best rule is simple: tight where it protects function, standard where it doesn’t.

Tips for IT5–IT8 Grades Machining

These are some practically applied tips for machining the IT5 – IT8 tolerance grades:

Match IT Grade to Material

IT tolerance grades vary from material to material. For example, for a hardened or cast iron, the machinability is poor. So, generally, IT 7 or IT8 is chosen.

Keep Strict on Critical Features

While choosing the IT5 – IT8 tolerance grades, the feature of the workpiece should be considered. If the feature is critical, choose the smaller tolerance grade.

Tolerance Cost vs Machining Effort

Unnecessary tight tolerances add machining efforts and costs. So, tolerance should be selected with respect to machining effort.

Conclusion

The precision of a part is directly controlled by IT grades. IT grades are defined by ISO. These grades guide for permissible variations in the dimensions. The unit of tolerance depends on the basic size of a part, e.g., tolerance in mm if the basic size is 50mm. To avoid machining errors and maintain the efficiency of the parts, ISO 2768 and GD&T are used along with the tolerance grades. The factors, such as choosing the IT grade number with respect to the machining process, play a crucial role in achieving the tolerances while machining a part.

FAQs about IT Grades

What do IT5 and IT6 mean in practice

In practice:

- IT5 means ultra-high precision

- IT6 means high precision

How do IT grades relate to H7 and h6 fits

- H means hole

- h means the shaft

- 7 and 6 define the IT grade

For instance, H7 means IT7 tolerance grade for a hole.

What IT grade can standard CNC machining achieve

IT7 and IT8 tolerance grades can be achieved by standard CNC machining.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What Is An Electrical Bus Bar? A Complete Engineering Guide 2026

What Is An Electrical Bus Bar? A Complete Engineering Guide 2026