Contract Manufacturing: How It Works and How to Find One

Jan 30,2026

Jan 30,2026

Contract manufacturing has a vital role in global supply chains. It helps those businesses to collaborate with other companies in order fulfilling which may not have sufficient resources or funds to invest in heavy machinery. Contract manufacturing operations have many benefits like cost-effectiveness, operational efficiency and others that are discussed in detail in this article along with other important aspects.

What Is Contract Manufacturing?

Contract manufacturing is basically a strategic and outsourced partnership. In this, a third-party who is a specialized manufacturer and produces goods, parts, or components based on a hiring company's designs and specifications. It is also called outsourced manufacturing, contract fabrication, or private label manufacturing.

Contract Manufacturing Definition

Contract manufacturing is defined as a business model where a client firm hires a contractor to manufacture components or end-products under the client's brand. It works like client provides blueprints, specifications, and quality standards. And the manufacturer takes care of material sourcing, assembling, and packaging.

Contract Manufacturing vs In-House Production

Contract manufacturing has lower capital investment and access to specialized expertise. It has faster production scaling with minimum overhead. However, there is no direct control over daily operations and has potential intellectual property risks.

While the In-house manufacturing gives full control over quality with production speed and design privacy. But in-house making needs high capital investment, managing labor, machinery, and facility maintenance.

Will You Need a Contract Manufacturing Machining

Contract manufacturing machining is needed when you want to reduce costs while maintaining high quality in custom parts production. This occurs when you need low to medium volume production, require specialized equipment like 5-axis milling, limited internal resources, prototyping and quick turnaround and higher precision and quality control.

Main Types of Contract Manufacturing

Contract manufacturing has a broad scale of services. It ranges from outsourcing simple parts to assigning the entire production process. These arrangements are classified by their scope of services. All have different levels of control, customization, and involvement for the hiring company.

Component and Parts Manufacturing

In this approach, a specialized third party produces specific parts. Then, hiring company assembled these parts into a finished product. This model is best for businesses that need high-precision manufacturing or parts machining and for flexible production volume like small batch or large batch.

Private Label and White Label Production

In these models, the manufacturer creates finished products that are branded by the client. In private label, the manufacturer produces goods exclusively for one client. And in white label, manufacturers produce generic or already available products that are sold to multiple retailers.

Labor-Only and Capacity Subcontracting

In this model, a company has the design and materials but lacks labor or machines. In labor cost, the manufacturer provides skilled labor to perform specific tasks. And in capacity subcontracting, manufacturers take on a portion of the production process.

Full Turnkey and End-to-End Manufacturing

The turnkey supplier manages the entire product development and production process. And in End-to-End management, the turnkey supplier takes full responsibility for the supply chain. It often gives feedbacks to optimize the product design for manufacturing.

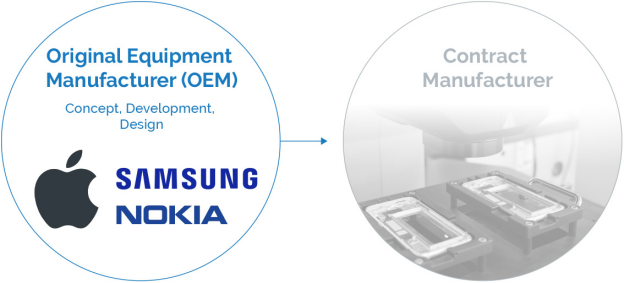

OEM and ODM Manufacturing

OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) are primary contract manufacturing models. They are classified by which party who owns the design, intellectual property (IP), and R&D effort. In OEM, there are branded manufacturers, who produce goods based on the client's exact design, specifications, and branding. And in ODM, manufacturers develop their own designs for products. These are then sold to other companies, who label them as their own.

Contract Manufacturing vs OEM and ODM

Contract Manufacturing is a broader term. In this, client hires a manufacturer to produce goods and also provides the exact design. It is often in high-volume and specialized manufacturing. While Toll Production (OEM or ODM) is a specific type of contract manufacturing operation. The client provides the raw materials to the manufacturer, who charges only for the conversion/processing services.

Is Apple an OEM or ODM?

Apple is an OEM. Apple research, designs, and develops its products in-house, retaining all IP and design rights. Because it does not use pre-designed or generic products from a factory catalog.

Custom Manufacturing

Custom manufacturing is used for special needs that differ from generic products. It focuses on creating unique parts made with specific requirements like custom CNC machining or on-demand manufacturing.

Toll Manufacturing vs Contract Manufacturing

Toll manufacturing and contract manufacturing are both outsourcing methods used to control external production facilities. They both some similarities and differences which are discussed below:

Similar Features

The similar features of toll and contract manufacturing are they both are outsourcing production, access to expertise and specialized equipment and have scalability. They are focused on core competencies like can hire companies to focus on branding, marketing, and sales

Biggest Differences

The differences between these productions are more than their similarities which are:

|

Feature |

Toll Manufacturing |

Contract Manufacturing |

|

Raw Material Supply |

Client supplies raw materials. |

Manufacturer sources materials. |

|

Ownership |

Client has the retains ownership |

Manufacturer owns materials until finished. |

|

Control |

High control over and quality |

Lower control. |

|

Pricing |

Pay a fee |

Have bundled per-unit cost. |

|

IP Protection |

High |

Risky |

|

Logistics |

Client manages transportation |

Manufacturers handle logistics. |

When to Choose?

Toll manufacturing is chosen when client:

- Owns propriety formulas

- Controls the supply chain

- Needs to control quality

- Needs specialized equipment

- Needs cost transparency

And contract manufacturing is chosen when client:

- Wants a "Turnkey" solution

- Needs speed to market

- Wants to minimize responsibility

- Launches a new product

- Lacks supply chain infrastructure

How Contract Manufacturing Works Step by Step

Contract manufacturing is a strategic partnership. In Custom CNC machining contract manufacturers handle everything from prototyping to full-scale production. The step-tp-step guide of this manufacturing involves CAD data to produce components via milling, turning, or 5-axis machining.

CNC RFQ Process

The process starts by providing the manufacturer with the necessary data, like a CAD file with STEP (.stp) or IGS (.igs) formats for CNC milling and turning. The technical drawings (PDF, DWG, or DXF) have information like tolerances, thread specifications, surface roughness, and GD&T. This also has information on material and quantity.

DFM Reviews & Suggestions

Before final quotation, the manufacturer performs a DFM (Design for Machining) review. This optimizes the part for efficiency and cost reduction to perform feasibility check before quotations. Normally the DFM suggestions are like:

- Adding fillets to internal corners to match standard tool radii.

- Reducing depth-to-width ratios in pockets to reduce tool chatter.

- Relaxing tolerances to reduce costs.

Prototype CNC Machining

After the design validation, the manufacturer does prototype production to test fit, and function before production. For example, aluminum prototypes to check functional testing due to, light weight, medical prototypes to check extreme precision and tight tolerance of implants

Production of CNC Machining

After prototyping, the process moves to production. They can be in small batch parts that is Ideal for low to medium volume and for custom production that uses 3-axis, 4-axis, or 5-axis machines to create complex geometries.

Inspection and Delivery

It is the final quality control and logistics. During inspection. The manufacturer verifies the part meets the tolerances specified in the technical drawings. And then finished parts are packaged and shipped.

Benefits of Contract Manufacturing for Your Business

Contract manufacturing allows businesses like CNC machining to outsource the production of parts or finished goods to a third party. This model is highly beneficial for high-precision CNC machining processes without the need for massive capital investment. Other operational, financial, and technical advantages are also significant.

Advantages of Contract Manufacturing

The advantages of contract manufacturing products are:

- It reduces costs by eliminating need to buy or maintain machinery.

- Has access to advanced technology like multi-axis CNC machining from contract manufacturing company

- Improved product quality

- Faster time to market

Flexibility and Scalability

Contract manufacturing provides the ability to adapt to market fluctuations without the risks. It also allows for rapid scaling, and high or low volume production.

Pros of Contract CNC Machining

Contract CNC machining offer benefits regarding creating precise and high-quality metal or plastic components.it provides:

- Unmatched Precision and Consistency

- Easy complex part production

- All day production capacity

- Reduced waste

What are The Disadvantages of Contract Manufacturing for a Company?

The drawbacks associated with contract manufacturing are:

- No direct control

- Intellectual Property (IP) risks:

- Communication gaps

- flexibility limitations

- Higher potential for hidden costs

How to Find a Contract Manufacturer?

The process works with identifying the requirements, researching manufacturers, conducting feasibility studies, and auditing the best facilities before the agreement.

List Your Requirements

To find a suitable manufacturer, define your projects with:

- Technical Specifications and CAD drawings

- Production Volume

- Budget and Costs

- Certifications and industrial standards

What to Look for When Choosing Ones

When looking for contract manufacturer, consider the following:

- Relevant Experience

- In-House Manufacturing

- Feasibility Check or DFM Support

- IP Protection

- Capacity and Scalability

- Financial Stability

Top 10 Contract Manufacturers in The World 2026

The global contract manufacturing market is dominated by large-scale Electronics Manufacturing Services (EMS) firms, semiconductor foundries, and the pharmaceutical sector.

Who Are the Biggest Contract Manufacturers?

Based on industry data for 2025–2026, the following table lists the top 10 contract manufacturing companies.

|

Rank |

Manufacturer |

Primary Industry |

Major Manufacturing Methods |

|

1 |

Foxconn (Hon Hai) |

Electronics/EMS |

High-volume Assembly, Injection Molding, CNC |

|

2 |

TSMC |

Semiconductors |

Wafer Fabrication, Advanced Packaging |

|

3 |

Flex Ltd. |

Electronics/Medical |

Design-to-manufacture, Automation, PCB Assembly |

|

4 |

Jabil Inc. |

Electronics/Medical |

Product Design, Precision Machining |

|

5 |

BYD Electronic |

Electronics |

Mobile Devices, Automotive Electronics, |

|

6 |

Pegatron |

Electronics |

Consumer Electronics, IoT, |

|

7 |

Sanmina Corp. |

Electronics/Medical |

PCB Fabrication, High-precision |

|

8 |

Lonza Group |

Pharmaceuticals |

Bioprocessing, Cell and Gene Therapy, API Synthesis |

|

9 |

Celestica Inc. |

Electronics/Aerospace |

Low-volume EMS, Systems Integration |

|

10 |

Tuofa CNC Machining |

Motorcycle/Medical/Industrial/Automotive |

Precision custom CNC machining, metal and plastic machining |

**Data taken from industry reports and real customer testimonials.

Contract Manufacturers in USA/CA

The top contract manufacturing company in USA/CA is:

- Jabil Healthcare:Known for end-to-end manufacturing.

- Phillips Medisize:for diagnostic, drug delivery, and medical device components.

Contract Manufacturers in China

The one of the tops contract manufacturers in China are:

- Quasar:for precision electromechanical and mechanical medical devices

- Tuofa CNC Machining:for rapid prototyping tests, providing high-precision CNC machining services.

Tuofa CNC Machining is a contract manufacturer based on Shenzhen, Guangdong. For nearly 20 years, Tuofa has earned its reputation through high-quality service and integrity. Long-standing customers are willing to recommend Tuofa's contract manufacturing services to their friends. Many international companies also choose to trust us and visit our factory in person.

Contract Manufacturers in German

A well-known contract manufacturer in Germany is:

- Gerresheimer AG:leading global partner for the pharma and biotech industry.

Contract Manufacturing for Custom CNC Parts

Contract manufacturing for custom CNC parts provides precision and material versatility. Companies can create functional components directly from digital files without expensive molds.

What Parts Are CNC Machining Best for?

CNC machining is best for parts that need high precision, tight tolerances and superior surface finishes. These parts are:

Rapid Prototyping

Rapid prototyping through CNC allows for quick and iterative development. It makes design to a physical part like medical prototypes for surgical tools or implant and aluminum prototypes for automotive and aerospace testing

Structural Parts

CNC machining is best for functional and structural components. It is used for parts that need structural integrity, wear resistance, and high load-bearing capacity during services.

Complex Parts

5-axis CNC machining can create highly complex geometries, such as impellers, turbine blades, and orthopedic implants in a single setup. The 5 Axis machining robotic joints helps in achieving extremely tight tolerances and improves accuracy.

Custom Part Solutions

Contract manufacturers like Tuofa outsourcing services provide tailored solutions for specialized requirements. These are high-mix and low-volume production, diverse material handling and End-to-End services.

DFM Support from Contract Manufacturers

DFM support is important in reducing costs and production time. Contract manufacturers provide design optimization by identifying potential issues and material selection by recommending the best alloys for application.

When to Use CNC Contract Manufacturing vs Other Processes

- Choose CNC: When you need accuracy, strength and material variety, for small-to-medium batches.

- Choose 3D Printing: For early-stage, complex, or prototypes.

- Choose Injection Molding: Only for high-volume production

Is Contract Manufacturing Risky?

Yes, contract manufacturing is inherently risky. It involves compromising direct control over the production process to a third party. Common Pitfalls of Contract Manufacturing are quality inconsistency, intellectual property (IP) theft, communication gaps, hidden costs and supplier dependency and delays.

To mitigate these risks:

- Sign Comprehensive Contracts (NDAs)

- Implementing Precise Quality Agreements

- Conduct On-site Audits and Inspections

- Start with Pilot Runs

- Use Split up Manufacturing

- Maintain Clear Communication Practices

- Expand Suppliers list

Conclusion

Contract manufacturing is a business model. In this, a company outsources the production of components or products to a specialized manufacturer. The client maintains ownership of the design and intellectual property (IP). And the manufacturer provides expertise, labor, and machinery for production. Top contract manufacturers of the world are Foxconn (Hon Hai), Jabil Inc., Celestica Inc., Plexus Corp., Phillips Medisize, Sanmina Corp. and more. Tuofa CNC Machining will provide Top quality custom services to countries all over the world.

FAQs

How does a contract manufacturing agreement work?

It is a legally binding arrangement. The client outsources the production of its goods to a third-party manufacturer based on the client's specifications.

Is contract manufacturing the same as outsourcing?

It’s not exactly the same as outsourcing, but rather a specific type of it. Outsourcing is the broad business practice for any task. And the contract manufacturing strictly refers to outsourcing the production of components to specialized manufacturers.

Does Apple use contract manufacturing?

Yes, Apple greatly uses contract manufacturing for its products.

What is a contract manufacturer FDA?

A contract manufacturer FDA is a third-party firm. It produces medical devices or drugs on behalf of another company according to Food and Drug Administration regulations.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Guide for Custom Bumper Latches: Types, Functions & CNC Machining

Guide for Custom Bumper Latches: Types, Functions & CNC Machining