Rough CNC in Machining: How to Machine Parts?

Jul 18,2025

Jul 18,2025

Rough CNC in machining is employed for quick material removal and for improving production efficiency. After that finishing is done to further improve the surface quality of workpiece. But rough CNC is important to understand to cope up with actual application scenarios and to apply optimization strategies in CNC machining. This article will help to explore all the details of Rough CNC in machining including its purpose, tooling and process parameters. So, let’s dive in!

What is CNC Roughing?

It is the initial process of material removal in CNC machining. It is designed to remove large amounts of material quickly from a workpiece to shape it desired form. Precision is not a priority in this step as it prioritizes speed and efficiency over precision and leaves a small amount of material for later finishing operations.

What Is the Process of Roughing CNC?

The process of rough machining involves using robust cutting tools like Rough CNC Milling & Machining or Rough boring at high speed and feed to remove large amounts of material, shape it to final form and prepare it for finishing. It normally involves high material removal rates (MRR), large depths of cut, and high feed rates.

What Is the G Code for Roughing?

G-codes are used to cut along the Z-axis and leave some material for a finishing cut and to define parameters like depth of cut, the amount of retraction, and the start and end points of the part that is machined. The major purpose is to automate the process along a specified profile by breaking it down into multiple passes on a CNC lathe. Few examples of G7 codes for roughing are:

|

G7 code |

Purpose |

|

G71 |

Turning cycle |

|

G72 |

Facing cycle |

|

G73 |

Pattern repeating cycle |

|

G20/21 |

Define measurements |

|

G00 |

Rapid non-cutting movement |

|

G01 |

Linear cutting movements |

Common Rough CNC Toolpath Types

Some common rough CNC rough paths are facing, pocketing, contouring, and 3D roughing strategies.

Zig-Offset Pocketing

It is a very common roughing strategy in 2.5-axis CNC machining. In this, rough toolpath moves back and forth in parallel lines for material removal in a pocket area.

Plunge Roughing

It is also known as Z-axis milling. It utilizes the rigidity of the Z-axis (vertical) on a machine to remove material in deep cavities and for rigid mills.

Rest Cut Cleanup

It involves removing debris, cleaning surfaces, and sanitizing after a cutting operation.

Primary Goals of Rough CNC Operations

The primary goal of rough CNC machining is to quickly remove material and increase the material removal rate for tool protection in subsequent finishing operations and stabilize the parts.

Raise Material-Removal Rate

In roughing, speed and efficiency are prioritized for large material removal from workpieces. It is done by using larger cutting depths, higher feed rates, and faster spindle speeds. By optimizing the MRR reduces cycle times, overall productivity of the operation is maximized.

Protect Finish Tools

The bulk material removal in the rough saves the tool and the finishing tools can be spared from heavy wear and tear. This increases the tool life and allows to focus on achieving the required surface finish and dimensional accuracy.

Stabilise Part and Fixture

It is essential to securely hold the workpiece during roughing for accuracy. It also prevents damage from vibrations or forces exerted by the cutting tool. A stable setup reduces runout and helps to machine the part into desired shape and dimensions.

Pros and Cons of Rough CNC Machining

There are several advantages of rough machining:

- It offers a faster removal rate and reduces overall machining time.

- It is a cost-effective option.

- It can expose defects in the raw material and allow for correction.

- It improves tool life and finishing tools experience less wear and tear.

However, there are a few disadvantages of Rough CNC Machining:

- It offers a lower accuracy and only focuses on speed and material removal.

- Roughing leaves visible tools marks on workpiece.

- It is not suitable for the final parts and applications requiring a smooth surface or precise dimensions.

Material-Specific CNC Cutting Parameters

Some common CNC material used in roughing are as follows.

1.7075 Aluminum

7075 aluminum is known for its high strength, fatigue strength and corrosion resistance. However, it is susceptible to stress corrosion cracking. It has many applications in aerospace and high-performance applications. For CNC roughing, the cutting parameters of 7075 Aluminum are 350 m/min (surface speed), 0.15 mm/tooth (feed rate), 8 mm (depth of cut).

2.4140 Steel

4140 is a low-alloy steel and has a good balance of strength, toughness, and wear resistance. It is used in applications which require high strength, such as gears, shafts, and axles. For CNC roughing, the cutting parameters of 4040 steel are 170 m/min, 0.10 mm/tooth, 4 mm DOC.

3.Ti-6Al-4V

Ti-6Al-4V has high strength, corrosion resistance and is a lightweight titanium alloy. It is widely used in aerospace, medical implants, and other demanding applications. For CNC roughing, the cutting parameters of Ti-6Al-4V are 80 m/min, 0.06 mm/tooth, 2 mm DOC.

4.304 Stainless Steel

304 is a versatile austenitic stainless steel. It offers good corrosion resistance, weldability, and formability. It has most of the applications in food processing, chemical processing, and various architectural applications. For CNC roughing, the cutting parameters of 304 stainless steel are140 m/min, 0.10 mm/tooth, 3 mm DOC.

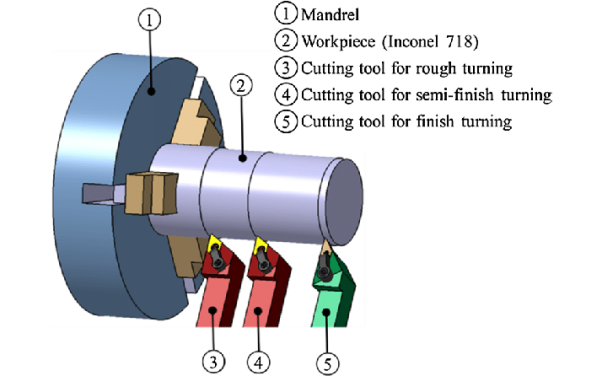

5.Inconel 718 (Ni-Alloy)

Inconel 718 is a superalloy and known for its high strength, excellent corrosion resistance, and high-temperature strength. It has many applications for aerospace engines and gas turbines. For CNC roughing, the cutting parameters of Inconel 718 are 60 m/min, 0.05 mm/tooth, 1.5 mm DOC.

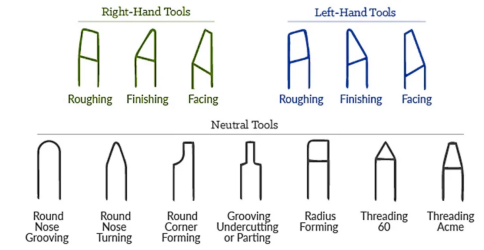

What Are the Major Roughing Tools?

Major roughing tools are indexable face mills and solid-carbide roughers. The details of these tools are as follows:

Indexable Face Mills

Indexable face mills create flat surfaces in roughing operations. They have a tool body that holds replaceable cutting inserts made of carbides. These inserts can be rotated or indexed to expose a fresh cutting edge when the previous one becomes dull and thus extends the tool's lifespan. The size and number of inserts can vary based on the specific application. For example, larger diameters and more inserts remove material fatly. Face mills are designed for roughing to remove bulk material quickly.

Solid-Carbide Roughers

These roughers are made entirely from solid carbide. They have high wear resistance and can easily maintain sharpness for a longer period. These roughers are commonly employed for aggressive material removal and are available in various shapes and sizes depending on the application.

What Are the Best Coatings for Tools?

The best and most effective coating for cutting tools is TiAlN which can deal with steel and high-temperature applications. It has high wear resistance and thermal stability, that works with higher cutting speeds and increases tool life. Other than that, TiN (Titanium Nitride) or DLC (Diamond-Like Carbon) are also used depending on the specific material and the machining conditions.

Roughing Fits in A Complete CNC Machining Process

A complete rough CNC machining process consists of a series of steps to get optimized results. These steps are as follows:

Step 1 - Stock Prep & Fixturing

This is the initial phase and raw material, or stock is prepared in this step and properly secured in the CNC machine's fixture. It helps to give accuracy and stability in machining throughout the process.

Step 2 - High-Efficiency Roughing CNC

This is the core stage of roughing and primarily focuses on bulk removal of material. The robust cutting tools like Rough CNC Milling & Machining or Rough boring are used with the goal is to quickly create a rough shape close to the final part, with no focus on precision or surface finish.

Step 3 - Semi-Finish (Datum Creation)

A precise datum (reference surface or point) is created on the workpiece in this stage. This point is used as a reference for following finishing operations and helps to attain accuracy and consistency.

Step 4 - Rest Machining & Corner Cleanup

After semi-finishing, the remaining material is removed from the corners and from hard-to-reach areas. This makes the part further close to its final dimensions.

Step 5 - Finish Pass

This is the final stage of roughing and has focus to achieve the desired surface finish and dimensional accuracy. Very light cuts are made at this stage to eliminate any remaining imperfections.

Precision CNC machining setup, includes rough, semi-finish, and finish operations.

Roughing Strategies for Custom Parts

There are few rough CNC machining strategies for complex custom parts like 5-axis swarf cutting for impellers and hybrid additive builds for hard-metal brackets. These techniques have the focus of efficient material removal and preparation for finishing.

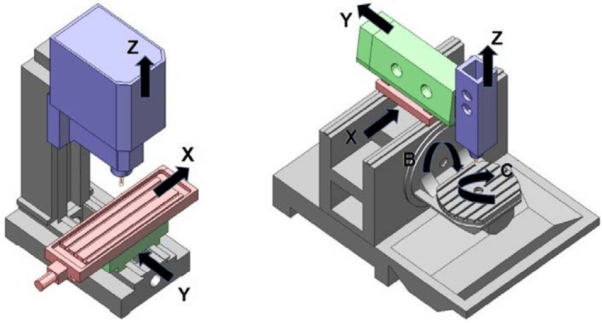

Rough CNC 5-Axis Impeller

A 5-axis CNC machine can efficiently remove material from the impeller's complex geometry in a single setup. It performs all the operation in one setup and minimizes material handling and setup time, improving accuracy and efficiency. Optimal material removal and surface finish on impeller's curved surfaces can be achieved by adjusting the cutting tool angle (swarf tilt).

a) 3-axis CNC Machining, b) 5-axis CNC Machining

Rough CNC Hard-Metal Bracket

Rough CNC for hard-metal brackets require a combination of optimized cutting parameters, specialized tooling, and appropriate machine capabilities. Multi-flute tools help to secure toolholders and fixtures, and coolants are essential to apply when machining difficult materials like stainless steel and titanium.

Hybrid Additive Build

This strategy is combined with 3D printing to build a rough shape and then uses CNC machining for finishing. It is normally carried out for hard materials that are difficult to manage. After roughing, finishing cuts are done to get desired surface finish and dimensional accuracy.

What Is the Difference Between Roughing and Finishing CNC?

Roughing and finishing are two processes in CNC Machining and are entirely different in their purpose and operation. The key differences between them are as follows:

1.Purpose

Roughing has primary goal to remove the bulk material from the part quickly and creates a basic shape of part. This process is focused on high material removal rate and not on dimensional accuracy or surface finish.

Finishing removes small amount of material with high precision. It focuses on achieving final dimensions, tight tolerances, and a smooth surface finish.

2.Rate of Material Removal

Roughing uses a high MRR with larger chips load and deep cuts for material removal. It results in faster machining times but potentially lower surface quality.

While finishing uses a lower MRR with smaller chip loads and shallower cuts. It has finer tolerances and better surface finish which results in slower machining times but higher precision.

3.Fixturing Approach

Roughing normally utilizes simpler fixturing to manage bulk material removal and this requires less critical alignment.

Finishing needs more precise fixturing for accurate positioning of the workpiece and to get tight tolerances during machining.

4.Programming Philosophy

Rough paths are built by using standard toolpaths and are derived from reusable templates to increase the material removal efficiency.

Finishing paths are typically more customized. It typically considers specific tool selection, feed and speed parameters, and surface quality requirements to get the required finish.

Conclusion

Rough CNC machining has an important role in the initial stage of material removal and for preparing parts for the following finishing process. It focuses on bulk material removal to get the workpiece close to the final shape. Rough machining is essential for material reduction, rough shape creation and cost efficiency. The process parameters for rough machining are high material removal rates (MRR), large depths of cut, and high feed rates.

TUOFA CNC Machining offers one-stop custom solutions from rough CNC to ultra-precision machining. This approach streamlines the manufacturing process and offers benefits such as low lead times, cost savings, and good quality control through a single, reliable source.

CNC Roughing FAQs

Can I rough titanium dry?

No, it is not recommended to because of low thermal conductivity and tendency to gall of titanium.

What is the roughness of CNC turning?

The typical surface roughness in CNC turning ranges from 0.8 to 3.2 μm Ra. It is achieved by a combination of cutting parameters like speed, feed, and depth of cut.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What Is Flexible Manufacturing? - Guide to Improve Your Production

What Is Flexible Manufacturing? - Guide to Improve Your Production