What Is Flexible Manufacturing? - Guide to Improve Your Production

Aug 13,2025

Aug 13,2025

Flexible manufacturing for CNC machining focuses on standards, modular fixturing, and controlled programs—not just robots. We show a practical roadmap for building a flexible CNC cell, from zero-point bases and probing to DNC control and basic scheduling. Use it to shorten lead time and protect margins.

What is Flexible Manufacturing

Flexible manufacturing is a way to build a factory that handles change without drama. Orders shift, designs evolve, suppliers miss dates; the system still moves. The method sits between a rigid high-volume line and an all-custom job shop. It blends standards, fast changeovers, and clear data so work keeps flowing even when the plan bends.

Plain Definition

At its core, flexibility means the plant can switch product mix, volume, and schedule with minimal downtime. Programmable equipment, quick-change workholding, and consistent methods make that possible. Once a part family is defined, machines, fixtures, and programs align around it. The same playbook runs every time, so variation in demand does not become variation in quality.

Why It Matters Now

Lead time drops because changeovers shrink. Small batches stay profitable, so inventory no longer hides problems. Utilization improves as multiple routes can build the same item. Quality rises when checks move into the process rather than waiting at the end. These gains show up in simple outcomes: steadier schedules, fewer expedites, and stronger on-time delivery.

Types of Flexibility You Can Build

Different plants need different levers. The sections below outline the main types and how each one improves daily work. Start with the bottleneck that hurts most, then expand to the next lever once the first is stable.

Machine Flexibility

Multi-axis capability, generous tool magazines, and in-process probing allow more features in one clamping. Travel between departments fades and first-piece approval arrives sooner. Operators lean on a common method, so new staff reach confidence faster and seasoned staff spend less time firefighting.

Routing Flexibility

Two or more cells can make the same part thanks to shared bases, common offsets, and consistent program structure. When one machine is busy or down, another path takes over. Queue time shrinks and the schedule survives small failures without a meeting.

Mix Flexibility

Switching between SKUs becomes routine. SMED methods, zero-point clamping, and repeatable datums keep steps identical across variants. Batches can be smaller yet still make money. “Build ahead just in case” stops being the default answer.

Volume and Expansion Flexibility

Output scales without redesigning the plant. Parallel cells, cross-skilled teams, and repeatable layouts make it easy to add hours or a shift. When a program grows, a new machine drops into the pattern and the standards copy across. Ramp-up takes days, not months.

New-Product Flexibility

Launches move faster when CAD/CAM templates, probing cycles, and fixture foundations already exist. Short setup sheets with photos guide the first run. First article passes sooner because the process matches measurement rules from the start.

What Is a Flexible Manufacturing System (FMS)?

An FMS is a coordinated cell built for high-mix work. For example, in the CNC machining process, it links CNC machines, pallet or quick-change workholding, material movement, and a controller that dispatches jobs. Understanding the building blocks and the daily rhythm makes the concept practical.

Core Elements

A typical cell includes CNCs with probing, a pallet pool or zero-point base, and either a robot or a simple cart system. Approved programs arrive from a DNC or server, not from USB sticks. Tool presetting and tool-life rules keep offsets under control. Near-line inspection—or checks in the cut—feeds results back to the queue.

Day-to-Day Flow

Orders drop into a live queue from ERP or a dispatch list. The cell verifies tools and fixtures, moves a pallet to the next free machine, and sets the zero with a probe. A critical feature is measured before the main cycle. If a limit trips, the job pauses with a clear message; if not, the cut runs and the pallet returns to storage. The queue updates in real time, so the next job starts without a huddle.

FMS vs. Traditional Line

Dedicated lines win on one stable SKU at a very high volume. FMS shines with many SKUs and mid-volume demand. Changeovers stay short and standardized. Routing is flexible, not fixed.

Flexible Manufacturing in CNC Machining

Most CNC shops already live with high mix and shifting priorities. That is why flexible methods fit so well. Standard workholding and disciplined program control remove guesswork; probing and simple dashboards keep the feedback loop tight.

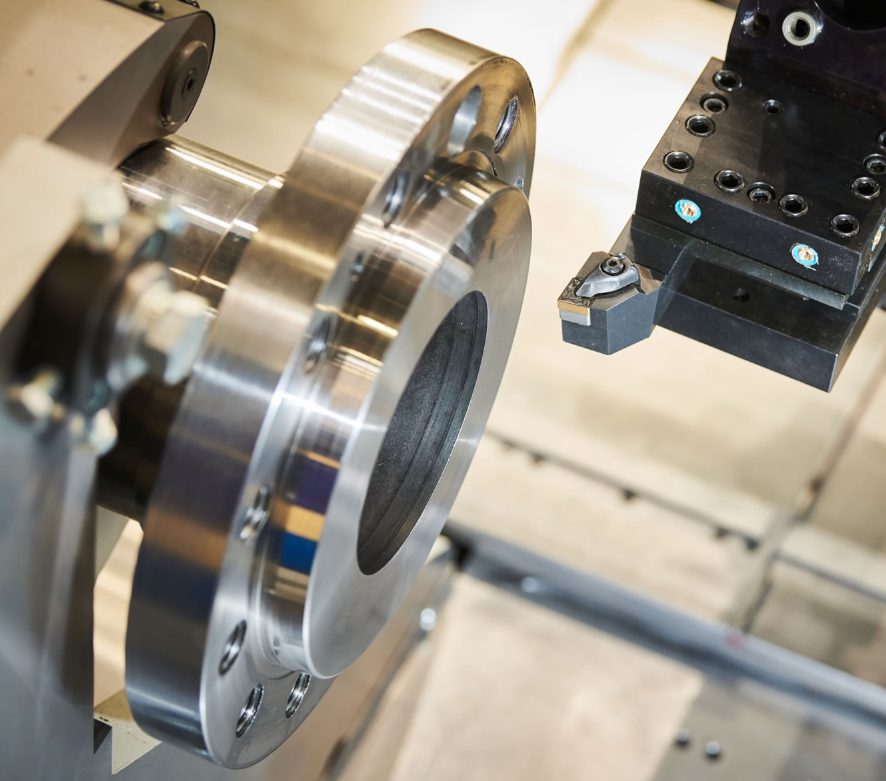

A Typical CNC Flexible Cell

Imagine two vertical machining centers, a shared pallet cart, and a modular base plate on each table. Kitted totes feed the cell. While one pallet cuts, the next pallet gets staged offline. When the spindle stops, the swap takes moments. A short probing cycle verifies the setup and the key size; then the cycle runs. Morning work may be aluminum housings; afternoon work, stainless brackets. Top plates, a few tools, and the program ID change; the flow does not.

How to Achieve Standards Manufacturing

The key to standardizing production is using the same references, tools, and procedures—and making every step traceable.

- Use the same references across machines (zero-point bases on all machines).

- Keep a master tool list with fixed IDs.

- Send only approved programs via DNC and enforce version control.

- Put QR codes on fixtures that open the latest work instructions.

- Calibrate probes on a regular schedule.

- Result: Traceable, standard work that lets people focus on machining and reduces variation and errors.

Benefits and Drawbacks of Flexible Manufacturing

Before investing, review the strengths and limits. The points below help you judge where flexibility fits and how far to go.

Benefits of Flexible Manufacturing

- Shorter changeovers and faster lead times.

- Smoother SKU switches for high-mix work.

- Better use of machines and shifts through routing options.

- Higher first-pass yield with in-process checks.

- Lower WIP and less cash tied up.

- Faster NPI/ECO using reusable fixtures and code.

Drawbacks

- Upfront spend on modular fixturing, training, and integration.

- Tighter coordination and data discipline (scheduling, revisions, permissions).

- Team change: standard work replaces ad-hoc fixes.

- Poor fit for single-SKU, ultra-high-volume products.

How does Flexible Manufacturing Save Money (in CNC Machining)?

People always want to save more money while maintaining quality. Here we try to figure it out: how to save more money in flexible manufacturing in CNC machining.

Cost Drivers in CNC Machining

The four items below account for most of the cost—and most of the potential savings.

Fixtures & Palletization

Modular bases and zero-point plates cut setup minutes and re-clamping errors. Reusable top plates spread fixture cost across SKUs. A pallet cart or small pool raises spindle utilization without adding robots.

Training & Changeover Time

Clear standard work, photo setup sheets, and SMED move tasks off the machine. Cross-skilled operators keep cells running when plans shift. Less waiting means fewer overtime hours.

Programming/Integration Overheads

CAM templates, standard posts, and DNC distribution reduce rework. Revision locks prevent wrong-code scrap. A light MES or dispatch board trims chasing and re-prioritizing time.

Tooling & Metrology Care

A master tool list with fixed IDs and lengths, speeds, offsets, and avoids mix-ups. Presetters and probe calibration keep the first piece right. Consistent tools extend life and reduce stops.

Setup Time → Spindle Time

Turn non-cutting time into cutting time. Externalize setups (preset tools, stage fixtures, kit hardware). Use zero-point workholding so swaps take minutes. Keep material kitted and close. The freed time becomes paid cutting and lifts OEE.

Quality & Scrap Reduction

Probe datums and one or two key features before the main cycle. Lock revisions and send programs only via DNC. Keep metrology close (in-machine probe plus a nearby CMM). Early detection reduces rework and scrap, and protects delivery dates.

Tips for Flexible Manufacturing in CNC Machining

In this section, we turn the approach into daily practice. Start small, standardize hard, and grow only after the pilot is stable.

Standardize First

Set one reference system across machines so setups look the same everywhere. Keep a master tool library with fixed IDs and lengths to prevent mix-ups. Control programs through DNC with clear version tags. Use short, photo-based setup sheets and link them by QR code so the latest method is always at hand.

Build a Flexible Cell

Begin with a small pilot to limit risk. Two VMCs with a pallet cart and modular plates are enough to prove the flow. Add probing templates for datums and one or two critical sizes to stabilize the first pieces. Group parts into families so fixtures, tools, and code repeat with minimal edits.

Run by the Numbers

Track three metrics per cell: changeover minutes, first-pass yield, and queue time. Post today’s jobs and yesterday’s results in the cell so the team can act without waiting for reports. Review weekly, remove steps that add no value, and update standard work when a better method appears.

Scale Safely

Hold calibration on a schedule for probes, presetters, and torque tools. Replicate a proven cell before adding robots or a larger pallet pool. Grow palletization in stages only when demand requires it. Cross-train operators for setup and first-piece checks to keep coverage stable across shifts.

Conclusion

Flexible manufacturing succeeds when three things align: clear standards, fast changeovers, and live data that drives action. In CNC machining, the return comes from more spindle time, fewer handoffs, and faster releases for new parts. CNC machining that combines these advantages will bring customers a better cooperation experience. If you want to experience a faster one-stop CNC custom machining solution, you can directly send us an online inquiry!

FAQs

Is flexible manufacturing only for large companies?

No. Many small shops begin with a zero-point base, a probe, and firm program control. Those three steps deliver most early gains without a large budget.

Do robots have to be part of the plan?

Not at the start. Robots help once the process is stable. Flexibility begins with standards, modular fixtures, and controlled programs; automation follows the pilot.

How does flexibility affect quality?

In-process checks catch problems early. Probing confirms datums and key features before scrap appears. Fewer surprises reach final inspection.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Tight Tolerance Machining: Guide to A Better Machined Part

Tight Tolerance Machining: Guide to A Better Machined Part