Honing Definition and Process Guide for Precision Surface Finishing

Jun 14,2025

Jun 14,2025

Do you know how medical tools, aerospace or automotive parts achieve such a high precise surface? The answer is honing. It is a crucial process for achieving perfection in metalwork and has an essential role in other industries such as aerospace, automotive and aerospace for offering tight tolerance and smooth finishes. This article will give you insight into deep understanding of honing, its process and tools.

Honing Definition

Honing is used in manufacturing to improve geometric accuracy of cylindrical bores and internal surfaces. It helps to achieve desired tolerances and refines surface finish.

What Is Honing?

It is a fine-tuning process that refines the surface. A rotating abrasive stone or hone are used to remove a very small amount of material normally 0.005 mm.

How Does Honing Work?

Abrasive stones or hones rotate across the surface through a controlled movement in honing operations. The hone expands against the surface by applying controlled pressure and removes the material.

Benefits of Honing for Precision Parts

There are several benefits of honing operations when done for precision parts. Some of the benefits are listed below along with their applications briefly.

1.Improve Accuracy

It allows you to have precise control over bore size and helps to achieve tolerances as tight as ±0.002 mm and surface finishes of Ra 0.2 µm.

Honing Applications

Honing is normally carried out for automotive parts like cylinders, fuel rails, engine blocks, and other components that need tight tolerances and smooth surfaces.

2.Roundness and Straightness Corrections

Honing processing can help you correct geometric errors such as out-of-roundness and straightness in bores. This process is crucial for components like aerospace actuator bores.

Honing Applications

Honing is used in aerospace parts like actuator bores, hydraulic cylinders, and other critical components where precision and reliability are dominant.

3.Extended Tool and Seal Life

Honing creates a smooth, consistent surface finish and optimal clearance between assemblies. It also reduces friction and wear which ultimately increases the tool and seal life.

Honing Applications

Hydraulic and pneumatic cylinders, pistons, and other parts in hydraulic systems require honing to get leak-free sealing and extended component life.

4.Efficient Production

It is a relatively fast process, and its automation further increases production efficiency and reduces labor costs.

Honing Applications

High production rates make Honing operations suitable for large scale manufacturing for the applications where precise dimensions, smooth surfaces, and reliable sealing are required.

Common Types of Honing Operations

For your better understanding, honing operations can be categorized by their level of automation and production capacity like manual or automated, low-cost, or small batch finishing to high-volume process.

1.Manual Honing Operations

Manual process is generally low cost and is suitable for single parts or small batch production. Manual honing is often used for finishing pre-machined surfaces or to finish individual parts with precision. It involves a handheld honing tool stroked against the workpiece.

2.Reciprocating Machine Honing

This process is suitable for medium production capacity of parts with precise bore dimensions and surface finish. It uses machines that move the honing tool back and forth (reciprocate) while rotating it to generate a crosshatch pattern on the workpiece.

Vertical Honing vs. Horizontal Honing

Vertical machines are used for long bores. And horizontal machines are suitable for larger or heavier parts.

3.Diamond Single-Pass Hone

This process is suitable for hardened steel due to its fast cycle times.It uses a diamond abrasive tool to remove a small amount of material in a single pass. This honing process requires precise pre-location of the bore due to the high speed and material removal rate. It is recommended for high-volume production of parts with tight tolerances and good surface finish.

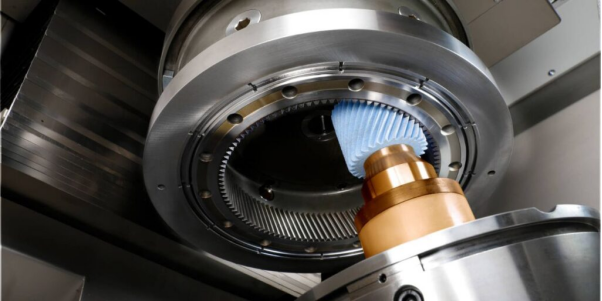

4.CNC Adaptive Honing

CNC Honing is a highly automated process with servo-controlled pressure and in-process gauging. Honing CNC machines adjust the honing pressure and dwell time automatically based on feedback from the gauging system. If you are looking for high-precision, high-volume production with complex geometries and tight tolerances, then this process is highly recommended.

Honing Machines: Vertical, Horizontal, CNC Systems

Honing machines come in vertical, horizontal, and CNC configurations. These are used to get high precision and surface finish on internal cylindrical surfaces.

Vertical Honing Centers

These CNC honing machines are designed for high precision and accuracy. Vertical honing machines are especially beneficial for long bores or components requiring strict tolerances. Long tubes and shafts can be easily loaded vertically in automated honing systems and offer efficient material handling. Coolant is added from the top into the bores and flushes away swarf and debris downwards.

Horizontal Honing Machines

These honing CNC machines have faster cycle times for shorter parts and are well-suited for batch production. Loading and unloading of workpiece is easy due to the horizontal orientation. Coolant is added from one end and flushed through the component and out the other.

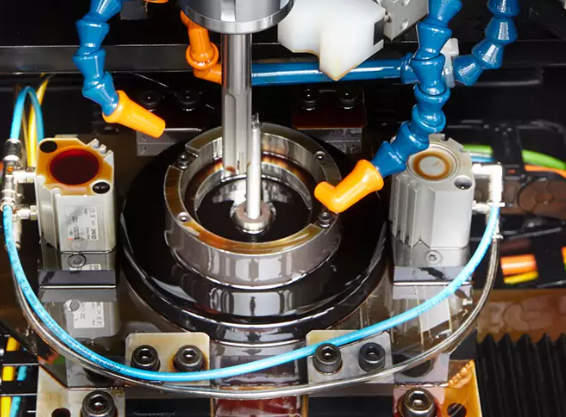

Multi-Spindle or Rotary Index Systems

These honing CNC machines use multiple honing spindles or a rotary index table and process several parts simultaneously. They have greater advantage of parallel processing and minimizing idle time between honing cycles. A rotary index table has multiple stations and parts move from one station to the next stages of honing like roughing, semi-finishing, and finishing.

Process Guide for Precision Surface Finishing

A typical precision surface finishing process using honing involves multiple steps which are discussed below:

Process of Honing

- Secure the workpiece and mount it on CNC honing machines. Select appropriate honing tools (stones or wheels) according to material and desired finish.

- Remove small material amount to get preliminary surface finish and geometric form.

- Measure the surface finish and dimensions regularly for adherence to specifications. Use profilometer or other measuring instruments for this purpose.

- Finish the process by using finer abrasive tools for final surface finish and geometric precision.

- Clean the workpiece thoroughly and remove abrasive particles and contaminants.

- Perform final inspection of the finished surface to verify dimensions, surface finish and honing quality.

Honing Surface Finish Chart by Material

Honing surface finish (Ra) for some common materials are as:

|

Materials |

Surface finish (Ra) |

|

Cast Iron |

0.2-0.8 Ra |

|

Alloy Steel |

0.1-0.4 Ra |

|

Aluminum |

0.2-0.6 Ra |

|

Ceramics |

0.1-0.4 Ra |

Tips for Better Honing Processing

Some tips for better honing processing are:

- For taper and out-of-roundness, adjust hone pressure, feed rate and honing time.

- For surface finish irregularities, Adjust abrasive grit size and honing parameters.

- For chatter marks reduce pressure, optimize honing motion, and check machine stability.

- For loading stones use a dressing tool to clean and sharpen the stones.

- For lack of stock removal, increase cutting pressure and use coarser grit abrasive.

Honing vs Grinding, Lapping, Reaming

These all are machining processes used to refine the surface finish and dimensional accuracy of a workpiece. But all have distinct features and applications.

Honing Vs Sharpening

Sharpening has a higher material removal rate than honing and is a faster process. But honing is more cost effective and has longer tool life. It also offers better surface finish and refines edges with better precision than sharpening. CNC honing machines require simpler tools than sharpening and is easier to learn.

Honing Vs Lapping

Honing offers a higher material removal rate and is faster than lapping. Honing is more cost effective to get high precision in bores, but honing oil management can increase the overall cost. Honing can get tight tolerances as low as 0.005mm but lapping is good for creating very flat surfaces.

Honing Vs Grinding

Grinding has a higher material removal rate than honing. Honing is better for fine finishes. Grinding is overall a cost-effective process, but honing is cost-effective for final tight tolerances and surface finish.

Honing Vs Reaming

Reaming offers a higher material removal rate than honing. Honing is better for high precision and surface finish on internal diameters. Reaming is overall cost-effective than honing and it also has simpler and less tools than honing. However, honing tools are inherently self-centering in bores, which is better than reaming. It is best for when the bore is not perfectly aligned with the machine axis.

Conclusion

Honing is a precision machining process. It uses abrasive stones and refines the surface finish and geometry of internal cylindrical surfaces by removing small amounts of material. Honing processing is a crucial bridge between rough machining and the final performance of parts. It offers higher accuracy, surface quality, and optimal functionality. If you need to improve the performance of your components through precision honing, consider requesting a quote for your specific needs at TUOFA.

FAQ

How much metal does honing typically remove?

Honing operations are precision processes and remove very small amounts of material usually less than 0.005inches (0.13mm).

When should I choose honing over grinding or lapping?

Honing operations are more precise than grinding or lapping. It is perfect for precise internal diameter dimensions and tight tolerance of cylindrical parts.

What surface finish can I expect after honing cast iron?

You can expect a surface finish with a roughness value between Ra 0.8-2.0 μm (or 32-80 microinches) after honing processing.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Cavity Milling Guide: Strategies, Tools, and CAM Tactics

Cavity Milling Guide: Strategies, Tools, and CAM Tactics