Copper CPU Heatsink: Design & Manufacturing Guide

Dec 05,2025

Dec 05,2025

Copper is an incredible material. People often value it for its high electrical conductivity. But besides it, copper is also a very good conductor of heat. So, it has the ability to conduct and transfer heat quickly. In CPU processors where dozens of transistors are switching on and off thousands of times a second, an astounding amount of heat is generated. If this heat is left there as it is, it will hamper the stability of the processors. Copper heatsinks provide a pertinent solution in maintaining a conducive thermal environment for the efficient working of CPU, GPU and AI servers.

What Is a Copper CPU Heatsink?

A copper CPU heatsink is a thermal management component found in computers. Copper heatsinks are installed with CPU processors. They dissipate heat away from the processor to the surroundings. Use of copper as a material in heat sinks is an ideal choice. Copper is one of the best conductors of heat, so it dissipates heat faster than most other metals.

What Is a Copper CPU Heatsink Used for

Copper heatsinks are widely used in high-performance computers. Copper heatsinks are mainly used in CPUs and GPUs to drive heat away. They are installed over the IHS integrated heat spreader in processors. Fan or liquid cooling is used to facilitate heat removal. In CPUs, copper heatsinks enhance the performance and life of processors. The role of copper heatsinks becomes critical in high-end applications like performing simulations, rendering, or AI processing.

How a Copper CPU Heatsink Works

Copper CPU heatsink capitalises on the high thermal conductivity of copper. In CPU/GPU processors where thousands of transistors switch on and off at GHz order of frequency, a very high amount of heat is generated. A heat sink in a computer provides a thermal path for this heat to dissipate to the outside. Heatsinks are designed in a way that heat is not allowed to raise the temperature above an acceptable range.

Heat Path in the CPU Stack

The smart design of the copper CPU heatsink enables every component to transfer heat as a unified thermal pathway. It utilises the conduction and convection modes for heat transfer. Heat flows from the HIS of the CPU or GPU to the thermal paste. It then travels copper base. Fins attached to the copper base absorb heat. The large surface area of fins coupled with fans allows heat to dissipate rapidly to the outwards-moving air.

Main Parts

- Heatsink Base: It is the first area of contact of the heat sink with the processor.

- Heatsink Fins: These fins increase the surface area manifolds for rapid heat transfer.

- Heatsink Heat Pipes: Liquid inside these pipes aids in heat removal through evaporation.

How to Design a CPU Heatsink?

The foundation of a smart design for a CPU heatsink is to understand the thermal and cooling requirements. Below is the list of steps that lead to good design:

1. Understanding The Thermal Requirements

There should be an accurate estimation of power dissipation and cooling requirements for the system. The CPU heatsink must be used to keep the temperature in the allowable range.

2. Material Selection

Depending on the power dissipation, size limitations and cost, commonly a choice between copper and aluminium exists. Pure metals conduct heat faster than alloys. But alloys are also selected depending on the rigidity and strength requirements.

3. Designing of CPU Heatsink Base

Based on the heat capacity and conduction requirements dimensions of the base are selected. Provision of attachment of pipes and fins is made.

4. Designing the Fins of the CPU heatsink

The fins' geometry and spacing impact heat dissipation profoundly. The manufacturing method determines the heat conduction at joints.

5. Heat Pipes or Vapour Chamber.

The dimensions and piping design also influence heat dissipation. The liquid inside the pipes removes heat by evaporation and condensation.

6. Thermal Simulation Testing

Thermal simulation testing in CAE software like Abaqus or COMSOL highlights the weak areas. Deigning can be reiterated to make the CPU heatsink efficient.

Copper vs Aluminium, Which one is better for heatsinks?

Copper and aluminium are both commercially used in heat sink manufacturing. Both materials have their own advantages and limitations. The choice depends on factors like heat flow, space constraints, cost, rigidity, etc. Normally, copper is used in end-demanding applications while aluminium is used in common electronic and small computers.

When Copper Heatsink Wins

Copper heatsinks are prioritised wherever stability of the system and prevention of hotspots are utmost. The only downsides are the high cost and the heavy weight. Commonly they copper heatsinks are used in high TDP processors, gaming GPUs, and servers.

Copper Materials Properties

Generally, copper with a thermal conductivity of 390-400 W/m.K is amongst the excellent heat-conducting metals. Its high density of 8.96 g/cm3 limits its usage in space-constrained applications. Due to softness and ductility, pure grades of copper are difficult to machine. Copper has a susceptibility to oxidise its surface. So, surface coatings might be required.

Pros

- Very high thermal conductivity

- Good at preventing hotspots on small dies

- Better thermal spreading

- Ideal for vapour chambers and heat pipes

Cons

- Way heavier than aluminium

- More costly than aluminium

- The production process is slow

- Require nickel plating

- Not suitable for a large aspect ratio

When Aluminium Heatsink Wins

Aluminium is a less costly and faster to produce solution for heatsinks. Comparatively, its thermal conductivity is lower. But designers can make it efficient for heat removal similar to copper at the expense of volume expansion. It is commonly used in consumer electronics, LED systems, and general PC cooling.

Aluminium Materials Properties

Aluminium has a good thermal conductivity of 200-235 W/m.K. But its way lower than that of copper. The low thermal conductivity is usually compensated by increasing the volume. Its low density of just 2.70 g/cm3 is of great benefit. Aluminum has a melting point at 6600C which making extrusion process highly feasible. Aluminum has a comparatively better machinability than copper.

Pros

- Lightweight

- Cheaper than copper

- Easy to manufacture

- Excellent for tall fin arrays

- Natural oxide layer prevents corrosion

- Ideal for mass production

Cons

- Lower thermal conductivity than copper

- Weaker heat spreading compared

- Not ideal for hotspot-heavy chips

- Requires thicker fins to match copper performance

Custom Solution: Copper Base + Aluminum Fins

The selection of copper as base material and aluminum as the fins material is good approach. It reduces cost while optimizing efficiency. Copper base extracts heat rapidly which prevents hot spots. Aluminum fins are relatively easier to manufacture which supports mass production. This hybrid design reduces the overall weight of the heat sink. Aluminum also allows for higher heights of fins which increases dissipation of heat.

Other Materials Choices

Although copper and aluminum are the most widely used heat sink materials novel materials are also gaining traction. Newer options include:

- Graphite

- CVD Diamond

- Magnesium alloys

- Phase change materials

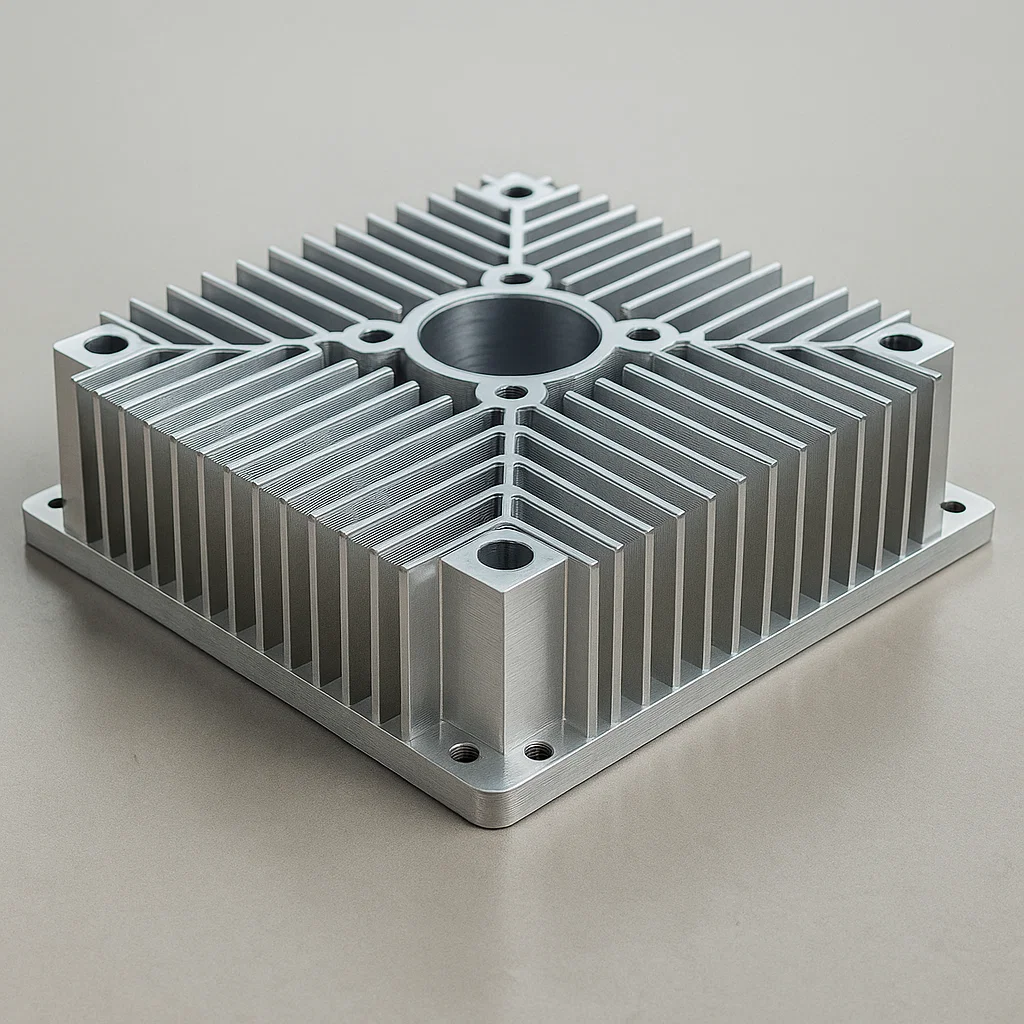

Common Designs for Copper CPU Heatsink

Common designs for copper CPU heatsinks include skived fin blocks, vapour chamber bases, heat pipe towers and pin fin blocks. Lets discuss a bit about these processes.

Skived Fin Blocks

Skiving is usually done on copper solid blocks to carve out thin fins. The biggest advantage is that there are no joints. So, heat conduction occurs fairly easy. Cost is very high. Skived fin blocks are commonly used in High density servers, overclocked CPUs and GPU VRM cooling.

Vapor Chamber Bases

Vapor chamber bases are copper plates filled with a coolant liquid. The coolant aids in uniform heat spreading rapidly. It is best to use vapor chamber bases with aluminum fin stacks.

Heat Pipe Towers

Copper pipes in heat pipe towers transfer heat rapidly from the CPU/GPU to the fins. They capitalize on air cooling. Commonly they are used in desktop CPUs, overclocked systems and tower heatsink designs.

Pin Fin Blocks

Pin fin blocks have a dense grid of copper pins. Forced-air cooling create airflow turbulence. It offers a compact design. Pin fin blocks are great for small form-factor PCs, VRM cooling, LED modules and low profile CPU coolers.

How to Design for CNC Precision Machining

Some key considerations greatly help in the efficient machining of heatsinks:

- Maintain reasonable fin thickness

- Use rounded internal corners

- Control depth-to-width ratios

- Avoid deep pockets

- Add chamfers or fillets

- Plan for tool access

- Minimize material removal

- Provide flat reference surfaces

- Consider hybrid design

How Many Copper Grades Can You Choose from?

Not all the types of copper are suitable for heatsinks. Heatsinks require a high thermal conductivity. The higher the thermal conductivity the better it is. Pure copper offers a very high thermal conductivity in a range of around 400 W/m.K. But pure copper has substantial difficulties in machining. So, some free machining grades are used complex CNC milling. The below table gives a comparison of common copper grades used in heat sinks

|

Grade |

Chemical Composition |

Thermal Conductivity |

Machinability |

Strength |

Applications |

|

C101 (OFE) |

Cu ≥ 99.99%, O ≤ 0.0005% |

391- 400 W/m·K |

Low |

Medium |

Vapor chambers, CPU/GPU heat pipes |

|

C102 (OF) |

Cu ≥ 99.95%, low O |

390 W/m·K |

Low to medium |

Medium |

CPU bases, copper heat pipes, copper cold plates |

|

C110 (ETP) |

Cu ≥ 99.90%, O = 0.02–0.04% |

385-390 W/m·K |

Medium |

Medium |

General-purpose heatsinks, skived fins, vapor chambers |

|

C145 (Tellurium) |

Cu ~99.5%, Te 0.4–0.7% |

320-340 W/m·K |

Very high |

Good |

CNC-milled heatsinks, pin-fin blocks |

|

C147 (Sulfurized) |

Cu ~99.8%, S 0.2–0.5% |

330-350 W/m·K |

High |

Good |

Copper heatsinks, inserts, precision components |

C101 (OFE) Copper

“OFE” stands for Oxygen Free Electronic Copper. It has a 99.99% copper content which is the highest commercially possible. Due to the extreme thermal conductivity, C101 copper grade is used in critical heat transfer components like vapor chamber bases and copper heat pipe.

C102 (OF) Copper

C102 is also an oxygen free grade. C102 copper has a slightly higher oxygen content than C101 copper grade. It has a less cost but still a very high thermal conductivity. It is a cost effective alternative to C101 grade.

C110 (ETP) Copper

C110 is an Electrolytic Tough Pitch Copper grade. It has a copper content of 99.90%. The thermal conductivity remains very high. C110 is also an alternative to the C101 and C102 grades with a lower cost.

C145 Tellurium Copper

Addition of Tellurium in copper makes machinability very high. So complex shaped components like pin fin heatsinks and copper cold plates can be made with ease.

C147 Sulfurised Copper

Sulfurised copper is also a free machining grade. But it is more cost effective than C145 copper. However, machineability is a bit less.

How to Manufacture Copper CPU Heatsinks

Heatsink manufacturing can be done by adopting certain manufacturing processes. Each manufacturing process has its pros and cons. Some processes require lesser need for assembling components. While other processes are not suitable for mass production. It is up to the heatsink manufacturer to select the optimum process that delivers good results at a low cost.

Skiving for Integral Fins

Skiving is a process used in heat sink manufacturing where a skiving blade carves out fins from a solid block of copper. The biggest advantage of skiving is that no solder joints are involved. So, heat transfer becomes rapid. A fins density presents a larger surface area for high heat dissipation.

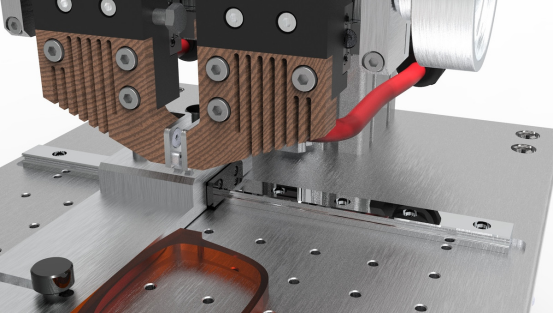

CNC Machining for Base Features

CNC machining offers a high precision in base features like mounting holes, channels and micro-structures. Complex features for mounting of fins can be made with tight tolerances.

Brazing or Soldering Fin Stacks

Brazing or soldering is required where base and fin stacks are separate component.

Custom Machining Solutions

Newer designs and their prototyping require custom machining solution for heat sink manufacturing. Non standard or newly designed components can be designed in CAD software. The CAM files allow for complex features to be produced ina CNC machine.

Challenges of Machining Copper CPU Heatsink

The role of copper CPU heatsink is crucial in maintaining the stability of the system. Machining of copper CPU heatsink is thus in a very high demand. However, there are multiple challenges pertaining to the manufacturing of copper CPU heatsinks. Lets discuss some of those.

Deformation and Warping

The high ductility and softness of copper cause it to deform or warp during machining. It is one of the most difficult to machine metals.

Tight Tolerances in Fin Spacing

Maintaining tight tolerances is difficult in machining of copper heatsinks. Formation of burr outsizes the dimensions. Suboptimal setup rigidity affects the parallelism of fins. Thus, fin spacing can become variable.

Tips for Better CNC Machining Performance

- Use sharp and high rake angle geometry

- Set high RPM and low depth of cut

- Optimize workholding

- Use stable, multi-axis toolpaths

Custom Copper CPU Heatsink Services

With the adoption of constant R&D in many heatsink manufacturing industries, newer and smarter designs have evolved. Some components of these custom designs might not be found commonly in the market. Custom machining provides solutions of such manufacturing.

When to Custom Parts

Custom CNC machining solution should be sought in the following situations:

- UnusualLayouts

- Tight Spaces

- Hot-Spot Cooling

- Special Mounting Requirements

- Thermal prototyping and R&D

Custom CNC Milling Services

Custom CNC milling delivers high precision results in heatsink manufacturing. It is ideal to produce:

- High-precision bases with smooth surface profiles and tight flatness.

- Complex geometric features like stepped bases, recessed pockets, micro-channels, or asymmetric shapes.

- Hybrid cooling designs like copper bases paired with aluminum fin stacks, heat pipes, or vapor chambers

- Small to medium batch flexibility

How to Find a Machining Shop Online

Many CNC machining factories can be found online on internet. China is a big marketplace where manufacturing orders can be given remotely. But, it should be made sure that the CNC factory is credible with a good history of delivering results. TOUFA machining is one such name. Please feel free to share your query. Our dedicated team will get back to you.

What Can You Choose for Surface Finish?

Different surface finish choices are available for copper heatsinks. The choice depends on factors like aesthetic appeal, corrosion resistance, durability and thermal conductivity.

Bare Copper Surfaces

It is the highest in thermal conductivity but prone to oxidation.

Nickel Plated Surfaces

Nickel plating provides an aesthetically pleasing and corrosion-resistant layer over the copper surface.

Black Coated Heatsinks

Black color enhances the emissivity copper heatsinks. It also protects against oxidation.

Conclusion

Copper heatsinks are an integral part of CPUs, GPUs, AI servers and modern electronics. They prevent hot spots from processors. High thermal loads are evaded by driving the heat away.

Heatsink manufacturing involves certain processes and steps. With each manufacturing process there are some advantages and limitations attached. Custom CNC machining offers the best in terms of rapid prototyping and production of parts that are unavailable from the market.

FAQs

How thick should the copper base be?

Commonly 3-6mm thick copper base is used in copper heatsinks.

Do copper heatsinks tarnish and does it matter?

Copper heatsinks tarnish due to oxidation. It will not significantly hamper its function as long as contacts are intact.

Can I machine very fine fins directly in copper?

Skiving procees can produce very fine fins.

Why don’t CPUs use full copper?

Thermal paste, coatings and silicon are other materials used in CPUs.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

A Complete Guide to Know Product Development Life Cycle

A Complete Guide to Know Product Development Life Cycle