Thread Pitch: Charts, Design, Measurement & Machining

Nov 21,2025

Nov 21,2025

Thread pitch seems like a small detail. But, in actual, it can cause serious problems like bad fits, misalignment or even mechanical failure in extreme cases, if it goes wrong. For product designers, it is important to know how pitch works and its proper fit and function. This article will highlight all the essential details about thread pitch before giving your part for manufacturing to CNC machining services.

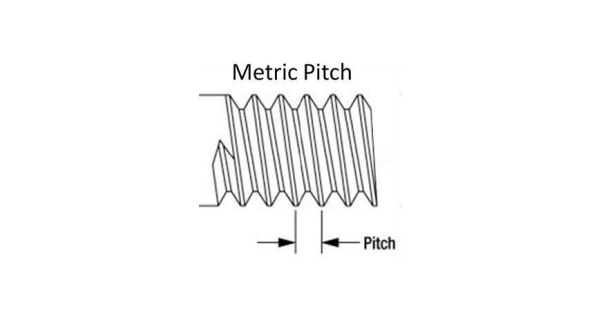

What Is Thread Pitch?

Thread pitch is a distance between adjacent threads. Wrong pitch can cause improper threads in fasteners which leads to damage or poor connection.

Thread Pitch Definition

Thread pitch is measured from the roots of two neighboring threads. It tells how many turns are required to place the fastener a certain distance.

Pitch Units

It is measured in mm for metric fasteners like M10 x 1.5 that are 1.5mm apart.

Thread Inserts

It is measured in Threads per inch (TPI) for imperial fasteners like 1/4"−20 a metric bolt dimension with 20 threads per inch.

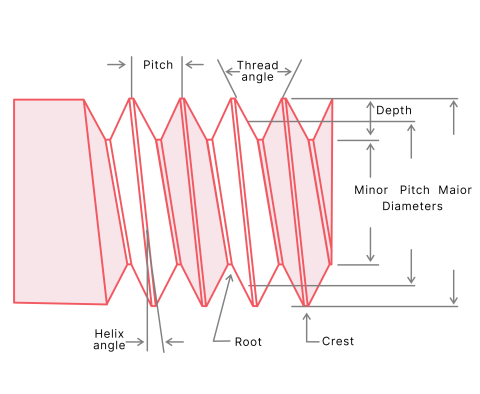

Thread Pitch vs Thread Lead

Thread pitch is a measurement of the distance between individual threads while the thread lead is the linear distance the screw advances during one full 360∘rotation.

Multi Start Threads

Single-start threads have only one continuous thread and the lead is equal to the pitch. While the multi-start threads have two or more parallel threads.

The lead is measured as lead = pitch × number of starts

How to Identify Thread Pitch (Step-By-Step)

To identify the correct pitch, follow these steps:

- Identify the type of thread like its external (shaft) or internal (tapped hole)

- Use the best tool like thread pitch gauge. Ruler or caliper can also be used.

- If you are measuring without a gauge, use ruler for metric threads to measure the distance in mm. For imperial threads, use ruler and count number of threads within a 1-inch distance.

- Identify the pitch. If its metric, use unit mm and for imperial pitch use TPI.

External vs Internal Threads

To measure the thread pitch for external threads, match the teeth of the gauge to the threads on the shaft. The correct gauge will fit without gaps.

For internal threads, insert the pitch gauge into the hole. Or you can use a known external screw or bolt and thread it into the hole. If it fits smoothly, the threads match.

Measuring Tools

Thread pitch gauge is the best measuring tool for thread pitch without any error. Rulers and calipers are used when gauges are not being used. But there is chance of error in measuring without gauges

Measuring Without a Gauge

Common mistakes occur when measuring without gauges

- Incorrect tool for pitch on metric threads without measuring a long span

- Mixing two systems like metric and imperial

- Not checking the Go/No-Go, means, like If the thread goes in easily but then stops, it's not the correct pitch.

- Not identifying the thread types like internal or external

- Not noticing the thread wear

How to Design Thread Pitch on Parts?

The design of thread pitch on a screw depends on design purpose like fine or coarse pair, material types, wall thickness and other different parameters which are explained below:

Depends on Design Purposes

Coarse threads are used for general purposes and fine threads are for high strength and more precision requirements. The Thread Pitch Chart are as:

|

Size |

Coarse Pitch |

Fine Pitch |

Uses |

|

M4 |

1.0mm |

N/A |

General purpose |

|

M5 |

0.8mm |

N/A |

General purpose |

|

M6 |

1.0mm |

N/A |

General purpose |

|

M8 |

1.25 mm |

1.0 mm |

High strength and precision |

|

M10 |

1.5 mm |

1.25mm |

High strength and precision |

|

M12 |

1.75mm |

1.25mm |

High-strength and fine-tuning |

|

M16 |

2.0mm |

1.5mm |

Heavy-duty and high-load applications |

|

M20 |

2.5mm |

1.5mm |

Very high-strength applications |

Material Types

Common material used for threads is 6061 T6 aluminum. It is relatively soft, and its engagement length can prevent stripping. Fine threads of 6061 T6 aluminum have better holding power.

Wall Thickness

Wall thickness must be sufficient to support the engaged threads. A common rule for better strength is to have a minimum wall thickness of twice the major diameter of the thread.

Engagement Length and Strength

Thread engagement is a critical factor for better strength. Longer engagement length means higher strength. For aluminum, longer engagement is recommended and fine threads can be used to increase the number of threads in each length.

Assembly Conditions and Vibration

Coarse threads are used in low to moderate vibration applications and fine threads are for high vibrations. Fine threads are self-locking with more intimate contact and thus prevent loosening from vibration. However, these are sensitive to cross-threading and need care during assembly. Coarse threads are easier to assemble.

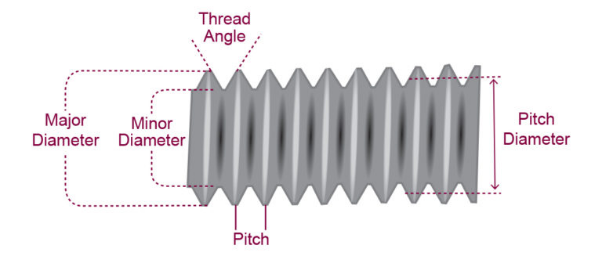

Thread Pitch vs Major/Minor Diameter

As we know now, thread pitch is the distance between adjacent crests and controls thread engagement. While major and minor diameters are the thread's outer and inner boundaries, respectively.

What Is Pitch Diameter

Pitch diameter is an imaginary diameter where the thread and grooves widths are equals to each other. It is an important dimension because it controls the threads engagement on two parts engage. Pitch diameter is a central value between the major and minor diameters.

What Thread Pitch Controls

It controls the axial distance between threads. A smaller pitch means more thread per unit length with a secure fit. It is also responsible for fine-tuning of thread engagement and the strength of the fastener.

What Major Diameter Controls

It is the largest dimension of the thread and controls its overall size and where the thread crests sit. It is critical for clearance and prevent part from binding against the surrounding material.

What Minor Diameter Controls

It is the minor diameter of the root of the internal thread. It controls the strength of the thinnest part of the thread and the thread's resistance to stripping

How Pitch Changes Thread Height

Pitch directly does not control thread height. It is controlled by the difference between the major and minor diameters. Their relationship is defined by the geometry of the thread.

Choosing Coarse vs Fine Pitch in Engineering

Coarse threads are best for general assembly. Fine threads provide a stronger hold and better vibration resistance.

Define Coarse Thread and Fine Thread

Coarse threads have larger pitch with fewer threads per axial distance. Fine threads have a smaller pitch with more threads per axial distance.

Strength and Strip Resistance

Coarse threads have less strength in brittle materials but have higher strength for sizes over one inch. Fine threads have higher tensile and shear strength and are less prone to stripping in hard materials.

Vibration and Loosening Resistance

Coarse threads are susceptible to loosening under vibration. Fine threads have resistance to loosening from vibration due to better surface contact.

Assembly Speed and Cross-Thread Risk

Coarse threads have quick assembly and do not cross-thread because of wider spacing. Fine threads have slow assembly and have higher risk of cross-threading.

Required Engagement Length

Coarse threads need less thread engagement for the same clamping force while fine threads need longer length for the same force.

Tapped Holes and Thread Milling in CNC

Tapping is a fast method of creating internal threads and thread milling offers greater flexibility and quality for both internal and external threads.

What Are Tapping and Threading?

Tapping is done by rotating a tap tool in a pre-drilled hole. The steps to tap are as:

- Drill a pilot hole for the tap.

- Choose the tap based of correct thread size, type and material.

- Place the tap at the center of hole

- Rotate the tap by hand or with a CNC machine tapping cycle.

- Back the tap out to remove chips and prevent breakage.

Threading uses a multi-tooth cutter to mill threads in a helical path. The steps to create threads are:

- Drill the pilot hole for thread mill’s path

- Choose the thread mill with correct pitch and other parameters.

- Program the tool path to create threads.

- Thread mill will rotate and move in helical path to cut the threads.

- Finish the process when tool reaches the desired depth

Tap Drill Size Selection (Charts and formula)

To calculate the tap drill size, the thread pitch formula formula to use is:

Tap Drill Size =Major Diameter - (Pitch / TPI).

For metric threads, the thread pitch formula and an example of size chart is below:

Tap Drill Size = Major Diameter - Pitch.

|

Tap Size |

Drill Size |

|

M10 x 1.5 |

8.5 mm |

|

M12 x 1.75 |

10.5 mm |

|

M14 x 1.5 |

12.5 mm |

|

M16 x 1.5 |

14.5 mm |

|

M18 x 1.5 |

16.5 mm |

Class Of Fit Charts

It refers to the allowable deviation in the diameter of thread pitch. Tap has its own pitch diameter, and its class of fit is determined by its tolerance range of diameter. The common classes are:

- Class 1: loose fit for easy assembly

- Class 2: standard fit for common use

- class 3: tight fit for precision

Choose Tapping vs Thread Milling

There are several factors to consider when selecting tapping or thread milling

|

Factors |

Tapping |

Thread Milling |

|

Speed |

Faster, for high-volume production |

Slower, for smaller production runs. |

|

Flexibility |

Less flexible, limited to internal threads. |

More flexible; a single mill for multiple hole sizes. |

|

Accuracy |

Less accurate, tap wear and misalignment |

More accurate, better control over thread size and shape |

Common Problems from Wrong Thread Pitch

Some of the common problems that occur from wrong thread pitch on a screw are explained below:

Parts Won’t Fit or Start

Threads from two different pitches cannot align properly. It is almost impossible to start or fully engage the parts

Threads Strip or Seize

Force application on misaligned threads can damage or shear the thread during assembly. It is also called cross-threading and can cause galling.

Leaks or Loosens after Assembly

Improper assembly due to incorrect pitch results in leakage or poor sealing. It might seem tight initially, but joint gets loosens over time due to vibration or threads.

Breaks or Fails under Load

Wrong thread pitch causes poor stress distribution and then stress concentrations. This can cause premature failure of fasteners as the material capabilities are exceeded.

Why Choose TUOFA CNC Machining?

TUOFA CNC Machining offers high-quality, precision threading and tapping services, which are essential for industries like aerospace and automotive. We offer a high level of accuracy, flexibility, and efficiency in producing both tapping and threading.

CNC Precision Threading

TUOFA has advanced machines that can handle various CNC precision threading, NPT thread or BSP threads, with high speed, especially with rigid tapping technology that matches the tool's rotation and axial movement for accuracy.

CNC Precision Tapping

TUOFA Precision tapping services are noted for its flexibility, accuracy, and ability to create custom threads.

Applications

TUOFA manufactures parts with high structural integrity and those that can withstand high temperatures or abrasive conditions. We offer CNC precision machining services for industries like aerospace, electronics, automotive and medical.

Conclusion

Thread pitch is measured from the roots of two neighboring threads. The Thread Pitch Charts are used in design and machining to provide key specifications like major diameter, pitch, and TPI for compatibility. Engineers use these measurements for design to select compatible fasteners before giving them to manufacturing service providers. Thread pitches are measured with pitch gauge, ruler or calipers. These dimensions are verified from charts, and drill size are determined before CNC machining.

FAQs

How does thread pitch affect bolt strength?

It affects bolt strength by affecting tensile, shear strength and fatigue life by bolt’s size and material

What is the most common thread pitch?

The most common thread pitch for metric fasteners is M10 x 1.5 pitch and for imperial, it is 1/4" - 20, (20 TPI).

What do 2A and 2B mean for threads?

2A means general-purpose external thread and 2B means general-purpose internal thread

What is the meaning of m8 x1.25 6H?

It is a metric bolt dimension, where M is metric, 8 is diameter in mm, 1.25 is pitch in mm and 6H is a tolerance class for internal thread.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Copper CPU Heatsink: Design & Manufacturing Guide

Copper CPU Heatsink: Design & Manufacturing Guide