Cold Rolled Steel: Knowing Its Grades, Manufacturing, and More

Oct 23,2025

Oct 23,2025

Cold rolled steel is the most used metal in every other manufacturing industry. Cold rolled steel is the steel which is super smooth and really strong. It is made by compressing the steel metal at room temperature. You will find it everywhere like car doors and different appliances. You will see below in this article, the grades of it, how it is made, its properties and many more things.

What Is Cold Rolled Steel?

Cold rolled steel is the steel which is rolled at room temperature means the steel is passed through different rollers. By passing through different rollers if becomes strong but also has smooth surface.

How to Define Cold Rolled Steel?

Cold rolled steel is defined as the finished steel. Means it is mostly the last step which steel goes through. Firstly material is hot rolled because at high temperature it becomes soft. If is rolled there to make it strong at it is easy to compress the steel when hot. After that steel comes to normal temperature and then cold rolled. It is used to make the smooth surface and strong steel by compressing it cold. The smoothness and strength for cold steel is always higher than hot rolled.

This has usually different names like CRS, Cold finished steel, or Cold-forming steel.

What Is The Difference between Steel and Cold Rolled Steel?

Cold rolled steel and hot rolled steel are different terms although the main concept of the process is same. Let's discuss the difference between them:

|

Property |

Normal Steel |

Cold Rolled Steel |

|

Processing |

Hot rolled at high temp |

Rolled at room temperature |

|

Surface |

Rough, scaly |

Smooth, shiny |

|

Strength |

Lower |

Higher |

|

Dimensional Accuracy |

Less precise |

More precise |

|

Use |

Structural beams, bars |

Appliances, automotive parts |

Table 1- A table showing the difference between a normal steel and cold rolled steel

Fig 1- The smoothness between hot rolled and cold rolled steel

How Cold Rolling Works

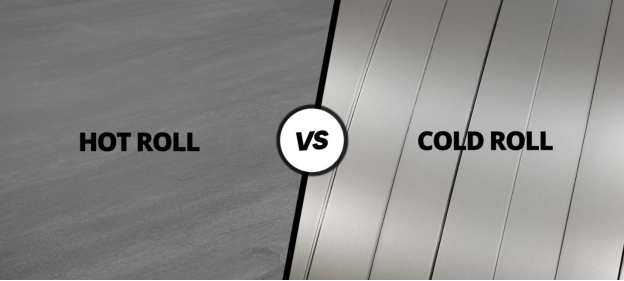

Cold rolling of the steel is done through a proper process which has different stages. This process turns the steel into high quality metal. Firstly lets discus the process of cold rolling.

1. Pickling then Skin Pass

First the steel is pickled means it is dipped and taken out from an acid. What acid do is actually it removes all the rust and scale from the steel. After that it is skin passed means the still is lightly colled roll. It actually prepares the steel for the next step.

2. Batch Anneal vs Continuous Anneal

After rolling, the steel becomes very hard and it gains a lot of strength. It is then batch annealed or continuous annealed depending on the demand. Annealing is a process in which a metal is heated to a specific temperature and then colled really slowly. Let's discuss both terms:

- Batch Annealed: When a specific number of Steel coils or metals are annealed at one time

- Continuous Annealed: When the steel is continuously annealed and passed through like a chain

3. Temper Rolling, Oiling, Surface Finish

After annealing, steel is then rolled to get the required surface finish and strength. Temper in this is basically done to remove the brittleness from a material. After this oiling of the steel is done so that rust doesn't form one metal during storing or shipping. This will make a smooth shiny surface of the steel.

|

Step |

Purpose |

Result |

|

Pickling |

Removes scale |

Clean surface |

|

Rolling |

Reduces thickness |

Increases strength |

|

Annealing |

Softens material |

Better formability |

|

Temper Rolling |

Improves flatness |

Controls hardness |

|

Oiling |

Prevents rust |

Long shelf life |

Table 2- Complete process of cold rolling

Fig 2- Complete process of Cold rolled steel working

How to Classify Cold Rolled Steel Grades

Not all the cold rolled steel are the same. They have different types and they are actually classified on the basis of their grades, strength and microstructure. Let's discuss them:

By Standards and Grade Systems

1- ASTM A1008 CS Type B

- Properties: Good formability, smooth surface, moderate strength.

- Best for: Automotive panels, appliances, and furniture.

2- EN 10130 DC01

- Properties: Low carbon, excellent surface finish, uniform thickness.

- Best for: Deep drawing parts like car doors and washing machine bodies.

3- JIS G3141 SPCC

- Properties: Good dimensional accuracy and easy forming.

- Best for: Electrical cabinets, tubes, and containers.

By Strength Levels and Mechanical Bands

1- Commercial/Mild CRS (Low Yield Strength)

- Properties: Easy to bend, good surface.

- Best for: Body panels, covers, and general fabrication.

2- HSLA-340 CRS

- Properties: High strength, good weldability.

- Best for: Automotive frames, wheel rims.

3- HSLA-550 CRS

- Properties: Very strong and durable.

- Best for: Structural and load-bearing parts.

By Metallurgical Families and Microstructures

1- IF (Interstitial-Free) Steel

- Properties: No carbon or nitrogen atoms, very soft and ductile.

- Best for: Deep drawing parts such as car roofs.

2- BH (Bake-Hardening) Steel

- Properties: Strengthens after paint baking.

- Best for: Automotive body outer panels.

3- DP (Dual-Phase) Steel

- Properties: Mix of soft ferrite and hard martensite, strong yet formable.

- Best for: Crash-resistant car parts.

By Temper and Annealing State

1- Full Hard (CRFH)

- Properties: Maximum strength, limited formability.

- Best for: Flat applications, where bending isn't required.

2- Annealed (Batch/Continuous Annealed)

- Properties: Soft, ductile, easy to form.

- Best for: Parts that need deep drawing or shaping.

Fig 3- Diagram showing steel with variety of shapes

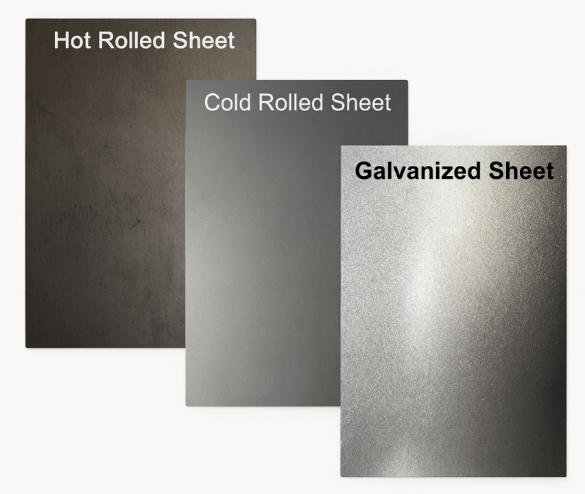

Cold Rolled vs Hot Rolled vs Galvanized Steel

Choosing a type of steel from between hot rolled, cold rolled or galvanized is relatively very hard. So in order to choose it correctly, lets compare some of their properties.

For more information, see this video: https://youtu.be/TxpW8anyu3U?si=haqQBE_fb0z9JPU4

Dimensional Accuracy

Cold rolled steel is the winner of the Dimensional accuracy. It offers the highest dimensional accuracy as it is rolled in rollers at room temperature. It can give tolerance up to ±0.005 inches. Whereas hot rolled steel shrinks up on cooling. This changes its dimensions by some points. Galvanized steel gives medium tolerance as it is just coated on hot or cold rolled steel.

Surface Quality

Cold rolled steel again gives the highest quality surface. It is smooth and gives finish ready for painting service. Hot rolled steel has a scale on hop of its surface. Galvanized steel has a coating of zins on its surface which provides protection against Rust and corrosion.

Fig 4- A clear demonstration of Surface finishes between Cold, hot and Galvanized steel

Price Compare

Price of every steel vary from highest to lowest. Each depend on the processes that are done on the steel to improve its properties. Like hot rolled are the cheapest whereas Galvanized have the highest price because it is coated with zinc. Price also depends from region to region and time to time.

|

Type |

Avg. Price (USD/Ton)* |

|

Hot Rolled Steel |

550 – 600 |

|

Cold Rolled Steel |

650 – 750 |

|

Galvanized Steel |

750 – 850 |

Table 3- Average price of cold rolled, hot rolled and galvanized steel

Welding & Machining Cold Rolled Steel

This section will cover details about how to work with the cold rolled steel. Like which techniques can be used to weld cold rolled steel or can we bend them.

Can Cold Rolled Steel Be Welded?

Yes! Cold rolled steel can be welded easily. The most common methods are MIG or TIG Welding. But there are also complexities in it like around the welded region due to extreme heat, material properties can change. It is commonly referred to as Heat Affected Zone.

Does Cold Rolled Steel Bend?

Yes cold rolled steel can be bend easily and especially in the annealed zone. Full hard cold rolled steel is difficult to bend as it can also crack.

Fig 5- Cold rolled steel coils which are bend or rolled

Is Cold Rolled Steel Hard to Machine?

It is generally easy to machine the cold rolled machine but as we go into its alloys. It becomes difficult to machine. But overall it can be machined according to requirement.

Turning Cold Rolled Steel

Use sharp carbide tools to turn the cold rolled steel. It becomes really heat up when turned so try to use a coolant or use moderate speed to turn.

Milling Cold Rolled Steel

Slowly feed the material during milling as it will provide better result. It will provide high quality surface finish which is mostly required in case of steel applications.

Fig 5- Turning and milling of steel

Custom Machining Cold Rolled Steel

Cold rolled steel can be machined according to demand. Shops like TUOFA CNC offer precision machining of parts for automotive or home appliances.

Manufacturing Tips to Cold Rolled Steel

Here we will focus on tips and tricks about the manufacturing processes of the cold rolled steel. Like how to design them and how to machine them.

Design for Manufacturing (DFM) Tips

- Avoid Sharp Corners to prevent cracking.

- Design steel so that it goes across the material grains, not parallel.

- Make sure to keep tight tolerances but only if necessary.

Machining Tips for Beginners

- Use sharp tools as it's easier to cut through them.

- Use proper speed so that the chips don't scatter everywhere.

- Use coolant or lubricant to get the food surface quality of steel.

Benefits and Limits of Cold Rolled Steel

Cold rolled steel has a lot of benefits but on the other side it has some downside or limitations too. Let's discuss some Advantages and disadvantages.

Benefits of Cold Rolled Steel

- Superior Strength

- Excellent Surface Finish

- Tight Tolerances

- Good Consistency

Limits of Cold Rolled Steel

- Higher Cost

- Limited Thickness

- Internal Stress

- Not Rust-Proof

TUOFA CNC Machining Offer Quality Custom Services

TUOFA CNC Machining and services can help you with the cold rolled steel projects. They have a really qualified and experienced staff. They can convert your ideas into reality projects.

Precision and Accurate Machining

TUOFA CNC use high precision CNC to cut your cold steel parts. These provide the highest accuracy possible for steel parts. Which means every part of yours will get exact specification required.

Custom Steel Machining Services

TUOFA CNC provides custom services from small parts like nails to big complex parts. They will also help you to find the exact cold rolled steel grades from strength, structure and costs.

Fig 7- CNC milling services by TUOFA CNC Machining

Conclusion

Cold rolled Steel is known for its strength, precision and high surface finish. It is usually classified using its grades, strength and microstructure. So choosing a specific type of grade according to the right type of application is very important and crucial. It can be welded, rolled, painted means it can be used in every part of the automotive, steel or aerospace industry. TUOFA CNC can help you identify the right type of steel, custom parts and can turn your dream part into reality.

CRS FAQs

Does cold rolled steel rust without coating?

The simple answer is yes. Cold rolled steel will rust without coating. The dust particles from environment will rust the part. Rain water and many other factors play a big part in the rusting of the cold rolled parts so it is better to coat them with Zincs or other material.

Is cold rolled steel good for knives?

It can be used for some knives but it is not a preferable choice as it will rust after some time. Stainless steel knife should always be preferred in this scenario.

Can cold rolled steel be hardened?

Yes! Cold rolled steel can be hardened. Heat treatment processes like quenching can be used to increase hardness of the cold rolled parts. These processes are commonly used when you require high wear resistance.

Can you paint cold rolled steel?

As this steel has already good surface finish so painting it is really good as it will adhere to the surface really good.

Is cold rolled steel fire proof?

No! cold rolled steel is not fire proof. At higher temperatures like 500C to 600C. it starts to loose its strength.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What Is EN 1.7366? -Some Must Knows

What Is EN 1.7366? -Some Must Knows