What Is EN 1.7366? -Some Must Knows

Oct 27,2025

Oct 27,2025

Do you know which material is used for pressure vessels?

First, let us introduce you to pressure vessels. In power generation plants and the oil & gas industry, the pressure vessels are an important part and are used in many forms, such as boilers. Since these are used to store crude oil, natural gas, or hydrogen gas, among other substances, they are designed to withstand the higher pressures and temperatures of the fluids, gases, or steam inside. It means the material used for these pressure vessels must have high strength and temperature resistance to withstand such conditions.

Well, this article focuses on EN 1.7366 steel, a known steel alloy, used for high-temperature applications, such as pressure vessels. This article covers each aspect of how it is best for high-temperature applications.

What Is EN 1.7366 (X16CrMo5-1) Steel?

This is an introductory section for EN 1.7366 steel. You will study the meaning of EN 1.7366 and X16CrMo5-1 and where it stands in heat-resistant steel alloys.

EN 1.7366 Definition

In the European standard, EN 10028-2, EN 1.7366 is a designation for steel material. This standard covers the aspects of non-alloy and alloy steels with high-temperature properties. One of the common materials in this standard used for high-temperature applications is EN 1.7366 steel.

Position in Heat-Resistant Stainless and Cr-Mo Steels

X16CrMo5-1 is neither a full stainless steel due to the Cr content nor a non-alloy steel. It stands with high-temperature resistant alloy and non-alloy steels, but between low-CrMo steels to full stainless steel, like SS 304.

What Does X16CrMo5-1 Stand for?

To better understand the meaning of X16CrMo5-1, let’s break it down.

X => total alloying content is greater than 5%

16 => 0.16% Carbon

Cr => main alloying element in this steel

Mo => Molybdenum, another important element for creep strength

5-1 => 5% Cr and 1% Mo

Chemical Composition of EN 1.7366

The chemical composition of any steel defines its properties, which further lead to applications in different environments. For example, Cr is responsible for corrosion resistance. Let’s discuss the chemical composition of this important steel grade in this section.

Nominal Chemistry Ranges

The following figure shows the chemical composition of 1.7366 steel according to EN 10222-2 : 2000.

|

C |

Si |

Mn |

P |

S |

Cr |

Mo |

|

0.18 |

0.4 |

0.3 – 0.8 |

0.025 |

0.015 |

4-6 |

0.45 – 0.65 |

C, Cr, Mo, Si, Mn, P, S

Let’s figure out the role of each element in the composition of EN 1.7366 steel:

Role of Alloying Elements in Performance

C => responsible for strength and hardenability

Si => limits scaling at high T, because it is a deoxidizer

Mn => essential for toughness

P => greater than 0.025% induces brittleness in the steel

S => greater than 0.015% will reduce toughness

Cr => provides corrosion resistance by reacting with Oxygen

Mo => essential element for high-temperature strength and to resist softness

Mechanical Properties of EN 1.7366

This section discusses the mechanical properties of EN 1.7366 at room and high temperatures. These mechanical properties make any material useful for different conditions.

Properties at Room Temperature

In the following table, the mechanical properties of EN 1.7366 steel are given.

|

Property |

Value |

|

190 GPa |

|

|

Ultimate Tensile Strength |

460-710 MPa |

|

Yield Strength |

230-480 MPa |

|

Elongation at break |

17-19% |

|

Brinell Hardness |

140-210 HB |

Some values are given in a range because the actual mechanical properties of any steel grade vary with respect to heat treatment. Values for annealed EN 1.7366 steel are different compared to mechanical values after normalizing.

Elevated Temperature Properties

At high temperatures, the mechanical properties such as creep strength, tensile, and yield strength start to fall. For EN 1.7366 steel, the bottom line is 510°C. After that temperature, the mechanical strength starts to reduce, and creep becomes a problem.

Typical Data Points Across 400–650 °C

The following table shows the different data points between 400-600°C temperatures:

|

Temperature |

1 % Creep Limit (10 000 h) |

1 % Creep Limit (100 000 h) |

|

510 °C |

~ 83 MPa |

~ 54 MPa |

|

540 °C |

~ 67 MPa |

~ 47 MPa |

|

570 °C |

~ 52 MPa |

~ 35 MPa |

|

600 °C |

~30-40 MPa |

~20-30 MPa |

|

650 °C |

~24 MPa (100 000 h) |

~17 MPa (annealed version) |

Creep Strength

It is the strength to withstand creep for a given time at constant T. For EN 1.7366 steel, the creep strength with 1% strain at different temperatures is:

- At 510 °C, the strength is approximately 83 MPa for 10,000 h with 1% strain

- At 570 °C, the strength is approximately 52 MPa for 10,000 h with 1% strain

- At 650 °C, the strength is approximately 24 MPa for 100,000 h with 1% strain

What Are EN 1.7366’s Physical and Thermal Properties

Physical and thermal properties have a significant effect on the applications of EN 1.7366 steel. This section shows the physical and thermal properties of EN 1.7366 steel.

Density and Elastic Modulus

Density of EN 1.7366 steel is ~7.75 g/cm³.

Elastic Modulus (E) at room temperature is 215 GPa, but it decreases with increasing temperature. At 500oC, E reduces to 180 GPa.

Thermal Expansion and Thermal Conductivity

- Coefficient of Thermal Expansion at 20-100oC: ~12.3 × 10⁻⁶ /K

- Thermal Conductivity at 20-100oC: ~42 W/m·K

- Coefficient of Thermal Expansion at 500oC: ~14.5 × 10⁻⁶ /K

- Thermal Conductivity at 20-100oC: ~28 W/m·K

It means that with increasing temperature, thermal expansion of EN 1.7366 steel increases while thermal conductivity increases.

Is EN 1.7366 Magnetic?

Yes, it is magnetic because of the ferritic-bainitic microstructure. This microstructure has Body Centered Cubic (BCC) crystal structure, which allows unpaired electron spins to align, leading towards ferromagnetic behavior.

What Is the Electrical Resistivity?

The electrical resistivity of EN 1.7366 steel at room temperature is 0.20 µΩ·m. At 500oC, it can increase up to 0.8 - 1 µΩ·m

Why Heat Treat EN 1.7366?

Heat treatments play a vital role in the performance of metals in different conditions. Quenching and tempering are the main heat treatments for EN 1.7366 steel. This section shows the theory why EN 1.7366 is best for elevated temperatures up to 510°C.

Raise High-Temperature Strength

Quenching produces a martensite microstructure, providing strength to the steel. To overcome the hardness and induce some toughness in the structure, tempering is performed. Quenching also produces carbide precipitates, further increasing its strength. Due to carbide precipitates, tensile and yield strength are enhanced to 560°C.

Improve Creep Resistance

The main reason for creep failure is the slippage of grains. Fine and stable M23C6 and M6C carbides pin the dislocations and stop the slipping of grains at elevated temperatures, thus increasing the creep resistance.

Relieve Residual Stress Before Machining

Some residual stresses remain in the workpiece after solidification or cold working. These stresses make it brittle, hard, and difficult for further machining. Heat treatments make its machining easier.

Mitigate Temper Embrittlement

When alloys are tempered, segregation of alloying elements and a subsequent reduction in toughness are common phenomena during the tempering process. It can be mitigated by controlled tempering at 650 - 700°C and then rapid air cooling.

How to Heat Treat EN 1.7366

These are some steps to heat treat 1.7366 steel:

Normalizing => heat from 920 – 950°C, then air cool.

Annealing => heat from 920 – 950°C, then very slow furnace cooling.

Quenching => heat from 920 – 950°C, then spontaneously dip into water or oil.

Tempering => heat in the range of 650 - 700°C, then rapid air cooling

How to Machine, Weld, and Form EN 1.7366

To convert raw material EN 1.7366 into a product, it is important to know about its machinability, weldability, and formability. This section is all about these concepts of En 1.7366.

Is EN 1.7366 Hard to Machine?

Yes, it is hard to machine EN 1.7366 steel because of its chemical composition. There are two main reasons:

- Cr and Mo elements increase its strength and hardness.

- During quenching and tempering, M23C6 and M6C carbides form in its structure, which act as abrasives, wearing down and scratching the cutting tool.

Through CNC operations, you can still have excellent dimensional stability and surface finish.

CNC Turning EN 1.7366

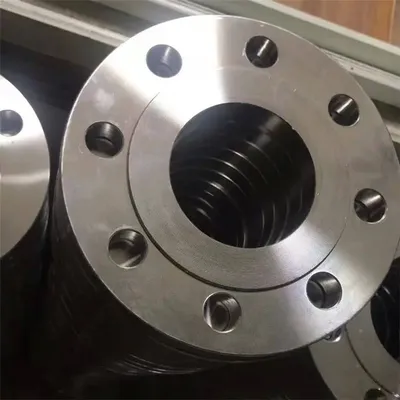

To make cylindrical components from EN 1.7366 steel, such as pipes, flanges, etc., for high-temperature applications, you will need a CNC turning process because of its efficiency in achieving tight tolerances in diameters and surface finish.

CNC Milling EN 1.7366

To make complex-designed components such as valves, pressure vessels, and turbine components, CNC milling operation is used for EN 1.7366 steel. This operation can successfully achieve perfection-level accuracy in the dimensions and surface finish.

In milling processes, the commonly used types are climb milling and trochoidal milling.

CNC Drilling EN 1.7366

This operation is most difficult in terms of machining EN 1.7366 because, due to the high hardness of this grade, the cutting tool faces maximum heat and pressure directly. For bolting, fluid passage, or instrumentation, the holes are made in EN 1.7366 steel products through this CNC operation.

Machining Tips

When machining any workpiece, always prefer cutting tool life and surface finish. For best results, choose:

- Carbide tools with slower cutting speeds

- Proper lubrication

- A stable setup

IF you need more expert tips or personalized machining, contact us today for the best guidance and tight-tolerance machining at the best rates and delivery terms.

How to Welding EN 1.7366

The welding of EN 1.7366 needs proper care because, after welding, martensite forms in the HAZ, which induces brittleness in the structure. Here are the common welding operations performed for EN 1.7366 steel:

- SMAW for thicker parts and controlled input heat

- GTAWfor root passes and thin sections

- Submerged Arc Weldingfor thick parts like pressure vessels

EN 1.7366 Forming Tips

For EN 1.7366 forming:

- Always form in an annealed or normalized condition

- After cold forming, perform stress relief annealing at ~650 °C

- For hot forming, use a good graphite or molybdenum disulfide lubricant

- After forming, post-forming treatment, like stress-relief annealing, is important to restore toughness

What Are Equivalent Grades of EN 1.7366

It is important to know the equivalent standard because sometimes the exact standard can be difficult to meet, so the alternative standards are followed.

What Are EN/DIN Standards

DIN stands for Deutsches Institut fur Normung, which means German Institute for Standardization.

Older than European standards and covers every aspect of materials in Germany. For instance, EN 1.7366 steel comes under DIN 17243 in German standards.

EN stands for European Norm, which covers materials-related aspects in the European Union. For instance, you can study EN 1.7366 steel in EN 10028-2:2017.

Equivalent Materials of EN 1.7366

You can find the alternate standards, given below, in British and American standards:

- BS 621/622B

- ASTM A182 Grade F

How to Choose A Right Material?

To choose the right material, you must know:

- Application Requirements

- Manufacturability

- Cost and Availability

- Environmental and Regulatory Factors

- Factors Regarding Life Cycle and Maintenance

EN 1.7366 vs EN 1.7182

EN 1.7182 is another Cr, Mo steel, but it is a bit different than 1.7366 steel in terms of main properties and applications. In this section, the main differences are discussed.

Main Differences

These are the four main differences between the EN 1.7366 and EN 1.7182 steel grades:

|

Basis of Difference |

EN 1.7366 |

EN 1.7182 |

|

Carbon & Alloy Content |

C: ~0.10%, Cr: ~4-5%, Mo: ~1.0% |

C: ~0.40%, Cr: ~1.0%, Mo: ~0.25% |

|

Main Property Focus |

Excellent creep strength and oxidation resistance |

High tensile strength and toughness |

|

Service Temperature Range |

Best for temperatures up to 600 °C |

Mainly for room to <400 °C |

|

Typical Applications |

Power plant piping, boilers, steam lines |

Shafts, gears, crankshafts, high-strength components |

1. Composition Differences

The difference between the chemical composition of EN 1.7366 and EN 1.7182 steel grades is given below in the following table:

|

Element |

EN 1.7366 |

EN 1.7182 |

|

C |

0.08–0.12% |

0.38–0.45% |

|

Si |

0.20–0.35% |

0.10–0.40% |

|

Mn |

0.40–0.70% |

0.60–0.90% |

|

P |

≤0.025% |

≤0.025% |

|

S |

≤0.020% |

≤0.035% |

|

Cr |

2.00–2.50% |

0.90–1.20% |

|

Mo |

0.90–1.10% |

0.15–0.30% |

|

Ni |

≤0.30% |

≤0.40% |

|

Cu |

≤0.30% |

≤0.30% |

2. Mechanical Strength at Room Temperature

EN 1.7182 steel is known for its strength and toughness at room temperature. This steel shows the strength of 1000-1200 MPa depending on the heat treatment. While 1.7366 steel shows 430-650 MPa.

3. Machinability

Due to the high carbon content in 1.7182 steel, it is more difficult to machine than EN 1.7366 steel. It is often machined after annealing heat treatment.

Where Are They Best for?

- EN 1.7182 is the best choice if the primary requirement is strength at room to moderate temperatures up to 400 °C.

- Use EN 1.7366 steel if creep resistance is required at high temperatures.

Advantages and Limitations of EN 1.7366

This section addresses this issue using the advantages and limitations of this steel grade.

Pros of EN 1.7366

- Good oxidation and creep resistance

- Microstructure remains stable even at elevated temperatures

- Maintains its strength up to 600oC, so it is the best suited for boilers, turbines, and refinery parts.

- Standardized under ASTM A182, widely accepted in the petrochemical and power generation sectors.

Cons of EN 1.7366

- Susceptible to tempering embrittlement

- Limited corrosion resistance, so not suitable for wet or acidic environments

- Requires post-forming treatments to restore toughness

- Needs pre-heating and post-welding treatments

- Susceptible to tempering embrittlement

Applications and Industry Use Cases

Here are the applications and industry use cases of EN 1.7366 steel:

Power Generation Components

- Used for steam turbine casings and rotors because of excellent creep strength

- It is used in boiler tubes and heads to maintain strength up to 500 – 600 oC

- Flanges and fittings are made of EN 1.7366 steel for pressure-retaining joints in high-T pipelines.

Petrochemical and Refinery Service

Since EN 1.7366 maintains its strength during continuous performance at 500 – 600oC, that is why it is used in:

- Furnace hardware (Supports, radiant tubes, etc.)

- Heat Exchangers and Pressure Vessels

- To make gas manifolds in steam reforming units

General Industrial Uses at Elevated Temperature

- Heat Treatment Fixtures:Trays, jigs, baskets, etc., that hold components during furnace cycles

- Hot tooling:Dies, tooling inserts, etc., exposed to continuous heat

- High Temperature Fasteners/Brackets:bolts, studs, structural supports in furnaces

Conclusion

EN 1.7366 steel is difficult to machine because of the Cr and Mo elements in the composition. These elements increase its strength and hardness, so the machining becomes difficult.

To machine this steel grade, you will need expertise in CNC operations such as turning, milling, and drilling. If you need an excellent surface finish with tight tolerances in the dimensions, come to us. We will provide you with our machining services and knowledge to get the best machining results of EN 1.7366.

FAQs

Is en 1.7366 considered stainless steel?

No, because for stainless steel, it must have at least 10% Cr content in the composition.

What is the difference between 1.7366 and 1.7362?

The basic difference between these steel grades is the content of C. EN 1.7366 has slightly higher C content, which makes it harder and more high strength. While EN 1.7362 is easy to machine, weldable, and tough at lower temperatures.

Is 1.7366 stronger than Grade 6 Titanium?

Grade 6 Titanium has higher strength than EN 1.7366 at room temperature, but EN 1.7366 steel excels at elevated temperatures due to higher creep resistance.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

12L14 Steel Guide: Properties, Machinability, and Uses

12L14 Steel Guide: Properties, Machinability, and Uses