Guide for Custom Bumper Latches: Types, Functions & CNC Machining

Jan 28,2026

Jan 28,2026

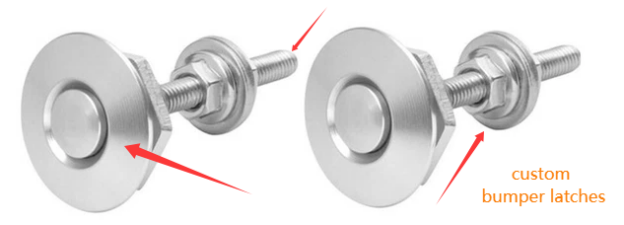

Bumper latches are one of the most significant aftersales auto parts for modified vehicles. They not only secure bumpers in place but also provide it the flexibility of quick release. Whether it is the quick replacement of bumpers for aesthetic purposes or the securing of a bumper whose fitting is damaged, bumper latches get relevance. Enthusiasts can take on or off their bumpers with super convenience as many times as they will. Just a simple mechanism in bumper latches locks the bumper in place. It takes only a few minutes in attachment and detachment of bumpers if they are secured with latches. Customized designs of bumper latches give cars a classy look. Here is complete guide about custom bumper latches. Stay onboard!

What Are Bumper Latches?

Car bumper latches or quick release bumper latches are the mechanical fastening system with the help of which car bumpers can detached and reattached without additional tools. Car bumper latches provide great convenience for off-road car owners. They consist of a lever or pull pin system which locks strongly when loaded. Car bumpers can thus be detached with a single motion. On the other hand, bolts and car bumper clips require wrenches or screwdrivers.

Functions of car bumper latches

|

Function |

Convenience |

Mounting Style |

Compared to Other Fasteners |

|---|---|---|---|

|

Bumper retention |

Secure locking without additonal tools |

Hidden panel mount |

Stronger than clips and quicker than bolts |

|

Quick release |

Fast detachment |

Recessed mount |

Faster than screws |

|

Alignment Control |

Consistent gaps |

Cam-adjustable mounting |

Precise than snap clips |

|

Vibration Control |

Maintains preload under movement |

Spring loaded or cam type |

Better NVH than rigid bolts |

|

Aero load Holding |

Stable at high speed |

Reinforced bumper mount |

better than plastic clips |

|

Service access |

Easy access to front-end parts |

Front-access latch points |

Faster than multi-bolt systems |

|

Modular Design |

Easy bumper swap |

Indexed multi-point mount |

Bolts need full removal |

|

Weight Reduction |

Fewer fasteners used |

Multi-latch layout |

Lighter than bolt systems |

|

Thermal Flexibility |

Allows controlled expansion |

Slotted mount |

More forgiving than screws |

|

Safety retention |

Prevents accidental release |

Secondary-lock designs |

More reliable than push clips |

Why Use Bumper Latches?

Bumper latches are auto parts used to safely fasten bumpers of cars. They keep the car bumpers in position as it were in the new condition. However, bumper latches give bumper quick release. Quality materials such as anodized aluminum and rubber are employed for creating a sound set of bumper quick release kit.

When Do You Need Custom Bumper Latches?

Custom bumper latches are required when the market-available designs cannot meet the requirements. They are needed in conditions where correct fit and robustness need enhancement. Custom bumper latches find relevance when standard sizes of bumper latches do not match the fitting requirements. Quite often securing points locations mismatch trigger this requirement.

Custom bumper quick release latch designs could offer advantages in prototype and low-volume production. The tooling costs associated with injection molded fasteners are often not considered economic. Customization done by CNC machines is considered ideal because of rapid design deployment, modification, and functionality provided.

Applications of Bumper Latches

|

Application |

Benefits |

Typical Latch Type |

|---|---|---|

|

Passenger Cars |

Secure removable bumper sections |

Cam latch |

|

Sports and performance Cars |

Quick removal and aero stability |

Quarter-turn |

|

Racing vehicles |

Rapid pit access and weight saving |

Quarter-turn |

|

Off-Road vehicles |

High retention under impact and vibration |

Over-center toggle and Heavy cam |

|

Electric Vehicles (EVs) |

Easy access to sensors and cooling systems |

Cam latch and Push-button |

|

Commercial vehicles |

Simplified maintenance |

Cam latch |

|

Aftermarket body Kits |

Modular installation |

Quarter-turn and Push-button |

|

Motorsports Prototype |

Quick panel replacement |

Quarter-turn |

|

Fleet & Service Vehicles |

Reduced downtime |

Cam latch |

|

Customized cars |

functional and aestheic appeal |

quarter-turn |

Types of Bumper Latches

A few types of quick release bumper latches are used frequently in modified vehicles. While the main purpose remains to be bumper quick release, these types distinguish bumper latches based on position and mechanism. Bumper latches are installed for securing bottom panels, lining up trims, and ensuring that bumper cover is properly attached to the car body. Identifying their specific function is helpful in determining their right types, which include quarter turn latches, compression latches, push button latches, draw Latches, and sliding Latches.

Quarter Turn Type Latches

It is a very simple and economical type. The operation of Quarter Turn Latches requires a simple twisting or turning action This type of bumper latches comprises of a body that is usually fixed to a movable panel or door. It has a cam lever that can be turned to lock a fixed panel. After fixing, the cam lever can be turned backwards in front of the fixed panel to retain the movable panel or door.

Compression Latch

This type of latch is very similar to that of Quarter Turn Cam Latches. Instead of a turning action, a clamping force acts between the two surfaces. This clamping force prevents vibrations or rattling. The compressive force on the gasket keeps out environmental elements such as dust or water.

Push-Button Latch

A push-to-close latch, sometimes referred as a “slam latch,”. It secures panels by pushing them shut without requiring the handle to be turned for locking. The slam latch is simpler in function than the other types of latches because the handle does not need to be turned. A slam latch is made up of a body using a spring-loaded cam. In some designs, security is enhanced through a keyed lock.

Draw Latches

Drawing latches employ tension to pull two surfaces together. These latches consist of an operating mechanism fixed to one surface and a securing mechanism mounted on another surface. They assist in damping vibrations as well as rattling effects. The simplicity of this system makes draw latches externally mounted on engine hoods and HVAC systems.

Sliding Latch

Sliding latches have a combination of a rotating body attached to one surface and a fixed keeper on another surface. After the sliding component locks into place behind the keeper, the two surfaces will be joined together. They have the advantage of withstanding vibrations.

Advantages of Bumper Latches

Advantages of bumper latches are numerous. They save cost, enhance strength and provide quick release of bumpers. There are more pronounced in off road conditions. Instead of ruining the car bumpers off track, bumpers can simply be detached to prevent them from wearing.

Secure and Stable Fixing

Bumper latches provide a stable fixing in many conditions. Be it repairs or enhancement in strength bumper latches serve their purpose.

Easy Release without Tools

Bumper latches give the flexibility of quick removal and reattachment.

Durability

In comparison to other fastener types, custom bumper latches are extremely durable. They withstand years without deterioration.

Plastic Rivets vs Bumper Latches

Cars that come out of factories are installed with plastic rivets. Usually, these plastic rivets break soon under excessive loading. In order to keep the bumper in place bumper latches are installed. Here's a comparison between plastic rivets and bumper latches:

|

Aspect |

Plastic Rivets |

Bumper Latches |

|---|---|---|

|

Purpose |

Fastening of light panels and bumpers |

Releasable fastening of bumpers |

|

Usual condition |

Factory fitted |

Modified afterwards |

|

Installation |

Push- fit |

Quick: depending on latch types |

|

Removal |

Usually single-use |

Reusable |

|

Strength |

Low -medium |

Medium-high |

|

Vibration Control |

Limited |

Excellent |

|

Impact Handling |

Poor |

Good |

|

Materials |

Nylon, PP plastics |

Metal, rubber, plastic |

|

Cost |

Very low |

Moderate |

|

Applications |

Trim panels and splash guards |

Vehicle bumpers and service panels |

|

Usage |

Low load and low budget |

Durability and serviceability |

Materials

Plastic rivets are made up of plastics like nylon. They are flexible, and corrosion resistant but not quite strong. They degrade under UV light exposure and excessive loading. On the other hand, metal made bumper latches can withstand heavier loads. They are durable and strong. Stainless steel latches are the most commonly used. 304 and 316 grades of stainless steel are promising in terms of luster, strength and aesthetics, Aluminum is a considered to be a good substitute for stainless steel. It is corrosion-resistant and light. Common grade of aluminum that are used in bumper latches is 6061-T6.

Durability

The design and materials of bumper latches make them more durable than conventionally used plastic rivets. This is the reason that where plastic rivets stand for a few months, bumper latched stand for decades.

Appearance

Plastic rivets are normally concealed. On the contrary, bumper latches give a classy look to the car that stand it out among others.

Cost Comparison

Installation of bumper latches is way more cost effective than replacement of a complete bumper.

What Materials Can be Used for Bumper Latches?

In fact, bumper latches are usually made from aluminum, steel and stainless steel based on their strength, durability, corrosion resistance, and manufacturability.

Aluminum Bumper Latches

Aluminum is a lightweight, corrosion resistant and elegant latch material. Bumper latches such as quarter turn latches and push-button latches are usually made up of aluminum can be anodized for an enhanced surface finish. CNC machined solid billet aluminum is used to make durable parts like aluminum jeep hood latches. A spectrum of colors can be attained by anodization.

6061-T6

6061 -T6 is a structural aluminum grade that offers good machinability. It gives a good moderation between strength, machinability and formability. So, complex designs can be carved out of solid billet aluminum. 6061 grade is ideal for machined aftermarket latches and brackets.

7075-T6

7075- T6 is one of the strongest aluminum alloys. Due to its exception strength to weight ratio it is used in aerospace and high-performance applications. It offers excellent rigidity and fatigue resistance.

Stainless Steel Bumper Latches

Stainless steel is the common engineer material for making compression latches because it offers excellent corrosion resistance for all sort of environments. The lustrous look makes latches appealing. Stainless steel is comparatively lower in cost than aluminum. Therefore, a good combination of strength, aesthetics and durability can be bought at a lower cost.

- 304: It is the most common grade of stainless steel used for all sort of general purposes.

- 316: It is a marine grade specifically suitable for corrosive media like salt water and weak acids.

Steel Bumper Latches

Mild steel is lower in cost than almost every other latch making material. It has high strength, stiffness, and wear resistance. The only downside is its ability to corrode. Quite often powder coating is applied on steel bumper latches to enhance corrosion resistance as well as to improve aesthetics. Powder coated latches come in a variety of colors.

Can Bumper Latches be CNC Machined?

As bumper latches are mostly made up of metals, logically, the most convenient manufacturing method is CNC machining. Although other methods like die casting and powder metallurgy can be used for latch manufacturing, but, CNC machining offers the most in terms of customization. It's both: convenient and scalable. It's precision is higher than other manufacturing processes. CNC work centers can entertain all sorts of materials. This facilitates precision manufacturing from the material of choice. CNC machining has the ability to shift from prototypes manufacturing to mass production in a short time. It's is scalable and consistent in quality.

Can You Custom Bumper Latches by CNC?

For customized manufacturing of bumper latches, CNC machining is a highly recommended option. A CAD file of the custom design will begin the process. This CAD file can be processed in the CAM software. Then, as many pieces as required can be CNC machined.

Machining Processes for Bumper Latches

Rapid redesigning, modification, and functionality validation are achieved through CNC machining processing. 3, 4, and 5 axes in CNC machines have the capability to create custom prototypes and components in no time. Whether a complicated item from a 3D design is required or a finished product CNC machining is the solution.

Materials Selection

The most used materials for this machining are aluminum, steel, and stainless steel. Each material has its own unique applicability. Depending on the customer's needs, budget and subsequent surface treatment, materials can be selected for CNC machining. A wide range of metals and plastics can be CNC machines to produce bumper latches.

CNC Machining Techniques

3 axes CNC milling is often used to machine bumper latches with simple designs, and 4 or 5 axes milling techniques are usually suitable for high-end bumper latches that require complex shapes or structures, high precision and high surface quality. What's more, CNC hybrid machining deliver unparalleled accuracy, reduced material wastage, and design flexibility to several sectors. Consequently, the hybrid machining of bumper latches promotes the production of parts with accurate precision and the detailed milling of complexes.

Surface Treatment

For manufacturers and OEMs, the most common surface treatment options are polishing, anodization and powder coating. Polishing is done mainly for stainless steels. Latch surfaces shine our lustrously after mirror finish polishing.

- Anodization is only used for aluminum latches. Anodization makes the surface stronger while giving it different colors and hues.

- Powder coating is although applied mainly on mild steel bumper latches, but they can be used on other materials as well. It creates an entirely new surface with the desired colors.

Advantages of Using CNC Machining for Bumper Latches?

CNC machining is known for providing unmatched accuracy, versatility, and efficiency. It has been a significant tool in many industries. Some of the notable advantages in employing this process for bumper latches productions are discussed here.

High Precision

CNC machining gives an unmatched precision. It produces parts with a tolerance down to ±0.01-0.05mm. So, proper fit can be ensured.

Complex Geometry

No matter how much intricate the designs are, CNC machining is capable of doing it right. Tool position and workpiece movement are automatically controlled by the G Codes given by the CAM software. A high repeatability even for complex shapes can be expected for CNC machining.

Rapid Manufacturing

As soon as the designing process is done, production can be started immediately. All processes are automatic. The CNC control itself governs the production to make it swift.

High Quality

The quality of CNC manufactured parts is incredible. It keeps a consistency in quality while giving high accuracy of dimensions.

How to Install Bumper Latches Easily?

Bumper latches do not require too long time for their installation and are not difficult to install. These can, therefore, be installed by oneself quite easily.

Can You Install by Yourself?

Bumper latches are a DIY auto part for cars. They are meant to the installed by car owners themselves. Just a drill machine and some measuring tools are sufficient to begin the installation process.

Steps of Installing Bumper Latches

Steps involve in installing these are:

- Remove the Bumper

- Mark the Position

- Drill the Hole

- Install the Parts

Mount the aluminum knot. Put the washer on the other side of the fender or bumper. A wrench and a hex tool are to be needed to secure everything.

- Reinstall and Test

Conclusion

Bumper latches are a very critical part related to the safety and quality of the vehicle as well as its look. In conditions where factory fitted fastening of bumper gets damaged, replacement of new bumpers costs a lot. Bumper latches can fasten the same bumper securely at a fraction of the cost. For enthusiasts who need to take bumper off an on frequently, bumper quick release gets importance. Bumper latches give this bumper quick release.

Compatibility, accuracy, and quality of materials are the most important things while choosing the right bumper latches. Out of all common manufacturing methods CNC machining is the most pertinent when it comes to precision, customization and scalability. As a result, Tuofa automotive CNC machining is the process of choices for manufacturing customized bumper latches.

FAQ

Where to find rapid CNC machining services for custom parts?

There are many online companies that are providing CNC services for custom parts. Tuofa CNC machining is one of the best options for custom CNC services in China.

What is bumper quick release kit?

It is made of high-quality rubber O rings and aluminum fasteners that have an anodized finish, which will assists in disassembling and reassembling of hatch lid, trunk, or even the car's bumper. It gives access to certain parts so that they can be loaded to a trailer or even be repaired.

How much does it cost to replace bumper clips?

Based on the vehicle's make and model number, the average cost to replace clips on car's bumpers may range from $10 to $50 on average. Labor prices may range from $50 to $150 depending on location.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

On-Machine Inspection in CNC Machining: A Mechanical Inspection Guide

On-Machine Inspection in CNC Machining: A Mechanical Inspection Guide