On-Machine Inspection in CNC Machining: A Mechanical Inspection Guide

Jan 24,2026

Jan 24,2026

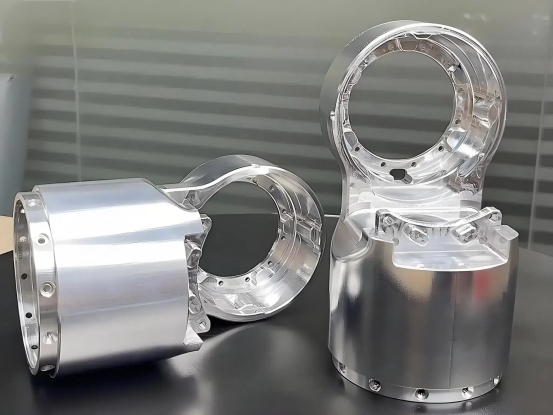

On-machine inspection is a contemporary method to test parts in a machine whereby parts are still under process in the CNC machine. It ensures that the parts are with very small quality deviations before the next manufacturing process. In modern super-fast manufacturing environment quality, speed and precision matter the most. On-machine inspection gives machine shops the opportunity to make improvements in all the three factors. Here is the complete guide about on-machine inspection in CNC machining. Stay tuned!

What is On-Machine Inspection (OMI)?

On machine inspection the measurement and verification check of part during machining. In contrast to a regular QA where parts are checked after machining, OMI monitors the dimension during manufacturing. Thus, early detection of errors helps in immediate adjustments in machine setting. It thus prevents parts manufacturing with inaccurate dimensions.

Defined On-Machine Inspection

On-machine inspection or OMI refers to a process in which inspection of parts is done within the CNC machine. It can also be termed as "on machine measurement". The part does not have to be removed or moved to another inspection tool but remains in place. This mechanical inspection is time saving process and increase the production rate.

OMI in the Inspection Workflow

To achieve the primary purpose of minimizing the dimensional errors in production, probes, sensors, or touch-trigger systems are used. It allows for early detection of deviations. Thus, corrective action can be taken immediately. Dimensions of parts are thus ensured to be complaint with the design even before the QA.

Why On-Machine Inspection Matters in CNC Machining?

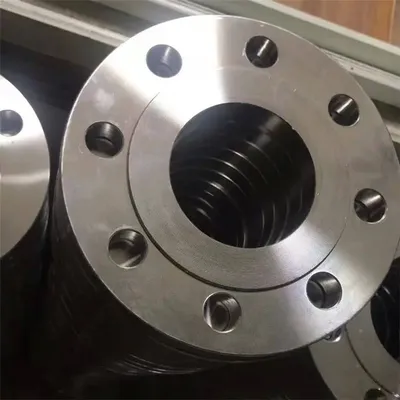

In conventional inspection, the part is taken off the machine and measured. This wastes a lot of time. If the part is checked after production, it may be rendered useless due to dimensional errors. In on-machine measurement, the measuring tools in the CNC measure dimensions of the part as it is being manufactured. This is in-process inspection, which helps in preventing defects before they get bad. On machine inspection is highly important for precision machined part. It saves both: time and money.

OMI vs CMM vs Offline Measurement

Although OMI is a very useful method in ensuring dimensional accuracy, other methods still find their relevance. As an example, CMMs are still used to detailed dimensional verification of finished parts. The reason is that its accuracy supersedes the accuracy of OMI. Another example is of VMMs which are used for dimensional checking of small or delicate parts. OMI might not be suitable for this. In short, each method has its own relevance.

Common Testing Methods (2025–2026 List)

In manufacturing industry, inspection techniques are employed based on inspection accuracy, inspection speeds, as well as automation. As of 2025-2026, some popular inspection techniques used today are on machine inspection (OMI), coordinate measuring machines (CMM), as well as offline measurement. These technologies coexist in most CNC machine shops. Each playing a different part in the quality process, rather than replacing each other.

- OMI is used for in-process or immediate feedback.

- CMM is used in the end verification process for higher precision

- Offline measurements allow for rapid and inexpensive dimensional checks.

CMM

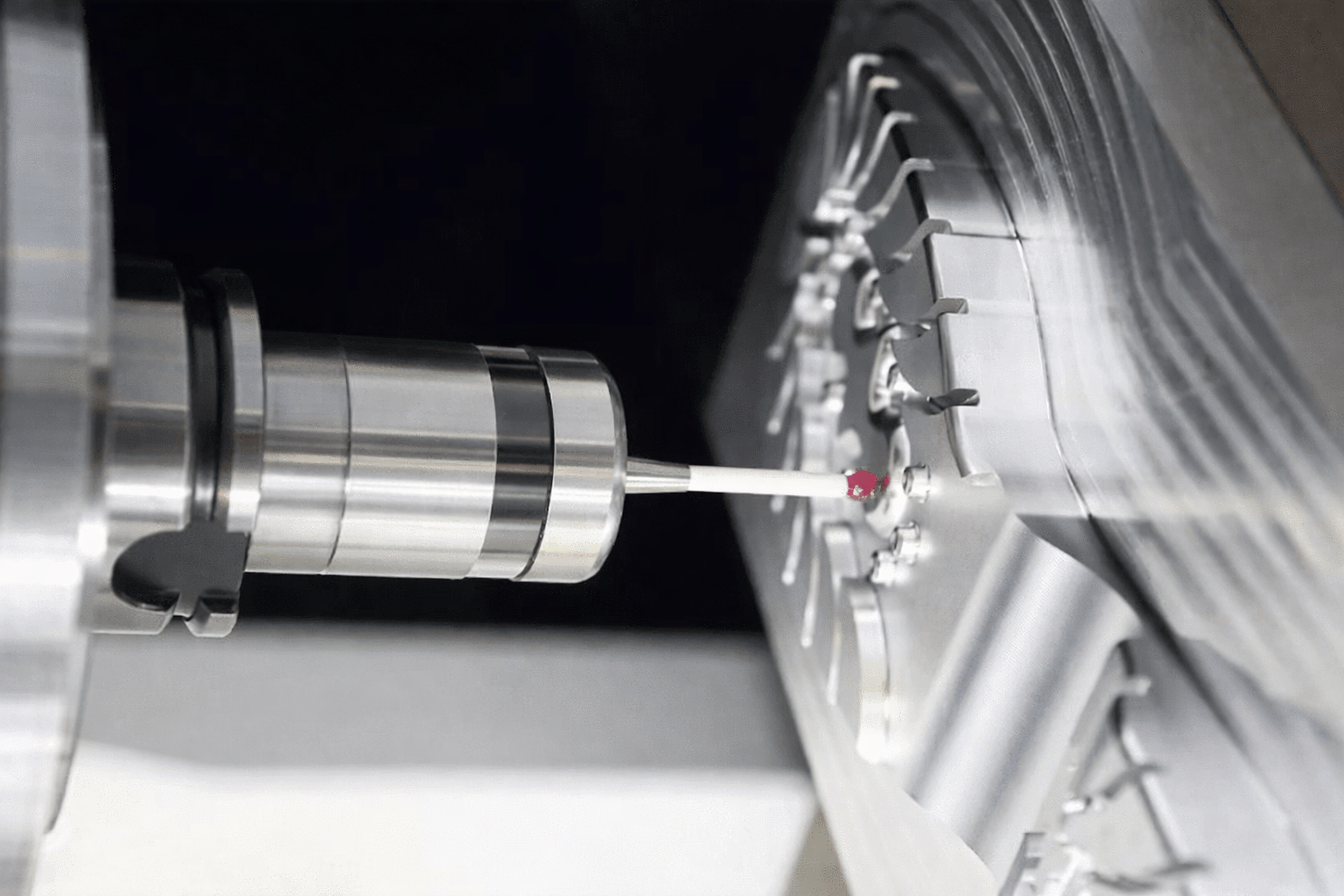

CMMs are commonly used after machining. They provide accurate of a component's dimensions, surfaces and geometric features. It does this using a probing system that moves through three axes to capture data points. CMMs can be relied upon to verify tight tolerances, confirm complex geometries and validate machined features that cannot be checked reliably with manual tools. They are mainly used for first off inspection and final verification of CNC machined components before shipment. It generates a CMM report that can be used for formal QA/QC documentation.

VMM

VMM or Video Measuring Machine is a non-contact method for the measurement of delicate parts. VMMs apply laser scanning technology in determining the geometry of three-dimensional parts. Relative to CMMs, optical measuring machines are considered the best equipment for measuring small parts with complex geometry. In addition, optical measuring machines are also very good at measuring the surface of the part for any type of defect or flaw like porosity or crack.

OMT

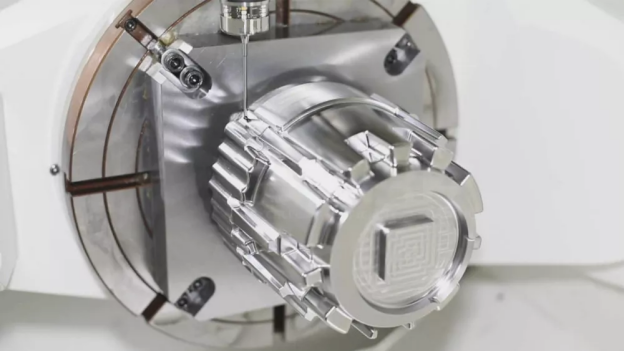

Measurements made directly on CNC machines are referred to as OMM or on machine measurements. The tools used in this regard are called OMT or on machine tools. These are mainly sensors and probes. A touch probe can be used to make precision measurements in a CNC machining process. They can help in making adjustments for tool lengths, diameter and length offsets as well as in measuring various other workpiece dimensions. Probing systems can greatly reduce time required for tool changes and adjustments. Some machines have built in sensors which can measure the features or dimensions while cutting. The sensed data is sent to the machine's controller and the parameters of cutting are adjusted instantly. This improves accuracy and prevents flaws.

Key Differences of On-Machine vs CMM Measurement

|

Features |

OMI |

CMM |

|

Operating Environment |

Runs on the CNC shop floor |

It functions in controlled environments. |

|

Vibrational impact |

More susceptibility |

Vibration isolation |

|

Precision and Reliability |

It gives sufficient accuracy for process control purposes |

It offers very tighter GD&T tolerances. |

|

Working Role |

It's a process control tool that is utilized to make offset adjustments to avoid scrap. |

These are quality assurance tools used in validating finished parts. |

|

Production Time |

It eliminates additional time by avoiding part removal. |

It involves transportation, set-up, and waiting in the queue line which lead to increases time. |

When to Use On-Machine vs Offline Inspection

The decision to inspect with offline or on machine will depend on the complexity of the part, the tolerance, and the units of production.

Apply On-Machine Inspection when:

- When tolerances are tight and constant observation is necessary

- compensation of tool wear is required

- scrap prevention is absolutely essential.

- low volume manufacturing.

Apply Offline Inspection when:

- dimensions are non-complex and non-critical

- quick verification is enough

- equipment accessibility is a constraint

- Inspection of operator level is acceptable

Offline inspection in many shops follows up on OMI with secondary verification without interfering with machining.

Key Steps of On-Machine Inspection

On-Machine Inspection (OMI) involves a series of steps that will ensure proper measurement, feedback, and process control. Every step in the process has a vital part in the integration of the inspection process in CNC machining.

Step 1: Probe Installation

First of all, the appropriate probing system is installed on a CNC machine spindle, such as either a touch trigger probe or laser-based probe depending on the inspection requirement.

Some key considerations for the probe installation:

- Calibration with respect to the machine coordinate system

- Adequate mechanical mounting and alignment.

- Probe Verification

Proper probe installation guarantees reliable measurement data for the entire period of the inspection.

Step 2: Workpiece Loading

After the probe has been mounted, the workpiece is loaded into the fixture. OMI is used at this step to ensure the workpiece position is correct before any machining or inspection process.

During this phase, probing is employed in the following way:

- Ensure fixture and part alignment

- Makes a coordinate system on the work

- Identify misloading or clamping mistakes

Accurate placement of the tooling and work pieces ensures correct assembly and eliminates possible mistakes and errors

Step 3: In-Process Inspection

In this step, the inspection is carried out on the machined part during machining, in order to check critical dimensions and features. It does not require the removal of the part from the machine, but the inspection is conducted at predetermined stages.

This step enables:

- Early identification of tool wear or breakages

- Compensating for Thermal Drift or Deflection

- Automatic tool offset adjustments

In Process Inspection enables OMI to transform from a passive measurement function to an active process control tool.

Step 4: Final Inspection

After the machining operations have been completed, on-machine inspection may be employed to check the desired characteristics on the part before the part is removed from the machine. This give instant feedback.

Final inspection of the machine ensures the following:

- Verify important dimensions

- Verify the stability of the process

- Determine whether additional offline examination is needed or not

Although OMI final inspection enhances efficiency, it usually serves as a complement to high-precision CMM inspection.

Benefits of On-Machine Inspection for CNC Machining

In CNC machining, stability and consistency of product quality are key to winning customer trust. Whether it is aerospace, medical devices, or semiconductors industry even the smallest error in part precision creates big malfunctions. For the manufacturers, on machine inspection is very useful as it helps to verify the part while the machining is still in process.

The following reasons make on machine inspection a considerable choice for producer/manufacturer:

Faster Dimensional Feedback

The transfer of parts to another inspection tools takes additional time. This process is eliminated by on-machine inspection. This inspection takes place in the process of, machining. This not only save time but also enhances process speeds.

The client benefits in this is:

- Problems are identified earlier in the process stream rather than in finished goods at delivery or final inspection.

- It takes less time to validate the design intent when prototyping

- A quicker feedback cycle gives clients faster confirmation for critical dimensions.

- Reduction in delays resulting from inspection bottlenecks

Higher Tolerance Confidence

During the production process the on-machine inspection of parts helps in detecting error as early as possible. This eliminates a lot of scrap or rework of machined parts. Higher accuracy means fewer defects, which develops customer confidence.

Client benefits in this is:

- More confidence that the tighter tolerance is achieved.

- Minimized risk of out of specification parts at final inspection

- enhancing functional reliability of précised parts

For customers with precision parts and high tolerance, quality risk is greatly reduced.

Shorter Lead Times for New Parts

With on-machine inspection there will be less scrap and rework, which means a reduction in costs. It also eliminates delays and ensures that parts are within tolerance right from the start.

During the creation of the first article or when introducing a new part, on machine inspection cuts down on trial and error for machining parameters. Because of the instant feedback on dimensions, optimization can be quickly carried out.

Client benefits in this is:

- Speeding up the approval

- design to production time reduced

- Lower iteration cycles in prototyping

If you need to reduce your lead time without sacrificing tolerance, please feel free to avail Tuofa CNC machining manufacturing. Our CNC machines are fully equipped with on machine inspection tools (OMT). We can deliver good results in a short lead time.

More Stable Quality in Long-Run Production

In the long run on machine inspection always tracks key dimensions and compensates for tool wear and thermal variation.

Client benefit in this:

- Quality of parts over large batches

- less variation between initial and final product components

- Assembled components performance is predictable

Typical Use Cases for On-Machine Inspection

OMI is widely applied in CNC machining to enhance the reliability of processes and reduce scrap. The following use cases represent the most practical applications of OMI. It is employed for setup verification, datum confirmation and process checks.

Setup Verification

One of the most frequent applications of on-machine inspection is setup verification. Once the first workpiece is placed in the machine and positioned using the fixtures, on-machine inspection follows to verify that the workpiece is properly located in relation to the machine coordinate system.

Through datums or reference surfaces inspected before machining, the operators can:

- Check fixture orientation

- Detect Clamping/Loading Errors

- Prevent machining on incorrectly positioned parts

It cuts down on the probability of rejecting the first piece and guarantees the starting process of machining with a confirmed setup.

Datum Confirmation

Confirmation of the datums ensures that the part coordinate system is established correctly before and during the machining process. OMI probes critical datum features such as faces, bores, or edges to confirm location and orientation.

This is particularly important for:

- Multi axis machining

- Complex requirements in GD&T

- Parts that are subject to multiple operations in which some repositioning occurs

Accurate confirmation of the datum helps to maintain consistency in dimensions through different operations and on different machines.

Process Checks on Critical Features

OMI is often employed to inspect critical dimensions during the machining process, as opposed to when the part is finished. Such checks in the process enable the early detection of tool wear, tool deviation, or thermal drifts.

Typical features that are assessed for include:

- Bore diameters

- Slot widths

- Depths of Pockets

- Position of Critical Holes

In case there are deviations, tool offset values can be automatically changed to avoid scraps and ensure consistent product quality.

Conclusion

On machine inspection has nowadays become an essential part of CNC machining processes. This technique speeds up the inspection procedure, make part error free, saves money and helps to keep up the good quality. On one hand, conventional methods such as CMMs are still needed for minute inspections. On machine measuring has completely changed the idea of in process inspection and production planning. By using the right tools and techniques, manufacturers can remain competitive in the market.

FAQs

Is CMM the same as CNC?

CMM and CNC might sound same but are different. CMMs are specialized equipment used to inspect and measure the geometrical characteristics of objects. CNCs are automated systems used to manufacture components by following programmed instructions.

How accurate is on-machine inspection?

On-machine Inspection (OMI) has strong accuracy in the control of the process and in error detection. This has the advantage of micron-level precision in checking parts in-process. This is more efficient since it allows immediate correction. However, it is less accurate than CMM since it is environment-dependent.

Can on-machine inspection replace final inspection?

On-Machine Inspection (OMI) can almost never completely replace the need for final inspection; however, it can certainly decrease it substantially, especially when it comes to moving from a 'Detection' approach for quality control towards a 'Prevention' approach. Although On-Machine Inspection (via probes in CNC machines) is very accurate and provides for real-time correction of errors, it is considered more of a 'verification' step than a final check-off before shipping out the product.

What is the main difference of on-machine and in-process inspection?

The basic difference between on-machine and in-process inspection methods primarily revolves around the time and place at which the inspection activity takes place in relation to the manufacturing machine. On-machine inspection is conducted by making use of probes present on the CNC machine itself, while an in-process inspection can be considered an encompassing strategy.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Golf Putters CNC Guide: Why Choose Milled Putters?

Golf Putters CNC Guide: Why Choose Milled Putters?