OEM Aluminum Parts Guide: Processes, Alloys, & Designs

Nov 24,2025

Nov 24,2025

If you are sourcing auto parts in bulk for retail, dealership supply or for regional distribution, understanding and choosing the right part is key for customer satisfaction, long-term cost-effectiveness and for product efficiency. This article will give you deep insights to analyze different types of aluminum parts, such as evaluating OEM, OES, or aftermarket options, their pros and cons, and the best type for your case.

What are OEM Aluminum Parts?

OEM (Original Equipment Manufacturer) aluminum parts are made by the same company that produced them originally for a product's manufacturer. They are identical to the factory aluminum parts. OEM parts are categorized based on function, like structural, enclosure, or precision parts, for new product development or when a supplier change occurs. However, these are normally costly than after-market parts.

OEM vs OE vs Aftermarket

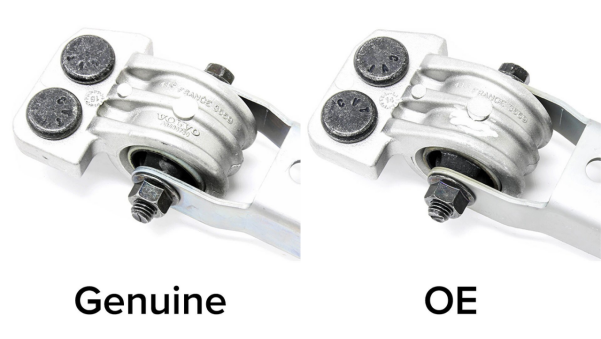

OEM is when a company produces parts for other brands. These parts are identical to the original ones. OE is when a part is originally installed in a vehicle during manufacturing. This is the same as an OEM part, but specifically mentions the part that is used in the final product. Aftermarket is the parts made by a different company that are compatible with vehicles but not original.

Aluminum Parts by Function

Based on function, aluminum parts are categorized as:

- Aluminum Structural Parts: provide a framework and integrity of a product, like a chassis or engine block part

- Aluminum Enclosure Parts: form a protective outer shell, like housing or panels

- Aluminum Precision Parts: that need high accuracy and tight tolerance, like engine or gear parts

When to Look for OEM Aluminum Parts

You may need an OEM aluminum part:

- when designing new products, to have the OEM part with the same specification and quality as the original.

- when the supplier changes, but the part needs an exact specification.

- when high-quality repairs are needed, and the OEM parts are expected to perform at the same level as the original.

- and when there is a warranty requirement.

Common Aluminum Grades for OEM Parts

Common aluminum series for OEM parts include 1xxx, 5xxx, 6xxx, and 7xxx. The choice depends on application requirements, like strength, weldability, and surface finish.

Common Aluminum Series Choices

The common aluminum series used in OEM parts are:

- 1xxx Series: Pure aluminum grades with high corrosion resistance and conduction properties. These are ductile and not very strong.

- 5xxx Series: have high strength, weldability, and corrosion resistance in marine environments.

- 6xxx Series: are versatile, with good strength, formability, and weldability.

- 7xxx Series: are the strongest aluminum alloys available, with high strength and hardness, used for aerospace and defense applications.

6061-T6 vs 6063-T5 OEM Aluminum

Both are strong and hard alloys. Their machining properties are comparable. 6061-T6 has good machinability for high-speed CNC machining and is stronger and harder. While 6063-T5 has fair machinability for simple shapes and extrusions, and has less strength and high formability.

7075-T6 OEM Aluminum

It is the strongest aluminum alloy with a high strength-to-weight ratio. 7075-T6 is best for high-stress applications because it is less corrosion resistant than other alloys and has lower weldability and machinability than the 6000 series.

5052/5083 Aluminum Parts

They have remarkable bending and welding properties due to high ductility and formability. 5052 and 5083 are better suited for marine applications for their high corrosion resistance in salt water.

6082-T6 Aluminum Parts

6082-T6 alloy is a common structural alloy and is mostly used in bridges, cranes, and frameworks. It has good strength, toughness, and corrosion resistance, and is suitable for heavy-duty applications for EU standards.

What Are the Better Methods to Manufacture OEM Aluminum Parts

The better methods for OEM aluminum parts manufacturing are CNC machining, sheet metal fabrication and die casting.

#1 CNC Machining OEM Aluminum Parts

CNC machining, like Milling, Turning, 5-Axis of OEM aluminum part offers:

- High precision and tight tolerances, to ±0.005

- Intricate details and complex geometries and intricate details.

- Versatile for part size, from small to large OEM components.

However, it has some limitations:

- High material waste

- Slower and expensive for simple parts

CNC machining is best for attaining high accuracy, complex designs, and tight tolerances for aerospace, medical, or electronics industries.

#2 Sheet Metal Fabrication Parts

Sheet metal fabrication like laser cutting or CNC bending of OEM parts, offers:

- Efficient process of OEM aluminum parts with flat, folded, or modular shapes.

- Cost-effectiveness for low-to-medium volume production.

- Customization with a variety of shapes and sizes.

However, it has some limitations like:

- Not suitable for creating parts with complex or 3D shapes

- Less precision than CNC machining

Sheet metal fabrication is best for enclosures, brackets, housings, and other parts used in consumer electronics, automotive, and construction.

#3 Die Casting plus CNC

Die casting for OEM aluminum parts offer:

- High production efficiency with quick cycle times,

- Thin-wall and internal OEM components with complex features

- fine crystalline structure that improves mechanical properties.

- Good surface finishes

However, it has some limitations like

- High capital investment for expensive tooling

- Not suitable for low-volume or prototyping.

Die casting is best for mass production because high initial cost can pay off large number of parts like for automotive parts, appliance components, and consumer goods.

Design for Manufacturability (DFM) for CNC Aluminum

To DFM for CNC aluminum parts, prefer ease of manufacturing, optimizing design and choosing right material with simple geometry.

Products Purposes

Consider the purpose of choosing the right aluminum alloy like some are harder or stickier that can increase tool wear and lower cutting speed.

Aluminum Machining Challenges

Some common aluminum machining challenges are:

- Soft metals are prone to warping due to heat and stress during machining

- Aluminum stickiness causes tool wear

- Small features can be damaged during machining

- Chip evacuation is difficult

Wall Thickness and Feature Design

Wall thickness must be high to prevent warping and vibration and do not use large variation in wall thickness. Feature design must be consistent with large radii and avoid deep and narrow pockets to make all the features within reach.

Avoiding Common DFM Errors in Aluminum

Avoid these DFM errors to increase process efficiency:

- Tight tolerance

- Unmachinable geometry like pockets or sharp corners

- Material incompatibility

- Misaligned features

Surface Finishes for OEM Aluminum Parts

Some common surface finishes process of OEM aluminum parts are:

- Anodizing is an electrochemical process to convert surface into a durable aluminum oxide layer. It can be clear, black or in other colors which provides durability, hardness, and corrosion resistance.

- Powder coating is applying the dry powder electrostatically and then cured with heat to form a tough finish like polyester, epoxy, and hybrid coatings. It has high UV and weather resistance

- Physical Vapor Deposition (PVD) is vacuum coating that deposits ultra-thin aluminum films onto a surface. it has high surface hardness, wear resistance, and corrosion protection.

Applications for CNC OEM Aluminum Parts

Common applications for CNC OEM parts are as follows

Medical and Lab Devices

6061-T6 is biocompatible and used in surgical instrument and implantable device housings.

Automotive and EV Assemblies

6063 is used in battery enclosures, structural components, motor housings for its corrosion resistance and thermal conductivity.

Robotics, Drones and Automation

6061-T6 and 7075 are used for structural, automated hardware, precision-turned, and motor housings parts.

Electronics Enclosures and Heat Sinks

6061 and 6063 are used in heat sinks and enclosures because of their high thermal conductivity and also for CPUs, power supplies, and inverters.

How to Choose a Proper OEM Aluminum Parts Supplier

There are some important points to consider when choosing right supplier for your OEM aluminum parts.

OEM Manufacturers Check List

Consider this checklist before selecting the supplier:

|

Factor |

Considerations |

|

Experience and Reputation |

Business years with customer reviews |

|

Quality and Certification |

Verify if they are ISO certified |

|

Technical Capabilities |

Machine quality, tolerance and finishing requirements. |

|

Material and Tooling |

expertise with aluminum and other materials |

|

Production Capacity |

production volume |

|

Cost and Value |

initial costs, total cost and potential ROI. |

|

Communication and Support |

responsiveness and communication style. |

Why Choose TUOFA CNC Machining

TUOFA CNC Machining offers custom CNC machining with variety of material options other than aluminum alloys. We offer efficient services for both rapid prototyping and mass production with 99.88% on-time delivery rate with 10 days turnaround time.

Conclusion

OEM aluminum parts require selecting the right alloy, for example 6061 for general use, 7075 for high-strength aerospace applications. These are manufactured with CNC machining, sheet metal fabrication and die casting. Design considerations are important in all processes, like adding draft angles for casting for easy part removal from mold.

10 Common OEM Custom Aluminum Parts FAQs

1. What files do you need to quote?

To quote OEM custom aluminum part, you need 3D CAD file, with detail of quantity, material, surface finish, and any required tolerances.

2. What is the typical MOQ for OEM aluminum parts?

MOQ for OEM aluminum part can vary from 100-200 pieces to 1,000 or more.

3. How long do first articles usually take?

It may take 2-6 weeks for custom parts.

4. Can you make parts from a sample if I don’t have drawings?

Yes. OEM manufacturers can make it from a sample even if you don't have drawings.

5. Who is the largest OEM in the world?

Apple is the world's largest OEM by revenue for $391 billion in 2024

6. How are threads handled when anodizing?

They are handled either by masking or by machining the threads to accommodate the anodize layer.

7. Do you provide material and finish certificates?

Yes, we provide material and finish certificates for OEM custom aluminum parts.

8. Can you install PEM inserts or helicoils before shipping?

Yes, we can install PEM inserts or helicoils before shipping for custom aluminum parts.

9. How do you label and package parts for traceability?

OEM manufacturers use direct part marking (DPM) methods and apply barcodes on the parts and their packaging.

10. Can you keep revision control and notify me of changes?

Yes, revision control and change notifications are possible with software for factory aluminum parts.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Steel Sleeve Machining: Types, Applications & Process

Steel Sleeve Machining: Types, Applications & Process