What Is Slot Milling? The Newest Guide for You in 2026

Feb 07,2026

Feb 07,2026

CNC machines are among the most important tools in the manufacturing field. Every CNC milling operation has different types that are used for different applications. This article particularly focuses on the milling operation type, i.e., Slot Milling. All the important aspects of this type are discussed in this newest article on slot milling.

What Is Slot Milling?

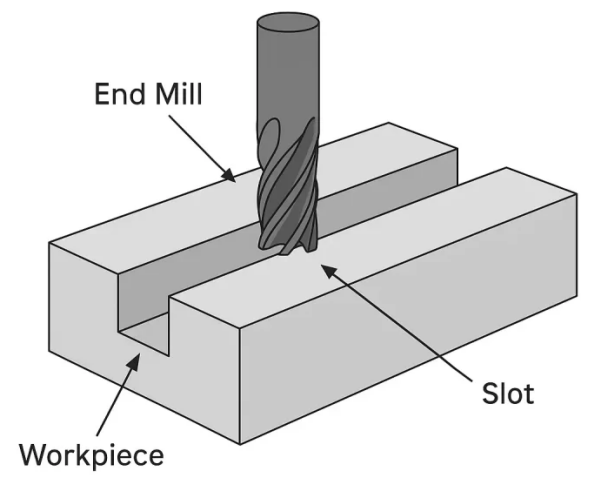

To place a seal or gasket, or for other purposes, slots are manufactured on the workpiece. These slots can be inside a part or can be on the surface. The process used to create these slots on a workpiece is called slot milling. It is one of the major types of CNC milling operations and is widely used in important industries, including aerospace and medical implants.

Is Slot Milling Important?

The slots inside or outside of the parts are made for different reasons. The advantages of these slots are:

- Used to place seals, gaskets

- Helpful in weight reduction

- Allow parts to thermally expand without creating distortion

These are some main advantages that show the importance of slots in a part. To make these slots. So, yes, slot milling is an important machining operation.

How Does Slot Milling Work?

The general rule of subtractive manufacturing is to remove the excessive material from the workpiece to get the final shape. Slot milling operates on the same rule. The depth of the slot milling operation is discussed here:

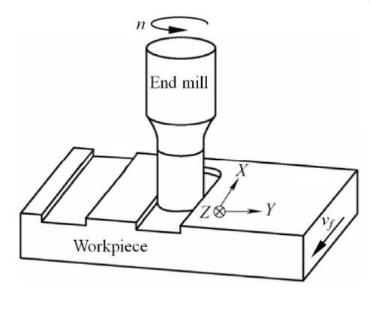

Principle of Slot Milling

The principle of slot milling is:

“Multipoint rotational slot cutters rotate about a fixed axis and remove the material from the workpiece.”

Please see the following figure:

The cutter enters the workpiece's material either axially or radially.

Step-by-Step Process of Slot Milling

- First, define the slot requirements, like slot width or slot length, etc.

- Select the cutting tool, such as an end mill or slot mill, etc.

- Now, arrange the workpiece setup & fixturing

- Arrange the machine and tool setups

- Set cutting parameters, such as spindle speed or feed rate

- Enter the tool into the workpiece

- First, rough slot milling, then chip evacuation and cooling

- Inspection and verification followed by further cleaning if required

Key Factors Affecting Slot Milling Performance

The factors, such as workpiece material, tool path strategy, or slot shapes, affect the efficiency of the slot milling process. Let's see how:

Workpiece Material

This is the fundamental in manufacturing, no matter if it is the designing stage or the actual machining process. For instance, if the material of the workpiece is hard (hardened steel), higher cutting forces will be required. If it is ductile, it will produce long continuous chips, which lead to chip clogging in the deep slots.

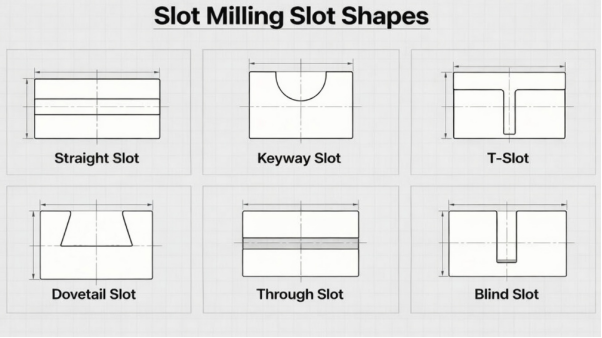

Slot Shapes

The geometry of the slot shapes affects the performance of slot milling to a great extent. For instance, in the case of narrow slots, the chip evacuation is poor and requires a higher cutting force.

Slot Milling Cutters

Multiple slots milling cutters (flat end mills, slotting end mills, etc.) are available, which are used in the production of grooves, keyways, and slots. So, a wise selection of slot milling cutters is required.

Toolpath Strategy

How the slot milling cutters enter the workpiece material, move, and exit is decided based on the toolpath strategy. This toolpath strategy is responsible for controlling tool wear, accuracy, and cutting force. So, it is important to select the toolpath based on these parameters.

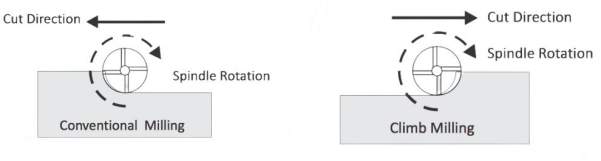

Milling Direction

The parameters, such as cutting force, surface finish, tool life, and accuracy, are directly affected by milling direction. For instance, conventional milling results in a poor surface finish.

Slot Milling: Shapes and Cutters

In slot milling, there are multiple milling cutters used. They can be used simultaneously or separately. These milling cutters are responsible for creating different kinds of shapes.

Types of Slot Shapes

For instance, the common slot shapes that are created on the workpiece are given below:

Straight Slot

On the workpiece, straight slots are made to serve the following purposes:

- Allow the sliding of the part in a controlled way

- House functional elements, like keys, wires, etc.

- Good for positional tuning during assembly

- Helpful in reducing the weight

Keyway Slot

Keyway slots are made on the workpiece when a component needs:

- Positive mechanical lock

- Torque transfer from the shaft to the hub

- Easy assembly and disassembly

- Maintained angular alignment of components

T-Slot

The geometry of T-slots is very important because the undercut “T” head prevents bolt pull-out, so the load distributes under the slot slips. Other functions include:

- Provides adjustability in position before tightening

- Enables strong clamping against the uplift and lateral forces

Dovetail Slot

The shape of the dovetail slots is very beneficial with respect to their functionality. Their angled walls create self-locking geometry. Besides the self-locking geometry, other purposes include vertical separation prevention and handling of lateral forces.

Through Slot

When a full-depth opening is required, this shape of slots is created on the workpiece, for instance, for fasteners and bolts. This shape is also beneficial for easy chip evacuation.

Blind Slot

In this shape, one end of the slot is closed and created on the workpiece for internal channels. This shape maintains the strength and appearance of the respective part.

Choose Suitable Slot Milling Cutters

The following table describes the recommended milling cutter for a respective slot shape.

|

Slot Shape |

Recommended Cutter |

Why This Cutter Is Suitable |

|---|---|---|

|

Straight, narrow slots |

End Mill |

Versatile, good dimensional control, suitable for shallow to medium-depth slots |

|

Wide or deep straight slots |

Side Cutter |

Cuts with side teeth, higher material removal rate, better for deep slots |

|

Shallow, wide slots or recesses |

Face Cutter |

Provides flat bottom surface with good surface finish |

|

Keyways (shaft hub slots) |

Keyseat Cutter |

Designed for precise keyway width and depth |

|

T-shaped slots |

T-Slot Cutter |

Allows undercutting after initial straight slot machining |

|

Multiple parallel slots |

Gang Mill |

Multiple cutters machine several slots simultaneously, high productivity |

What Materials Are Ideal for Slot Milling?

The mechanical properties of each material are different, which ultimately affect the machining processes. Different materials are listed below for slot milling. The understanding of which is better to choose for slot milling is important for greater efficiency of the machining processes, as well as the performance of the part.

Aluminum Alloys

Al alloys have an FCC crystal structure, which makes them soft and easy to machine. The common alloy in aerospace industries is Al 6061-T6. This alloy is commonly machined for making slots due to its good machinability and low cutting forces.

Brass Material

The reasons why brass material is slot milling friendly are:

- Excellent machinability, so lower cutting forces are required

- Forms brittle and short chips, easy to remove from the slots

- Low built-up edge (BUE)

- Always provides an excellent surface finish, so commonly used for decoration purposes

Medium Carbon Steel

This material has 0.3 - 0.6% C content, which provides a balance in strength and machinability. It is considered a good material for slot milling because:

- Resists tearing and edge deformation

- Chip formation is better

- Lower built-up edge than mild steel

- During machining, dimensions remain stable

Engineering Plastics

Generally, plastics are not employed for CNC machining because they are relatively weak materials. But engineering plastics, such as PEEK (Polyether ether ketone), Nylon, Polycarbonate, etc., offer sufficient strength to withstand the cutting forces, which is why considered slot milling friendly material.

What Are Slot Milling Toolpath Strategies?

A toolpath means the direction in which a cutting tool operates on the workpiece or from where it will enter or exit during CNC machining.

Why Is Slot Milling Toolpath Strategy Is Important?

During slot milling, the toolpath strategy is important because it directly controls the surface finish, tool wear, and its life, affects cutting forces, and determines the cycle time and accuracy.

Types of Slot Milling Toolpath Strategies

Based on requirements, a toolpath strategy is made for the machining process. For example:

Traditional

It is simple linear cutting with constant engagement of the tool with the workpiece. This type of toolpath strategy is used when:

- The part's geometry is simple

- The machinability of the material is good

- A shallow depth of the part is required

Trochoidal Slot Milling

In this strategy, the tool operates in a circular motion along the length of the workpiece. It is used to control the cutting force, manage thermal effects of machining on tool life, so increases the tool life.

Plunging Slot Milling

In this strategy, the material is primarily removed from the z-axis. It is used for deep slots, narrow slots, blind slots, and slots with a long depth-to-width ratio.

Traditional vs Trochoidal Slot Milling

Traditional and trochoidal slot milling strategies are used commonly. The points in which they differ from each other are:

|

Aspect |

Traditional Slot Milling |

Trochoidal Slot Milling |

|---|---|---|

|

Tool engagement |

Full slot width |

Partial, constant engagement |

|

Cutting forces |

High |

Low and stable |

|

Heat generation |

High |

Reduced |

|

Tool wear |

Rapid |

Significantly lower |

|

Slot depth |

Limited per pass |

Suitable for deep slots |

|

Productivity |

Moderate |

High (at higher speeds) |

Slot Milling: Climb vs. Conventional Milling

Based on the milling direction milling process is divided into two types, so the slot milling has also two types, i.e., Climb milling and conventional milling.

What are Climb & Conventional Milling?

1. Conventional Milling

In this type of milling operation, the cutter rotates in the opposite direction to the feed, which is why it is also called up milling. This process is still in use in old machines and taught to students as a foundation of milling operations.

2. Climb Milling

This is the opposite of the conventional milling operation. The cutter rotates in the direction of feed. It is only used in CNC milling and modern milling machines, which is the technology engineers care about more.

Climb Milling vs Conventional Milling

Besides the direction of milling tools, there are many other differences between conventional and climb milling operations. These differences are discussed briefly in the following table:

|

Aspect |

Conventional Milling (Up-milling) |

Climb Milling (Down-milling) |

|---|---|---|

|

Chip thickness |

Starts from zero → maximum |

Starts from maximum → zero |

|

Initial tool work contact |

Rubbing first, then cutting |

Immediate cutting, no rubbing |

|

Cutting force direction |

Tends to lift the workpiece |

Tends to pull workpiece into cutter |

|

Cutting forces |

Higher |

Lower |

|

Heat generation |

More (due to rubbing) |

Less |

|

Tool wear |

Faster, more flank wear |

Slower, more uniform wear |

|

Surface finish |

Rougher |

Better / smoother |

|

Typical application |

Rough machining |

Finish machining |

What Are Pros & Cons of Slot Milling?

Compared with end milling and face milling, slot milling can cut precise internal grooves that enable assembly and functional fit. In some cases, slot milling is very beneficial, like to create slots for weight reduction. But it also has some limitations.

Advantages of Slot Milling

Some advantages of slot milling include:

High Cutting Efficiency

Since the cutting tool in slot milling has multiple teeth along its length, that's why it engages the workpiece along its full tool width. It means multiple teeth remove the material simultaneously. When multiple teeth remove the material simultaneously, the material removal rate increases. Higher MRR increases cutting efficiency and productivity.

Flexibility for Shapes

Slot milling is equipped with multiple tools, which are used to create different shapes of slots on the workpiece; this means the flexibility in shapes is higher. For instance, an end mill is used for creating rectangular slots, and T-slot cutters for creating T-shaped slots.

Precise Slot Geometry

The reasons why slot milling provides precise slot geometry are controlled tool engagement predictable material removal rate, and accurate tool guidance.

Limitations of Slot Milling

There are some disadvantages of slot milling that limit its uses during the manufacturing of a part. For instance:

Tool Wear

There is a disadvantage of tool wear in the slot milling, let's see how:

- Due to continuous engagement of the cutting tool, higher is the heat is built-up, so the tool wears quickly.

- Poor chip evacuation, especially in deep or narrow slots rub the cutting edges of the slot milling tool.

Limited Slot Width

Tool slot width is limited because the width of the slots is directly controlled by the milling cutters. The width can only be adjusted by changing the cutting tool.

High Cutting Forces

During the slot milling, since the cutting tool continuously removes material from the workpiece, cutting machines have to provide higher cutting forces. The axial and radial cutting forces are due to the large contact area.

What Is Slot Milling Used For?

Slot milling is used in the aerospace and medical implant industries, which shows its importance in manufacturing the parts. Its primary applications include:

Mechanical Components

In mechanical components, such as robotic arm sliders, drawer slides, and tool holders, guide slots are used. The key slots are used in couplings and clutch hubs, motors, and flywheels on crankshafts.

Automotive Parts

For automotive parts, slot milling is used in transmission components (gear shafts, clutch hubs, and differential assemblies), engine components, etc.

Precision Equipment

In precision equipment, slot milling is used in heat sink grooves, linear slide guides, torque transmission slots, airflow channels, and component mounting slots.

Conclusion

Slot milling is a part of the CNC milling operation, which is responsible for making different types of slots in the parts. These slots have multiple shapes, which are different based on their geometry and applications. Every shape is dependent on the milling cutter; for instance, a straight slot can only be created by an end mill cutter. These slots are used for thermal management, weight reduction, etc., and employed in important industries like automotive parts and precision equipment. Tuofa advanced CNC milling is mature and can help you create precision and accurate slots shapes for assembly, fixturing or lightweighting.

FAQ

What is the depth of cut for slot milling?

The depth of cut varies with respect to material, slot width, tool diameter, and rigidity of the setup. Generally, the cut is 1 x the tool diameter per pass.

What is optimization of milling process parameters?

Optimization of milling parameters, such as cutting speed, feed rate, etc., is done to maximize the efficiency, surface quality, and tool life.

What is milling?

It is a subtractive manufacturing process in which the cutting tools remove the material from the workpiece to achieve the desired shape. It is generally used for complex geometries.

What are differences between end mill and face mill?

Both are rotating cutting tools. An end mill can remove the material from axial or radial directions. A face mill is used for a large Material Removal Rate (MRR) and flat surfaces.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What Is An Electrical Bus Bar? A Complete Engineering Guide 2026

What Is An Electrical Bus Bar? A Complete Engineering Guide 2026