Side Milling: All About Milling Process and Materials Choices

Nov 18,2025

Nov 18,2025

There are many CNC machining processes that have their own perks and results, and side milling is one of them. It creates different slots and cuts on a vertical surface. This article will highlight all the essential details of side milling processes to get optimized machining results.

What Is Side Milling?

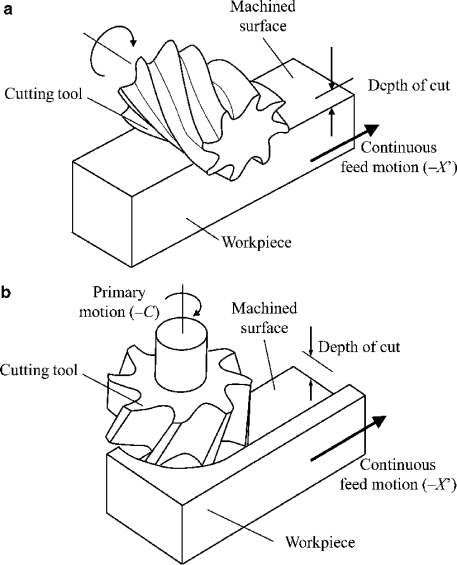

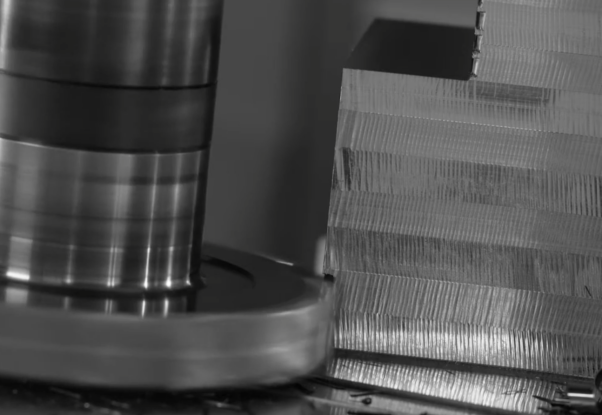

Side milling operation is a CNC machining process. It has a cutting tool to remove material from the side or edge of a workpiece. Side milling can create features like slots, grooves, and contours. It is perfect for creating parallel faces, such as presented in narrow slots or tall walls.

Explaining Side Milling

What is side milling? The rotating cutting tool is called endmill that carves into the walls of material. A CNC machine with computer code like G-code controls the precise movement of tools and cuts it with high accuracy.

How Side Milling Work on Workpieces?

The cutting tool's axis is parallel to the surface being machined, and the cutting action is done along the side of the workpiece. For a very deep cut in a single pass, the process is repeated at multiple depths.

When to Use Side Milling on CNC Parts

It is used to create two or more parallel surfaces simultaneously. It can create narrow slots or deep cuts with precision in a single pass. Other than these, it is used for complex contours, tall walls, thin walls and for fine and precise edges that are needed in aerospace manufacturing.

Machining Challenges in Side Milling

There are a few challenges in side milling operation and these are:

- Less consistent surface finish as compared to face milling

- Aggressive settings and wrong milling methods can cause tool wear

- Deep cuts cause vibration that can lead to poor finish

- Internal features cannot be created by side milling

Side Milling vs End Milling vs Face Milling

Side milling cuts along the side of material. End milling generates detailed profiles and slots on material. and face milling flattens large surfaces with a disc-like cutter.

Advantages and Disadvantages

A brief comparison of the pros and cons of all the methods are as:

|

Feature |

Side Milling |

End Milling |

Face Milling |

|

Advantages |

· Creates grooves, slots, and profile milling along the sides. · Used for roughing and finishing. |

· creates complex shapes. · Provides high precision. · versatile |

· quick material removal for smooth and flat surfaces. · Excellent surface finish. |

|

Disadvantages |

· vibration, tool wear, and tool breakage · need management of feed rate and coolant. |

· Slower material removal rate · Costly |

· Limited features · high capital investment · Limited cutting depth. |

What Is the Force Direction

The force direction of side milling is horizontally into the side of material.

End mill has forces on vertical and horizontal sides depending on the requirements.

Face milling has forces perpendicular to the surface pushing tool downward.

Wall Finish vs Floor Finish

Wall finish is called side milling. It can create profiles, edges, and channels on the vertical sides of a workpiece. However, floor finish or face milling creates smooth and flat top surface on a part like cylinder head or a machine base.

How Deep and Tall You Can Cut

Side milling and face milling cutting depths are limited. Face mill can cut up to around 2.8mm. While end mill is flexible for deep cuts and can reach into deep cavities.

And the aspect ratio control is excellent for end milling due to its cutting ability. Face mill and side mill are not suited for high aspect ratio features.

What are the Main Side Milling Processes in Operations

The common side milling processes used in operations is explained below briefly.

1. Plain Side Milling

Plain milling is a basic process to create flat surfaces along a linear path. A cylindrical cutter with peripheral teeth rotates parallelly and removes material from the workpiece.

2. Half-Side Milling

It is designed to machine only one face of workpiece. A cutter is used to cut a single vertical surface to create a flat and vertical face.

3. Straddle Milling

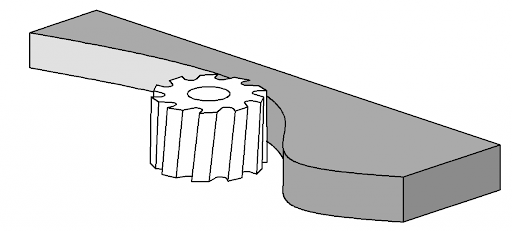

It can machine two parallel sides of a workpiece simultaneously. Two side milling cutters are mounted on the same arbor and mill two parallel vertical surfaces at the same time.

4. Slotting and Grooving

It creates slots or grooves in a workpiece. Cutter removes material of a desired channel shape on the side or through the workpiece.

5. Bevel/Angle Side Milling

It is also called angular milling and cuts at an angle to the main axis of the workpiece. A specialized cutter creates surfaces like bevels or chamfers, on the side of a part.

How to Choose the Right-Side Milling Cutter?

To choose the right-side milling cutter:

- Consider the surface like flat surface needs cylindrical cutter

- Use end mill for high precision and complex contours and for high volume use slab milling

- Choose cutter material based on workpiece material

- Account for operation like straddle milling needs two cutter and gang milling needs multiple cutter

What Common Materials Can Be Used in Side Milling?

The common materials used for side milling are aluminum, stainless steel and titanium.

Key Factors When Choosing Materials

Consider these factors when choosing materials.

Side Milling Aluminum

It is lightweight and has high machinability. Aluminum needs soft and high-chip load tools and is ideal for both prototyping and high-volume production.

Side Milling Stainless Steel

It has high corrosion resistance and strength. stainless steel needs carbide tools and used in different industries from food processing to aerospace.

Side Milling Titanium

It is lightweight, high strength, and high corrosion resistant. Titanium has difficult machining but is common for aerospace and high-performance applications.

Custom Side Milling Solutions for Complex Parts

If you are looking for service provider for custom side milling of any complex parts, contact TUOFA today! We are specialized in custom CNC machining, like side milling for complex parts, and offers one-stop services from prototyping to high-volume production.

Applications for Side Milling

The common applications of side milling are:

- It is used for cutting narrow channels, straight slots like keyways, and grooves into workpieces.

- It is used for creating 90-degree angles, steps, and shoulders on a part.

- It is used for contours and external profiles like machining complex shapes and external outlines on parts.

Conclusion

Side milling uses a rotating cutter to remove material from the side of workpiece. It creates flat surfaces, contours, and features like steps. Common tools used are end mills and side milling cutters. This process is suitable for metals, plastics, and composites depending on the application.

FAQs

What is the most common type of side milling in the shop?

End milling is the common type of side milling that uses end mill cutter to cut slot, profile milling and pockets.

Side milling vs end milling: which to choose?

Side milling is for creating large and flat surfaces while end milling is for intricate and complex shapes.

How deep is it safe to go with a side milling cutter?

It starts from 5-10% of cutter diameter in finishing side wall cuts to 100% in slot milling.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

OEM Aluminum Parts Guide: Processes, Alloys, & Designs

OEM Aluminum Parts Guide: Processes, Alloys, & Designs