What Is Insert Molding? When to Use It?

Sep 04,2025

Sep 04,2025

At times a designer needs to make a part light weight, easily manufacturable, fully functional with a limited number of assembling steps. Insert molding provides this solution. It is cost effective and have the ability to merge multiple materials and geometries into an integrated single component. Let's have an overview of this incredible manufacturing process.

What Is Insert Molding?

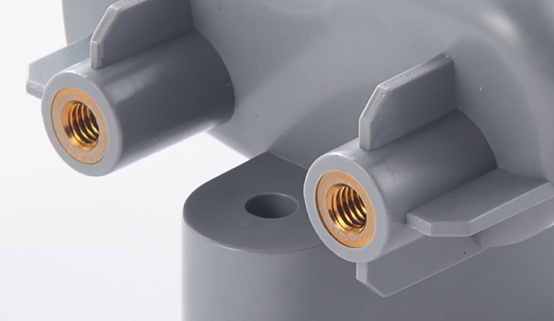

Insert molding is a specialized version for the injection molding process. It is being extensively used in manufacturing processes where benefits of multiple materials can be reaped. For instance, the strength or conductivity of metals can be combined with the insulation and low cost of plastics. Look around you! There are a lot of applications of insert moulding. Be it electronic switches, screw drivers, knobs or highly sophisticated medical devices, insert molding has its applications everywhere.

How to Define Insert Molding

Insert molding is very similar to the injection molding process. The only addition in insert molding process is that of placing molding inserts into the mold cavity. Inserts can be of metals, ceramic pieces, or other substrates. The injected plastic solidifies around the molding inserts. Upon solidifications it makes a good mechanical bond between the plastic and the inserts. Thus, it acts a single integrated component.

What is a molding?

Molding is a material shaping process in which a mold cavity is filled with plastic or metal in their fluid state. Once the material solidifies, it takes up the shape of the mold cavity.

Insert Molding vs. Standard Injection Molding

The below table contrasts some of the features of insert molding and injection molding:

|

Aspect |

Standard Molding |

Insert Molding |

|

Material |

All plastic |

Plastic and insert |

|

Assembly |

Post-assembly needed |

Integrated in mold |

|

Strength |

Low strength |

Stronger due to inserts |

|

Cost |

Higher because of extra assembly |

Lower due to a single step |

|

Durability |

Limited by plastic |

Enhanced by insert |

|

Precision |

Plastic tolerances only |

Better fit with insert |

|

Use |

Simple plastic parts |

Connectors, switches, threaded parts |

How Insert Molding Works

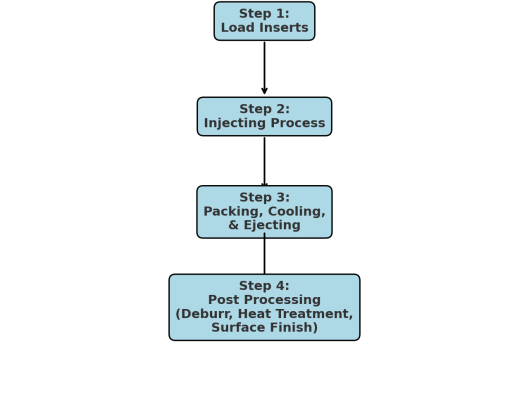

Insert molding adds a few additions to the injection molding process. It requires an injection molding machine, molding dies, plastic raw material and molding inserts. In the insert molding process, the encapsulation and solidification of plastic around the insert makes a single integrated component. Here is a step-by-step structured approach to the insert molding process:

Step-by-Step Process Flow

Step1-Load Inserts

The molding inserts are positioned inside the mold cavity according to the insert molding design. Making sure that the inserts are properly aligned and held securely is critical. It can be done manually or through automated robots.

Step2-Injecting Process

Once the inserts are positioned and held securely, molten plastic is injected into the mold cavity. All voids, air traps, or weak bonding areas should be avoided.

Step3-Packing-Colling-Ejecting

During cooling additional plastic is forced into the cavity to compensate for shrinkage. Upon full solidification the part is carefully ejected.

Step4-Post Processing

Depending on the application the insert molded part can be subjected to post processing. Deburring is commonly used to smooth out flash. Heat treatment is carried out to enhance the strength and durability. Surface treatment adds plating coats to enhance aesthetic appeal.

Manual vs. Automated Insertion

Manual insertion is usually done for larger parts that are smaller in number. Labor can manually position the inserts. In this way capital cost can be saved. On the other hand, automated inserts can maximize throughput and increase precision for large quantity of parts.

Tips for Hot Molds and Metal Inserts

It is always better to preheat molds and metal inserts. It helps to reduce thermal shock, improve bonding, and minimize internal stresses. As an example, stainless terminals can be preheated to 100-180OC depending on the polymer type.

Common Types of Molding Insert

Molding inserts come in a verity of materials and shapes. The suitability of a particular insert depends on the application of the component. In insert molding process, either molded in inserts are sourced or custom inserts are made via insert machining. It all depends on factors like cost, availability, ease of manufacturing and durability.

Insert Types by Materials

1.Metal Inserts

Metal inserts are widely available due to ease of shaping metals. Even if some insert designs are not available, they can be machined out to make custom inserts. Commonly metal inserts are added either due to their strength or conductivity, as in the case of fasteners or electrical terminals respectively. However, a good bonding between the injection molded plastics and the metal inserts should be ensured.

2.Plastic Inserts

Plastic inserts are very cost effective and are suitable for high volume production. However, low strength of plastics limits their use in mechanical applications. As an example, high performance plastics like PTFE or PEEK can be machined out to the desired shape and then used as inserts in insert moulding. It can cut the cost. The bulk of the component can be prepared from inexpensive plastic material while the critical parts can be made up of high performance plastics.

3.Ceramic inserts

Insert molding manufacturers capitalize on the extreme hardness and insulation of ceramics. These are commonly used in applications where high wear resistance or electrical insulation is required. However, due to the brittleness of ceramics it is prone to cracking under high mechanical stress or thermal shock.

4.Others

Composites or elastomers can also be used as inserts. Composite materials like fiber glass in polymer matrix offer better strength and durability than plastics. At the same time, they offer the ease of shaping. Elastomers are commonly used are seals or gaskets in insert molded components.

Fastening Inserts

Insert molding is also commonly used in fastening applications. As an example, threaded inserts of metal are insert molded with PPRC plastics for fastening parts in plumbing applications.

Locating & Structural Inserts

Locating and structural inserts like dowel pins, guide bushings and reinforced ribs are used as inserts in insert molding. They make precise positioning possible. Structural inserts like reinforced ribs enhance the load carrying capability of insert molded parts.

Materials & Compatibility in Insert Molding

There are variety of materials belonging to plastics, metals, ceramics and composite classifications. While selecting materials, a careful consideration about factors like cost, mechanical strength, transparency, ease of molding, machinability and conductivity is carried out.

Common Resins for Insert Molding

In plastic insert molding, there are various options. Each material has some appealing characteristics. While some materials maybe selected due to their transparency, other might have high creep and fatigue resistance. The selection depends on the applications. The below table highlights strengths of common plastic resins:

|

Resin |

Key Properties |

Common Application |

|

ABS (Acrylonitrile Butadiene Styrene) |

Toughness, impact resistance and dimensional stability |

Electronics housings |

|

PC (PolyCarbonate) |

High strength, transparency and ease of molding |

Lenses, durable housings |

|

PA (Nylon) |

Wear resistance, mechanical strength and toughness |

Automotive, gears |

|

PBT (Polybutylene Terephthalate) |

Electrical insulation, chemical resistance and high throughput |

Connectors |

|

PEEK (Polyetheretherketone) |

High thermal and chemical resistance, biocompatibility |

Aerospace, medical |

Metals and Other Insert Materials

Brass inserts

Brass inserts are ideal for high precision applications. Brass has an excellent machinability, good corrosion resistance and high wear resistance. As an example CNC machined C360 inserts are commonly used in fasteners.

Stainless steel inserts

Stainless steel offers the benefit of high corrosion resistance. It is easy to sterilize. So, stainless steel inserts are abundantly used in medical and food industry. The main limitation of stainless steel is its higher density and lower machinability as compared to brass and aluminum.

Aluminum inserts

Aluminum inserts are among the least dense inserts in almost all common metals. These inserts are preferred where weight reduction is a priority. The low strength of aluminum limits its use in high wear and load bearing application.

How to Bond?-Mechanical Lock vs. Chemical Adhesion

In insert molding designs, it is best inserts are secured by both chemical adhesion and mechanical locking. Design features such as knurls and holes allow plastic to flow in during insert molding injection. Upon solidification, the plastic makes a mechanical lock with the insert. Certain polymer resins make a chemical bond with the insert material. In this case, both chemical adhesion and mechanical lock hold the insert in place.

Major Factors Affecting Insert Molding

In order to get the best out of the insert molding process, some key considerations should be taken into account. It depends on both the type of materials and on design features. Let's discuss some of these factors

Resin-Insert Compatibility

If the material of the resin and the insert is compatible, it'll create chemical adhesion for joining the insert and the plastic material. Incompatible materials will rely solely on the mechanical interlocks.

Insert Geometry

Insert geometry can also affect the durability of the insert molded parts. Design features like knurls, grooves, undercuts, or through-holes can provide mechanical interlocks. Proper dimensions and configurations of these design features can improve the durability of insert molded parts.

Insert Thermal Mass

Insert materials with a high thermal mass can absorb a large amount of heat. It can lead to incomplete filling, internal stresses, or weak bonding. Preheating the insert material can rectify this problem.

Insert Positioning

Improper positioning or misalignment of the insert can ruin the functionality of the insert molded parts. It can also cause flow disturbances and voids. Errors in insert positioning can be greatly avoided by automation.

Other Considerations

If inserts are metallic, corrosion is a big concern. Application of coating on the insert can improve corrosion resistance. Certain types of primers can improve chemical adhesion.

Insert Molding vs. Overmolding

Custom insert molding and over molding are similar yet distinct manufacturing processes. Design features and materials maybe quite different in both of them. But both of these processes find their usefulness based on factors like ease of manufacturing, ergonomics, materials, and applications.

What Is Insert Molding Similar to Overmolding?

The biggest similarity between Insert molding and overmolding is that two different components or materials are joined using an injection molding machine.

Design Purpose Differences

Inserts in the insert molding process enhances functionality by providing strength, conductivity or wear resistance to a part. While the intent in overmolding process can be improvement of aesthetics or lowering of cost etc.

Molding Process Differences

In the insert molding process, a preformed insert is positioned inside the mold cavity. The resin injection fill the cavity and bonds with the insert. In the overmolding process, a layer of another resin is injected onto an injection molded part in the same mold cavity. Two or more different injections can be used.

Molding Substrate Differences

Inserts can be made up of metals, ceramics, plastics or composites. On the other hand, overmolding is primarily done by polymer resins.

Bonding Differences

Insert molding bonds primarily by mechanical interlocking while overmolding relies on chemical bonding between two or more types of polymers.

When to Use Insert Molding

Insert molding is used in countless products ranging from aerospace to automotive to electronic products. Benefits of multiple materials can be reaped in a single part. Insert molding improves precision and reduces steps in assembling. Here is a brief overview:

In Aerospace Parts

Low density and high strength are preferred in aerospace parts. Components like control modules, sensor housings, and lightweight interior fittings can be produced through insert molding. Metallic inserts provide strength and reinforcement while plastics reduce the overall weight.

In Automotive Parts

Numerous automotive parts are manufacturing by using insert molding. Insert molded parts reduce the assembling steps and increase precision in positioning. Plastics damp out vibrations while the inserts provide the functionality. In some applications elastomers adds the sealing function to a part.

In Medical Devices

Sterilization and biocompatibility are uncompromisable attributes in the medical industry. Medical grade polymers are added to stainless steel or ceramics in certain surgical equipment. Polymers offer ease of sterilization while steel or ceramics provide functionality.

In Consumer Electronics Parts

Insert molding has endless application in the electronics industry. Commonly metal inserts provide conductivity while the plastic encapsulation acts as an insulative barrier.

Benefits of Using Insert Molding

Lower Assembly Cost

Insert molding reduces the number of steps in assembling. In contrast to separate assembling of portions, the insert and the plastic portion acts as a single functional unit. Moreover, the precision of alignment of inserts is excellent.

Stronger Joints

The modes of joining in inset molding are two-fold. Mechanical interlocks and chemical adhesion strongly hold the inserts in place. On the contrary, if the plastic portion and the insert portion is to be assembled separately, mechanical fasteners provide limited strength of join only.

Flexible Designs

Insert molding gives greater freedom of designing. Multiple types of materials and complex geometries can be integrated into a single component.

Lighter and Smaller Parts

Insert molded parts are way lighter than separately assembled parts. The elimination of fasteners and introduction of lighter plastics reduce the overall weight.

Conclusion

Insert molding is an ideal manufacturing process to combine multiple material and complex geometries. Functional portions can be made of applicable materials and then inserted into the mold cavity. The bulk is made up of plastics. Insert molding offers numerous advantages like reduction of cost, lowering of weight, saving in assembling time and precision of component. We offer insert molding services as per your design specifications. Please feel free to send CAD for a quick DFM. We can provide custom insert molding and custom mold services.

FAQs

What materials work best for inserts?

Normally metals like stainless steel and brass work best for inserts. They can be precision CNC machined and provide strength and/or conductivity.

What are the key design rules for insert molding?

Ensuring materials compatibility and introduction of mechanical interlocks increase the overall performance of insert molded parts. Automation in insert positioning increase the precision in alignment.

How do I reduce defects around inserts?

If inserts are metallic, preheating to around 120-180oC minimizes mis runs and voids. Introduction of additional plastic during cooling compensates for shrinkage.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What is Lock Nut? -Types, Design, and Custom Solutions

What is Lock Nut? -Types, Design, and Custom Solutions