Drone Manufacturing: Types, Parts & CNC Custom Solutions

Aug 29,2025

Aug 29,2025

Most people think about drones manufacturing as a highly advanced and technologically sensitive process. It's a bit true. But there are a lot of misconceptions. High performance drones are although made by militaries in advanced military industrial complexes. But, nowadays most of the drones are used for other purposes like surveying, inspection, deliveries, photography or agriculture. Many a times drone manufacturers order drone custom made drone parts and then assemble those themselves. It involves the use of CNC factories a lot. Let's understand about the drone parts and how these are made!

Common Drone Types Explained

A high level of advancement in the engineering field has ushered a new era of drones. They can be seen now everywhere. Be it highly sophisticated military hardware or just merely a teenager's toy, drones show prominence. Quite often you might have heard the term UAVs (Unmanned Aerial Vehicles) in place of drones. Technically, it seems correct but there is a small difference. “Drone” is a more general term used for flying machines in applications like surveying, agriculture, deliveries, photography etc. The term UAV is more commonly used for drones in military hardware.

How to Define a Drone?

Drone can be defined as a remotely operated flying machine. It does not need an onboard pilot to fly it. Preprogrammed flight paths guide the drone to maneuver. Drone can be equipped by sensors, cameras, or other payloads to perform their desired functions.

Drones By Rotor Configuration

Multirotor Drones (Quad, Hexa, Octo)

Drones can also be classified based on the number of rotors they have. The more the number of rotors the more the stability and payload capacity. But it comes at the expense of efficiency. A quadcopter has four motors, a hexacopter has six motors and an octocopter has eight motors. Here is a comparison table for the common types:

|

Type |

Design |

Main Use |

Key Advantage |

|

Quadcopter |

4 rotors |

Photography, hobby |

Easy to fly |

|

Hexacopter |

6 rotors |

Mapping, inspection |

Stable, higher payload |

|

Octocopter |

8 rotors |

Industrial, filming |

Heavy lift |

|

Fixed-Wing |

Airplane-like |

Long surveys, agriculture |

Long flight time |

|

VTOL |

Hybrid |

Delivery, defense |

Hover and long range |

|

Racing (FPV) |

Small quad |

Racing, sport |

Fast and agile |

|

Agriculture |

Multi-rotor |

Crop spraying, monitoring |

Precision farming |

|

Nano/Mini |

Tiny quad |

Indoor, training |

Cheap and portable |

|

Large/Military |

Fixed/Hybrid |

Surveillance, cargo |

Long endurance |

Fixed-Wing Drones

Fixed wing drones resemble airplanes. These drones require a runway or catapult for take-off. Unlike other drones, these fixed wing drones need forward motion to remain airborne. Comparatively they are highly energy-efficient. Common applications include long-distance surveying, mapping, and agricultural monitoring.

VTOL Drones

As the name suggests Vertical Take-Off and Landing (VTOL) drones have the capability to take off and land vertically. It makes VTOL drones very flexible operationally. Once airborne, it can maintain a forward motion similar to Fixed Wing drones. In short, VTOL drones combine the hovering capability of multirotors with the efficiency of fixed-wing designs.

Drones By Applications

Racing Drones

Racing drones are for leisure and gaming experience. First Person View (FPV) goggles give a simulation experience. The operator feels like he/she is also airborne and flying the drone. These drones have high speeds and maneuverability.

Agriculture Drones

Agriculture drones have been assisting farmers who have a vast cultivation area. These drones are used for crop monitoring, precision spraying, soil analysis, and irrigation management.

Drones By Size

Small Drones

Smaller sized drones are commonly used for sports, filming and surveying

Heavy-Lift Drones

Heavy lift drones have the ability to cover long distances while carrying heavy payloads. These types of drones are commonly used by militaries.

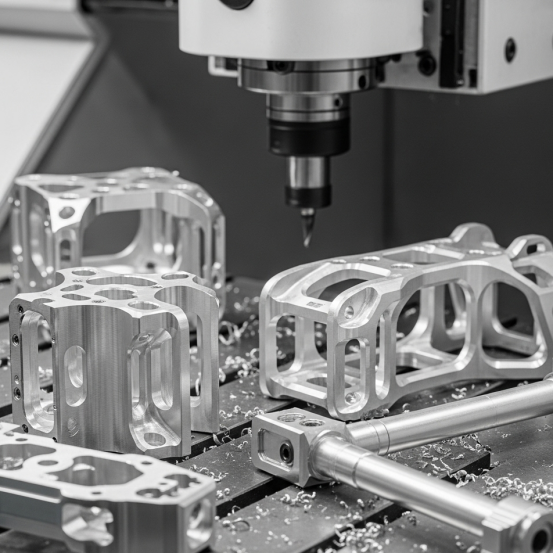

Drone Manufacturing and CNC Machining

Drone manufacturing includes assembling of a lot of different parts. Each drone part is manufactured involving methods like injection molding, 3D printing or CNC etc. Overall, CNC machining plays a vital role in manufacturing of drone parts. In this section we'll discuss the UAV parts that are manufactured using CNC machining.

Why Choose CNC Machining for Drones Parts

CNC machining is a highly pertinent manufacturing process for drone manufacturers. Drone parts like mechanical housings, drone brackets, drone frames and arms are commonly manufactured via CNC machining.

Tight Tolerances

Tight tolerances are critical in ensuring proper fit of UAV parts during assembly. CNC machining produces parts with a very high precision. Accurate CAM files maintain consistency for every batch. It all makes flight performance reliable.

Material Versatility

UAV parts manufacturing involves use of different materials for different UAV parts. CNC machines can handle a wide array of materials. From hard materials like titanium to soft materials like magnesium, CNC can machine it all. Here is an informative table which show common materials of UAV parts:

|

Material |

Parts |

Advantage |

|

Aluminum |

Frames, arms, landing gear |

Light and strong |

|

Titanium |

Motor mounts, brackets |

Very strong and durable |

|

Stainless Steel |

Fasteners, plates |

Tough and wear-resistant |

|

Plastics |

Housings, covers |

Light, impact-resistant |

|

Carbon Fiber |

Frames, gimbal mounts |

Ultra-light and stiff |

Rapid Prototype-to-Production Turnaround

CNC machining is a very flexible process. As the R&D department prepares a CAD design for prototyping, CNC can turn it into reality. Any changes can be incorporated with ease. As the design becomes perfect, it can be used for mass production with a high consistency.

Common CNC Machined Drone Components

Structural Components

- Frames

- Arms

- Landing gear

Connecting Components

- Motor mounts

- Bracket

- Fastening plate

Thermal Management Components

- Heat sinks

- Cooling plate

- Thermal housing

Protective Components

- Camera housing

- Sensor enclosure

- Protective cover

Payload Interfaces

- Gimbal mounts

- Payload brackets

- Connector housings

Key Components of Multirotor Drones

Multi rotor drones have several parts. There are structural and mechanical components, electrical systems, sensors etc. CNC machine is mainly used for manufacturing structural and mechanical parts of drones. Some of the CNC manufactured drone parts are discussed below:

Airframe and Arms

Airframe and arms are the first and the foremost structural drone parts. Airframe is the structural backbone of a drone. Arms connect the motors to the main body. These should be robust to withstand loads. Tight tolerance is also crucial in enabling proper fit of drone parts.

Carbon-Fiber vs. CNC-Machined Aluminum Arms

Carbon fiber has an incredible specific strength. It is lightweight and rigid. For smaller drones it helps in maintaining stability by damping vibrations. Carbon fiber arms are ideal for racing drones and lightweight photography drones. On the other hand, Aluminum is preferred for big drones. CNC machining ensures tight tolerances that are crucial in assembling complex mounting features. The superior strength of Aluminum gives payload stability.

Propulsion Pack: Motors, ESCs, Propellers

Motors, ESCs (Electronic Speed Controllers) and propellers together converts electrical energy into thrust. It gives maneuverability and lifts to the drone.

CNC Motor Mounts and Heat Sinks

CNC motor mounts secure the motors to the arms. To ensure a good performance and durability motors should fit properly. Tight tolerances are pertinent. CNC drilling gives exact hole placements for motor mounts.

Heat sinks are used to dissipate heat electrical systems. They are usually made up of aluminum. CNC milling carve out the exact design of heat sink.

Drone Power System

High performance batteries give long flight durations. Normally, Lithium-polymer (Li-Po) batteries are preferred because they have high energy density and fast discharge rates.

Flight Control Stack: FC, GPS, Telemetry

Flight control stack is the brain of a drone. Flight controller processes sensor input and control motor speed. GPS module helps in positioning and navigation. Telemetry establishes contact between the drone and the drone operator. It transmits data like altitude, battery status, and coordinates.

Key Components of Fixed-Wing and VTOL Drones

Just like multi rotor drone, fixed wing and VTOL drone also have a number of parts that assemble together to form a drone. Some of the key components are explained below:

Fuselage and Wing Structure

Fuselage includes electronics, payloads, and power systems. The housing should be spacious yet compact. Wings provide the lift to maintain flight. They have to be light yet strong. Reinforcement ribs or CNC machined mounting plates increase the structural strength.

Propulsion System

Motor mounts, gearboxes and propellers are key components of the propulsion system. Motor mounts secure the motors to the arms. Gearboxes optimize torque and propeller efficiency. Propellers provide the thrust.

Control Surfaces: Servos, Hinges, Horns

Lightweight CNC Aluminum Horns

Horns connect servos to control surfaces. In comparison to plastic horns CNC milled Aluminum horns provide greater accuracy, tighter tolerances and higher strength.

Payload Bays and Landing Gear

Payload bays contain payloads, cameras and sensors. Landing gears absorb impact during landing.

Materials Analysis: Composites vs Metals in UAV Parts

Drone manufacturing involves the use of several materials for different drone parts. Each material has its own strengths for a specific application. Some UAV parts require high specific strength while others require excellent precision. Cost factor is also important in material selection. Here we'll be discussing the use if common materials used in drones. Below is a comparative table of different materials:

|

Material |

Use |

Advantage |

|

Carbon Fiber Reinforced Polymer (CFRP) |

Frames, wings |

Ultra-light, stiff |

|

6061 Aluminium |

Brackets, housings |

Corrosion-resistant, cheap |

|

7075 Aluminium |

Arms, mounts |

Strong, durable |

|

Magnesium alloys |

Light parts, housings |

Very light |

|

Titanium alloys |

Mounts, fasteners |

Super strong, corrosion-proof |

|

PEEK and Nylon-GF |

Covers, enclosures |

Light, impact-resistant |

Carbon-Fiber-Reinforced Polymer (CFRP)

CFRP is basically a polymer matrix embedded with high strength carbon fibers. It has an excellent specific strength. It is commonly used for drone parts like frames, arms, fuselage panels and wing structures. The light weight of the CFRP structure increases the payload capacity and flight longevity. But the high cost limits its usage.

6000 and 7000-Series Aluminum Alloys

Aluminum is the most commonly used material for UAV parts. It is light weight, low cost and highly machinable. 6061 grade Aluminum alloy is mainly used for drone brackets, mounts, and housings. 7075 grade aluminum alloy is used in arms, motor mounts, and load-bearing brackets.

Magnesium and Titanium Alloys

The use of magnesium alloys in drone manufacturing has been a novelty. Magnesium alloys are the one of the least dense metals. On the other hand, they offer the advantage of using shaping techniques like CNC machining. Comparatively, Titanium offers excellent strength, durability and corrosion resistance but at a high cost. Titanium alloys are mainly preferred in heavy duty drone.

High-Performance Plastics: PEEK, Nylon-GF

Engineering plastics are mainly used for non-structural UAV parts like casings and enclosures. But still, they need to be good in strength to withstand impact resistance, UV attack and wear resistance. So, high performance plastics like PEEK and Nylon GF are preferred over other low cost plastics for these UAV parts.

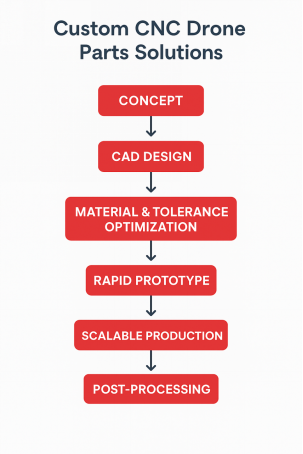

Custom CNC Drone Parts Solutions

CNC machining is a very versatile drone parts manufacturing process. It offers the ease of prototyping, design validation, mass production and product consistency. Most of the common engineering materials can be CNC machined easily.

Concept-to-CAD Design

Initial concepts can be translated into CAD designs though CAD software like CATIA or SolidWorks. The CAD design can be validated in FEA simulations. Once ready the CAD files can be converted to CAM files that can be sent to the CNC machines. The CNC can do it all automatically.

Material and Tolerance Optimization

A wide array of material with tight tolerances can be customized for UAV parts in a CNC machine.

Rapid Prototype Sprint

Prototypes can be created from the CAD design in a CNC machines in a matter of few days.

Scalable Production Pipeline

Once the CAD design is perfect, mass production can be initiated with consistency in a CNC machine.

Post-Processing and Assembly Integration

Post processing tasks like anodization, powder coating or chromating can be done with ease on CNC made UAV parts.

What is the Better Method for Drones Manufacturing?

The common techniques of drone parts manufacturing includes CNC machining, addictive manufacturing and injection molding. As a matter of fact CNC machining is the most widely used method due to a number of advantages. Let's see how?

Who Is More Precise

The most precise method is undoubtedly CNC machining. The high precision CAD design combined with perfect alignment of feed stock and tooling gives micrometer level tolerances.

Where Provide More Design Freedom

Injection molding requires molds which cannot be changed. So it is out of question. CNC machining and 3D printing offers the advantage of reiterations in designs with ease.

Which Method Costs Less per Part

For high volume moldable plastic parts injection molding is the winner. But generally for all common materials like metals and plastics CNC gives low cost. The setup cost of 3D printers its high and materials choice is limited, so it is out of question.

When to Combine Methods in One Drone Build

When combining all factors like precision, cost, and versatility CNC machining is unbeatable for large volumes production.

Design for Manufacturability: CAD Tips for Precision UAV Parts

A perfect CAD is the key for efficient manufacturing of drone parts in a CNC. Certain design feature can improve both strength and manufacturability.

Structural Optimization

To reduce stress concentration at sharp points, use fillet and chamfer. It improves strength without adding extra material.

Precision and Tolerance Planning

Tolerances should be well defined. Critical components need to have tight tolerances for proper fit. Non critical components can be left with loose tolernace to save manufacturing time.

Integrated Thermal Management

Some parts like fuselage can have integrated airflow paths to reduce to number of separate heat sinks.

Modular Fastening Strategy

All fasteners need to be standardized. It helps in the quick replacement of fastners whenever needed.

Conclusion

Drone manufacturing involves the assembling of several drone parts. Each drone part is made up with a suitable material. Depending on the drone part performance requirements, a suitable manufacturing route is selected. By far the most versatile manufacturing process is CNC machining. It offers tight tolerances, precision, product consistency and high manufacturability. CNC machines can handle a wide array of materials from polymers to high strength metals. CNC machining also offers a high flexibility. Any changes in the design can be easily incorporated in the CAD file. So, a drone manufacturer can quickly move from prototyping to mass production.

FAQs on Drone Manufacturing

Which material offers the best strength-to-weight ratio for UAVs

By far CRFP offers the best strength to weight ratio for drone parts.

How long does it take to prototype a custom drone part

Normally, 2-7 days should be sufficient. It includes CAD creation, CAD validation, FEA, CAM files creation, tool path generation and ultimately CNC machining.

Can CNC machining and 3D printing be combined in one drone design

Yes. Some highly complex geometries like drone frames an be made by 3D printing. While other high precision parts can be made on a CNC machine.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

What Is Insert Molding? When to Use It?

What Is Insert Molding? When to Use It?