What is Lock Nut? -Types, Design, and Custom Solutions

Sep 12,2025

Sep 12,2025

Almost all of us assemble some components in our daily lives. We have seen nuts locked in our houses, offices, and on roads. But did you think about how it works and why it is used in the components? A lock nut basically provides resistance against vibration. In many industries, components fail due to loosening of the lock nuts. So, right lock nuts should be used for different components and applications. In this article, you will explore how the design, types, materials, and standards are important while choosing custom lock nuts.

Figure 1: Lock Nut Example

What Is a Lock Nut?

A lock nut consists of different types of locking elements that help to resist against the torque and vibration. An ordinary nut is unable to maintain stability against the clamp force, while a lock nut joins and locks itself with the bolt to maintain the clamp force. Due to its locking with a bolt, it can work better against vibration as compared to an ordinary lock nut.

How to Identify a Lock Nut?

You might face difficulty in differentiating between an ordinary nut and a lock nut. An ordinary nut just consists of threads in the inner portion of the nut, while a lock should have some locking element that helps it to resist the vibrations. A lock nut should consist of a nylon ring at the top of the nut or a pin that helps to provide the locking feature to the lock nut.

Locking Nuts and Bolts

The relationship between locking nuts and bolts is interesting. First, you need to understand what a bolt is. A bolt is a fastener that consists of threads and a head at the top of the bolt. A bolt is used with a nut to join the materials. A bolt job is to maintain the clamp force while a nut remains stationary and avoid the rotation/opening.

What Is a Lock Nut Used for?

Its core purpose is to stay stationary and avoid loosening of the nut while increasing in vibration and torque. It helps to avoid the failure of the component by avoiding the loosening of the lock nut, and that's why its application range is wide, from household to critical parts such as aerospace components.

What Is the Difference between a Nut and a Locking Nut?

An ordinary nut consists of a metal piece with a threaded hole and while a locking nut relies on its design, such as a pin or nylon ring at the top of the nut. An ordinary nut is unable to provide resistance against the dynamic load, while a lock nut cannot loosen itself from the bolt due to its design.

How Lock Nuts Work

Have you ever thought about how lock nuts actually work? If not, then let's discuss. It basically follows the basic principles to lock itself with the bolt. Friction locking and mechanical locking are the two main principles to avoid the loosening of the lock nut.

Friction Locking Basics

The friction basically helps to overcome the dynamic vibration. For this, a nylon ring or slightly deformed threads are used to create friction against the threads of the bolt.

Mechanical Locking Basics

A cotter pin in a castle nut acts as a barrier (pin) to prevent rotation of the nut during the dynamic vibration or torque.

Vibration Loosening Basics

As we all know, a vibration cycle can make a tiny movement of the nut. This led to loosening of the nut, and it can be avoided by using the nylon ring at the nut or a cotter pin.

Lock Nut Types by Locking Mechanism

Different designs of lock nuts are used to avoid loosening of the nut. One of the key types is a self-locking nut, as you can identify from the name, it locks itself with the help of deformed threads. Some common types of nuts are discussed below:

1.Castle Nut

This is a type of mechanical lock nut. It consists of a bolt and a cotter pin. The cotter pin is inserted into the bolt and slot to prevent the opening of the nut.

2.Slotted Nut

This is also the type of mechanical locking nut due to pin is inserted into the slot. It is similar to the castle nut. But it has multiple, wide slots at the top of the nut.

3.Prevailing Torque Nut

This is the type of friction locking nut, and it absorbs the friction according to its capacity. For example, an oval lock nut and a distorted thread nut.

4.Pin Lock Nut

A pin lock nut consists of the pin and threaded section. It depends on your application; one or more holes can be drilled into this nut. It works by inserting the pin into the nut after tightening of the nut.

5.Jam Nut

The Jam nut is also called the counter nut (counter word taken from German Kontermutter). It works by tightening the primary nut against the thin nut.

6.Nylon Insert Lock Nut

It is a type of friction-based nut lock. This type of lock nut consists of a nylon band ring at the top of the nut. The nylon ring absorbs the vibration by elastically deforming and then returning to its position. It is unable to work in a high-temperature environment due to its polymer nature.

Nylon Insert Lock Nut vs All Metal Nut

A nylon nut lock consists of the nylon ring, which helps to absorb vibration, while a metal nut consists of a simple metal with threads inside. Metals nuts are worked by creating the friction between the bolt and the nut lock. A nylon lock nut has less life as compared to metal nuts.

7.Keps Nut

This is also a type of mechanical lock used for a single component. It consists of a nut and a free-spinning teeth washer attached at its top that attaches to the mounting surface.

8.Distorted Thread

This is the type of friction lock nut. In this, deform threads are created intentionally inside the nut, which then lock with the bolt to prevent the opening of the nut.

9.Split Beam

In this, a beam is flexed outward as the nut is tightened. Due to this, it is known for its excellent grip and reusability.

Lock Nut Types by Materials

The lifetime, corrosion resistance, strength, and durability of the nut depend on the material used. Some common types of materials are given below to give you an idea:

1. Carbon Steel Lock Nuts

The carbon steel lock nuts are known for their strength and durability. Carbon steel is easily available and economical.

2. Stainless Steel Lock Nuts

If the lock nuts are used in a corrosive environment, then it's a good option because it has excellent corrosion resistance. 304 stainless steel can be used where you need cost-effective and corrosion-resistant material. 316 stainless steel is best against the marine and chloride environment.

3. Brass / Bronze Lock Nuts

Brass consists of copper and zinc, while bronze is a mixture of copper and tin. Both have good corrosion resistance and can be easily shaped due to their good machinability.

4. Aluminum Alloy Lock Nuts

Aluminum alloy lock nuts can be used where less weight and more strength are required. For example, 7075-T6 is used for aerospace applications due to high strength requirements, while 6061-T6 is used where cost-effectiveness and less strength are required.

5. Titanium Alloy Lock Nuts

Titanium alloy lock nuts are used in applications such as aerospace and military, where high strength and less weight are required. Ti-6Al-4V (Grade 5) is an example of this type of alloy lock nut.

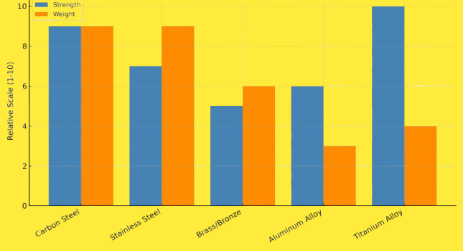

Table 1: Comparison of different material properties for lock nuts

|

Material |

Strength |

Weight |

Cost |

Corrosion resistance |

|

Brass/Bronze |

Low-Med |

Medium |

Medium |

High |

|

Titanium Alloy |

Very High |

Very Light |

High |

Very High |

|

Stainless Steel |

Medium |

Heavy |

Medium |

Very High |

|

Aluminum Alloy |

Medium |

Light |

Medium |

High |

|

Carbon Steel |

High |

Heavy |

Low |

Low |

Figure 2: Comparison of strength vs weight of different lock-nut materials

How to Design Custom Lock Nut for Your Project?

Are you thinking of designing a custom lock nut for your project? The section below will help you while designing your lock nut:

Design Purposes

First of all, define you application. It is not possible to select a nut with the same design and material for all applications.

1.Mechanical Locking Nuts

Choose these locking nuts if you cannot compromise on the safety of the component. Choose the castle top or pin hole that can perfectly interface with the bolt groove.

2.Friction Locking Nuts

It can be chosen where safety is not critical and reusability, cost effectiveness are important. Design your nylon cavity size, slit dimension to get better results for resistance against friction.

Thread Fit Class

Different thread classes are used, so specify your thread class that fits with your bolt.

Prevailing Torque Target

You must specify the torque required to rotate the nut to ensure consistent performance.

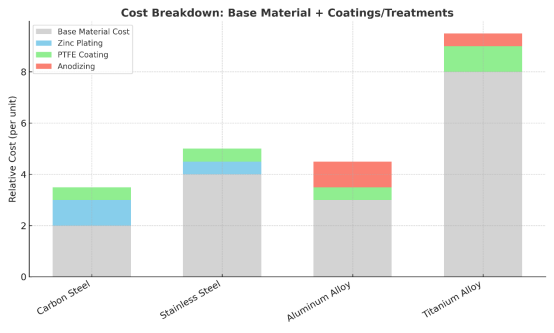

Coatings and Treatments

In the end, select your coatings and treatment to ensure the long lifecycle of the lock nut. Zinc plating is used to ensure good corrosion resistance, while case hardening methods are used to ensure the surface is hard and the core is soft.

Figure 3: Cost breakdown of base materials and coatings/treatments

Reuse Life

Different materials give different reuse life cycles. Due to its polymeric nature, a nylon nut provides a shorter reuse life as compared to a metal nut.

Common Strength Grades for Lock Nuts

Strength grades are defined according to their numbers. Grade 5 has more ultimate tensile strength compared to grade 2. The following section will give you an idea about the SAE and ASTM grades:

1.SAE Grades

SAE grades are common for carbon nuts used. Following the SAE grade shows their applications with their minimal ultimate tensile strength:

SAE Grade 2

It provides low tensile strength as compared to grades 5, 8, and can be used for non-critical applications.

SAE Grade 5

If your application is automotive, then use this because it provides medium tensile strength.

SAE Grade 8

Grade 8 provides a higher strength as compared to grades 2 and 5. It can be used in critical applications.

2.ASTM Grades

ASTM grades are used when a specific torque is required for some application. Common types of ASTM grades are given below:

Grade A

It is a low-carbon steel nut.

Grade B&F

It is a medium carbon steel nut, and its strength is medium.

Grade C&G

In these grades, carbon content is higher compared to the A, B & F grades.

Standards, Sizes, Torque Specifications of Lock Nut

You need to specify the requirement of torque and then, according to this, select the size of the lock nut. These size specifications should be followed according to different international standards.

Thread Series Options

Different thread series options are used, but UNCS, UNF are used for general and aerospace applications, respectively.

Across Flats Size

Across flat size determines the wrench size you need.

Prevailing Torque Spec

ASTM standards specify the acceptable torque range for quality control checks.

Nut Height Limits

It is critical for locking nuts, such as nylon inserts.

Lock Nut Applications by Industries

The following are industries in which lock nuts are used:

Automotive Powertrain

It protects the exhaust brackets and tie rod ends used in the automotive powertrain.

Rotating Equipment

In the rotating equipment, shafts, conveyers, and compressors rely on the locking nuts. Electrical Hardware

It can be used in the control box to protect the components inside it. It can be used in the ranks of transformers where there is always vibration.

Aerospace Hardware

Low-strength materials cannot be used in these lock nuts. Titanium alloy lock nut can be used in control linkages and engine accessories.

Table 2: Applications of lock nut materials by different industries

|

Industry |

Preferred Material |

Reason |

|

Automotive |

Carbon Steel, Aluminum |

High strength (steel), weight reduction (aluminum) |

|

Aerospace |

Titanium |

Superior strength-to-weight ratio |

|

Marine |

Stainless Steel 316 |

Exceptional resistance to saltwater corrosion |

|

Electrical |

Brass/Bronze |

Good electrical conductivity, corrosion resistance |

|

Construction |

Carbon Steel |

Cost-effective and strong |

|

Medical |

Titanium, Stainless Steel |

Biocompatibility, corrosion resistance |

Conclusion

The right choice of a Lock nut is important because it is used from cars to aerospace. Both friction-based and mechanical-based lock nuts have different applications to prevent loosening of the nut. It is important to consider the right design, mechanical properties such as durability, corrosion resistance, and strength, while designing the custom lock nuts. TOUFA is a company which have wide experience to provide a custom lock nut solution for your projects.

FAQs

How to tighten a lock nut on a bolt?

Tighten the nut on a bolt by hand and then use a wrench and insert the cotter pin inside the slot to ensure the locking.

Is a lock nut a lug nut?

A custom locking lug nut is a special type of lock nut used to protect the wheel in a car from thieves.

How do I know which locking nut I need?

You can select the right lock for your application by considering the vibration level, reusability, and environmental conditions.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Lock Nut vs Hex Nut: A Complete Comparing Guide

Lock Nut vs Hex Nut: A Complete Comparing Guide