Overmolding Guide: Process, Materials, Machining Solutions

May 23,2025

May 23,2025

Do you know that overmolding is used from your toothbrush to drones? Overmoulding provides comfort, aesthetic appeal and ease when using tools or machines. This article is a comprehensive guide about what overmoulding is, its process, for which materials it is used and how CNC machining elevates overmoulding. So, let's start!

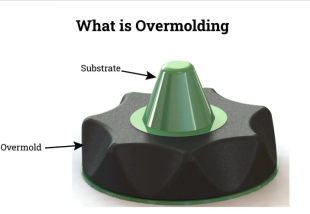

What is Overmolding?

Let us tell you about overmoulding using an example. Suppose a screwdriver, its handle is often covered with rubber. The process through which that rubber is moulded on the handle is called overmoulding. So, it is a manufacturing process in which the base metal is covered with a let's say coating material. This coating is responsible for enhancing durability and grip.

How Overmolding Works

Its process consists of 4 simple steps:

- Prepare your mould

- Mould the first layer on it

- Overmould the second layer

- Now, cool it and perform the required finishing steps

Key Types of Overmolding Processes

This section will make you familiar with different types of overmoulding processes.

Injection Overmolding

In this method, you will coat your already moulded substrate, meaning a second layer is deposited on the already coated material. It is used for high-volume production. One of the most common examples is smartphone cases with TPU edges.

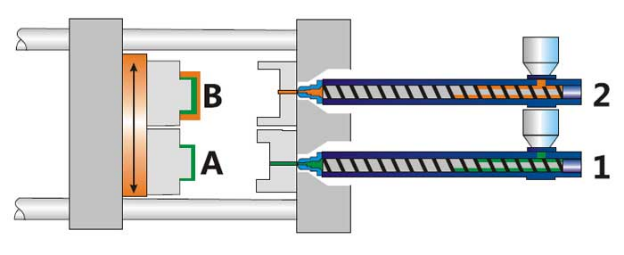

2K Moulding

You can call it two-shot moulding, and it is used mostly in Germany. Two different required materials are injected into a machine in sequence, and a single product is produced. It is best for keyboard keys.

2K Moulding vs. Overmolding

The following table provides a summary of the differences between 2 K moulding and overmoulding.

|

Feature |

2K Moulding |

Traditional Overmolding |

|

Speed |

Faster (one cycle) |

Slower (two cycles) |

|

Cost |

Higher machine cost |

Lower tooling cost |

|

Bond Strength |

Superior |

Good with surface prep |

Insert Moulding

Prefabricated parts are called inserts. Inserts are added into the cavities, and then moulding material is added. It is used for consumer products and surgical components.

Overmolding vs. Insert Moulding

You can explore the core differences between overmoulding and insert moulding.

|

Feature |

Overmolding |

Insert Molding |

|

Process |

Layers materials |

Encases pre-placed inserts |

|

Bond Strength |

Chemical adhesion |

Mechanical encapsulation |

|

Best For |

Soft grips, multi-material |

Metal/plastic hybrids |

|

Cost |

Higher tooling |

Lower for simple parts |

Urethane Casting

As the name “casting” shows that a liquid material is added into a mould of the required shape. You can use this process for prototyping or low-level production. Its common applications are medical handles and seals, etc.

Fabric and Mesh Overmolding

You can integrate your woven or fabric material with plastic during the moulding process. Its common applications include sporting goods and footwear. This process enhances the functionality and durability of the product.

Materials Used in Overmolding

This section of the article contains information related to the materials used for the overmoulding process.

Common Thermoplastics Used for Overmolding

We use thermoplastics for overmoulding because of their flowability and lower melting points.

TPE (Thermoplastic Elastomer)

TPE is a block-copolymer that melts like plastic but flexes like rubber. Due to its softness and flexibility, it is used in tool handles and seals.

TPU (Thermoplastic Polyurethane)

It is a polyurethane member of the TPE family, formulated for high strength and wear resistance. This material shows good abrasion resistance, and that is why it is used for phone cases and cables.

PVC (Polyvinyl Chloride)

PVC is a versatile vinyl plastic. We use this material for overmoulding because it is cost-effective and rigid. Its applications are pipes and medical tubing.

Overmolding Plastics on Metal

Plastics and metal are two different materials with different properties. So, by combining plastics and metal, you will get a hybrid material.

Benefits of Metal Substrates in Overmolding

The benefits of metal substrates are given below:

- Enhanced strength and durabilitybecause of increased impact strength.

- Metals dissipate heat betterthan plastics, so lower chances of deformation.

- A well-treated metal forms stronger chemical bonds with plastics, so it reduces delamination risks.

Types of Metals Suitable for Overmolding

The following table provides different materials suitable for overmoulding process(commonly used as inserts):

|

Metal |

Key Properties |

Common Applications |

|

Aluminum 6061 |

Lightweight, corrosion-resistant |

Aerospace, automotive components |

|

Stainless Steel |

High strength, sterilizable |

Medical instruments, food industry |

|

Brass |

Excellent conductivity, machinability |

Electrical connectors, valves |

|

Titanium |

Biocompatible, high-strength-to-weight |

Surgical implants, sports equipment |

- Types of Metals NOT Suitable for Overmolding

These are the reasons why you can't use these materials for overmoulding:

|

Metal |

Reason for Unsuitability |

|

Zinc |

Low melting point risks warping during moulding. |

|

Magnesium |

Reactive with many plastics can corrode or weaken bonds. |

|

Lead |

Toxic and incompatible with food/medical applications. |

|

Untreated Steel |

Prone to rust; requires plating or coating for adhesion. |

Advantages of Overmolding

If you use the overmoulding manufacturing process, you will have the following advantages:

Functional Advantages

Overmoulding is used for these functional advantages:

- Superior Durability & Weather Resistance

- Built-In Shock, Vibration, and Stress Dampening

Aesthetics Advantages

We often use overmoulding for aesthetic appeal:

- Premium Look, Feel, and Custom Branding

Production Advantages

Overmoulding also offers some production-related advantages as well, as you can see from the following points.

- Fewer Assembly Steps for Faster Production

- Lower Total Part and Tooling Cost

Applications of Overmolding Across Industries

Now, we will discuss common applications of overmoulding in the notable industries:

- In the automotive industry, you can use PC+TPU materials in overmoulding for making gearshift knobs.

- In the electronics industry, we use ABS+TPE for overmoulding for drone controllers.

- In the Medical industry, we use PEEL + LSR materials in overmoulding for making ergonomic scalpel handles.

Overmolding and Precision CNC Machining: One-Stop Solutions

In this section, we will focus mainly on how CNC machining helps overmolding.

Why Combine CNC Machining with Overmolding?

- Due to high precision, the CNC-machined parts will offer perfect dimensions, ensuring excellent bonding.

- CNC is a highly advanced machine through which we can make complex parts for overmoulding.

- CNC reduces material waste in machining parts.

- CNC can provide ±0.005" tolerances for the parts.

Design Workflow: From CAD to CNC to Overmold Tool

Here is a complete guide for an overmould tool:

|

Stage |

Key Actions |

Equipment |

|

CAD Design |

Model parts, DFM analysis |

CAD software |

|

CNC Machining |

Machine substrate |

5-axis CNC |

|

Surface Prep |

Blast, etch, clean |

Blaster, plasma |

|

Overmolding |

Inject, cool, eject |

Molding machine |

|

Final QC |

Test function, measure |

CMM, tester |

CNC-Prepped Inserts: Metals, Plastics, and Hybrid Cores

- Best alloys for overmolding

These are some materials which are prepared through CNC machining for overmoulding:

|

Material |

Bond Strength |

Typical Applications |

|

6061 Aluminum |

Excellent |

Consumer electronics |

|

4140 Steel |

Good |

Industrial tools |

|

C360 Brass |

Fair |

Plumbing fixtures |

|

PEEK Plastic |

Excellent |

Medical implants |

- Surface-prep methods

Some surface preparation is good to boost the strength of the parts. Some surface processes include blasting, chemical etching and plasma treatment.

Conclusion: Is Overmolding the Right Solution for Your Project?

We conclude this article on the question, “Is Overmolding the Right Solution for Your Project?”. Yes, because it is a versatile manufacturing process which can provide functional services and aesthetic appeal as well. You can use materials according to the conditions of the applications. For substrates, you should use CNC machining because of its advanced features.

Overmolding FAQs:

What industries benefit most from overmolding?

- Automotive

- Electronics

- Medical

What materials are best suited for overmolding?

In case of plastics, TPU and TPE, while the best metals are Al and steel.

Tel/WeChat:

Tel/WeChat:  Email:

Email:

Home

Home

Types of Metal Finishes: Machined Parts Finish

Types of Metal Finishes: Machined Parts Finish